engine JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1661 of 2490

1

. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

8. Raise the vehicle on the ramp.

9. Tigh

ten the mounting brac

ket securing bolts.

10

.

Connect the downpipe cataly tic converter to the front

muffler.

1. Position a new gasket to the flange studs at each side.

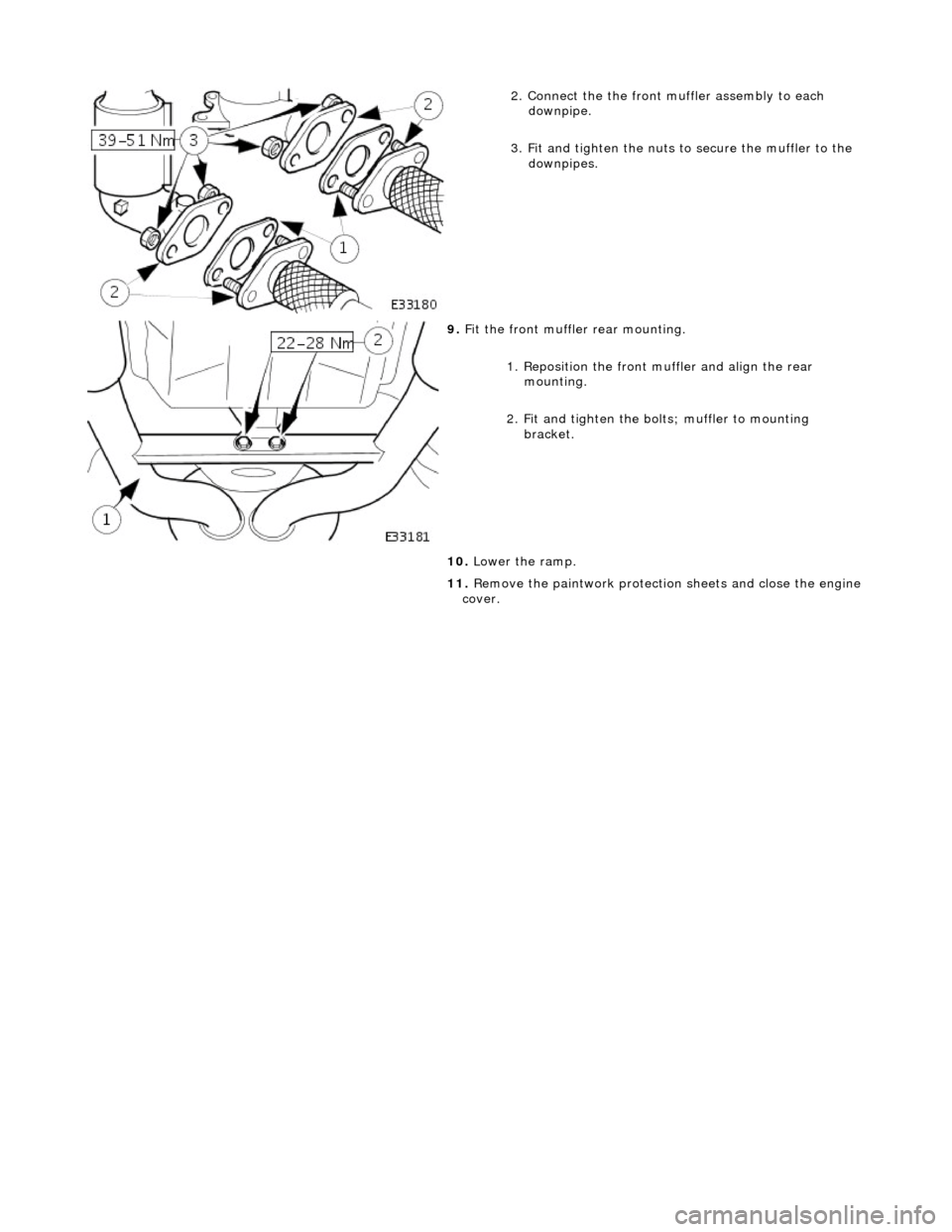

2. Connect the the front mu ffler assembly to each

downpipe.

3. Fit and tighten the nuts to secure the muffler to the downpipes.

11

.

Fit the front muffler rear mounting.

1. Reposition the front mu ffler and align the rear

mounting.

2. Fit and tighten the bolts; muffler to mounting bracket.

12. Lower the ramp.

13. Remove the paintwork protection sheets and close the engine

cover.

Page 1662 of 2490

Exha

ust System - Catalyti

c Converter Gasket RH4. 0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1. Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

пЃ¬Di spl

ace the multiplugs from the engine mounting bracket.

пЃ¬Dis

connect the plug(s) from the oxygen sensor(s).

4.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

5. Raise the vehicle on a ramp.

6. Re

move the downpipe catalytic converter.

пЃ¬R

e

move the bolts which se

cure the downpipe lower

mounting bracket.

пЃ¬Remove the down

pipe assembly.

7. Remove gasket from the manifold flange.

пЃ¬Clean and inspect th e manif

old joint faces.

пЃ¬Clean and inspect th

e threads on th

e downpipe studs.

1. Fit a new gasket to the mani fold mating flange on the

Page 1663 of 2490

do

wnpipe.

2. F

it the downpipe catalytic converter.

пЃ¬Fit the down

pipe assemb

ly to the manifold

пЃ¬Fi

t, but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh

ten the nuts securing the downpipe flange to the manifold

flange..

5. Connec

t the oxygen sensor multiplugs.

пЃ¬Con

nect the plug(s) to the respective (previously noted)

sensor(s).

пЃ¬Cor

rectly position the multiplu

gs on the mounting bracket.

6. Raise the ramp.

7. Tigh

ten the mounting brac

ket securing bolts.

8. Fit the front muffler; refer to Operation 30.10.18.

9. Lower the ramp.

10

.

Remove the paintwork protection sheets and close the engine

cover.

Page 1664 of 2490

Exha

ust System - Cataly

tic Converter Gasket RH 4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

пЃ¬Di spl

ace the multiplugs from the engine mounting bracket.

пЃ¬Dis

connect the plug(s) from the oxygen sensor(s)

3.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

4. Raise the vehicle on a ramp.

5. Re

move the bolts which secure

the rear of the front muffler

assembly to the engine rear mounting.

6. Remove the nuts which secure the front flanges of the front

muffler to the downpipe flanges.

Page 1667 of 2490

2

. Connect the the front mu

ffler assembly to each

downpipe.

3. Fit and tighten the nuts to secure the muffler to the downpipes.

9. F

it the front muffler rear mounting.

1. Reposition the front mu ffler and align the rear

mounting.

2. Fit and tighten the bolts; muffler to mounting bracket.

10. Lower the ramp.

11. Remove the paintwork protection sheets and close the engine

cover.

Page 1688 of 2490

Fuel System - General Inform

ation - Fuel System

Description an

d Operation

The fuel tank is mounted across the vehicle behind the passenger compartment bulkhead.

Fuel is drawn by the fuel pump from the tank and then supplied to the two fuel rails, via a filter.

Fuel injectors are installed in the fuel ra ils on each side of the intake manifold.

The amount of fuel injected into th e engine is controlled by the ECM.

A cross-over pipe connects the two fuel ra ils together at the front of the manifold.

A test valve in the cross-over pipe allo ws the fuel rail to be pressurized and de-pressurized during the servicing and

troubleshooting procedures.

A pressure regulator on the rear of the right fuel rail controls the pressure in the fuel rails.

A return line directs excess fuel from the pressure regulator back to the fuel tank.

Operation and service procedures

The fuel injector

s, rails, pres

sure regulator and, wher e fitted, supercharger are described in greater detail in Section 303-04

together with servicing procedures.

The fuel tank, pump, fuel level senders and fuel lines are similarly covered in Section 310-01.

Page 1689 of 2490

Fuel System - General Information - Fuel System Pre

ssure Check

Gen

eral Procedures

WARNING: Working on the fuel system re sults in fuel and fuel vapor being present in the atmosphere. Fuel vapor is

extremely flammable, hence great care must be taken whilst working on the fuel system. Adhere strictly to the following

precautions:

пЃ¬D

o not smoke in the work area

пЃ¬Di

splay

NO SMOKING signs around the work area

пЃ¬D

isconnect the battery before

working on the fuel system

пЃ¬Av

oid sparks

пЃ¬Make sure sui

table fire ex

tinguishers are at hand

пЃ¬Make sure absor

bent material is at

hand to soak up any spillage

пЃ¬Make sure the work area is

well ventilated

пЃ¬M

ake sure that the gauge is correctly conn

ected, and that all connections are secure BEFORE starting the engine

пЃ¬DO N

OT

disconnect the gauge from the schrader valve while the engine is running

пЃ¬Make su

re the schrader valve reseals once the gauge is disconnected

• NOTE: Depending on the design of the ga uge set, there may be a drain valve and tube. Make sure this valve is closed, and

the drain tube placed in a suitable container BEFORE connecting the gauge to the schrader valve.

1. Make sure the vehi

cle is in

Park for vehicles with automatic

transmission, Neutral for vehicles with manual transmission.

2. Apply the parking brake.

3. Place suitable absorbent material around the schrader valve to

absorb any spillage when connecting the gauge set.

4. Remove the protective cap from the schrader valve.

5. Connect the gauge, using adaptors if required.

6. Remove the absorbent material and dispose of safely.

7. Disconnect and plug the vacuum hose from the pressure

regulator.

8. Start the engine and record the fuel pressure reading.

пЃ¬As a gui

de, the fuel pressu

re should be approximately 3.0

bar (44.1 psi) with the regulator disconnected.

9. With the engine still running, reconnect the vacuum hose to

the pressure regulator an d record the reading.

пЃ¬Th

e pressure should dr

op to approximately 2.6 bar (38

psi) when the vacuum hose is reconnected.

10. Switch off the engine.

11. Place more absorbent material around the schrader valve.

12. Where fitted, open the drain valve and allow the fuel from the

gauge and line to flow into the container to depressurize the

system.

13. Disconnect and remove the gauge set and any adaptors.

14. Clean up any fuel which may have been spilt and remove the

absorbent material. Dispose of safely.

15. Refit and secure the protective cap to the schrader valve.

16. Reconnect the fuel pressure regulator vacuum hose.

17. Start the engine and make sure there are no leaks.

Page 1690 of 2490

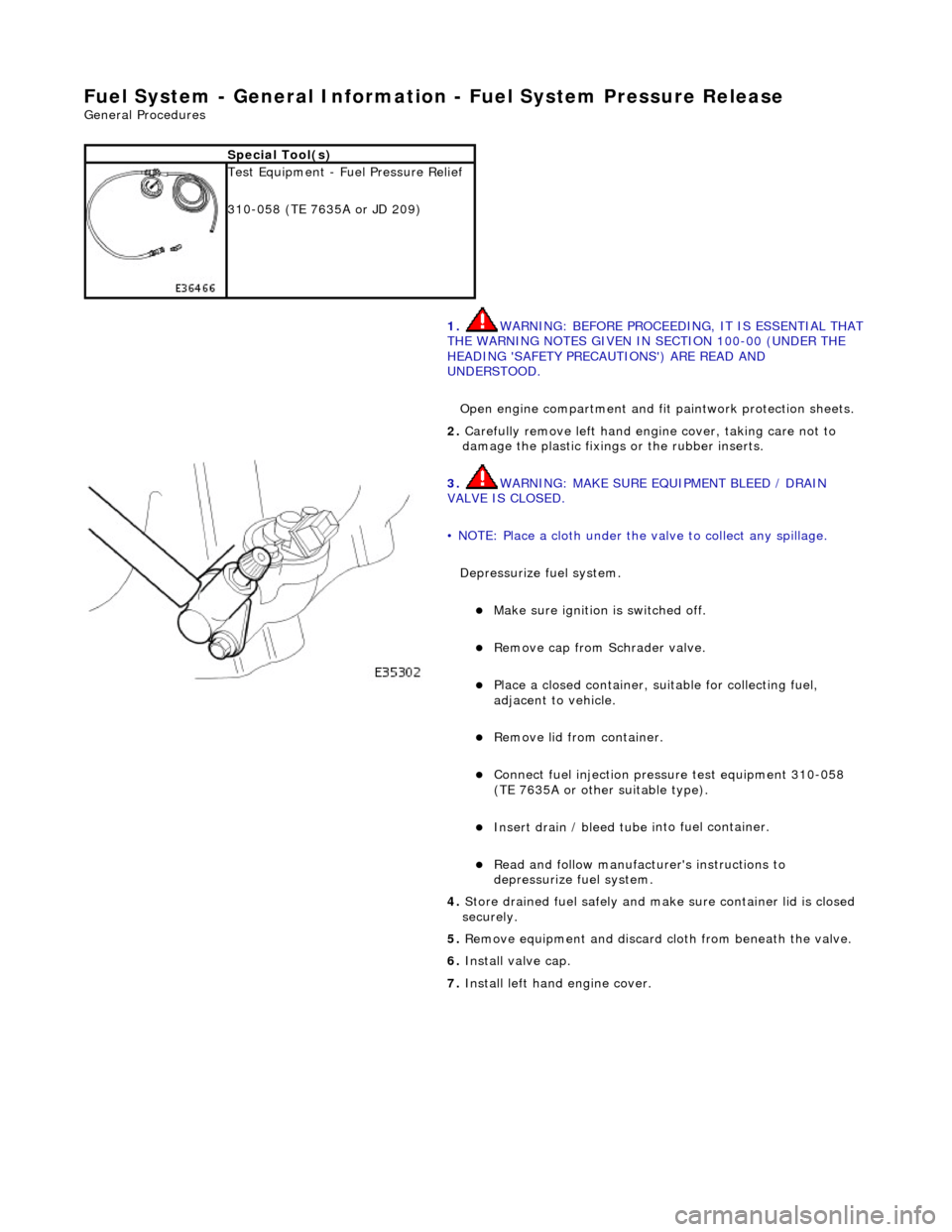

Fuel System - General Information - Fuel System Pressure Rele

ase

Gen

e

ral Procedures

S p

ecial Tool(s)

Tes

t

Equipment - Fuel Pressure Relief

310-058 (TE 7635A or JD 209)

1. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Open engine compartment and fi t paintwork protection sheets.

2. Carefull

y remove left

hand engine cover, taking care not to

damage the plasti c fixings or the rubber inserts.

3. WA

RNING: MAKE SURE EQUIPMENT BLEED / DRAIN

VALVE IS CLOSED.

• NOTE: Place a cloth under the valve to collect any spillage.

Depressurize fuel system.

пЃ¬Make sure ignition i s

switched off.

пЃ¬R

e

move cap from Schrader valve.

пЃ¬Pla

c

e a closed container, su

itable for collecting fuel,

adjacent to vehicle.

пЃ¬R e

move lid from container.

пЃ¬Conne

ct

fuel injection pressu

re test equipment 310-058

(TE 7635A or other suitable type).

пЃ¬Insert drain / bleed tu be i

nto fuel container.

пЃ¬R

e

ad and follow manufacturer's instructions to

depressurize fuel system.

4. Store drained f u

el safely and make

sure container lid is closed

securely.

5. Remove equipment and discard cloth from beneath the valve.

6. Install valve cap.

7. Install left hand engine cover.

Page 1691 of 2490

Fuel System - Gener

al Information - Fuel Tank Draining

Gen

eral Procedures

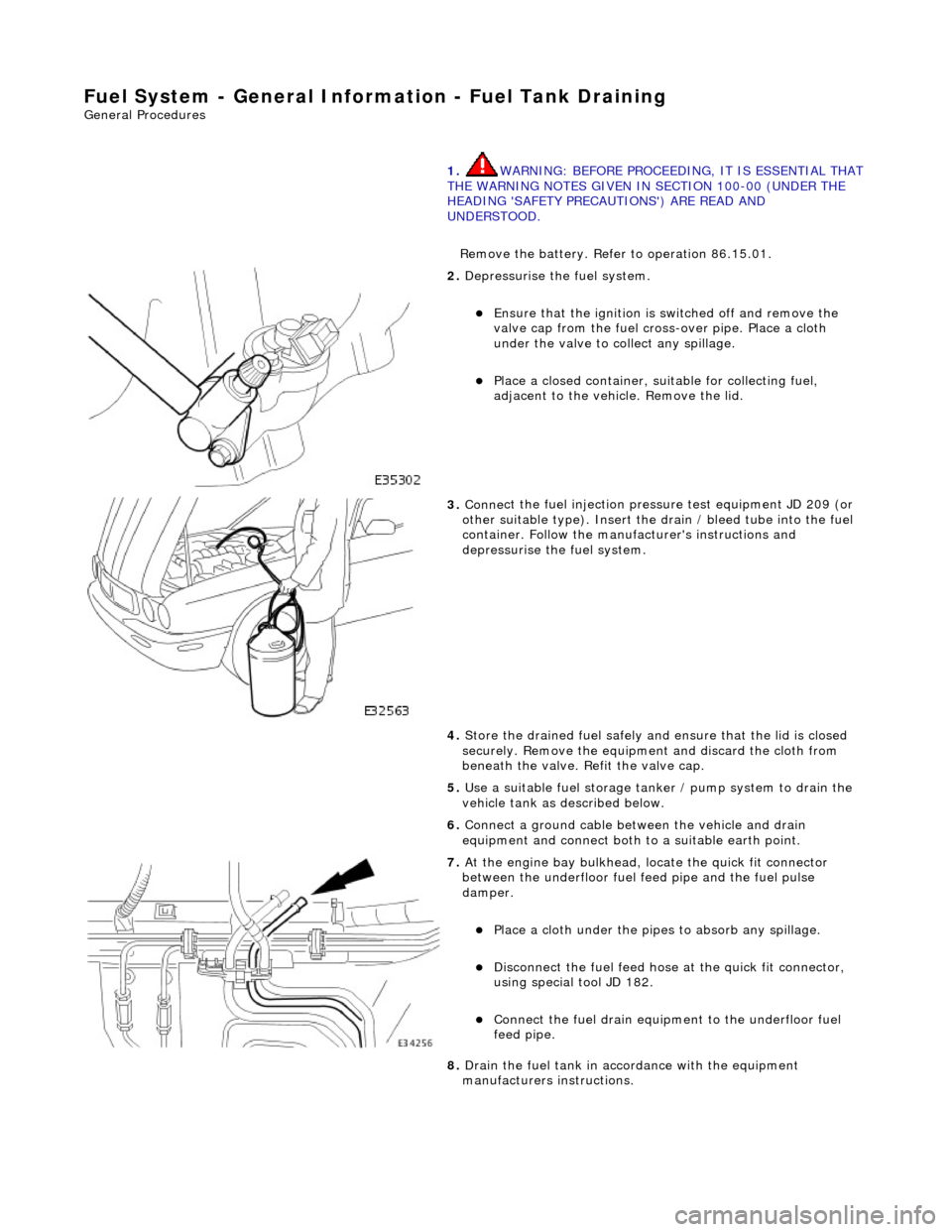

1.

WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the battery. Refer to operation 86.15.01.

2. De

pressurise the fuel system.

пЃ¬E

nsure that the ignition is

switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

пЃ¬Pla

ce a closed container, su

itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

3. Conne

ct the fuel injection pressu

re test equipment JD 209 (or

other suitable type). Insert the drain / bleed tube into the fuel

container. Follow the manufa cturer's instructions and

depressurise the fuel system.

4. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. Refit the valve cap.

5. Use a suitable fuel storage tank er / pump system to drain the

vehicle tank as described below.

6. Connect a ground cable betw een the vehicle and drain

equipment and connect both to a suitable earth point.

7. At the engine bay bulkhead, lo cate the quick fit connecto

r

between the underfloor fuel feed pipe and the fuel pulse

damper.

пЃ¬Pla

ce a cloth under the pipes

to absorb any spillage.

пЃ¬D

isconnect the fuel feed hose

at the quick fit connector,

using special tool JD 182.

пЃ¬Conne

ct the fuel drain equipment to the underfloor fuel

feed pipe.

8. Drain the fuel tank in accordance with the equipment

manufacturers instructions.

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe