warning JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 473 of 2490

6. NO

TE: The suitable funnel should have the a capacity of 4

litres and O-ring seal

• NOTE: The suitable funnel must be tightly sealed to the

power steering fluid reservoi r to avoid fluid leakage.

Install a suitable funnel onto the power steering fluid

reservoir.

7. WARNING: Do not work on or under a vehicle supported

only by a jack. Always support the vehicle on safety stands.

Raise and support the vehicle with the wheels just clear of the

ground.

8. CAUTI

ONS:

Steps 8 and 9 must be carried out within 2 - 3 seconds of

each other. Failure to follow this instruction may result in damage

to the power steering system.

Be prepared to collect escaping fluids.

Using the suitable funnel, top up the power steering system

with the specified fluid. Make su re the fluid level is maintained

at two thirds full in the funnel.

9. CAUTI

ONS:

Be prepared to collect escaping fluids.

Page 490 of 2490

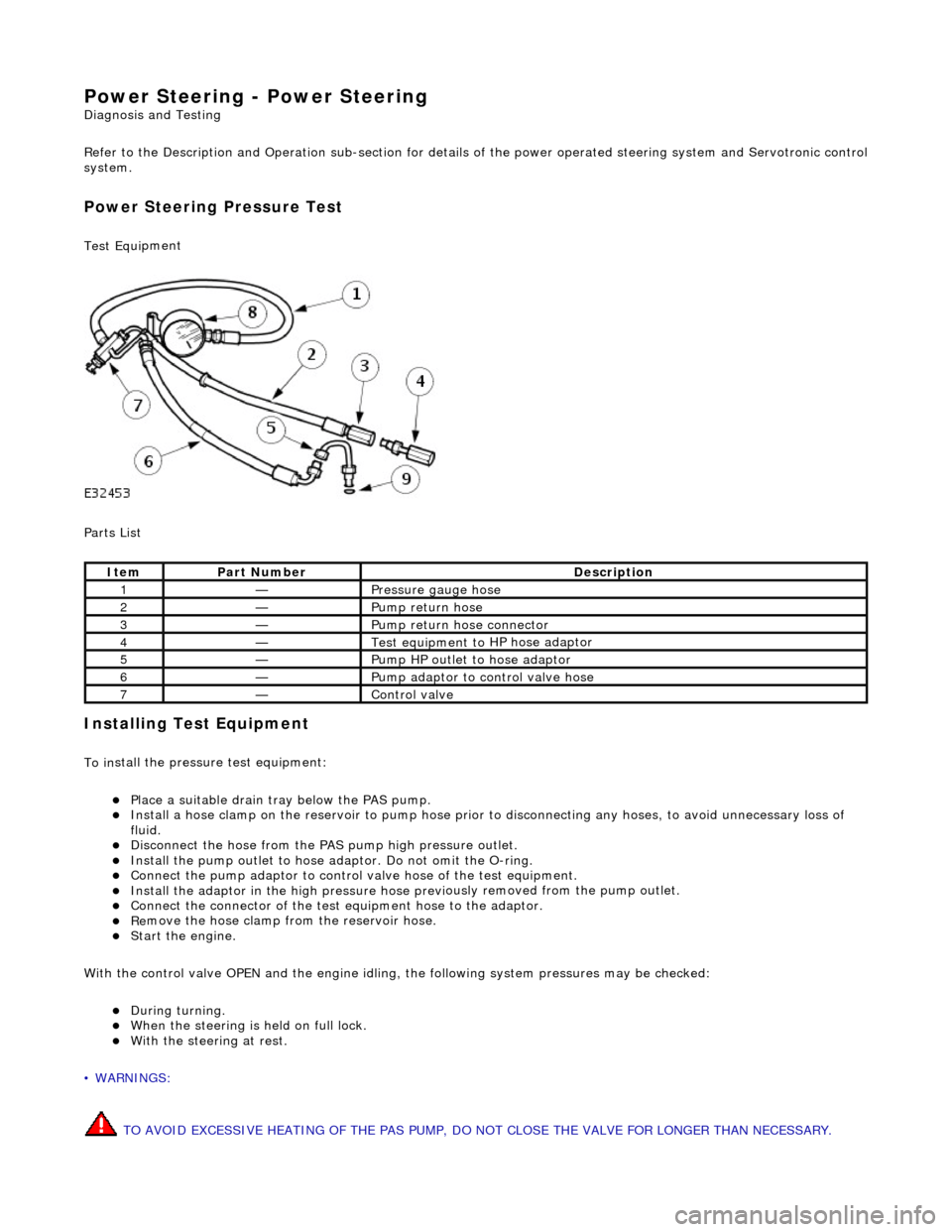

Power Steering - Power Steering

Diagn

osis and Testing

Refer to the Description and Operation sub-section for details of the power operated steering system and Servotronic control

system.

Power Steer ing Pressure Test

Test Equ

i

pment

Parts List

In

stalling Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray below the PAS pump.

Install a hose clamp

on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Di sc

onnect the hose from the PAS pump high pres

sure outlet.

Ins

tall the pump outlet to hose ad

aptor. Do not omit the O-ring.

Conn

ect the pump adaptor to control valve hose of the test equipment.

Install th

e adaptor in the high pressure hose previ

ously re

moved from the pump outlet.

Conne

ct the connector of the test equipment hose to the adaptor.

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve OPEN and the engine idling , the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• WARNINGS:

TO AVOID EXCESSIVE HEATING OF THE PAS PUMP, DO NOT CLOSE THE VALVE FOR LONGER THAN NECESSARY.

Ite

m

Par

t

Number

De

scr

iption

1—Pressure

gauge hose

2—Pump return hose

3—Pump return hose connector

4—Test equi

pment to

HP hose adaptor

5—Pump HP outlet to hose adaptor

6—Pump adaptor

to control valve hose

7—Control valve

Page 512 of 2490

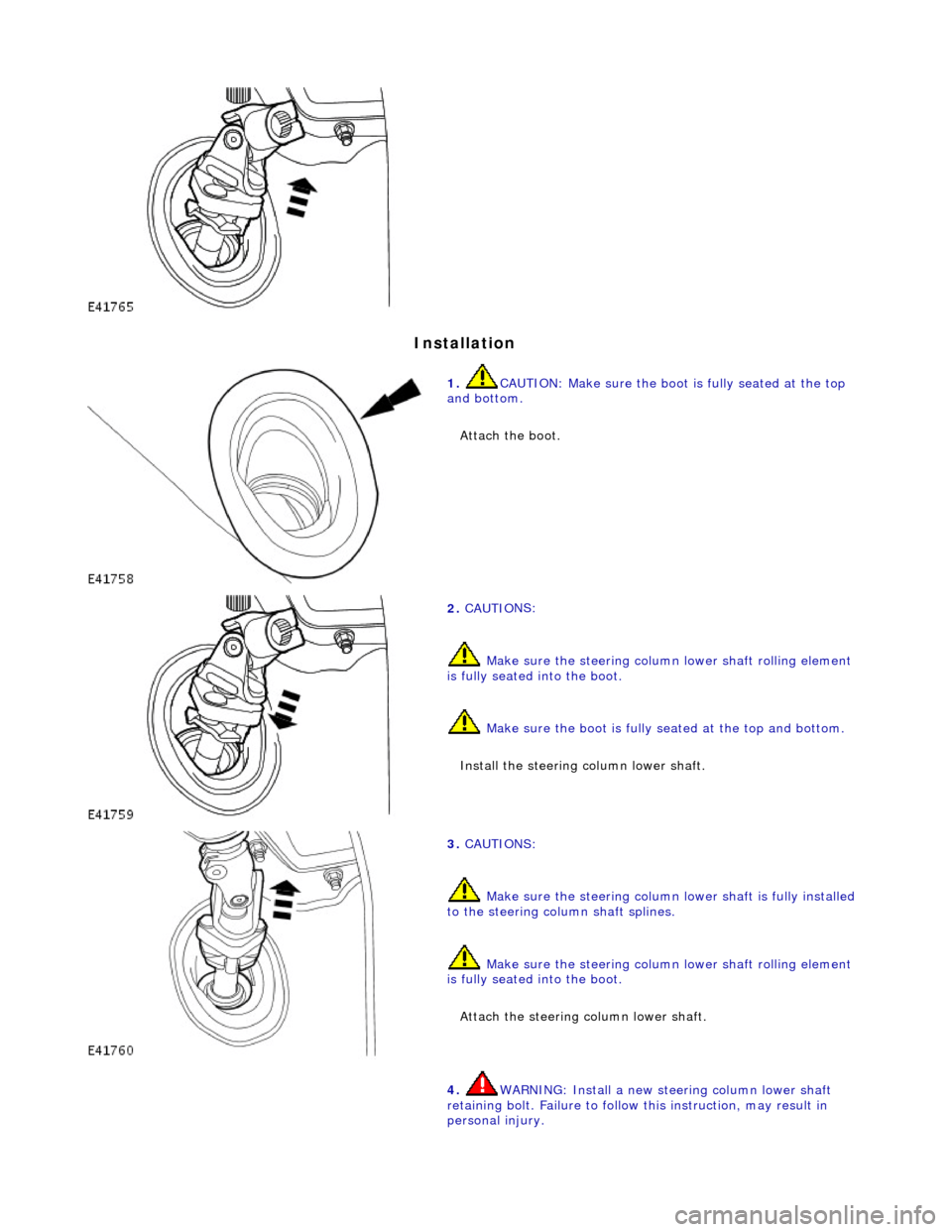

In

stallation

1.

CAUTIO

N: Make sure the boot

is fully seated at the top

and bottom.

Attach the boot.

2. CAUTI O

NS:

Make sure the steering column lower shaft rolling element

is fully seated into the boot.

Make sure the boot is fully seated at the top and bottom.

Install the steering column lower shaft.

3. CAUTI O

NS:

Make sure the steering column lower shaft is fully installed

to the steering column shaft splines.

Make sure the steering column lower shaft rolling element

is fully seated into the boot.

Attach the steering column lower shaft.

4. WARNING: In stall a new stee ring column lower shaft

r

etaining bolt. Failure to follow this instruction, may result in

personal injury.

Page 513 of 2490

CAUTI

ON: Make sure the steering

column lower shaft is fully

installed on the steering column shaft splines.

Install the steering column lower shaft retaining bolt.

Ti

ghten to 28 - 34 Nm.

5.

R

aise the vehicle.

6. WARNING: In

stall a new stee

ring column lower shaft

retaining bolt. Failure to follow this instruction, may result in

personal injury.

Attach the steering column lower shaft. 1. Attach the steering column lower shaft.

2. Install the steering column lower shaft retaining bolt.

1. Tighten to 28 - 34 Nm

.

3

. Tighten to 28 - 34 Nm.

Page 516 of 2490

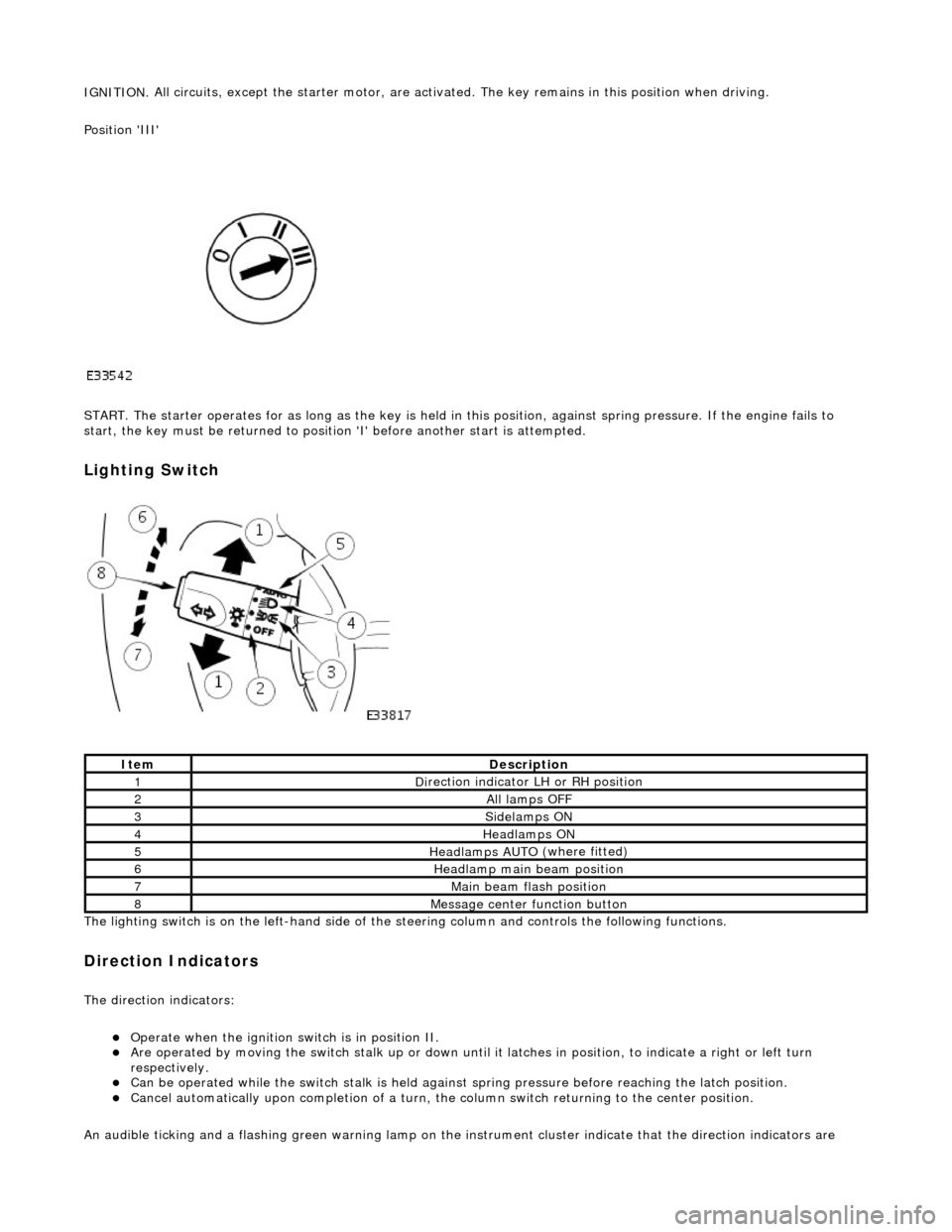

IGNITION.

All circuits, except the star

ter motor, are activated. The key rema ins in this position when driving.

Position 'III'

START. The starter operates for as long as the key is held in this position, ag ainst spring pressure. If the engine fails to

start, the key must be returned to position 'I' befo re another start is attempted.

Lighting Switch

The li

ghting switch is on the left-h

and side of the steering column and controls the following functions.

Direction Indicators

The direction in

dicators:

Operate

when the ignition switch is in position II.

Are operat

ed by movi

ng the switch stalk up or down until it latches in position, to in

dicate a right or left turn

respectively.

Can be o p

erated while the switch stalk is held against

spring pressure before reaching the latch position.

Cancel

automatically upon completion of a turn, the

column switch returning to the center position.

An audible ticking and a flashing green warning lamp on the in strument cluster indicate that the direction indicators are

Ite

m

De

scr

iption

1D

i

rection indicator LH or RH position

2All lamps OFF

3Side

lamps ON

4Headlamps ON

5Headlamps AUT O

(where fitted)

6He

adlam

p main beam position

7Mai

n

beam flash position

8M

e

ssage center function button

Page 517 of 2490

o

perating. If an indicator bulb fails, the warning

lamp and ticking operate at twice the normal rate.

Sidelam

ps and Headlamps

Thes

e are controlled by rotating the end of the column switch as follows.

In the OFF position:

All

exterior lamps are switched OFF.

In the sidelamp position:

The front

sidelamps, tail, license plate and any other la

mps required by local legislation are switched ON.

The

sidelamps tell-tale lamp illuminates.

In the headlamp position, with the ignition switch in position II:

The h

eadlamps are switched ON in addition to the lamps switched on in the sidelamp position.

If the ignition is switched to the OFF position with the column switch in the headlamp position, the sidelamps, tail and

license plate lamps will stay ON, but the headlamps will switch OFF.

In the AUTO position (where fitted), with the ignition switch in position II:

Th

e sensor mounted on the back of the interior rear view

mirror monitors exterior light levels and automatically

switches the sidelamps and di pped headlamps ON and OFF.

The sensitivity level can be adjusted by turn ing the sensor control knob on the back of the interior mirror, left to decrease or

right to increase. The sensor must not be covered and the windscreen must be kept clean.

Headlamp Main Bea

m Position

Wi

th the column switch in

the headlamp position:

Movin

g the switch stalk away fro

m the steering wheel switches the headlamps to main beam.

Movin

g the switch stalk towards the steering wheel switches the headlamps to dipped beam.

The main beam tell-tale lamp illuminates when the headlamps are switched to main beam.

Ma

in Beam Flash

Wi

th the ignition switch and column switch in any position:

Pulling the

switch stalk agains

t spring pressure towards th e steering wheel illuminates the headlamps on main beam

for as long as the switch is held.

The main beam tell-tale lamp illuminates while the headlamps are illuminated.

M

essage Center Functions

T

he message center functions:

Are se

lected by the button located at the end of the lighting switch stalk.

Are se

lected in turn, by repeatedly pressing the button,

from the odometer reading, through the trip computer data

in sequence, and back to th e odometer reading again.

Page 550 of 2490

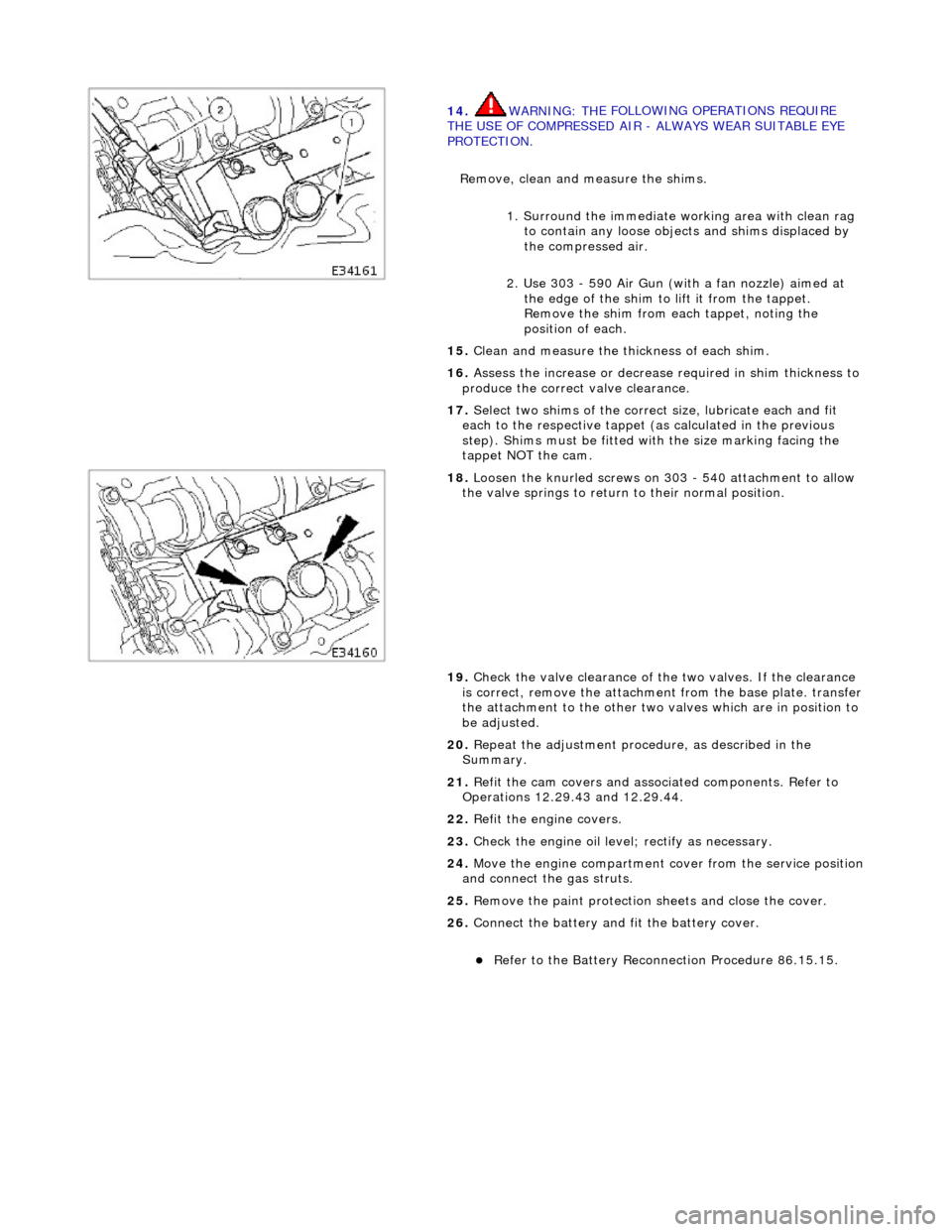

14

. WARNING: TH

E FOLLOWING OPERATIONS REQUIRE

THE USE OF COMPRESSED AIR - ALWAYS WEAR SUITABLE EYE

PROTECTION.

Remove, clean and measure the shims.

1. Surround the immediate wo rking area with clean rag

to contain any loose objects and shims displaced by

the compressed air.

2. Use 303 - 590 Air Gun (with a fan nozzle) aimed at the edge of the shim to lift it from the tappet.

Remove the shim from each tappet, noting the

position of each.

15 . Cl

ean and measure the thickness of each shim.

16. Assess the increase or decrease required in shim thickness to

produce the correct valve clearance.

17. Select two shims of the correct size, lubricate each and fit

each to the respective tappet (as calculated in the previous

step). Shims must be fitted with the size marking facing the

tappet NOT the cam.

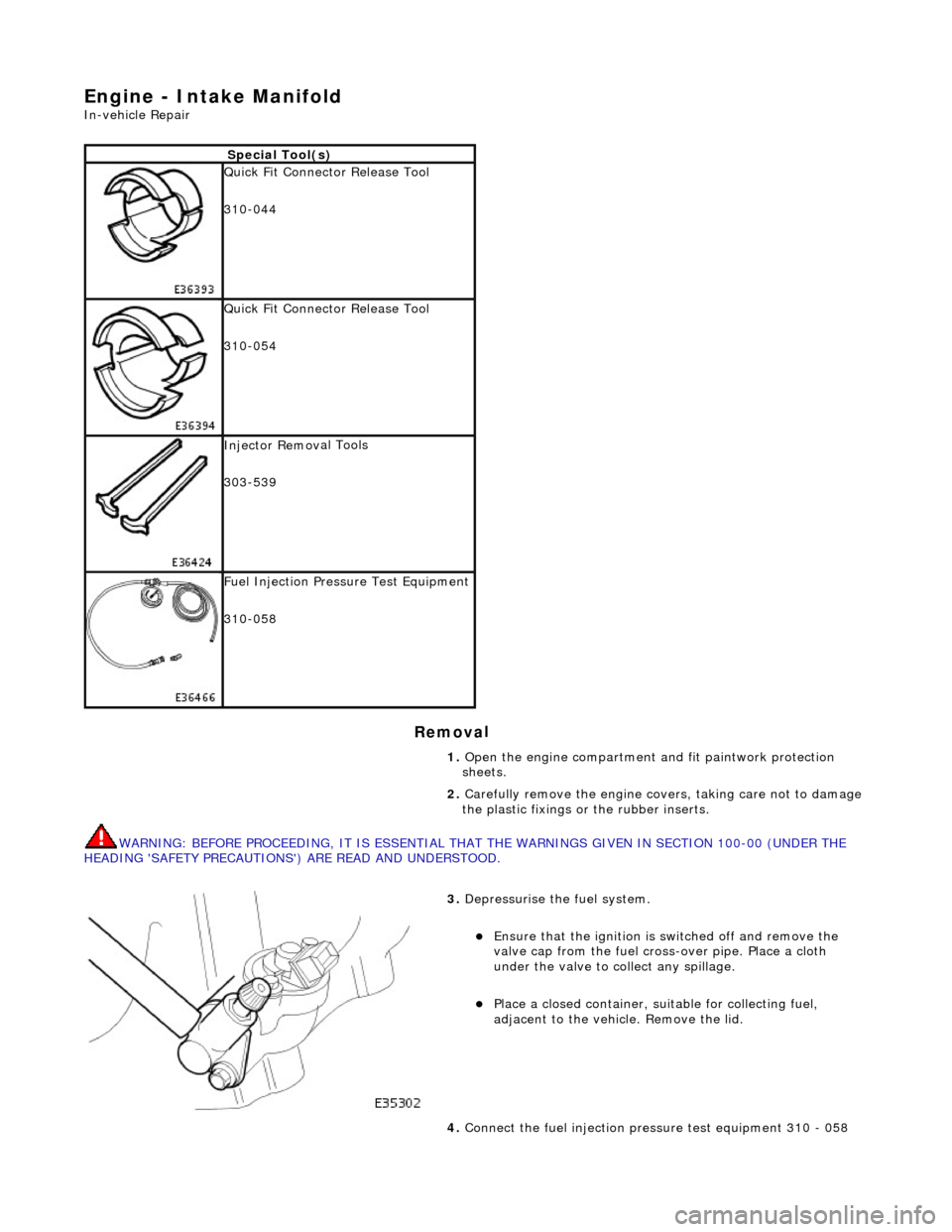

18 . Loos

en the knurled screws on 303 - 540 attachment to allow

the valve springs to return to their normal position.

19. Check the valve clearance of the two valves. If the clearance

is correct, remove the attachment from the base plate. transfer

the attachment to the other two valves which are in position to

be adjusted.

20. Repeat the adjustment procedure, as described in the

Summary.

21. Refit the cam covers and associated components. Refer to

Operations 12.29.43 and 12.29.44.

22. Refit the engine covers.

23. Check the engine oil level; rectify as necessary.

24. Move the engine compartment cover from the service position

and connect the gas struts.

25. Remove the paint protection sheets and close the cover.

26. Connect the battery and fit the battery cover.

Refe

r to the Battery Reconnection Procedure 86.15.15.

Page 704 of 2490

Engine - Intake Manifol

d

In-v

ehic

le Repair

Remov

a

l

W

A

RNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNINGS GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

S p

ecial Tool(s)

Qu

ic

k Fit Connector Release Tool

310-044

Qu ic

k Fit Connector Release Tool

310-054

Inject or Remov

al Tools

303-539

F u

el Injection Pressu

re Test Equipment

310-058

1. Open the engine compartment and fit paintwork protection

sheets.

2. Carefully remove the en gine covers, taking care not to damage

the plastic fixings or the rubber inserts.

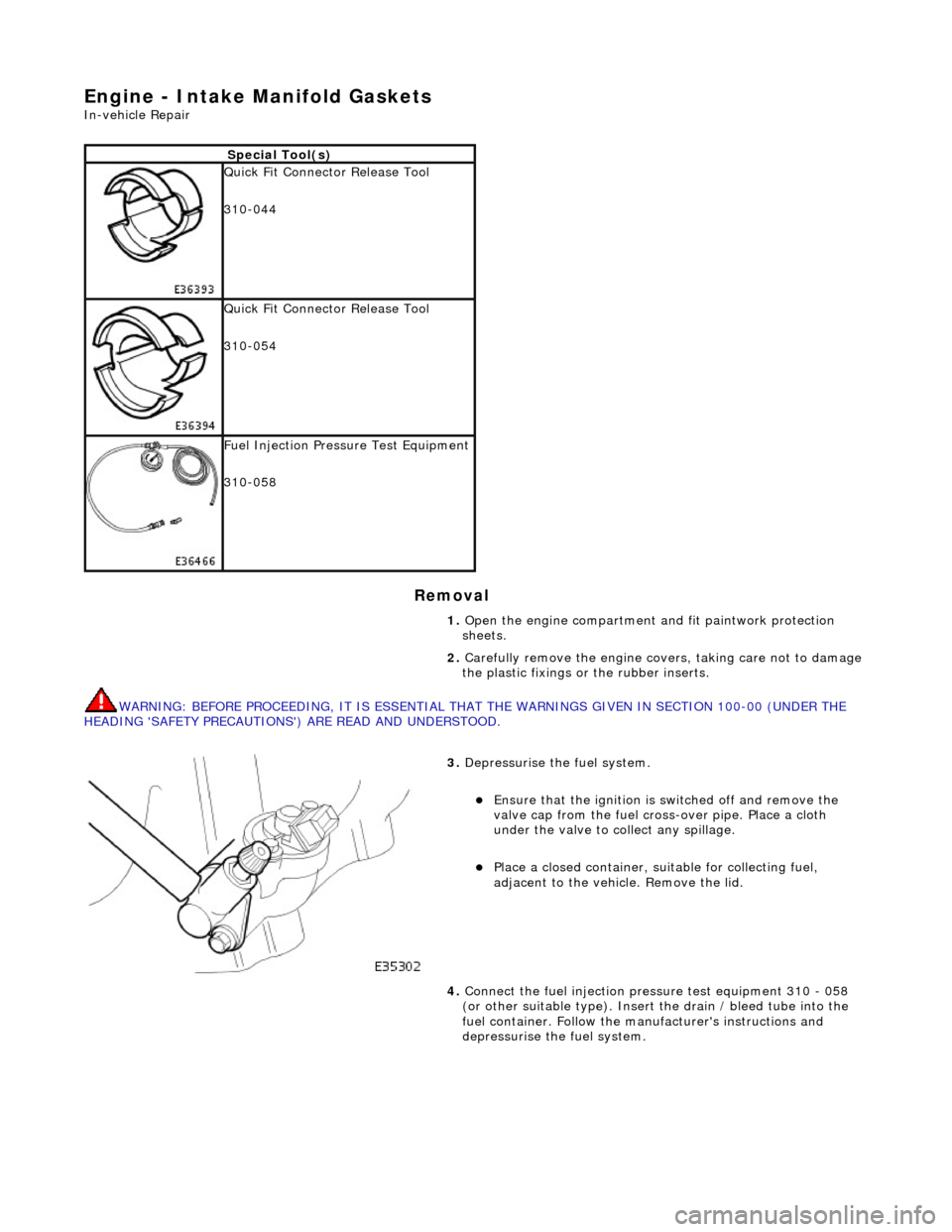

3. Depress

urise the fuel system.

E

n

sure that the ignition is

switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Pla c

e a closed container, su

itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

4. Connect the fuel injection pres sure test equipment 310 - 058

Page 718 of 2490

Engine - Intake Manifold Gaskets

In-vehicle Repair

Removal

WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE WARNINGS GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

Special Tool(s)

Quick Fit Connector Release Tool

310-044

Quick Fit Connector Release Tool

310-054

Fuel Injection Pressu re Test Equipment

310-058

1. Open the engine compartment and fit paintwork protection

sheets.

2. Carefully remove the en gine covers, taking care not to damage

the plastic fixings or the rubber inserts.

3. Depressurise the fuel system.

Ensure that the ignition is switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Place a closed container, su itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

4. Connect the fuel injection pres sure test equipment 310 - 058

(or other suitable type). Insert the drain / bleed tube into the

fuel container. Follow the ma nufacturer's instructions and

depressurise the fuel system.

Page 729 of 2490

Engine - Intake Manifold LH

In-vehicle Repair

Removal

WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT THE WARNINGS GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD. 1.

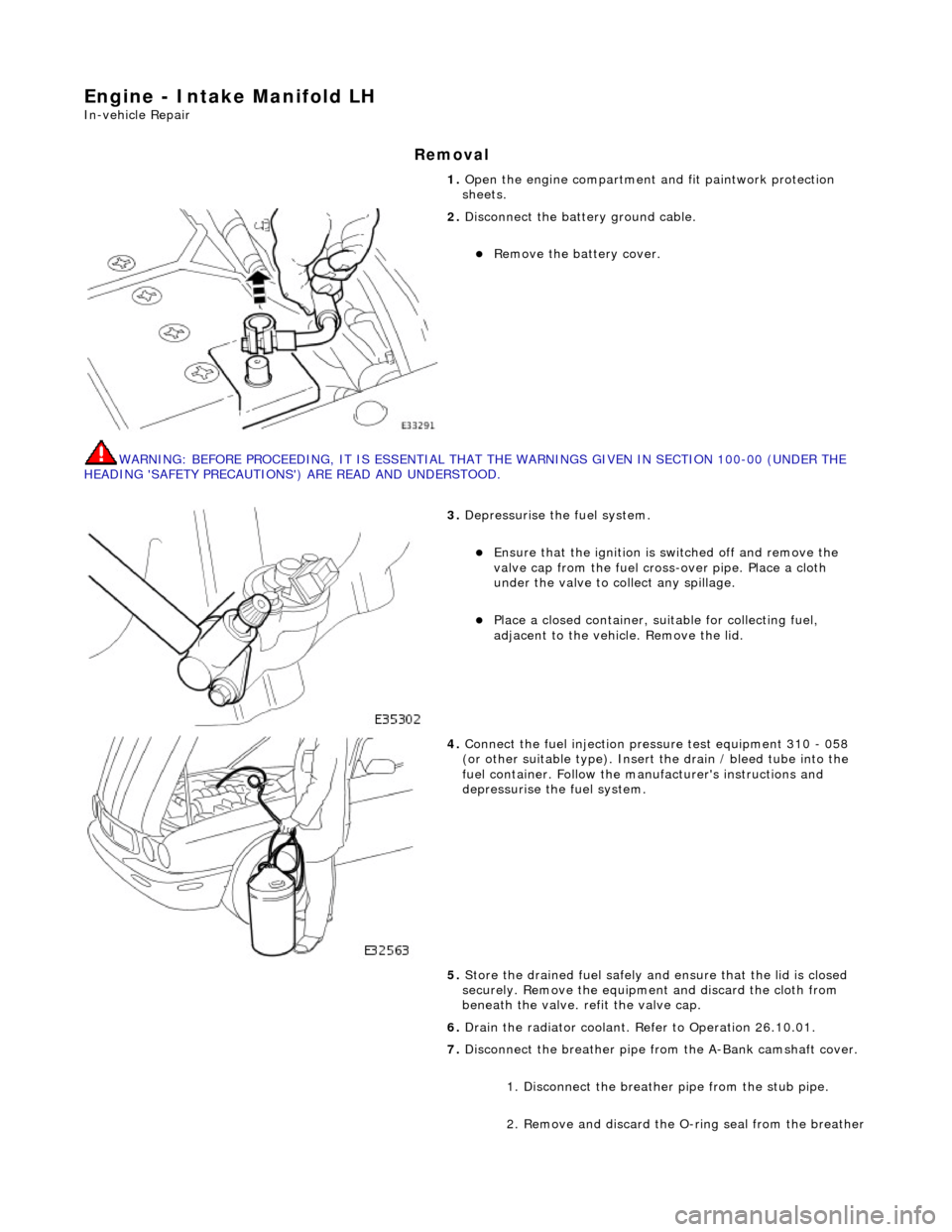

Open the engine compartment and fit paintwork protection

sheets.

2. Disconnect the batt ery ground cable.

Remove the battery cover.

3. Depressurise the fuel system.

Ensure that the ignition is switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

Place a closed container, su itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

4. Connect the fuel injection pres sure test equipment 310 - 058

(or other suitable type). Insert the drain / bleed tube into the

fuel container. Follow the ma nufacturer's instructions and

depressurise the fuel system.

5. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. refit the valve cap.

6. Drain the radiator coolant. Refer to Operation 26.10.01.

7. Disconnect the breather pipe fro m the A-Bank camshaft cover.

1. Disconnect the breather pipe from the stub pipe.

2. Remove and discard the O-ring seal from the breather