body JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 899 of 2490

16. Disconnect the air cleaner cover.

Remove the five clips which se cure the air cleaner cover.

17. Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the centre trim panel from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

19. Release the hoses (Quick Fit connections) from the expansion

tank, using 303 - 623.

1. Release the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

Page 907 of 2490

56. Disconnect the fuel feed and return hoses.

1. Disconnect the fuel hoses at the Quick Fit connectors,

using special tool 310 - 044 for the feed hose and

310 - 54 for the return hose.

Disconnect the return hose from the feed hose clip.

Fit blanking plugs to the pipes.

57. Disconnect the pipes from the purge valve.

1. Remove the clip which secu res the part load breather

hose to the purge valve.

2. Disconnect the part load breather hose.

3. Disconnect the vacuum hose from the purge valve and reposition the hose.

58. Disconnect the throttle cable.

1. Secure the cable abutment to the bracket with tape or a ratchet strap, if nece ssary (to save subsequent

adjustment procedure). Remove the bolts which

secure the abutment bracke t to the throttle body.

2. Rotate the butterfly actuator cam and disconnect the cable. Reposition the cable.

59. Disconnect the heater and brake servo hoses.

1. Disconnect the he ater return hose.

2. Release the heater feed hose locking lever and

disconnect the hose.

Page 909 of 2490

1. Remove the nut which secures the selector lever to

the transmission cross shaft.

2. Remove the selector cable abutment bolts.

3. Disconnect the selector arm from the cross shaft.

67. Loosen the bolt which secures the engine rear mounting

rubber to the transmission.

68. Position a transmission jack e.g. Epco V100 and raise the

support bed of the jack to take the weight of the transmission.

Fit and adjust the chains to secure the transmission to the jack.

69. Remove the engine rear mounting assembly.

Remove the mounting centre bolt.

Remove the four bolts which secure the crossmember to

the body.

Remove the crossmember and mounting assembly.

70. Release the engine and tran smission assembly from the

engine compartment.

Take the weight of the engine / transmission with the

hoist and move it towards th e front of the vehicle.

Lower the transmission jack slightly to release the

securing chains. Remove the ja ck from below the vehicle.

Page 912 of 2490

Align th

e engine front mountings and fit the securing nuts.

Tighte

n to the stated torque value.

3. Operate the crane controls and the ramp simultaneously (with

assistance) to raise the vehicle to a convenient working height.

4. Po

sition the transmission jack and raise it to take the weight of

the transmission. Fit and adjust the chains to secure the

transmission to the jack.

5. Fit th

e engine rear mounting bracket.

Fi

t the four bolts which secu

re the crossmember to the

body.

Fi t t

he bolt which secures the

engine rear mounting rubber

to the transmission.

6. Tigh ten th

e rear mounting bolts

to the stated torque figure.

7. Release and remove the transmission jack.

8. Operate the crane controls and the ramp simultaneously (with

assistance) to lower the vehicle to a convenient working height.

9. Lower th e cran

e and remove th

e chain assembly and lifting

eyes.

Page 916 of 2490

3. Conne

ct the brake servo hose.

26. Conne

ct the P.I. harness to the engine management

harness.

1. Reposition the engi ne management harness

connector to the bracket.

2. Fit the nut which secures the engine management harness connector to the mounting bracket.

3. Connect the connectors.

4. Fit the bolt which secures the P.I. harness connector to the engine management harness.

27 . Conne

ct the transmission rotary

switch harness connector.

Re

position and connect the harness.

28 . Con

nect the throttle cable.

1. Fit the bolts which secure the abutment bracket to the throttle body. Tighten to 4-6 Nm.

2. Rotate the butterfly actuator cam and connect the cable. Reposition the cable into the cam.

Re

move any tape or plastic

strap which was fitted when

disconnecting the cable abutment.

29. Connect the pipes to the purge valve.

1. Connect the part load breather hose.

2. Fit the clip which secures the part load breather hose

to the purge valve.

Page 922 of 2490

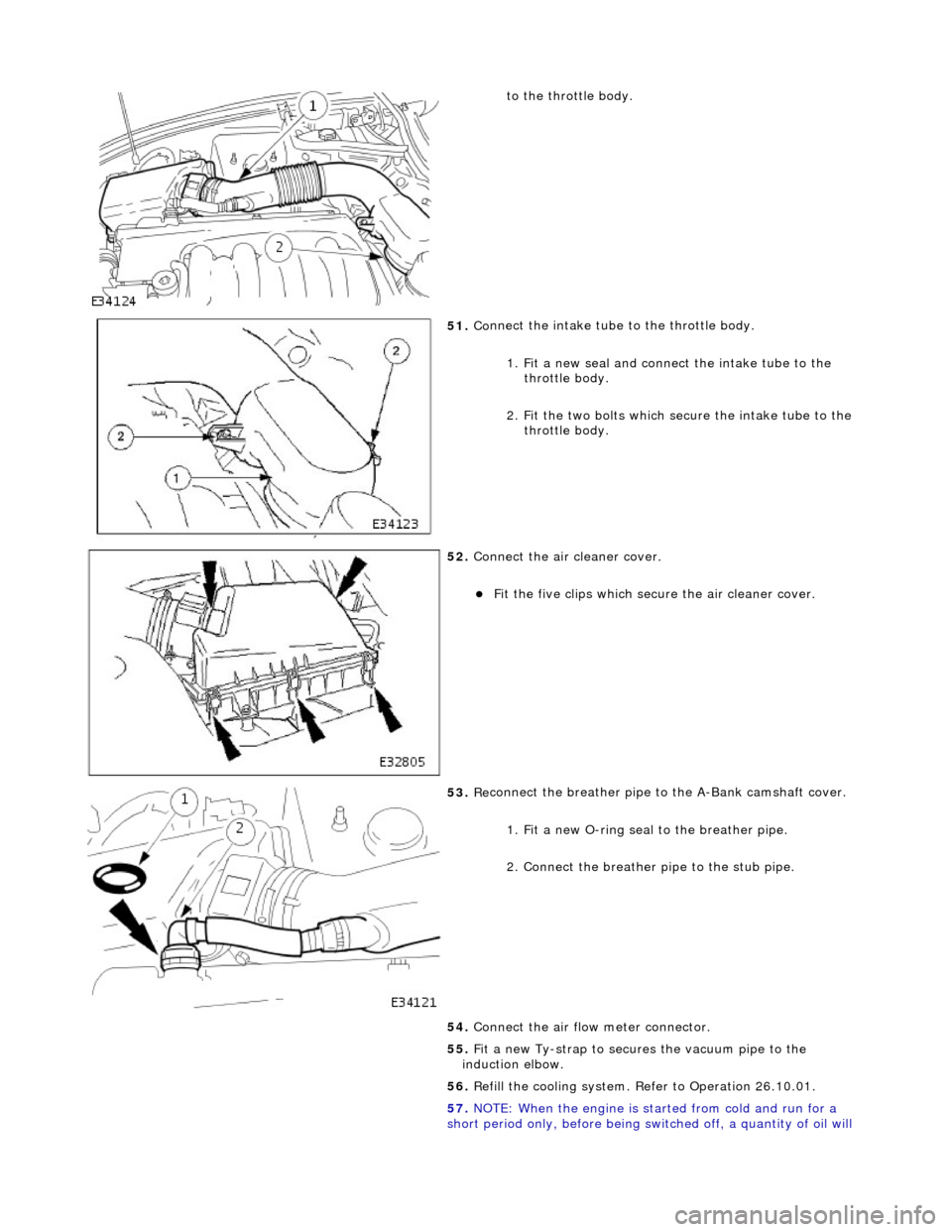

to th

e throttle body.

51 . Co

nnect the intake tube to the throttle body.

1. Fit a new seal and connect the intake tube to the throttle body.

2. Fit the two bolts which secure the intake tube to the throttle body.

52 . Conne

ct the air cleaner cover.

F

it

the five clips which secu

re the air cleaner cover.

53 . Re

connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Connect the breather pipe to the stub pipe.

54. Connect the air flow meter connector.

55. Fit a new Ty-strap to secures the vacuum pipe to the

induction elbow.

56. Refill the cooling system. Refer to Operation 26.10.01.

57. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

Page 925 of 2490

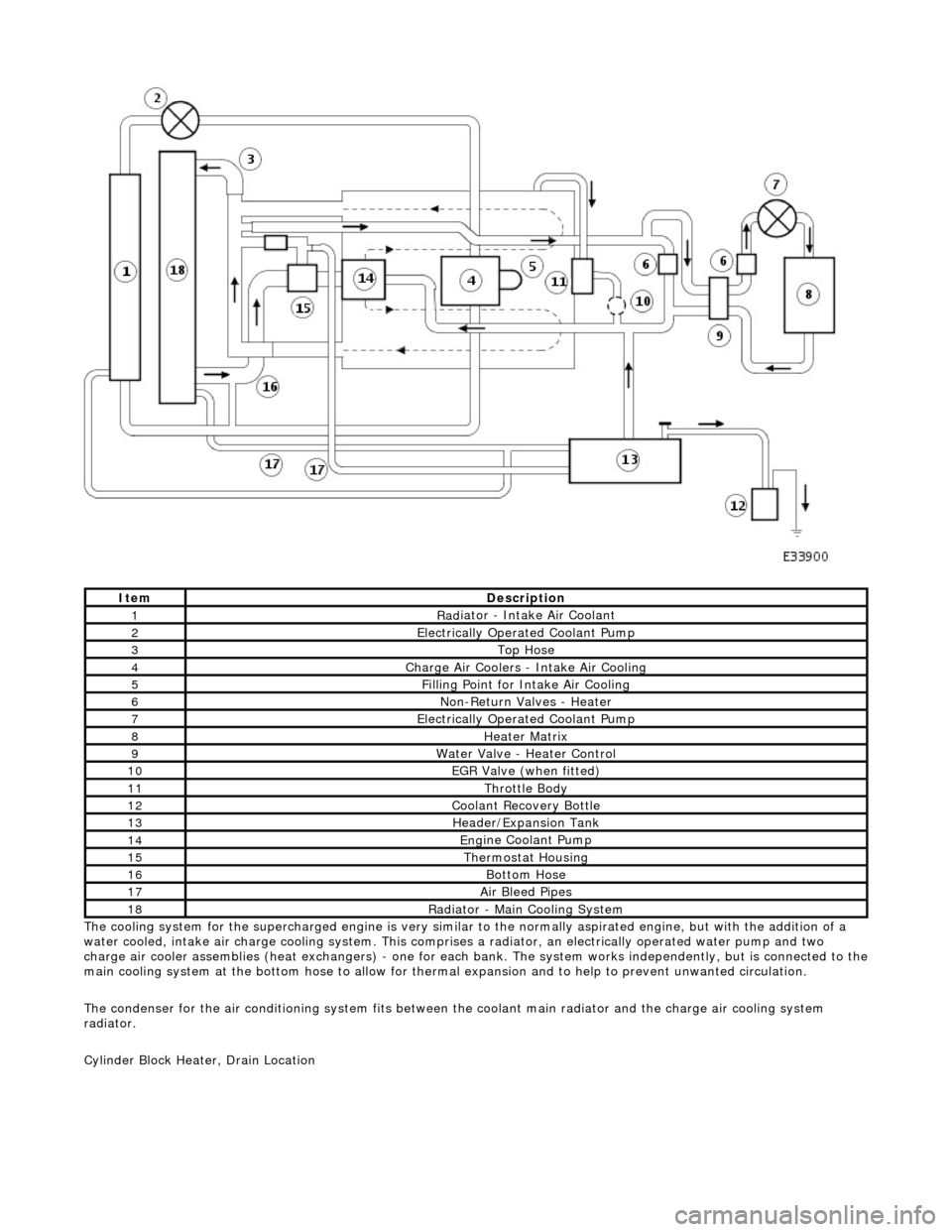

T

he cooling system for the supercharged engine is very similar

to the normally aspirated engine, but with the addition of a

water cooled, intake air charge cooling system. This comprises a radiator, an electrically operated water pump and two

charge air cooler assemblies (heat exchangers) - one for each bank. The system works independently, but is connected to the

main cooling system at the bottom hose to allow for therma l expansion and to help to prevent unwanted circulation.

The condenser for the air conditioning system fits between th e coolant main radiator and the charge air cooling system

radiator.

Cylinder Block Heater, Drain Location

ItemDe

scription

1Rad

iator - Intake Air Coolant

2Ele

ctrically Operated Coolant Pump

3Top Hose

4Charge Air Coo

lers -

Intake Air Cooling

5Fi

lling Point for Intake Air Cooling

6N

on-Return Valves - Heater

7Ele

ctrically Operated Coolant Pump

8Hea

ter Matrix

9Wate

r Valve - Heater Control

10EGR V

alve (when fitted)

11Thr

ottle Body

12Coolan

t Recovery Bottle

13H

eader/Expansion Tank

14Eng

ine Coolant Pump

15The

rmostat Housing

16Bottom

Hose

17Air Bleed

Pipes

18Rad

iator - Main Cooling System

Page 929 of 2490

The cooling

pack incorporates the radiator a

ssembly with integral transmission oil cool er (located in the radiator outlet tank),

an air conditioning condenser, and the cooling fans and cowl assembly.

The cooling pack on supercharged vehicles is the same as described above, but with the addition of a charge air cooler

coolant radiator located in front of the condenser.

Radiator Mounti

ng/Retention

T

he radiator is mounted on four rubber mounts, one on each

end of the upper and lower horizontal face. The two lower

mountings are supported on two isolated brackets mounted on the body; the lower cradle assembly has subsequently been

deleted.

A closing panel made from polypropylene, which retains the radiat or assembly, fits over the top of the radiator and is bolted

to the vehicle top panel.

Coolant Hoses - Engine

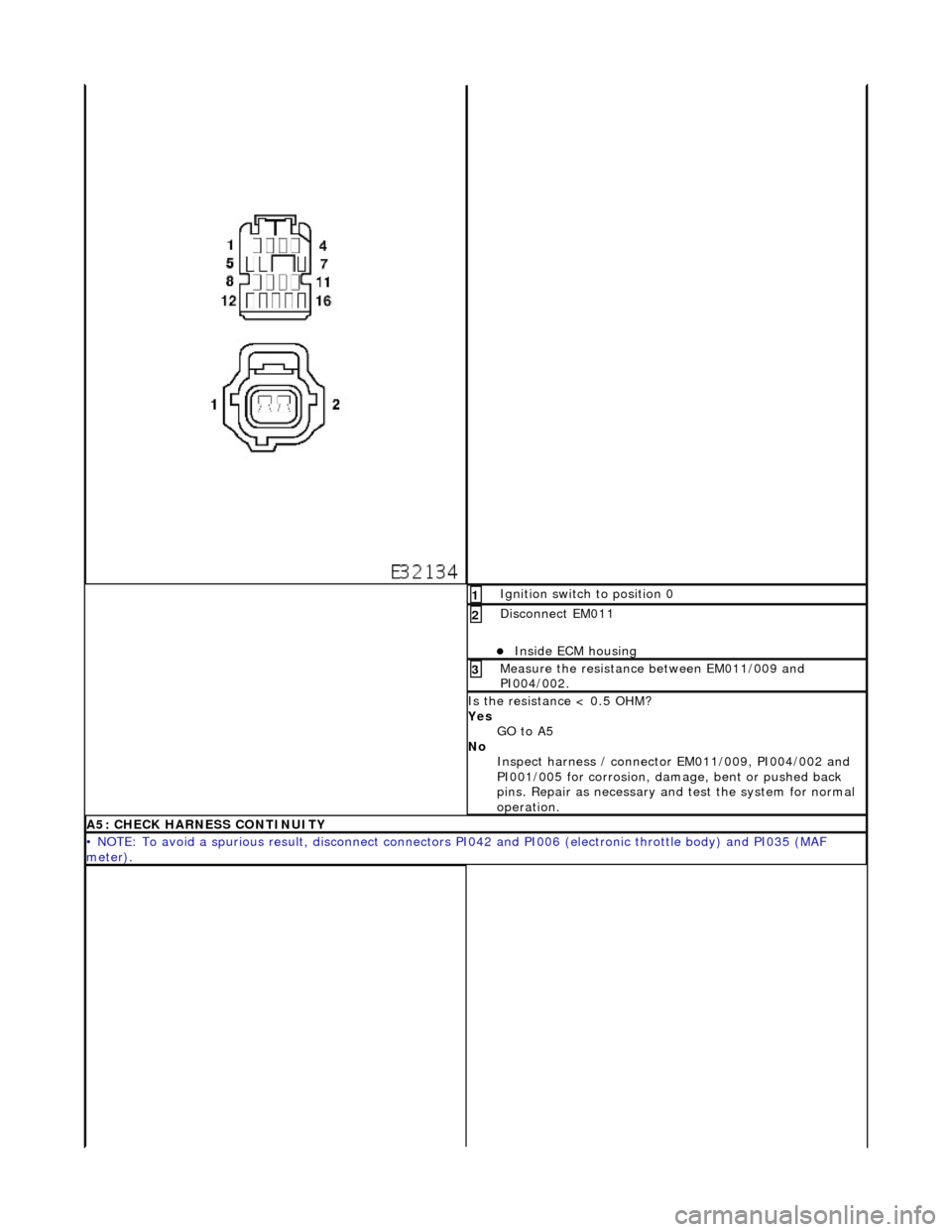

Page 937 of 2490

I

gnition switch to position 0

1

Di

sconnect EM011

Inside E

CM housing

2

Me

asure the resistance between EM011/009 and

PI004/002.

3

I

s the resistance < 0.5 OHM?

Yes GO to A5

No Inspect harness / connector EM011/009, PI004/002 and

PI001/005 for corrosion, damage , bent or pushed back

pins. Repair as necessary and test the system for normal

operation.

A5: CHECK

HARNESS CONTINUITY

•

NOTE: To avoid a spurious result, disconnect connectors PI042 and PI006 (electronic throttle body) and PI035 (MAF

meter).

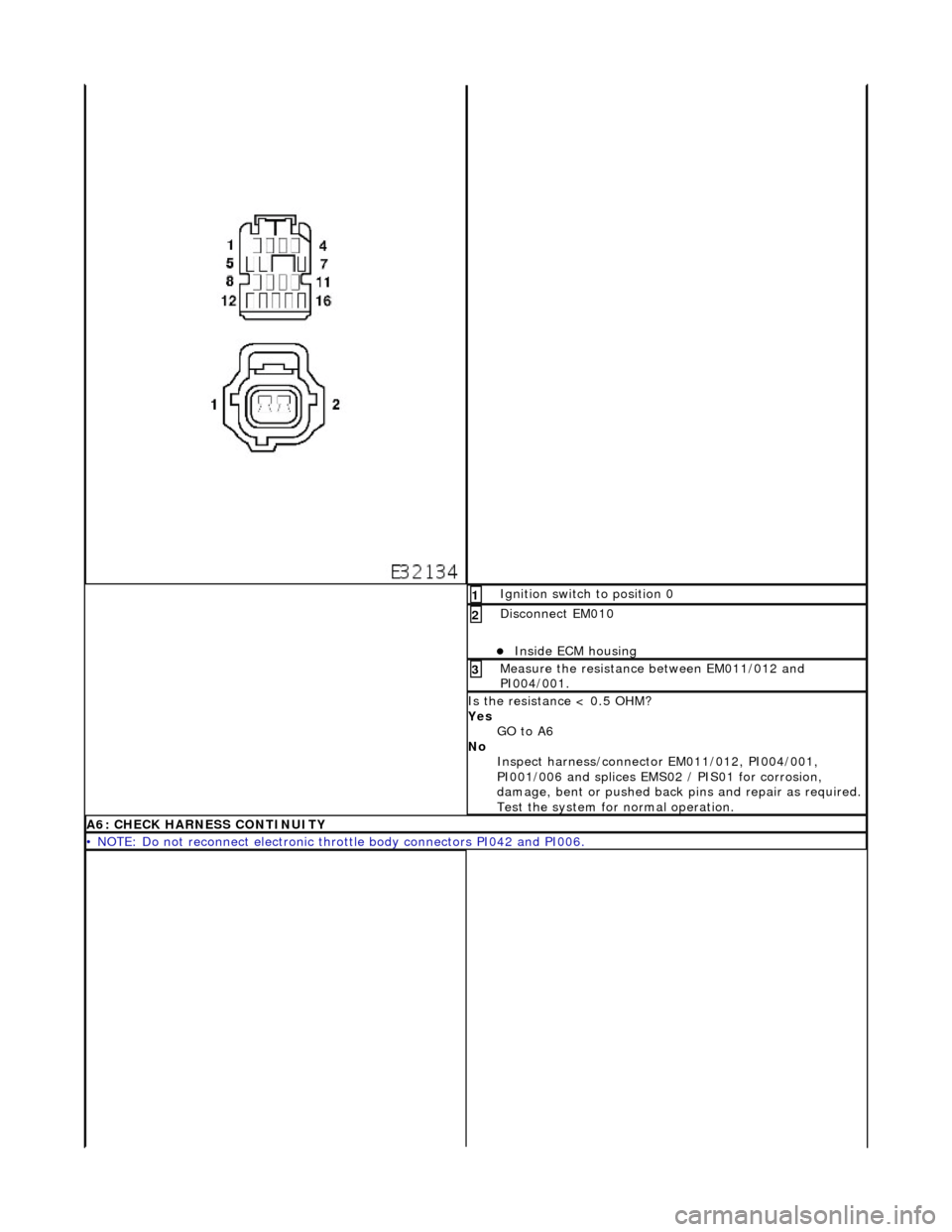

Page 938 of 2490

Ig

nition switch to position 0

1

Di

sc

onnect EM010

Inside E

C

M housing

2

Me

asure

the resistance between EM011/012 and

PI004/001.

3

I s

the resistance < 0.5 OHM?

Yes GO to A6

No Inspect harness/connector EM011/012, PI004/001,

PI001/006 and splices EMS02 / PIS01 for corrosion,

damage, bent or pushed back pins and repair as required.

Test the system for normal operation.

A6: CHECK HARNESS

CONTINUITY

•

NOTE

: Do not reconnect electronic thro

ttle body connectors PI042 and PI006.