door JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 49 of 2490

Identification

Codes -

Identification Codes

Descr

iption and Operation

En

gine Number

The en

gine number (10 digits) is stamped on a raised pad on th

e front of the engine block near the thermostat housing. The

piston grade reference (8 digits) is also shown.

Automatic Transmission

Number

The

serial number of the transmission unit is displayed on

a metal or bar code label attached to the LH side of the

transmission casing.

Veh

icle Identification

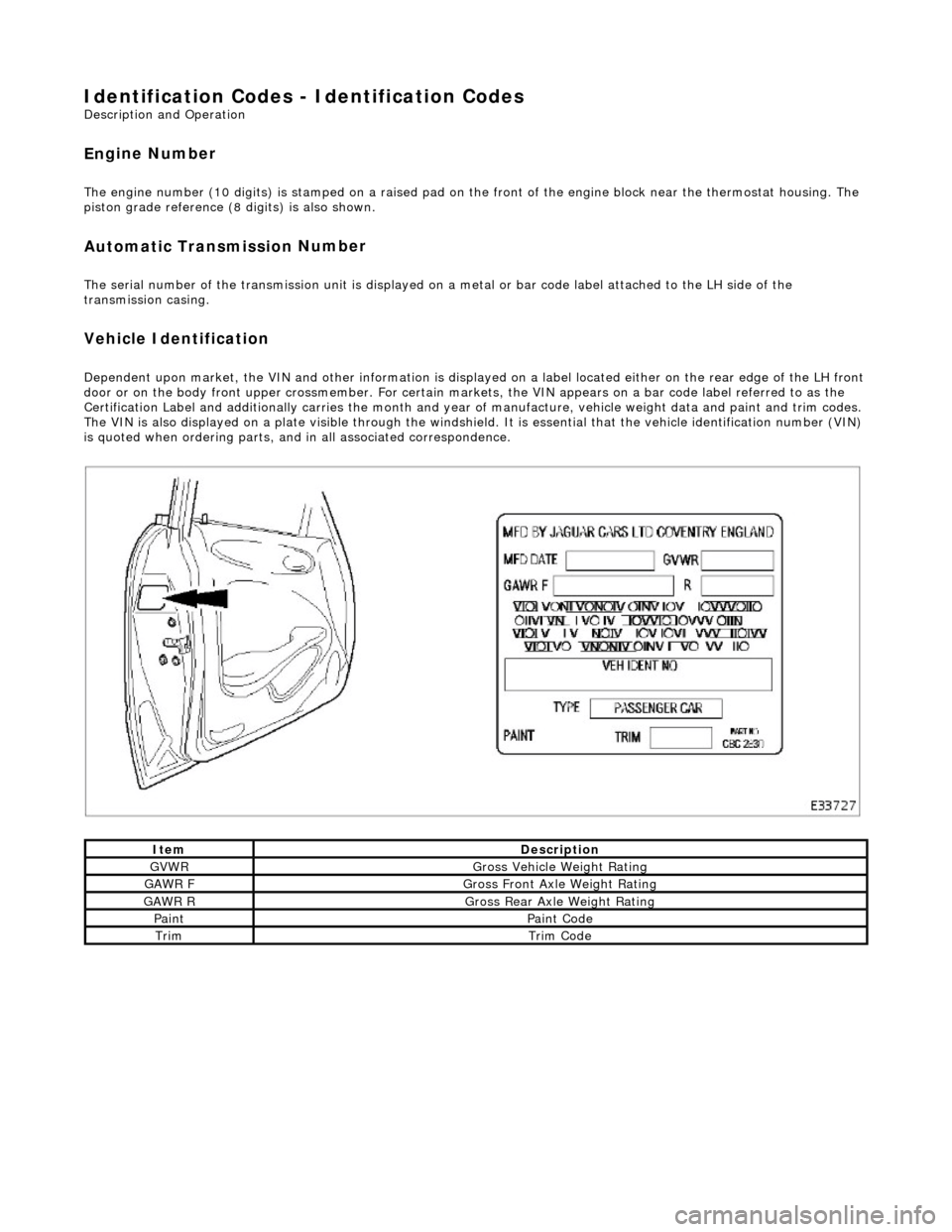

Dependent

upon market, the VIN and other info

rmation is displayed on a label located ei ther on the rear edge of the LH front

door or on the body front upper crossmember. For certain mark ets, the VIN appears on a bar code label referred to as the

Certification Label and additionally carries the month and year of manufacture, vehicle weight data and paint and trim codes.

The VIN is also displayed on a plate visible through the windshie ld. It is essential that the vehicle identification number (VIN)

is quoted when ordering parts, and in all associated correspondence.

ItemDe

scription

GVW

R

G

ross Vehicle Weight Rating

GAW

R F

Gros

s Front Axle Weight Rating

GAW

R R

Gros

s Rear Axle Weight Rating

Pai

nt

Pai

nt Code

TrimTrim

Code

Page 466 of 2490

High pitched rapidly repea

ting sound, like chirping birds.

Cli

c

k

Ligh

t sou

nd, like a ball point pen being clicked.

Click

/

Thump

Heav

y

metal-to-metal sound, li

ke a hammer striking steel.

Grin

d

Abrasiv

e

sound, like a grinding wheel or sandpaper rubbing against wood.

Gr

oan

/Moan

Continu

o

us, low-pitched humming sound.

Groan

/Howl

Low, guttural sound, like an an

gry do

g.

Hiss

Continuous sound

like air escaping from a tire valve.

Hum

Continu o

us sound of varying frequencie

s, like a wire humming in the wind.

Knock

Heavy, loud repeat

ing sound like a knock on a door.

Pi

n

g

Si

mi

lar to knock, except at higher frequency.

Ratt

le

A s

ound suggesting looseness, such as marbles rolling around in a can.

Roar

Deep, long, prolonged sou

nd like an

animal, or winds and ocean waves.

Rumble

Low, he

avy cont

inuous sound like that made by wagons or thunder.

Scrape

Grating no

ise l

ike one hard plastic ru

bbing part rubbing against another.

Chir

p

Page 717 of 2490

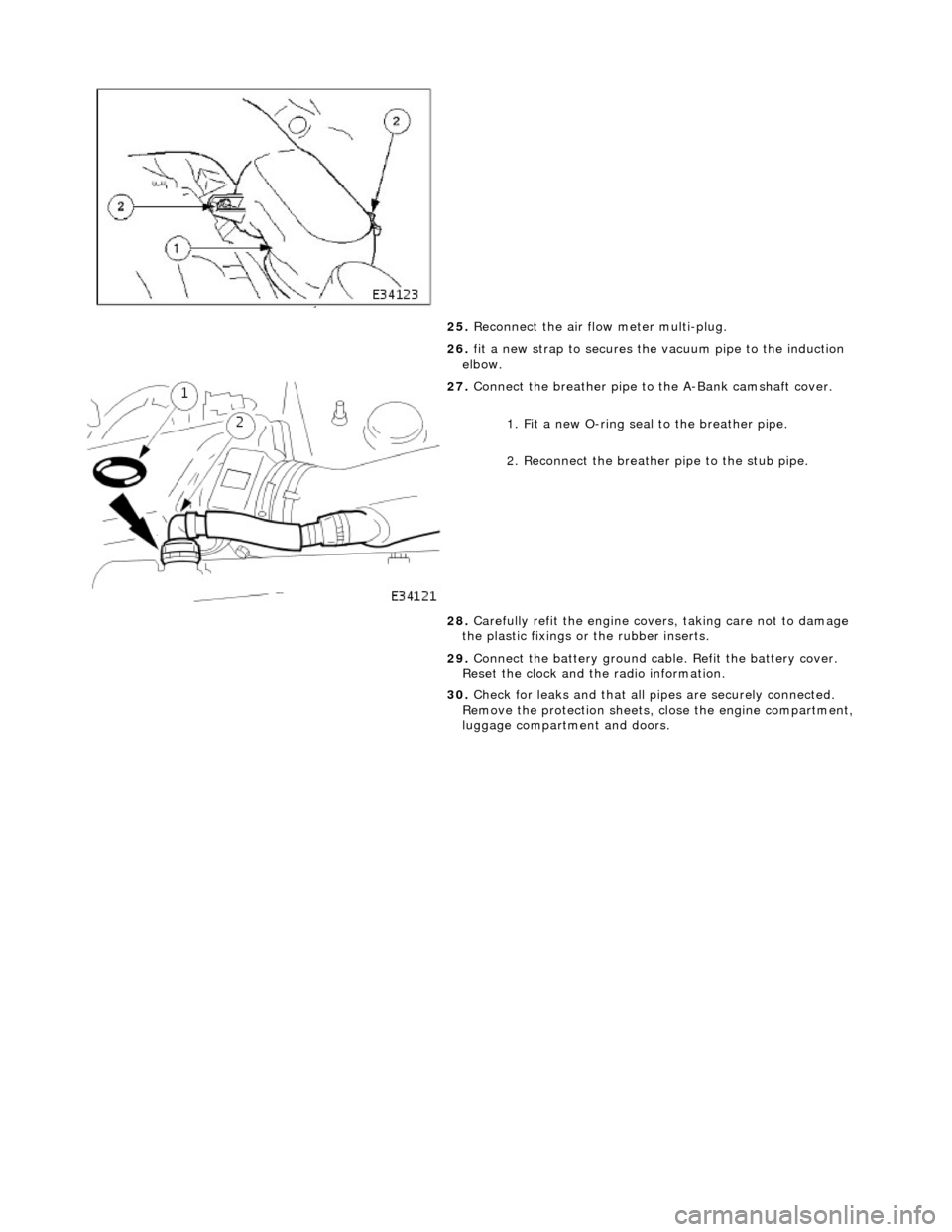

25. Reconnect the air flow meter multi-plug.

26. fit a new strap to secures the vacuum pipe to the induction

elbow.

27. Connect the breather pipe to the A-Bank camshaft cover.

1. Fit a new O-ring seal to the breather pipe.

2. Reconnect the breather pipe to the stub pipe.

28. Carefully refit the engine covers, taking care not to damage

the plastic fixings or the rubber inserts.

29. Connect the battery ground cabl e. Refit the battery cover.

Reset the clock and the radio information.

30. Check for leaks and that all pi pes are securely connected.

Remove the protection sheets, close the engine compartment,

luggage compartment and doors.

Page 728 of 2490

2. Reconnect the breather pipe to the stub pipe.

21. Carefully refit the engine covers, taking care not to damage

the plastic fixings or the rubber inserts.

22. Connect the battery ground cabl e. Refit the battery cover.

Reset the clock and the radio information.

23. Check for leaks and that all pi pes are securely connected.

Remove the protection sheets, close the engine compartment,

luggage compartment and doors.

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.

Page 1773 of 2490

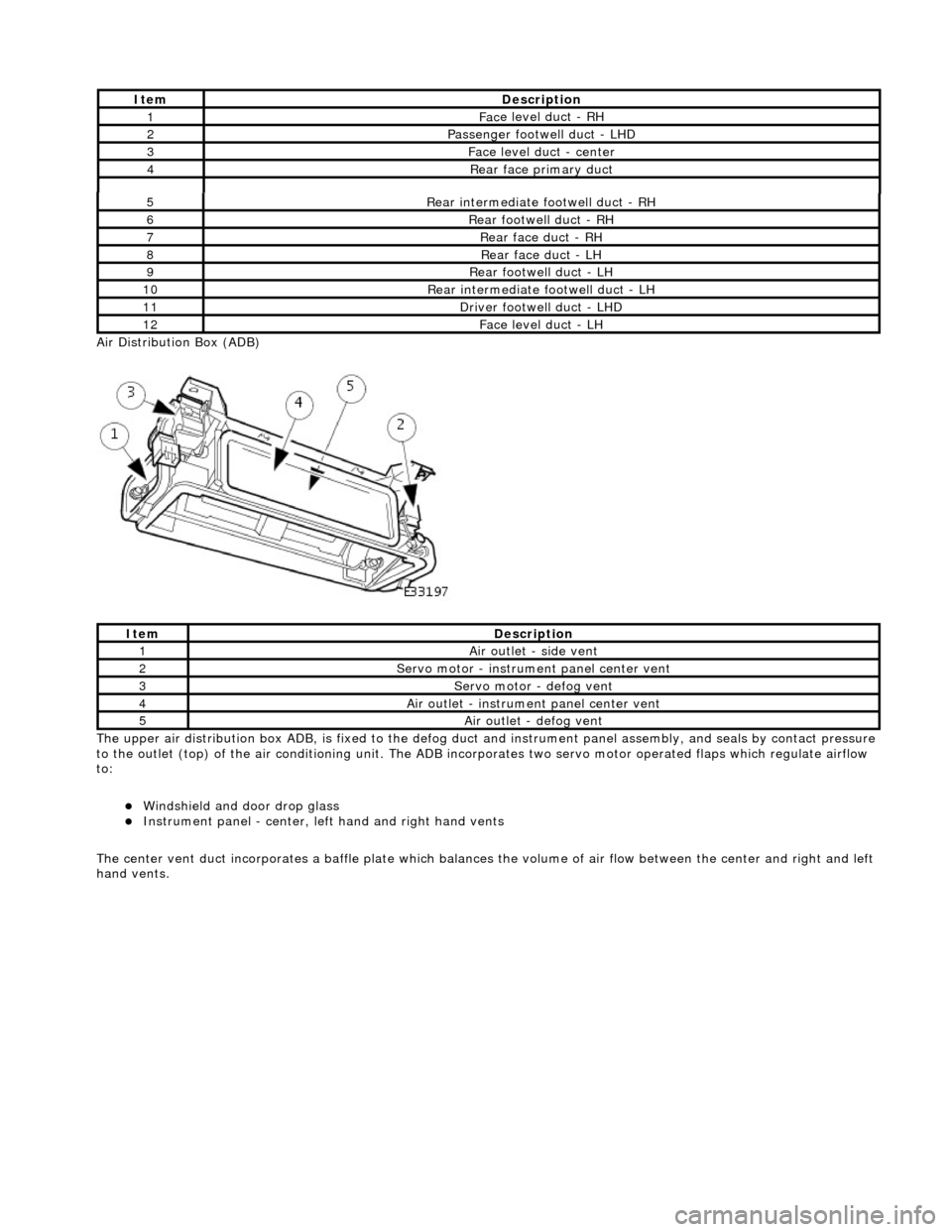

Ai

r Distribution Box (ADB)

The upper air distribution box ADB, is fixed to the defog duct and instrument panel assembly, and seals by contact pressure

to the outlet (top) of the air conditioning unit. The ADB inco rporates two servo motor operated flaps which regulate airflow

to:

Windshield and door drop

glass

Instrument panel

- center, left

hand and right hand vents

The center vent duct incorporat es a baffle plate which balances the volume of air flow between the center and right and left

hand vents.

5R

ear intermediate footwell duct - RH

6R

ear footwell duct - RH

7R

ear face duct - RH

8R

ear face duct - LH

9R

ear footwell duct - LH

10R

ear intermediate footwell duct - LH

11D

river footwell duct - LHD

12Fac

e level duct -

LH

It

em

De

scription

1Ai

r outlet - side vent

2Servo motor -

instrume

nt panel center vent

3Servo motor -

defog vent

4Ai

r outlet - instrume

nt panel center vent

5Ai

r outlet - defog vent

It

em

De

scription

1Fac

e level duct - RH

2Passenger footwel

l duct - LHD

3Fac

e level duct - center

4Rear

face primary duct

Page 1777 of 2490

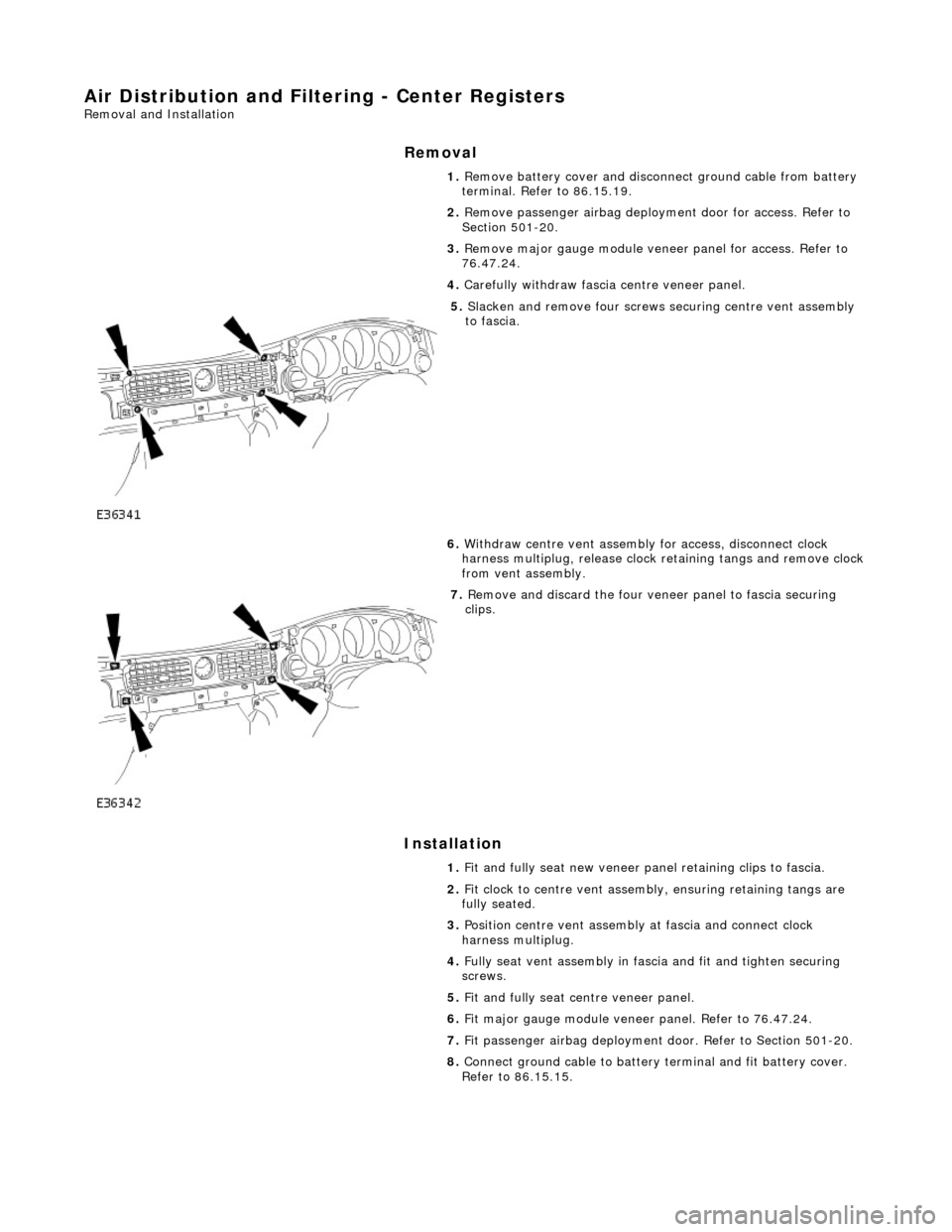

Air Distribution and Filtering - Center Registers

Removal and Installation

Removal

Installation

1.

Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove passenger airbag deployment door for access. Refer to

Section 501-20.

3. Remove major gauge module veneer panel for access. Refer to

76.47.24.

4. Carefully withdraw fascia centre veneer panel.

5. Slacken and remove four screws securing centre vent assembly

to fascia.

6. Withdraw centre vent assembly for access, disconnect clock

harness multiplug, release clock retaining tangs and remove clock

from vent assembly.

7. Remove and discard the four veneer panel to fascia securing

clips.

1. Fit and fully seat new veneer panel retaining clips to fascia.

2. Fit clock to centre vent assemb ly, ensuring retaining tangs are

fully seated.

3. Position centre vent assembly at fascia and connect clock

harness multiplug.

4. Fully seat vent assembly in fascia and fit and tighten securing

screws.

5. Fit and fully seat centre veneer panel.

6. Fit major gauge module veneer panel. Refer to 76.47.24.

7. Fit passenger airbag deployment door. Refer to Section 501-20.

8. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 1824 of 2490

External temperature < -10 °C Vehicle speed > 65 km / h The first two conditions exist > 2 minutes. Engine speed > 50 revs / min

14. 14. Heated Backlight (R)

Pressing the heated backlight button will simultaneously energize the heater elements for timed cycles of;

21 minutes backlight 11 minutes exterior mirrors

Pressing the button again within the 21 minute timer will cancel the request.

If the engine is stalled, or the ignition switched OFF, the backlight and door mirror timers will be cleared, resulting in both

functions being switched off.

• NOTE: Both the backlight and door mirrors may be activated with the climate control system OFF, but the engine must be

running.

15. 15. Temperature Decrease

Pressing this button (BLUE symbol) decreases the interior temperature setting in 1° increments. Should the button be

pressed when the setting temperature is below the lower automatic control temperature limit, the display will indicate 'LO'.

16. 16. Temperature Increase

Pressing this button (RED symbol) will raise the temperature setting in 1° increments Should the button be pressed when

the setting temperature is above the upper automatic control temperature limit, the display will indicate 'HI'.

Automatic Temperature Control Range

°C°F

LOLO

1761

62

1863

64

1965

66

2067

68

2169

70

2271

72

2373

74

2475

76

2577

78

2679

80

2781

82

2883

84

2985

86

3087

88

3189

Page 1833 of 2490

Control Components - Control Components

Diagnosis and Testing

Connector Pin Identity Chart for AC001

Connector Pin Identity Chart for AC002

Pin NumberCircuitCircuit Function

001Compressor ON signal

002Coolant valve

003RH Blower motor relay

004Heated windshield relays (where fitted)

005Heated door mirror relay

006Defrost servomotor (positive)

007Center vent servomotor (positive)

008LH air intake servomotor fre sh / recirculation (positive)

009RH air intake servomotor fresh / recirculation (positive)

010Not used

011Not used

012Foot servomotor (positive)

013Cool air bypass servomotor (positive)

014Not used

015Not used

016LH Blower motor relay

017Coolant pump motor relay

018Heated backlight relay

019Defrost servomotor (negative)

020Center vent servomotor (negative)

021LH air intake servomotor fresh / recirculation (negative)

022RH air intake servomotor fresh / recirculation (negative)

023Not used

024Not used

025Foot servomotor (negative)

026Cool air bypass servomotor (negative)

Page 1842 of 2490

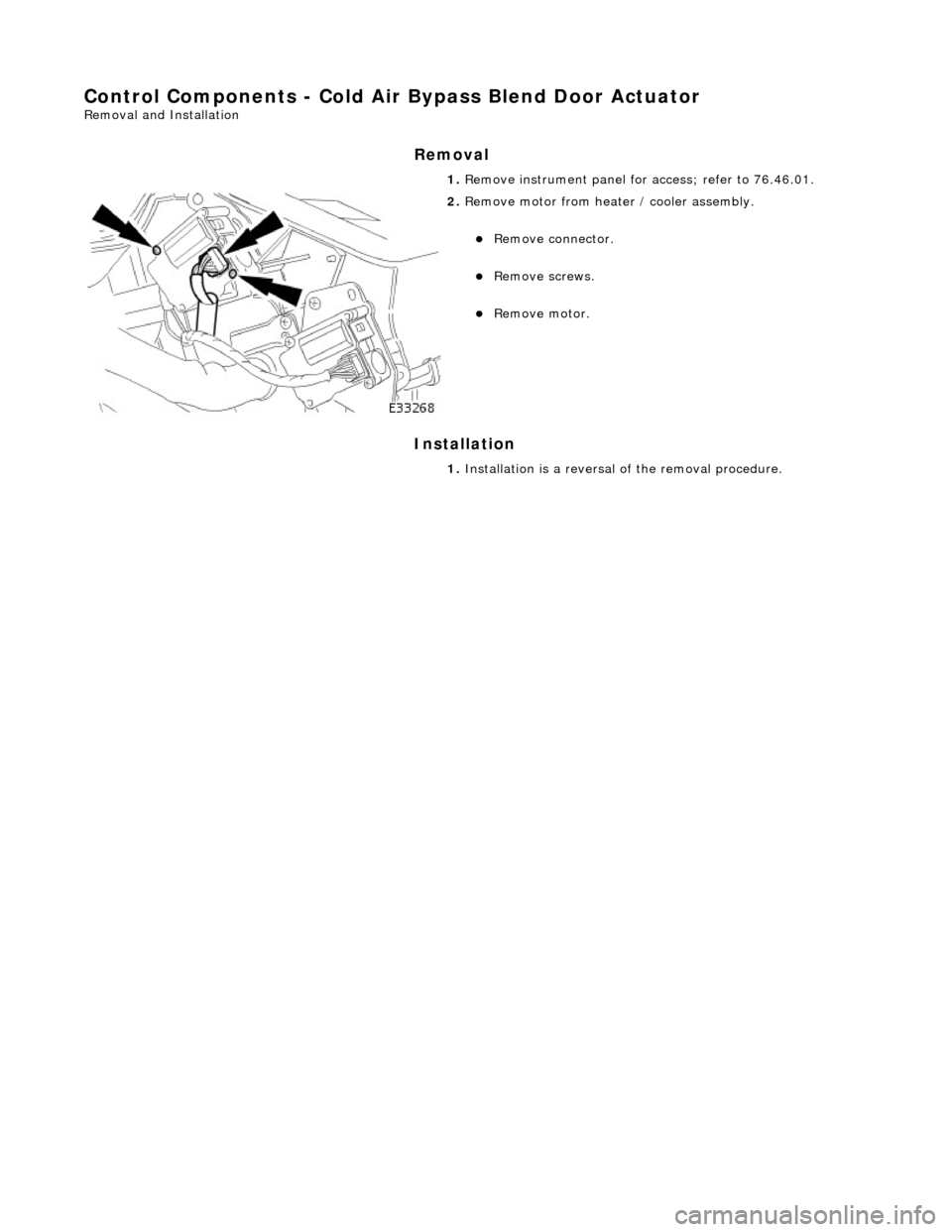

Control Components - Cold Air Bypass Blend Door Actuator

Removal and Installation

Removal

Installation

1.

Remove instrument panel for access; refer to 76.46.01.

2. Remove motor from heater / cooler assembly.

Remove connector.

Remove screws.

Remove motor.

1. Installation is a reversal of the removal procedure.