vin JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1271 of 2490

Controller Area Network (CAN)

The TCM is an integral part of the CAN system which facilitates the interchange of real-time data between control modules

and sensors. Please see section 303- 14 for a full description of CAN.

OBDII Interface

Data concerning OBDII related transmission failures is stored in the ECM for access via the J1962 socket.

System Functions

Range Selection

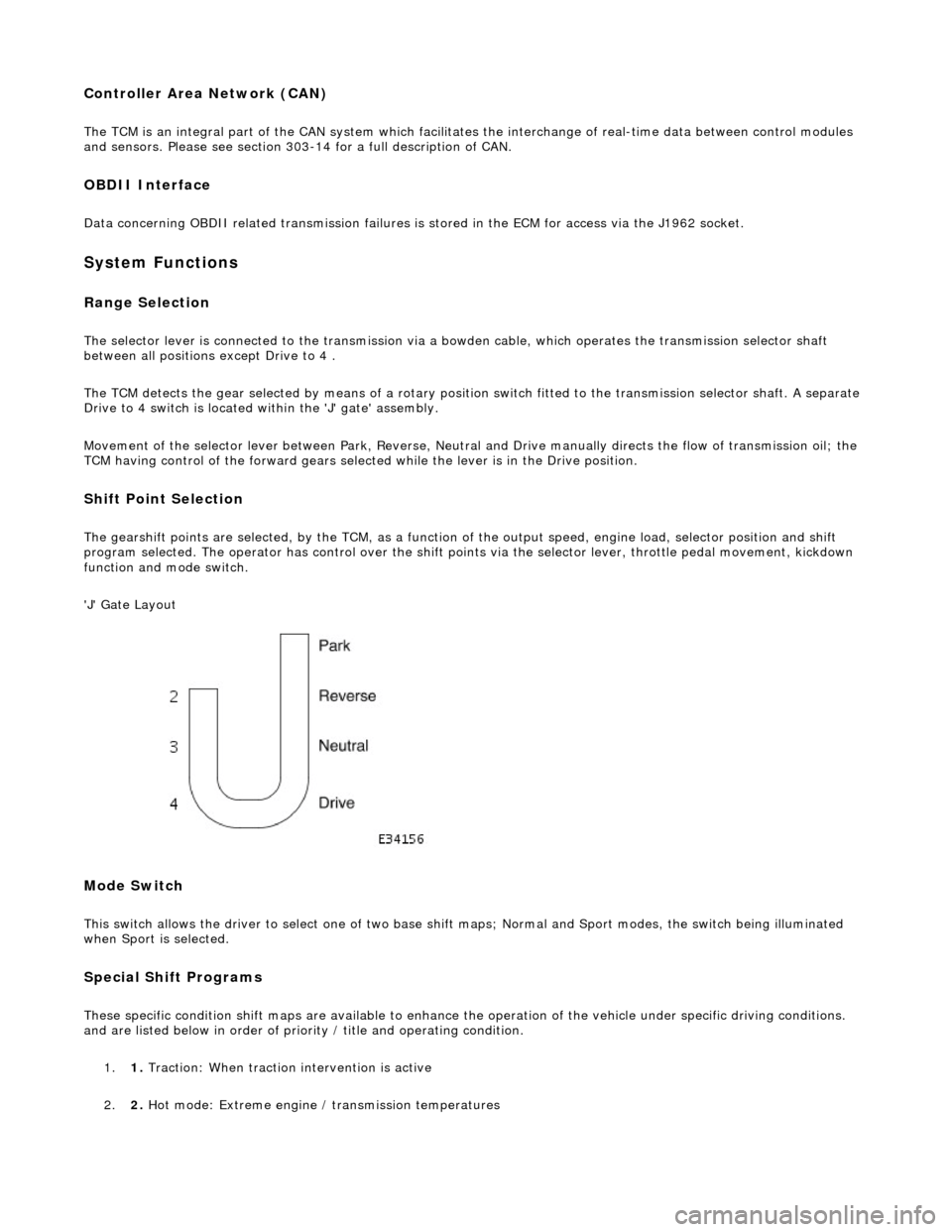

The selector lever is connected to the transmission via a bowden cable, which operates the transmission selector shaft

between all positions except Drive to 4 .

The TCM detects the gear selected by means of a rotary position switch fitted to the transmission selector shaft. A separate

Drive to 4 switch is located within the 'J' gate' assembly.

Movement of the selector lever between Park, Reverse, Neutral and Drive manually directs th e flow of transmission oil; the

TCM having control of the forward gears selected while the lever is in the Drive position.

Shift Point Selection

The gearshift points are selected, by the TCM, as a function of the output speed, engine load, selector position and shift

program selected. The operator has control over the shift points via the selector lever, throttle pedal movement, kickdown

function and mode switch.

'J' Gate Layout

Mode Switch

This switch allows the driver to select one of two base shift maps; Normal and Sport modes, the switch being illuminated

when Sport is selected.

Special Shift Programs

These specific condition shift maps are available to enhance the operation of the vehicle under specific driving conditions.

and are listed below in order of priority / title and operating condition.

1. 1. Traction: When traction intervention is active

2. 2. Hot mode: Extreme engine / transmission temperatures

Page 1272 of 2490

3.3. Gradient: Under specific speeds and loads

4. 4. Cruise: During cruise control

5. 5. Manual: Shift map when the LH side of the 'J gate' is used

Three specific condition shift maps have a higher priority than the two base shift maps and will intervene when appropriate

conditions prevail for traction, gradient or cruise.

When traction control (engine or brake system derived) is operational the TCM will implement the traction map to maximise

control of wheel slip.

The gradient maps are intended to enhance vehicle drivability when towing or climbing a gradient. The TCM will implement

the maps when increased driving resistan ce is detected and enhanced drivability, cooling and increa sed performance is

appropriate.

The cruise map is intended to minimize unwanted gearshifts and 'hunting' and is activated when cruising near to the set

speed, or resuming.

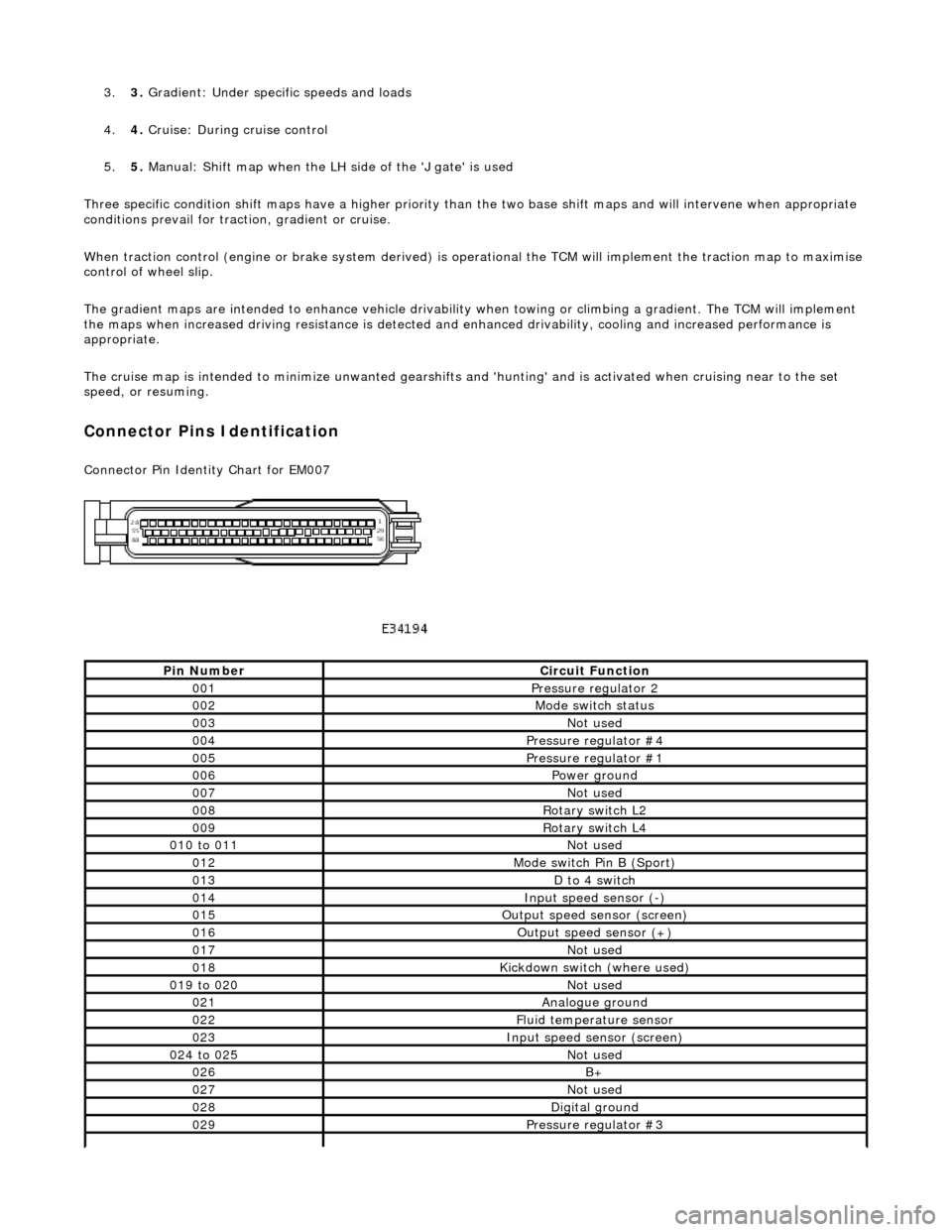

Connector Pins Identification

Connector Pin Identity Chart for EM007

Pin NumberCircuit Function

001Pressure regulator 2

002Mode switch status

003Not used

004Pressure regulator #4

005Pressure regulator #1

006Power ground

007Not used

008Rotary switch L2

009Rotary switch L4

010 to 011Not used

012Mode switch Pin B (Sport)

013D to 4 switch

014Input speed sensor (-)

015Output speed sensor (screen)

016Output speed sensor (+)

017Not used

018Kickdown switch (where used)

019 to 020Not used

021Analogue ground

022Fluid temperature sensor

023Input speed sensor (screen)

024 to 025Not used

026B+

027Not used

028Digital ground

029Pressure regulator #3

Page 1358 of 2490

Installation

1.

NOTE: A replacement TCM may only be obtained from an

authorized Jaguar dealer and MU ST be ordered against the VIN.

Fitting a new TCM is the revers e of the removal procedure.

At this point ensure that the ECM is correctly located and

pushed fully rearward against the housing.

2. Connect the battery and fit the battery cover..

Reset the radio and the clock.

Page 1384 of 2490

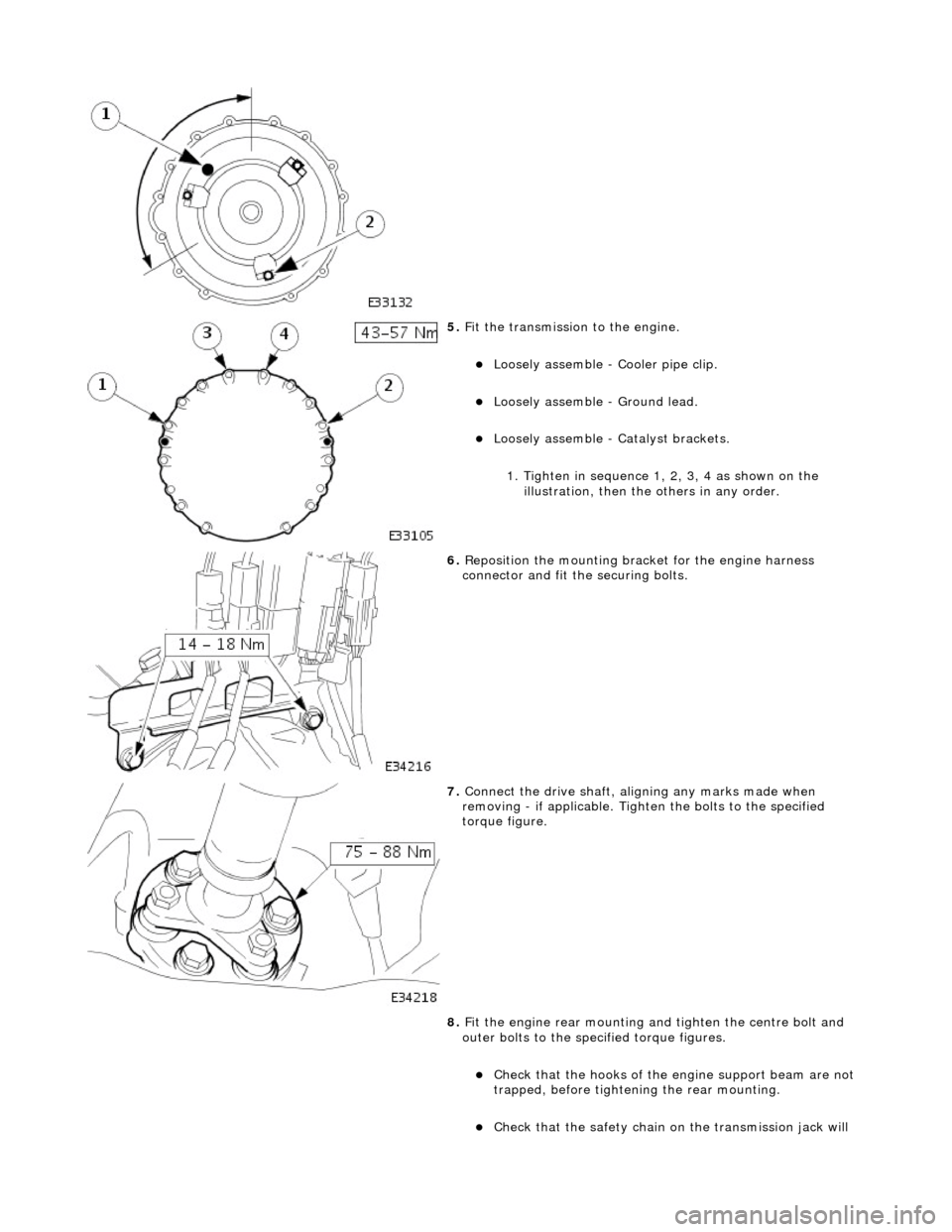

5. Fit the transmission to the engine.

Loosely assemble - Cooler pipe clip.

Loosely assemble - Ground lead.

Loosely assemble - Ca talyst brackets.

1. Tighten in sequence 1, 2, 3, 4 as shown on the illustration, then the others in any order.

6. Reposition the mounting brac ket for the engine harness

connector and fit the securing bolts.

7. Connect the drive shaft, aligning any marks made when

removing - if applicable. Tighten the bolts to the specified

torque figure.

8. Fit the engine rear mounting and tighten the centre bolt and

outer bolts to the specified torque figures.

Check that the hooks of the engine support beam are not

trapped, before tighteni ng the rear mounting.

Check that the safety chain on the transmission jack will

Page 1394 of 2490

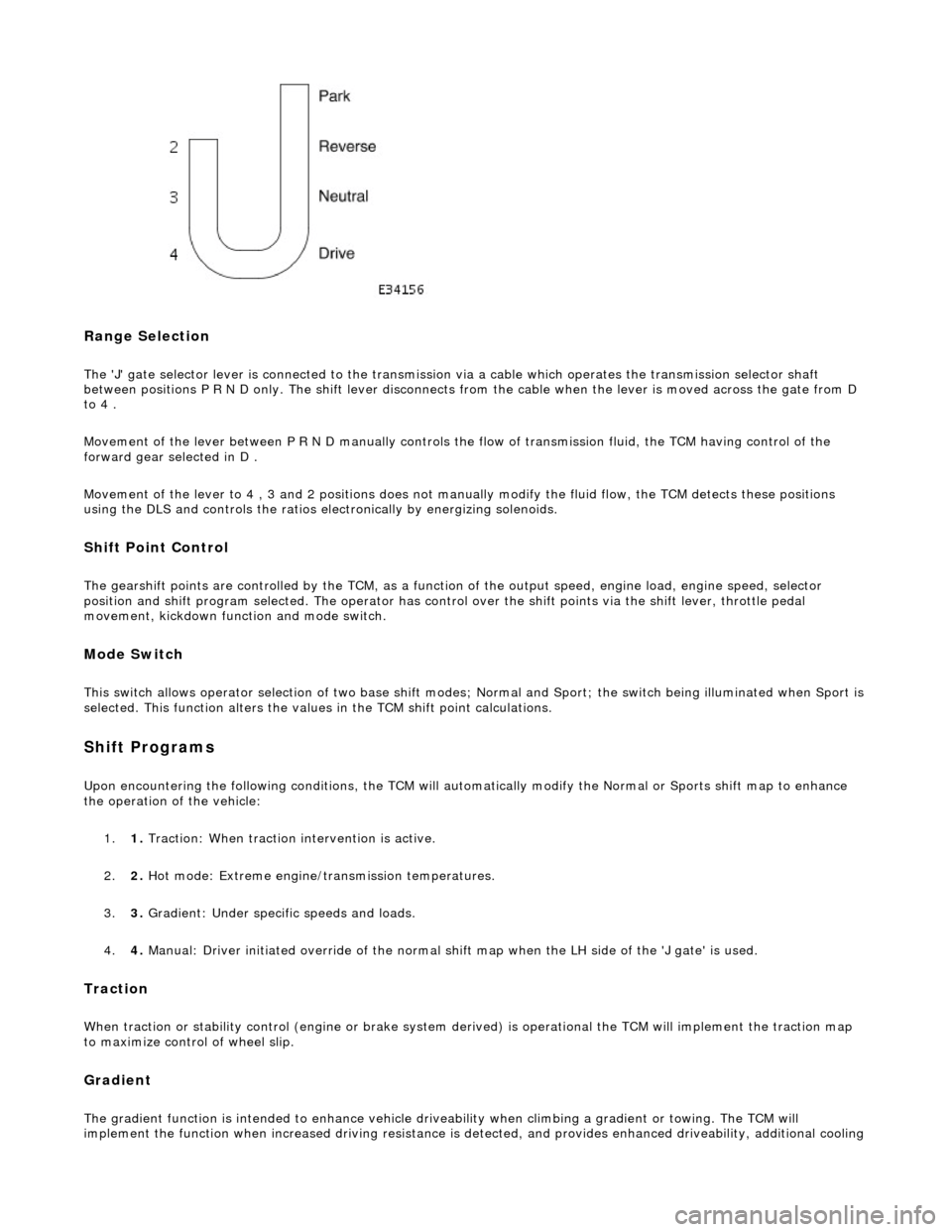

Range Selection

The 'J' gate selector lever is connected to the transmission via a cable which operates the transmission selector shaft

between positions P R N D only. The shift lever disconnects from the cable when the lever is moved across the gate from D

to 4 .

Movement of the lever between P R N D manu ally controls the flow of transmission fluid, the TCM having control of the

forward gear selected in D .

Movement of the lever to 4 , 3 and 2 positions does not manu ally modify the fluid flow, the TCM detects these positions

using the DLS and controls the ratios electronically by energizing solenoids.

Shift Point Control

The gearshift points are controlled by the TCM, as a function of the output speed, engine load, engine speed, selector

position and shift program selected. The operator has control over the shift points via the shift lever, throttle pedal

movement, kickdown function and mode switch.

Mode Switch

This switch allows operator selection of two base shift modes; Normal and Sport; th e switch being illuminated when Sport is

selected. This function alters the values in the TCM shift point calculations.

Shift Programs

Upon encountering the following conditions, the TCM will auto matically modify the Normal or Sports shift map to enhance

the operation of the vehicle:

1. 1. Traction: When traction intervention is active.

2. 2. Hot mode: Extreme engine/transmission temperatures.

3. 3. Gradient: Under specific speeds and loads.

4. 4. Manual: Driver initiated override of the normal shif t map when the LH side of the 'J gate' is used.

Traction

When traction or stability control (engine or brake system de rived) is operational the TCM will implement the traction map

to maximize control of wheel slip.

Gradient

The gradient function is intended to enhance vehicle drivea bility when climbing a gradient or towing. The TCM will

implement the function when increased driving resistance is de tected, and provides enhanced driveability, additional cooling

Page 1434 of 2490

Installation

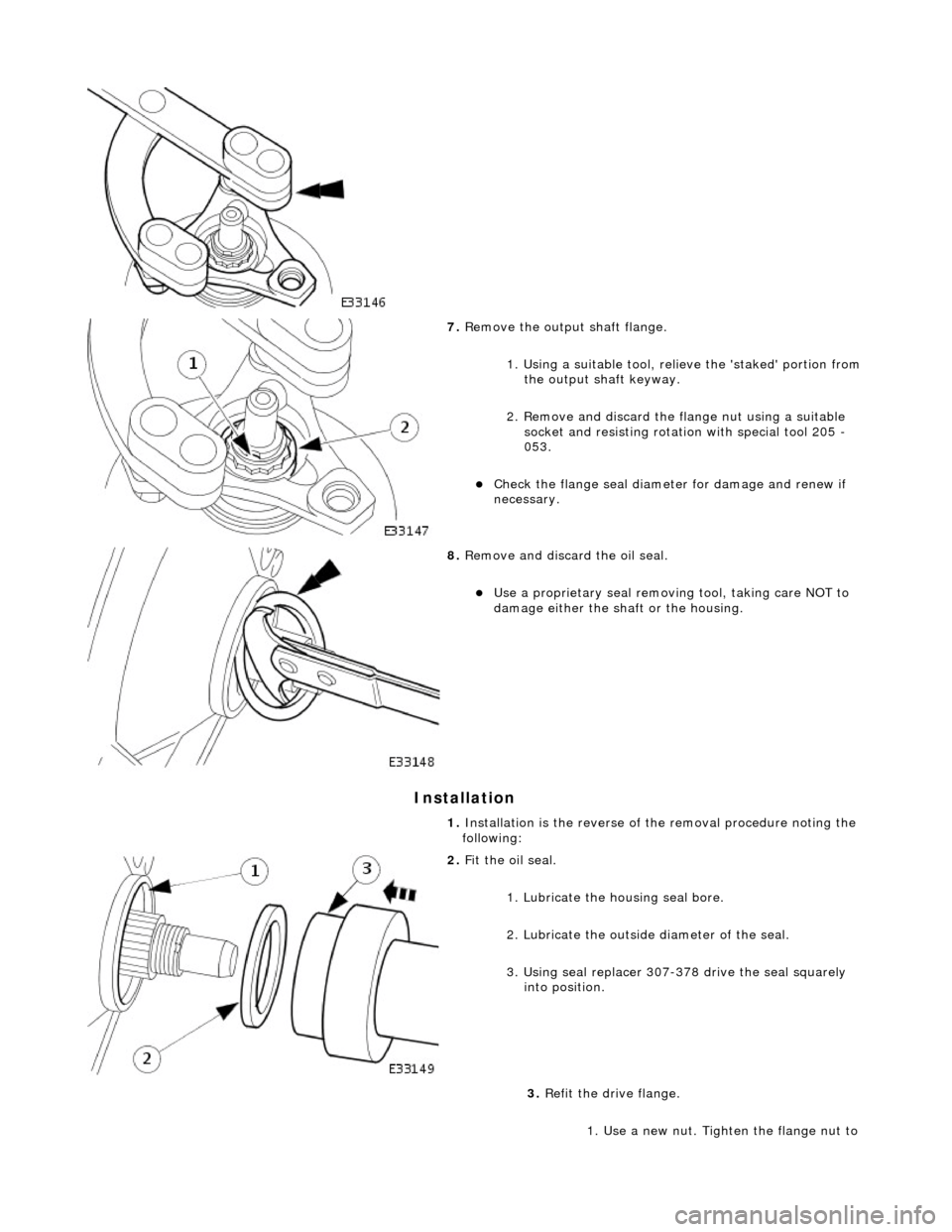

7. Remove the output shaft flange.

1. Using a suitable tool, reli eve the 'staked' portion from

the output shaft keyway.

2. Remove and discard the fl ange nut using a suitable

socket and resisting rotation with special tool 205 -

053.

Check the flange se al diameter for damage and renew if

necessary.

8. Remove and discard the oil seal.

Use a proprietary seal removing tool, taking care NOT to

damage either the shaft or the housing.

1. Installation is the re verse of the removal procedure noting the

following:

2. Fit the oil seal.

1. Lubricate the housing seal bore.

2. Lubricate the outside diameter of the seal.

3. Using seal replacer 307-378 drive the seal squarely into position.

3. Refit the drive flange.

1. Use a new nut. Tighten the flange nut to

Page 1470 of 2490

Move the selector lever slowly from P to 2 and back,

noting the illumination / positi on relationship as follows: 1

Does state illumination match the lever position in each

direction of travel?

Yes

GO to A4

No GO to A3

No With lever at D (when moving from 2 to P ) is 3 or 4

illuminated?

Yes GO to A3

No GO to A5

No With lever moved from P , to position 4 , is D illuminated?

Yes GO to A4

No GO to A5

A3: CHECK SELECTOR CABLE ADJUSTMENT

Verify and correct as requ ired the selector cable

adjustment 1

OK?

Yes GO to A4

No Correct adjustment error, see 44.15.07 Workshop Manual

307-05A and test the system for normal operation.

A4: CHECK HARNESS SIGNAL CONTINUITY - D TO 4 SWITCH

Page 1483 of 2490

moving the set position of either the shift lever or the selector lever.

3. Tighten the locknuts to the specified torque figure

4. Verify the N setting.

11. Further installation is the reve rse of the removal procedure.

12. Connect the battery and fit the battery cover.

Reset the radio and the clock.

Page 1501 of 2490

Selector lever:

Gear selector positions are:

P Transmission mechanically locked, starting available * R Reverse gear N Neutral gear, no power to the rear wheels (starting available) D Drive gear, all 5 forward gears available (see Performance Mode Pushbutton) 4 Upshift to 4th gear only 3 Upshift to 3rd gear only 2 Upshift to 2nd gear only

Gearshift Interlock Manual Override*

The interlock system which locks the sele ctor in P and prevents the ignition key from being removed except when P is

selected, may be manually overridden in the event of an emergency.

1. 1. With the parking brake applied

2. 2. Remove the access blank using a suitable Torx bit

3. 3. Insert a small screwdriver into the vacated hole

4. 4. Push the screwdriver downwards, gently, and hold whilst simultaneously moving the selector from P towards R ,

but do not engage R until the tool has been removed

5. 5. An audible warning may be heard when operation 4 is carried out

6. 6. With the selector in N and the access bl ank replaced, the vehicle may be started

Range Selection

The selector lever transmits operator demand to the transmission and TCM by means of a cable and Dual-Linear

Switch (DLS).

The lever operates the transmission assemb ly selector shaft, only for P R N D , by means of a cable. Movement of the

lever across the gate to 4, 3 and 2 positions disengages th e cable from the selector lever and engages the DLS which

controls gear selection electronically.

Gear selector module:

Provides illumination of the decal relevant to the gear sele cted. This information is provided by CAN from the TCM. Illuminates the security system Active LED on the gear selector surround, in response to an output from the BPM.

Transmission Switches

Performance Mode Pushbutton

7—Connector - Climate control

8—Solenoid - Gear selector

9—Security system Active LED

Page 1504 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L SC V8 - AJ26 -

External Controls

Diagnosis and Testing

Problem Solving - Transmission Shift

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scan tool

SymptomPossible SourcesAction

Shift stuck in P Selector cable seized

*GO to 44.15.08

*

Interlock solenoid not operating

*GO to PDU

*

Interlock latch seized

Transmission faulty

*

*Mechanical check

*

Operator sequence error

*Correct the sequence

*

Vehicle rolls on P Incorrect cable adjustment

*GO 44.15.07

*

Faulty parking pawl (transmission internal)

*Mechanical check

*

R does not engageIncorrect cable adjustment

*GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

N not achievedIncorrect cable adjustment

Transmission faulty

*

*GO to 44.15.07

*

D does not engageIncorrect cable adjustment *GO to 44.15.07

*

Transmission fluid level incorrect

*GO to 44.24.02

*

Transmission faulty

*Mechanical check

*

Lower ratios will not holdExcessive engine temperature

DLS fault

*

*GO to PDU

*

Shift lever position not visually correctIncorrect DLS adjustment

*GO to 44.15.07

*

Shift lever has no effect upon the

transmission and resistance cannot be

feltCable disconnected or broken

Transmission selector problem

Shift lever drive pin adrift

*

*

*Mechanical check

*

Shift lever position not align correctly

following manual selection of lower

ratiosSliding block drive pin displaced - following road debris contact

*Mechanical check. Renew the selector if

damaged, or re-align the drive pin and

sliding block

*

Shift lever detent indistinct in 3

causing poor locationDLS detent fault

*GO to Renew the DLS

*

Shift may be moved from P without

brake pedal operationInterlock latch fault

*Mechanical check

*

Solenoid permanently activated

*GO to PDU

*

Engine may be started in positions

other than P or N Incorrect cable adjustment

DLS fault

*

*GO to 44.15.07

*

Shift lever vibrationLoose selector assembly

Cable isolation fault

*

*Mechanical check

*

Noise / rattle from 'J' gateDebris in the mechanism

*Clean

*

Worn 'J' gate track gasket

allowing lever and moulding to

contact

*GO to 44.15.05

*