sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2995 of 6020

Engine Mechanical – V6 Page 6A1–218

Page 6A1–218

Left-hand Side (Bank 2) Cylinder Head

1 Remove the intake manifold assembly, refer to 3.10 Intake Manifold Assembly – Complete .

2 Remove the exhaust manifold, refer to 3.11 Exhaust Manifold Assembly.

3 Remove the power steering reservoi r and pump mounting brackets, refer to 3.8 Power Steering Pump Bracket.

NOTE

Do not disconnect the power steering pipes

and/or hoses.

4 Remove the oil filter adapter upper bolt. NOTE

Do not remove the oil filter adapter.

5 Remove the engine coolant temper ature (ECT) sensor, refer to Section 6C1-3 Engine Management – V6 – Service

Operations .

6 Remove engine harness ground terminal attach ing bolt from cylinder head, refer to Section 8A Electrical Body &

Chassis .

7 Remove the left-hand bank secondary timing chain, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

8 Remove the camshaft position actuators, refer to 3.18 Camshaft Sprocket.

9 Remove the front M8 (1) cylinder head attaching bolt, two places.

10 Remove the cylinder head attaching bolt (2), eight places.

11 Remove the cylinder head (3).

Figure 6A1 – 367

12 Remove and discard the cylinder head gasket (1).

Figure 6A1 – 368

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3017 of 6020

Engine Mechanical – V6 Page 6A1–240

Page 6A1–240

Remove

1 Remove the skid plate.

2 Drain the radiator coolant, refer to Section 6B1 Engine Cooling – V6.

3 Disconnect the battery negative and positive terminal, refer to Section 8A Electrical Body & Chassis.

4 Remove the battery from the vehicle.

5 Depressurise the fuel sy stem pressure, refer to Section 6C Fuel System – V6 .

6 Make alignment marks on the bonnet and hinges in order to return the bonnet to the exact original position.

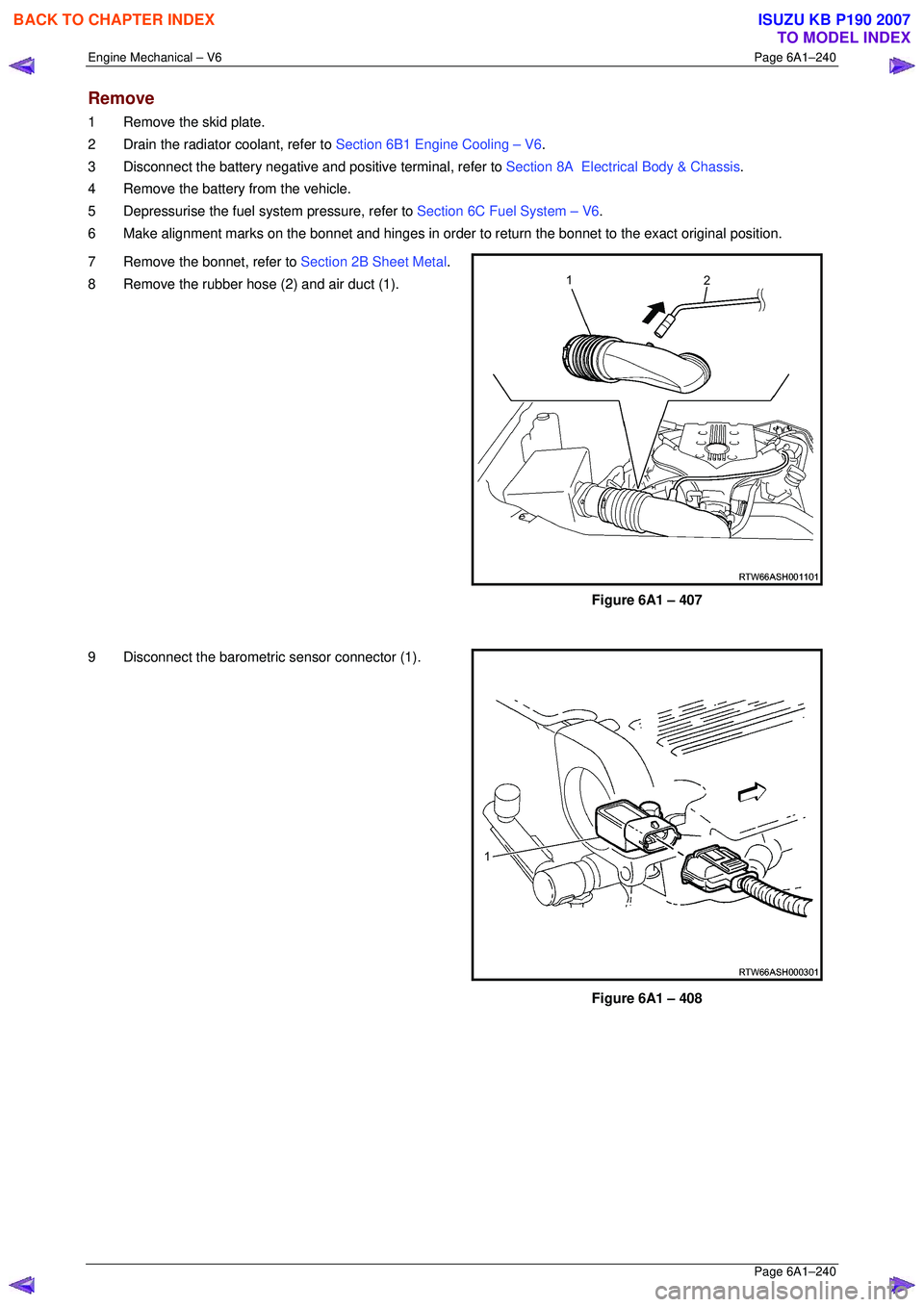

7 Remove the bonnet, refer to Section 2B Sheet Metal.

8 Remove the rubber hose (2) and air duct (1).

Figure 6A1 – 407

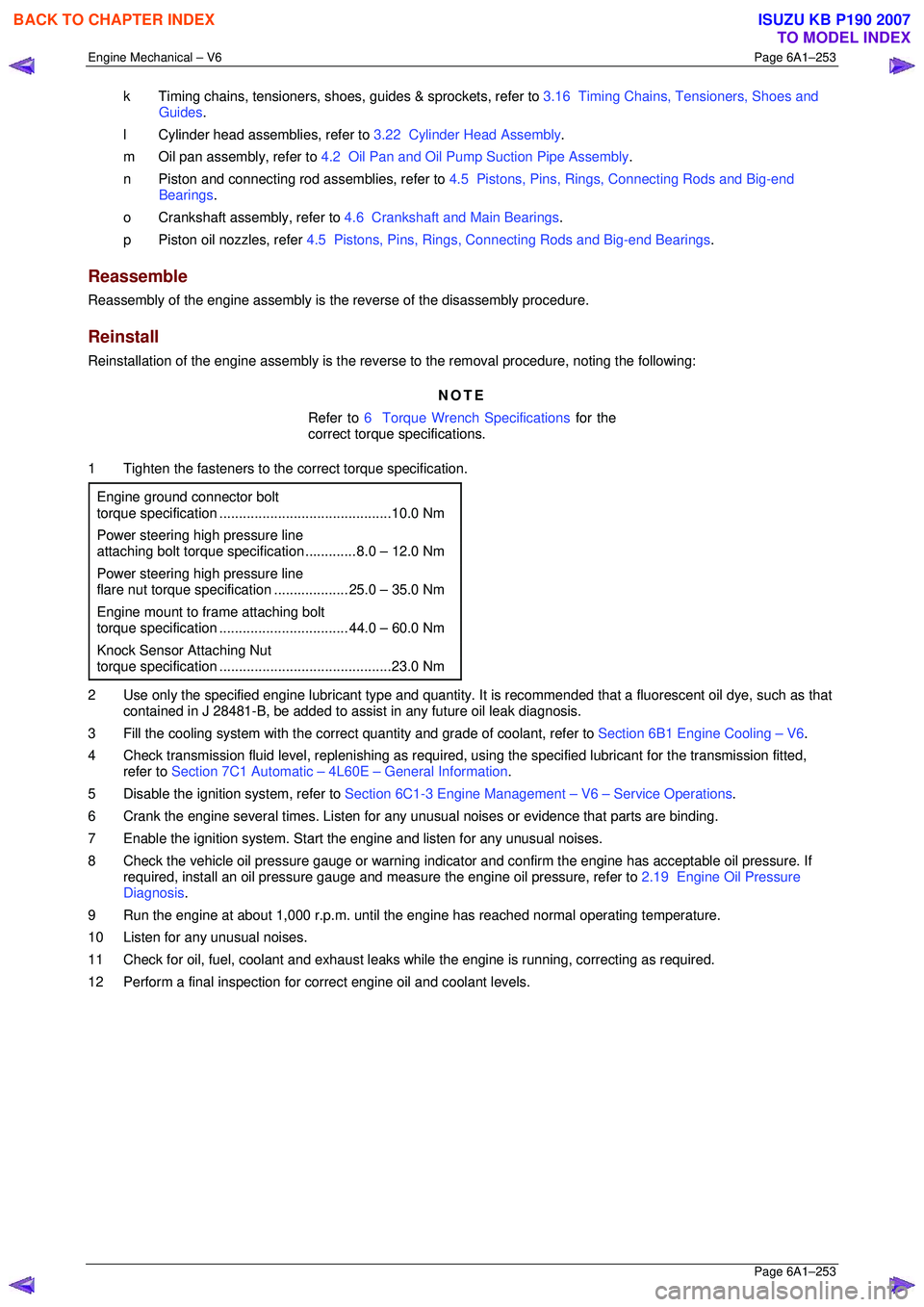

9 Disconnect the barometric sensor connector (1).

Figure 6A1 – 408

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3021 of 6020

Engine Mechanical – V6 Page 6A1–244

Page 6A1–244

28 Remove the centre exhaust pipe (1), refer to

Section 6F Exhaust System - V6 .

Figure 6A1 – 417

29 Disconnect the two post-catalytic converter oxygen sensor wiring harness connectors, 1 each bank.

Figure 6A1 – 418

30 Disconnect the two pre-catalytic converter oxygen sensor wiring harness connectors, 1 each bank.

31 Remove the front exhaust flange nuts, three each bank.

32 Remove the front left-hand exhaust pipe from the rubber mount.

33 Remove the front exhaust pipes from the vehicle, for further information, refer to Section 6F Exhaust

System - V6 .

Figure 6A1 – 419

34 Remove the transfer case from t he vehicle (4WD Only), refer to Section 7D Transfer Case and Adaptor Housing .

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3023 of 6020

Engine Mechanical – V6 Page 6A1–246

Page 6A1–246

Figure 6A1 – 423

Figure 6A1 – 424

42 Fit the engine lifting brackets (1), (EN–46114) and attach the engine hoist, raise the engine to take the weight off the engine mounts.

Engine Lift Bracket Attaching Bolt

torque specification

............................................................. 58.0 – 72.0.0 Nm

43 Remove the left-hand side knock sensor (1).

Figure 6A1 – 425

NOTE

Removal or the starter motor is only required for

vehicles with an Automatic Transmission.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3025 of 6020

Engine Mechanical – V6 Page 6A1–248

Page 6A1–248

50 Unplug the connector from the oil level sensor (1).

51 Remove the attaching bolt (2) holding the ground cable to the engine block.

Figure 6A1 – 429

52 Remove the accessory drive belt using a socket wrench (1), to reduce tension rotate the drive belt

tensioner (2) clockwise, then while holding the

tensioner in the reduced tens ion position, remove the

accessory drive belt (3).

Figure 6A1 – 430

53 Remove the power steering pump bolts (two places),

remove the pump (1) from the mounting bracket and

disconnect the power steering hoses (two places)

from the pump body.

NOTE

Plug the open ends of the power steering hoses

to prevent the ingre ss of contaminants.

Figure 6A1 – 431

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3028 of 6020

Engine Mechanical – V6 Page 6A1–251

Page 6A1–251

61 Remove the air cleaner cover assembly including the

MAF sensor assembly (1).

62 Remove the air cleaner filt er (2) from the air cleaner

body assembly (3).

Figure 6A1 – 438

63 Disconnect the ECM connectors (1).

Figure 6A1 – 439

64 Disconnect the canister hose (1).

Figure 6A1 – 440

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3029 of 6020

Engine Mechanical – V6 Page 6A1–252

Page 6A1–252

65 Remove the engine mount attaching nuts (1), (two

places) on the chassis si de of the left-hand and right-

hand engine mounts.

Figure 6A1 – 441

66 Slowly raise the engine using the engine hoist continue to lift and manoeuvre the engine assembly

clear of the engine compartment.

Figure 6A1 – 442

Disassemble

1 Remove the wiring harness connectors and ground connec tions from the engine and transmission assembly and

carefully set the wiring harness to one side, refer to Section 8A Electrical Body & Chassis.

2 Remove the engine control module (ECM) and mounting bracket, refer to Section 6C1-3 Engine Management – V6

– Service Operations .

3 Mount the engine assembly on a suitable engine stand.

5 Drain the engine oil into a suitable, clean container.

6 Remove the following components: a Oil filter adaptor, refer to 3.3 Oil Filter Adaptor.

b Engine coolant inlet pipe, refer to Section 6B1 Engine Cooling – V6.

c Heater pipe assembly, refer to Section 6B1 Engine Cooling – V6.

d Thermostat assembly, refer to Section 6B1 Engine Cooling – V6.

e Exhaust manifold a ssemblies, refer to 3.11 Exhaust Manifold Assembly .

f Engine coolant outlet pipe, refer to Section 6B1 Engine Cooling – V6.

g Crankshaft position sensor, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

h Knock sensors, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

i Engine mounts and brackets, refer to 3.23 Engine Mounts and Brackets.

j Flexplate assemblies, refer to 4.3 Flexplate Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3030 of 6020

Engine Mechanical – V6 Page 6A1–253

Page 6A1–253

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides .

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly .

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end

Bearings .

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings .

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the revers e to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications for the

correct torque specifications.

1 Tighten the fasteners to the co rrect torque specification.

Engine ground connector bolt

torque specificat ion ............................................ 10.0 Nm

Power steering high pressure line

attaching bolt torque specification ............. 8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specif ication ................... 25. 0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification ................................. 44. 0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................ 23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that

contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the corre ct quantity and grade of coolant, refer to Section 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted,

refer to Section 7C1 Automatic – 4L60E – General Information .

5 Disable the ignition system, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start t he engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indica tor and confirm the engine has acceptable oil pressure. If

required, install an oil pressure gauge and m easure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis .

9 Run the engine at about 1,000 r. p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks wh ile the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3032 of 6020

Engine Mechanical – V6 Page 6A1–255

Page 6A1–255

Disassemble

1 Remove the following:

2 Oil pan drain plug (7) and sleeve (8).

3 Oil level sensor (9).

4 Crankshaft oil deflector bolts (6) and remove the deflector.

5 Oil pump suction pipe bolts (5) and the suction pipe (3).

6 Oil pump suction pipe gasket (4) from the suction pipe and discard.

Figure 6A1 – 444

Clean

1 Remove any remaining thread sealant, gasket material or sealant using a commercially available wooden or plastic

scraper.

2 Clean the oil pan and oil pan components in solvent.

3 Clean out debris from the bolt holes.

Safety glasses must be worn when using

compressed air.

4 Dry the oil pan and oil pan components with compressed air.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3033 of 6020

Engine Mechanical – V6 Page 6A1–256

Page 6A1–256

Inspect

1 Inspect the exterior of the oil pan for the following

conditions:

• Damage to the drain plug or drain plug hole,

• Damage to the transmission mounting bosses,

• Damage to the oil level sensor threads, and

• Dents or damage to the exterior.

2 Inspect the interior of the oil pan for the following conditions:

• Gouges or damage to the oil pan sealing

surfaces,

• Damage to the crankshaft oil deflector,

• Damage to the bolt holes,

• Damage to the oil suction tube mounting

bosses, and

• Damage to the crankshaft oil deflector mounting

bosses.

Figure 6A1 – 445

3 Inspect the oil pan deflector for damage.

4 Repair or replace the o il pan deflector and/or oil pan

as required.

Figure 6A1 – 446

5 Inspect the following:

6 The mounting face (1) of the oil pump suction pipe for possible leakage paths.

7 The oil pump pipe support bracket (2) for cracks or damage.

8 The oil pump suction pipe tube (3) for cracks, imperfections and/or damage.

9 The oil pump screen (4) for blockage, foreign material, tears, cracks and/or damage.

10 Repair or replace the oil pan and/or oil pan components as required.

Figure 6A1 – 447

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007