JAGUAR X308 1998 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2211 of 2490

For additional information, refer to: C

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

15. Install the high mounted stoplamp.

For additional information, refer to: High Mounted Stoplamp

(417-01 Exterior Lighting, Removal and Installation).

Page 2212 of 2490

Glass, Frames and Mechanisms - Windshield Glass

Removal and Installation

Removal

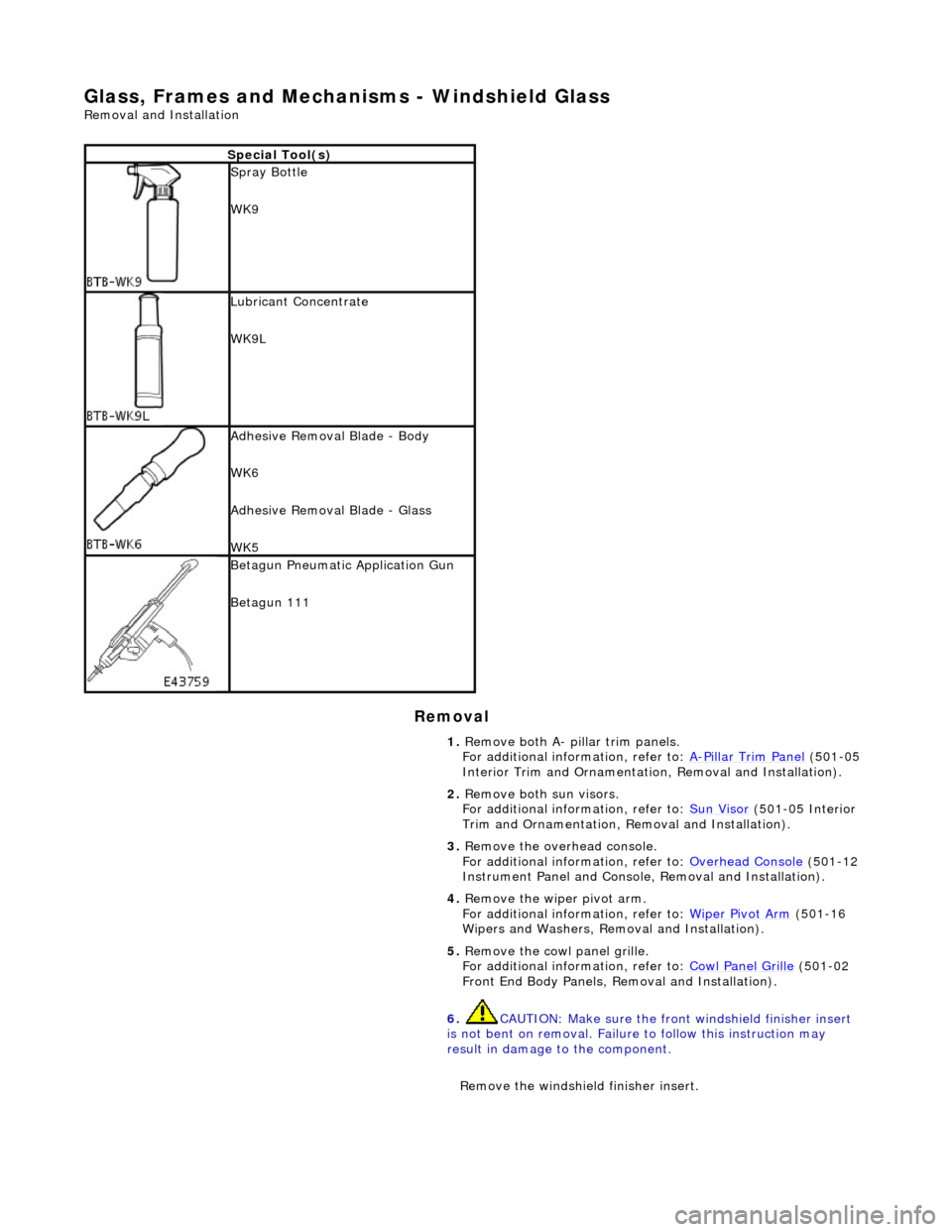

Special Tool(s)

Spray Bottle

WK9

Lubricant Concentrate

WK9L

Adhesive Removal Blade - Body

WK6

Adhesive Removal Blade - Glass

WK5

Betagun Pneumatic Application Gun

Betagun 111

1. Remove both A- pill ar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

2. Remove both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

3. Remove the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

4. Remove the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

5. Remove the cowl panel grille.

For additional information, refer to: Cowl Panel Grille

(501-02

Front End Body Panels, Removal and Installation).

6. CAUTION: Make sure the front windshield finisher insert

is not bent on removal. Failure to follow this instruction may

result in damage to the component.

Remove the windshield finisher insert.

Page 2213 of 2490

7. Remove the windshield finisher.

8. Apply a suitable protective ta pe around windshield glass

aperture to protect paintwork.

9. NOTE: Left-hand shown, right-hand similar

Apply a suitable protec tive tape to leading edge of headlining.

10. Place a suitable prot ective sheet over fascia and place a

protecting boar d over sheet

11. Prepare the cheese wire and cutting handle.

Position cutting handle cent ral tube fully upwards in

handle.

Page 2214 of 2490

Cut a suitable length of cheese wire and pass one end

through handle tube and locating aperture.

Move cutting handle central tube downwards to secure

cheese wire.

12. Using a suitable long bladed tool, penetrate Betaseal

approximately 150mm from the top of one A pillar.

13. Pass free end of cheese wire through penetration and install

second cutting handle.

14. WARNING: When removing the windshield glass,

personal protection must be worn. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Make sure the ch eese wire cannot contact the paintwork

while the the windshield adhesive is being cut. Failure to follow

this instruction may result in damage to the vehicle.

Make sure the cheese wire cannot contact the instrument

panel while the the windshield adhesive is being cut. Failure to

follow this instruction may result in damage to the vehicle.

Make sure the cheese wire passes the Vehicle Identification

Number (VIN) plate on the correct side. Failure to follow this

instruction may result in damage to the component.

When cutting, do not allow ch eese wire to contact edge of

windshield glass as this will crack the windshield glass.

• NOTE: Apply cutting lubricant to the cheese wire frequently

through out the cutting process.

With assistance and exercising care at the corners to avoid

damaging paintwork, cut around the windshield glass

Page 2215 of 2490

Installation

commencing downwards and along the bottom.

15. With assistance and exercising care, remove the windshield

glass.

1. Attach lifting handles to windshield glass.

2. Remove the windshield glass.

16. Remove lifting handles from windshield glass.

17. Remove cheese wire cutter fro m windshield glass aperture,

remove cutting handles and discard cheese wire.

1. WARNINGS:

If the windshield glass is being installed at a temperature of 23°C (73°F) or above make sure the vehicle is not driven for at

least 1 hour after installation.

If the windshield glass is being installed at a temperature of

11°C (52°F) make sure the vehicl e is not driven for at least 1.5

hours after installation.

If the windshield glass is being installed at a temperature of 5°C (41°F) make sure the vehicle is not driven for at least 2

hours after installation.

If the windshield glass is being installed at a temperature

below 5°C (41°F) use heat and ma ke sure the windshield glass

adhesive has set before the vehicle is driven.

• NOTE: If the original windshield glass is to be installed remove

the residual adhesive from windsh ield glass mating surface using

the special tool.

Using the special tool, remove any residual adhe sive from the

body.

2. Remove the protective tape from around windshield glass

aperture.

3. Apply glass primer to the mating face of the body flange.

Page 2216 of 2490

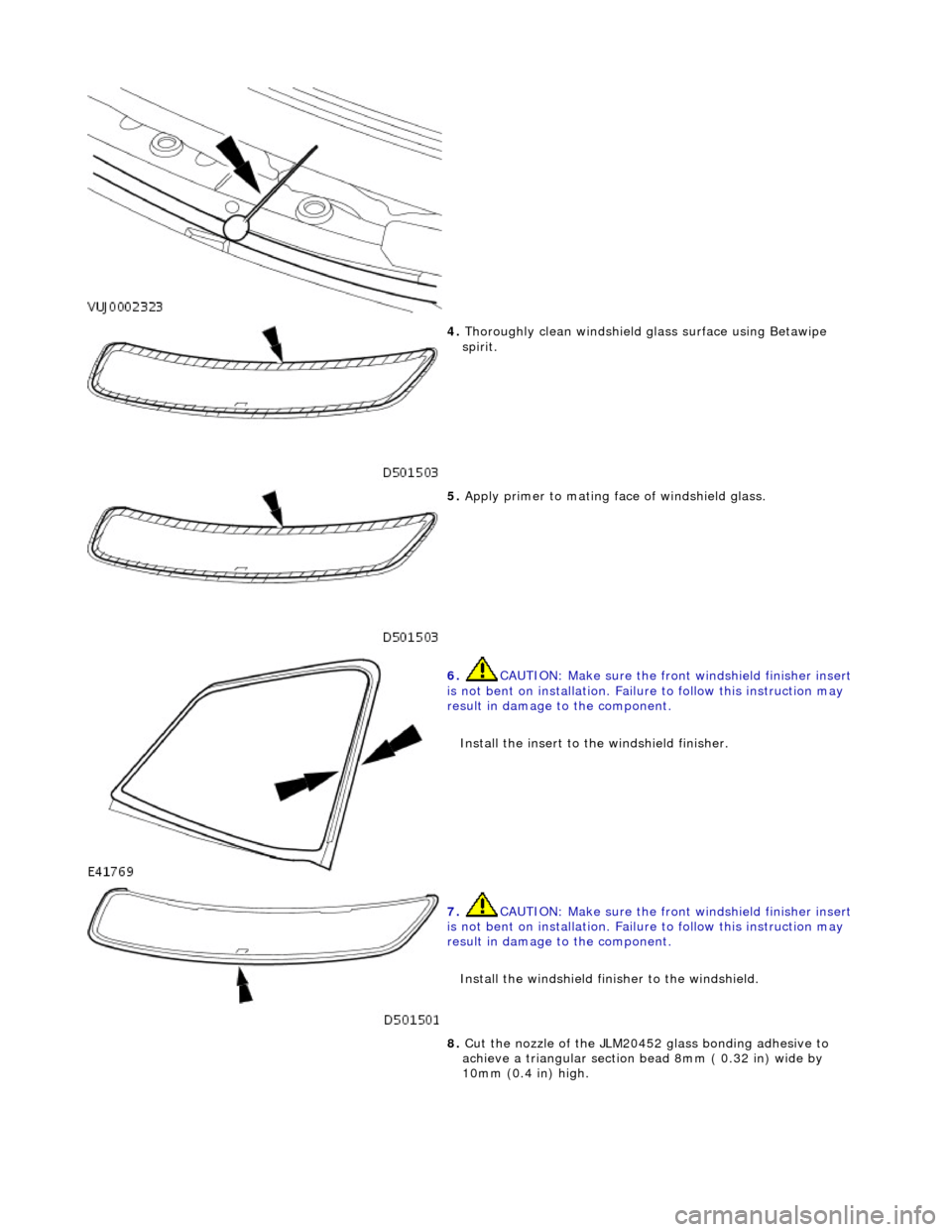

4. Thoroughly clean windshield glass surface using Betawipe

spirit.

5. Apply primer to mating fa ce of windshield glass.

6. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the insert to the windshield finisher.

7. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the windshield finisher to the windshield.

8. Cut the nozzle of the JLM20452 glass bonding adhesive to

achieve a triangular section bead 8mm ( 0.32 in) wide by

10mm (0.4 in) high.

Page 2217 of 2490

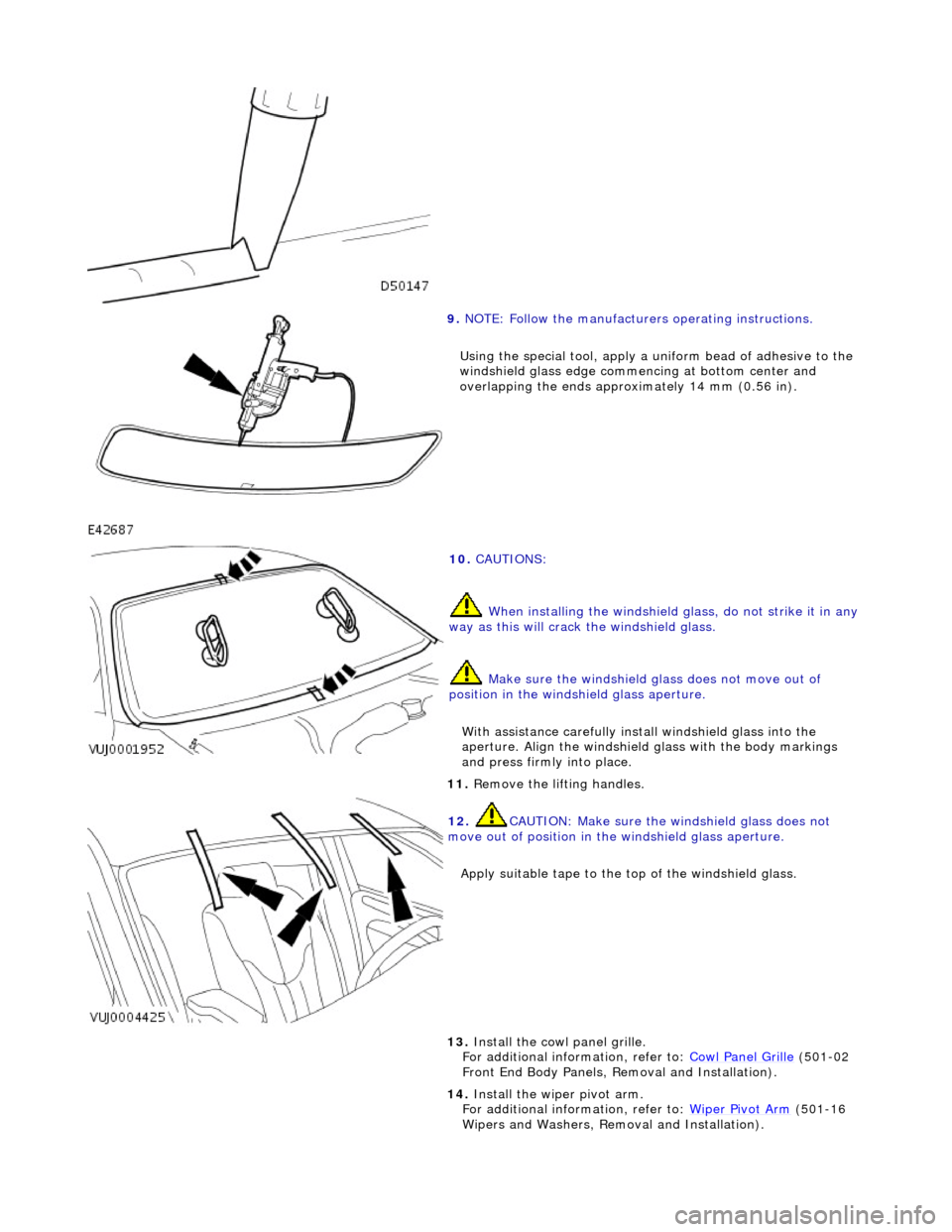

9. NOTE: Follow the manufacturers operating instructions.

Using the special tool, apply a uni form bead of adhesive to the

windshield glass edge commenc ing at bottom center and

overlapping the ends approximately 14 mm (0.56 in).

10. CAUTIONS:

When installing the windshield glass, do not strike it in any

way as this will crack the windshield glass.

Make sure the windshield glass does not move out of

position in the windshield glass aperture.

With assistance carefully install windshield glass into the

aperture. Align the windshield glass with the body markings

and press firmly into place.

11. Remove the lifting handles.

12. CAUTION: Make sure the windshield glass does not

move out of position in the windshield glass aperture.

Apply suitable tape to the to p of the windshield glass.

13. Install the cowl panel grille.

For additional information, refer to: Cowl Panel Grille (501-02

Front End Body Panels, Removal and Installation).

14. Install the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

Page 2218 of 2490

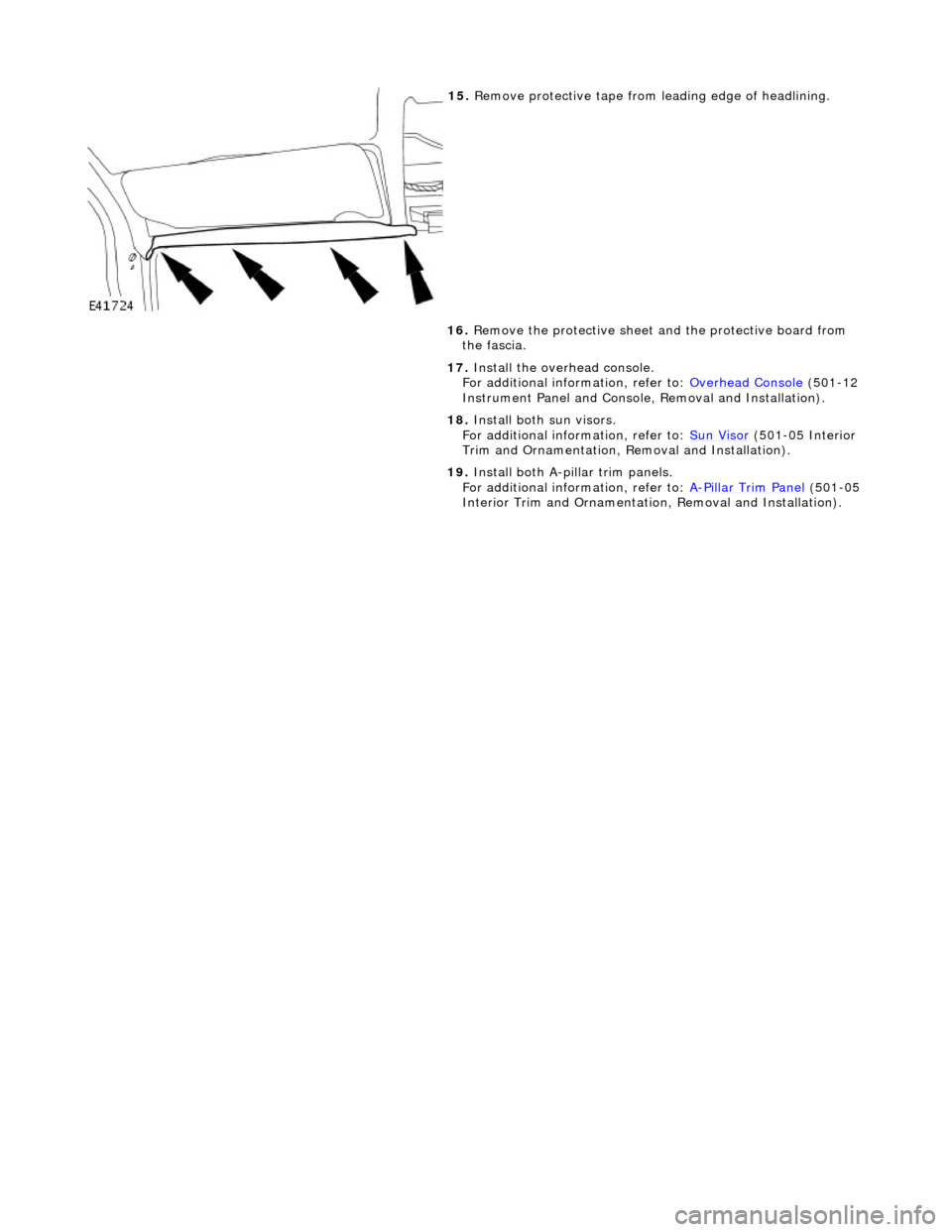

15. Remove protective tape from leading edge of headlining.

16. Remove the protective sheet and the protective board from

the fascia.

17. Install the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

18. Install both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

19. Install both A-pillar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

Page 2219 of 2490

Instrument Panel and Console - Instrument Panel and Instrument Panel

Console

Description and Operation

Fascia

The one-piece slush-moulded fascia has an injection-moulded ar mature and incorporates a steel transverse reinforcing rail.

Fascia side support brackets pre-set to th e BIW, determine fascia fore and aft, and height position s and a bush installed in a

BIW bracket centrally positioned on the upper fascia panel, similarly determines the correct transverse location of a fascia

dowel. These mountings together with access panels at each en d of the fascia and brackets at the top and sides of the BIW

tunnel, facilitate fascia removal and instal lation without the necessity for special tools or an alignment procedure. The fasci a

houses the main instrument panel, pass enger air bag module glovebox, air conditioning outlet vents and a centrally

mounted analogue clock, all of which can be readily removed wi thout disturbing the fascia. The fascia harness is located in

the nose of the fascia assembly to facilitate easy installati on in vehicle. The fascia must be removed from the vehicle to

access the harness.

Centre Console

The centre console is an injection moulded armature trimmed in matching ambla or leather with a wood veneer top finisher.

An iluminated smoker's compendium with pr ess and release lid is fitted at the rear of the 'J' gate. The centre section of the

console forms a deep stowage box with rear hinged lid which is padded to form a central arm rest. A hinged cup holder is

incorporated in the front end of the stowage box lid. A colour-keyed 'J' gate finisher surmounts the veneer top finisher and

the 'SPORT' mode and cruise control 'ON/OFF' selector switches are situated immediately to the rear of the 'J' gate. The rear

of the standard centre console houses a re ar air distribution grill and controls. On Daimler and 'Super 8' models, the centre

console incorporates a rear extensio n with rear seat heating controls.

Page 2220 of 2490

Instrument Panel and Console - Audio Unit Housing

Removal and Installation

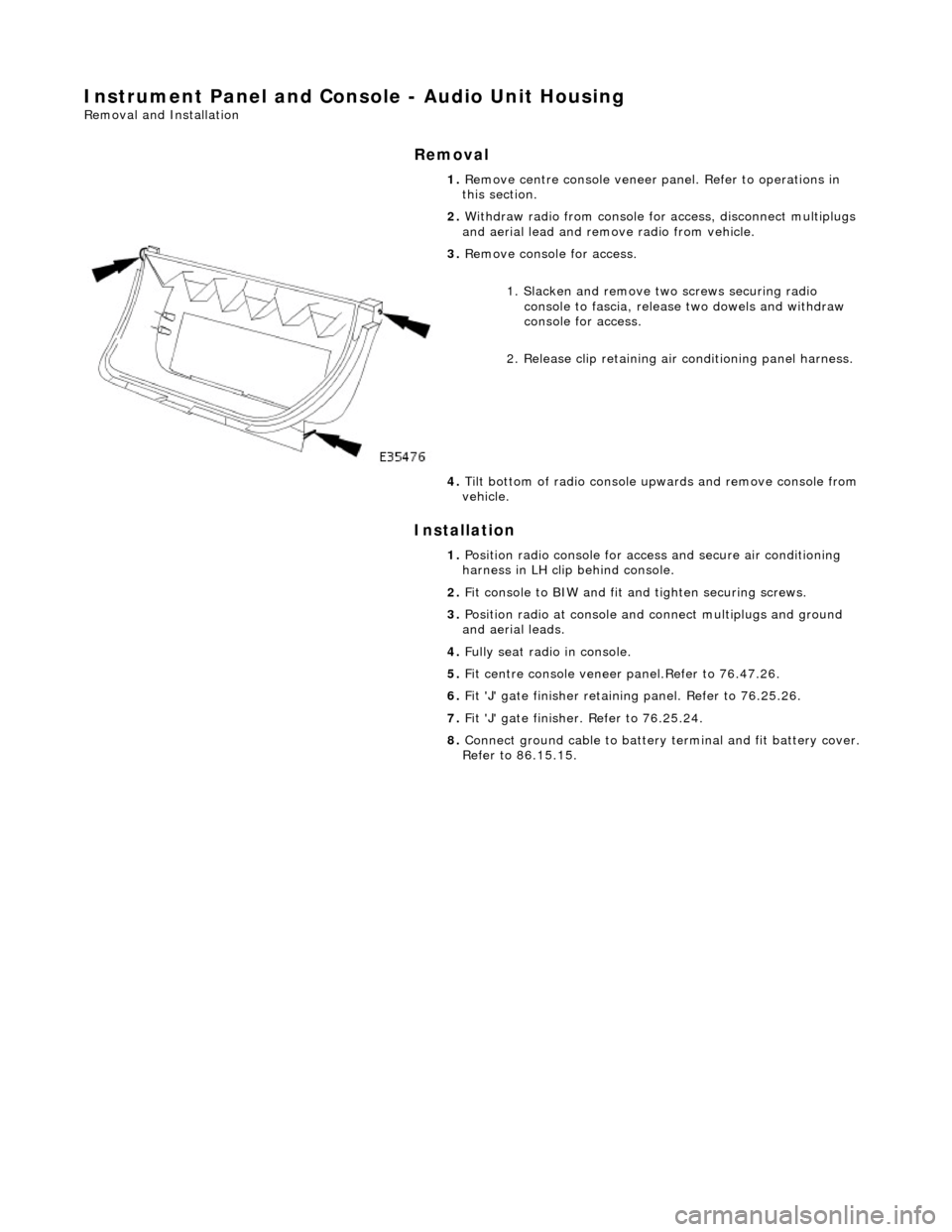

Removal

Installation

1.

Remove centre console veneer pa nel. Refer to operations in

this section.

2. Withdraw radio from console for access, disconnect multiplugs

and aerial lead and remo ve radio from vehicle.

3. Remove console for access.

1. Slacken and remove tw o screws securing radio

console to fascia, release two dowels and withdraw

console for access.

2. Release clip retaining air conditioning panel harness.

4. Tilt bottom of radio console upwards and remove console from

vehicle.

1. Position radio console for access and secure air conditioning

harness in LH clip behind console.

2. Fit console to BIW and fit an d tighten securing screws.

3. Position radio at console and connect multiplugs and ground

and aerial leads.

4. Fully seat radio in console.

5. Fit centre console veneer panel.Refer to 76.47.26.

6. Fit 'J' gate finisher retain ing panel. Refer to 76.25.26.

7. Fit 'J' gate finisher . Refer to 76.25.24.

8. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.