electrical JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 925 of 2490

T

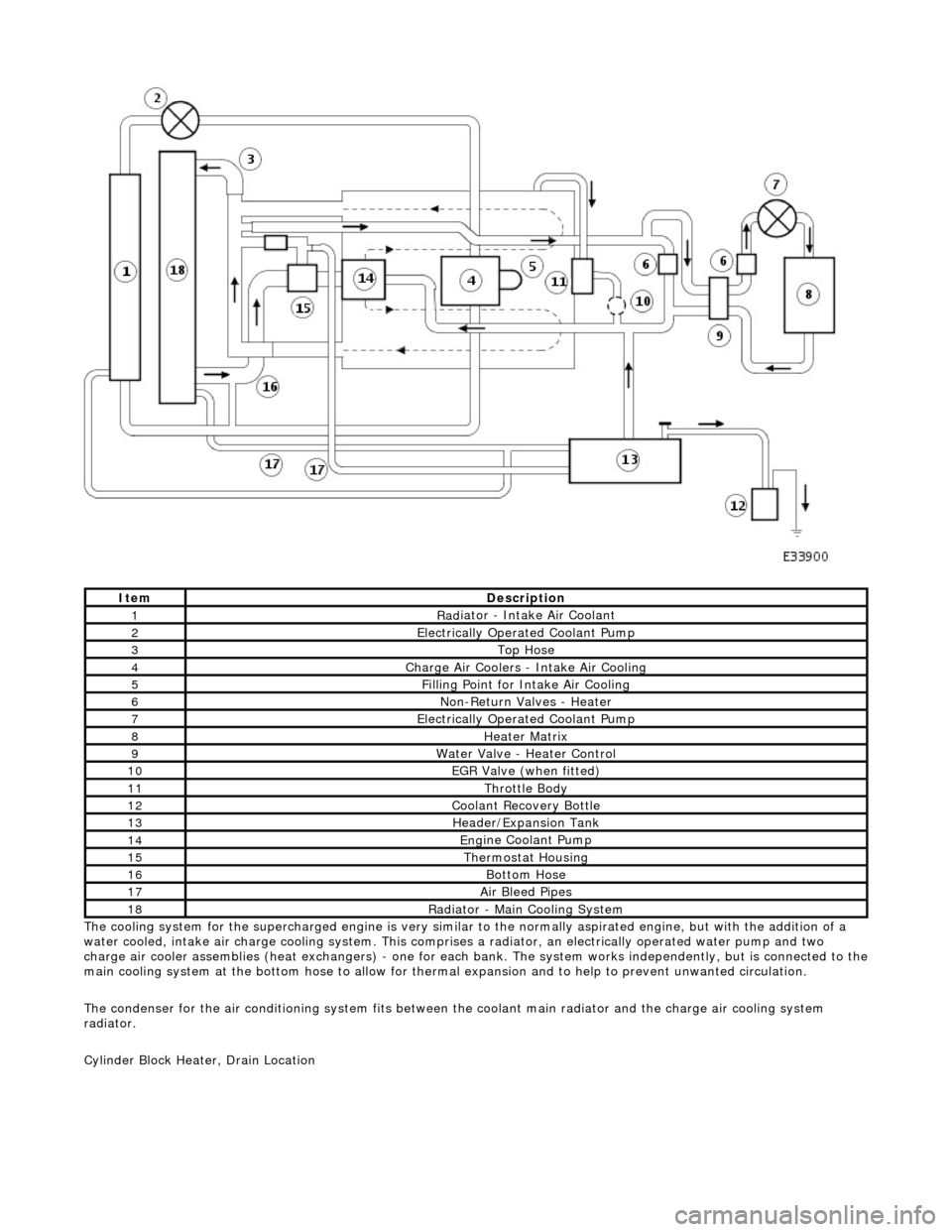

he cooling system for the supercharged engine is very similar

to the normally aspirated engine, but with the addition of a

water cooled, intake air charge cooling system. This comprises a radiator, an electrically operated water pump and two

charge air cooler assemblies (heat exchangers) - one for each bank. The system works independently, but is connected to the

main cooling system at the bottom hose to allow for therma l expansion and to help to prevent unwanted circulation.

The condenser for the air conditioning system fits between th e coolant main radiator and the charge air cooling system

radiator.

Cylinder Block Heater, Drain Location

ItemDe

scription

1Rad

iator - Intake Air Coolant

2Ele

ctrically Operated Coolant Pump

3Top Hose

4Charge Air Coo

lers -

Intake Air Cooling

5Fi

lling Point for Intake Air Cooling

6N

on-Return Valves - Heater

7Ele

ctrically Operated Coolant Pump

8Hea

ter Matrix

9Wate

r Valve - Heater Control

10EGR V

alve (when fitted)

11Thr

ottle Body

12Coolan

t Recovery Bottle

13H

eader/Expansion Tank

14Eng

ine Coolant Pump

15The

rmostat Housing

16Bottom

Hose

17Air Bleed

Pipes

18Rad

iator - Main Cooling System

Page 934 of 2490

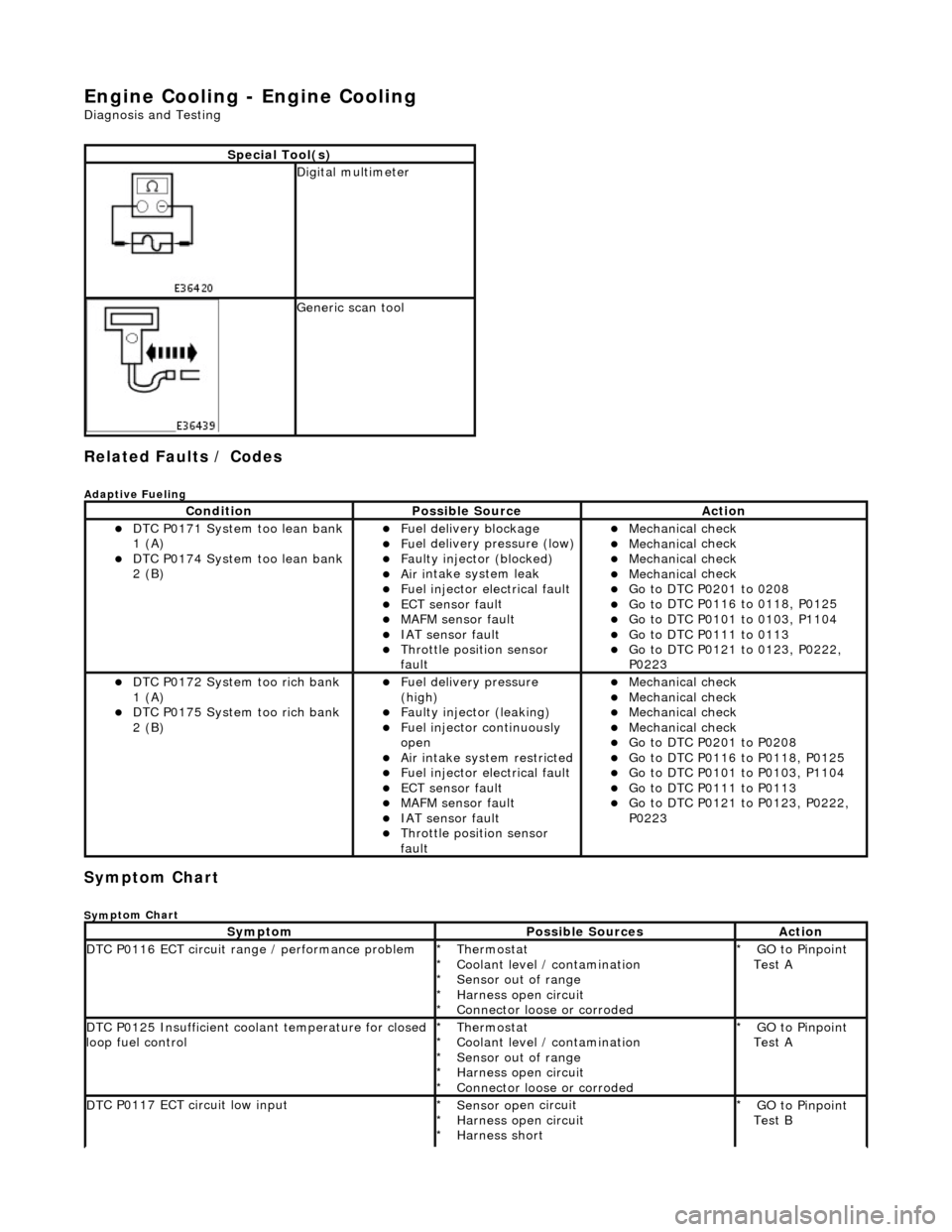

Engine Cooling - Engine Cooling

Diagn

osis and Testing

Related Faults / Codes

Adaptive

Fue

ling

Sym

p

tom Chart

Sy

m

ptom Chart

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

Conditi

on

Possib

l

e Source

Acti

o

n

пЃ¬D

T

C P0171 System too lean bank

1 (A)

пЃ¬D T

C P0174 System too lean bank

2 (B)

пЃ¬Fuel delivery blockage пЃ¬Fu

el delivery pressure (low)

пЃ¬F

a

ulty injector (blocked)

пЃ¬Ai

r i

ntake system leak

пЃ¬F

u

el injector electrical fault

пЃ¬ECT sensor

faul

t

пЃ¬MAFM sensor fault пЃ¬IAT se

nsor fault

пЃ¬Thro

tt

le position sensor

fault

пЃ¬Mec hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Go t

o DTC P020

1 to 0208

пЃ¬Go t

o

DTC P0116 to 0118, P0125

пЃ¬Go t

o

DTC P0101 to 0103, P1104

пЃ¬Go t

o DTC P011

1 to 0113

пЃ¬Go t

o

DTC P0121 to 0123, P0222,

P0223

пЃ¬D T

C P0172 System too rich bank

1 (A)

пЃ¬D T

C P0175 System too rich bank

2 (B)

пЃ¬F u

el delivery pressure

(high)

пЃ¬F a

ulty injector (leaking)

пЃ¬F

u

el injector continuously

open

пЃ¬Ai r i

ntake system restricted

пЃ¬Fu

el injector electrical fault

пЃ¬ECT sensor

faul

t

пЃ¬MAFM sensor fault пЃ¬IAT sensor fault

пЃ¬Thrott

le position sensor

fault

пЃ¬Mec hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Mec

hanica

l check

пЃ¬Go t

o DTC P020

1 to P0208

пЃ¬Go t

o

DTC P0116 to P0118, P0125

пЃ¬Go t

o

DTC P0101 to P0103, P1104

пЃ¬Go t

o DTC P011

1 to P0113

пЃ¬Go t

o

DTC P0121 to P0123, P0222,

P0223

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P0116 ECT circuit range / performance problem

Thermostat

Coo

l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0125 Insufficient coolant temperature for closed

loop fuel control

Thermostat

Coo l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0117 ECT circuit low input

Sensor o

p

en circuit

Harness open circuit

Harness short

*

*

*

GO to Pinpoint

Test B

*

Page 956 of 2490

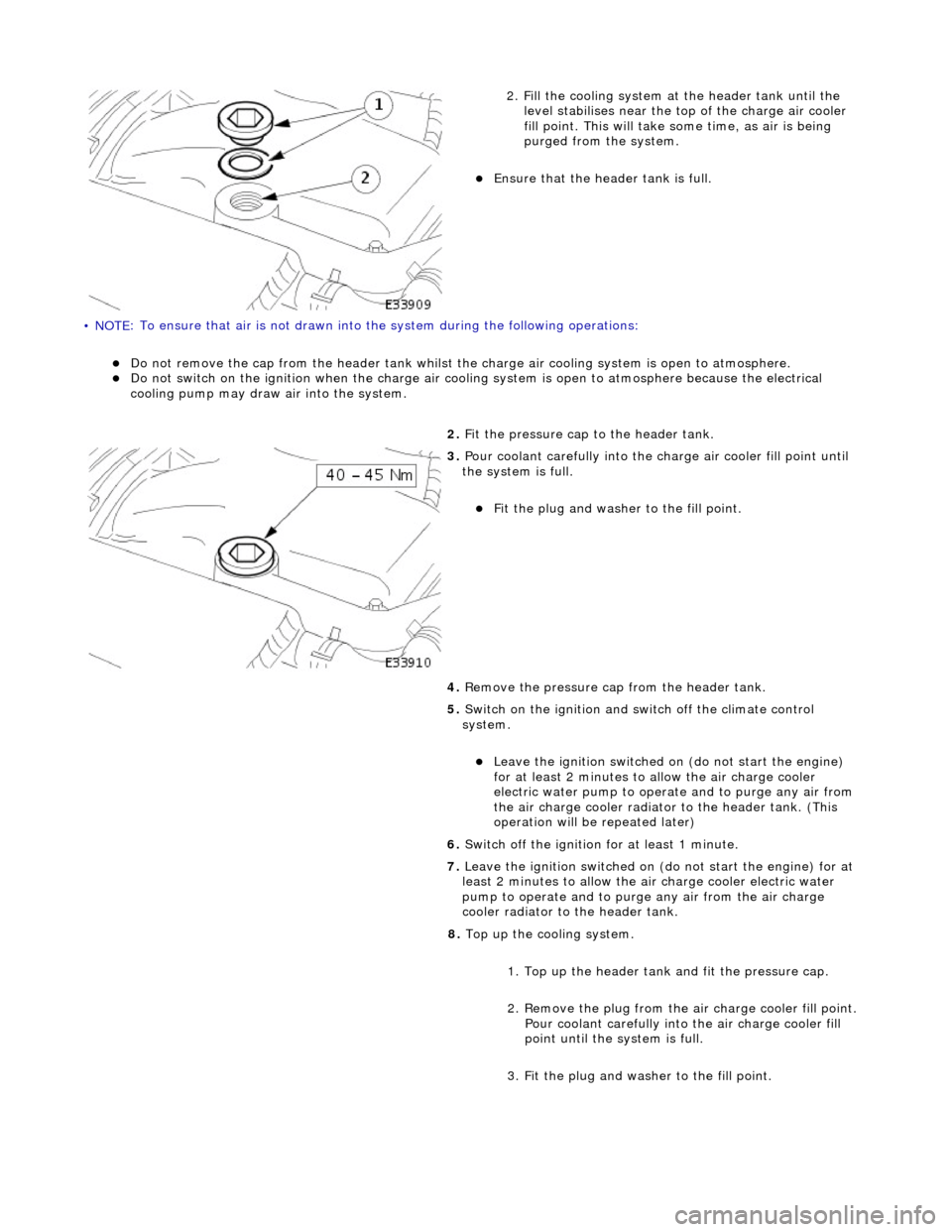

• NOTE

: To ensure that

air is not drawn into the system during the following operations:

пЃ¬Do

not remove the cap from the header tank whilst the

charge air cooling system is open to atmosphere.

пЃ¬Do

not switch on the ignition when th

e charge air cooling system is open to atmosphere because the electrical

cooling pump may draw air into the system.

2. Fi

ll the cooling system at the header tank until the

level stabilises near the to p of the charge air cooler

fill point. This will take some time, as air is being

purged from the system.

пЃ¬Ensure that the head

er tank is full.

2. Fit the pressure cap to the header tank.

3. Pour coolant careful l

y into the charge air cooler fill point until

the system is full.

пЃ¬Fi t t

he plug and washer to the fill point.

4. Remove the pressure cap from the header tank.

5. Switch on the ignition and switch off the climate control

system.

пЃ¬Le ave

the ignition switched on (do not start the engine)

for at least 2 minutes to allow the air charge cooler

electric water pump to oper ate and to purge any air from

the air charge cooler radiator to the header tank. (This

operation will be repeated later)

6. Switch off the ignition for at least 1 minute.

7. Leave the ignition switched on (do not start the engine) for at

least 2 minutes to allow the air charge cooler electric water

pump to operate and to purg e any air from the air charge

cooler radiator to the header tank.

8. Top up the cooling system.

1. Top up the header tank and fit the pressure cap.

2. Remove the plug from the air charge cooler fill point. Pour coolant carefully into the air charge cooler fill

point until the system is full.

3. Fit the plug and washer to the fill point.

Page 1011 of 2490

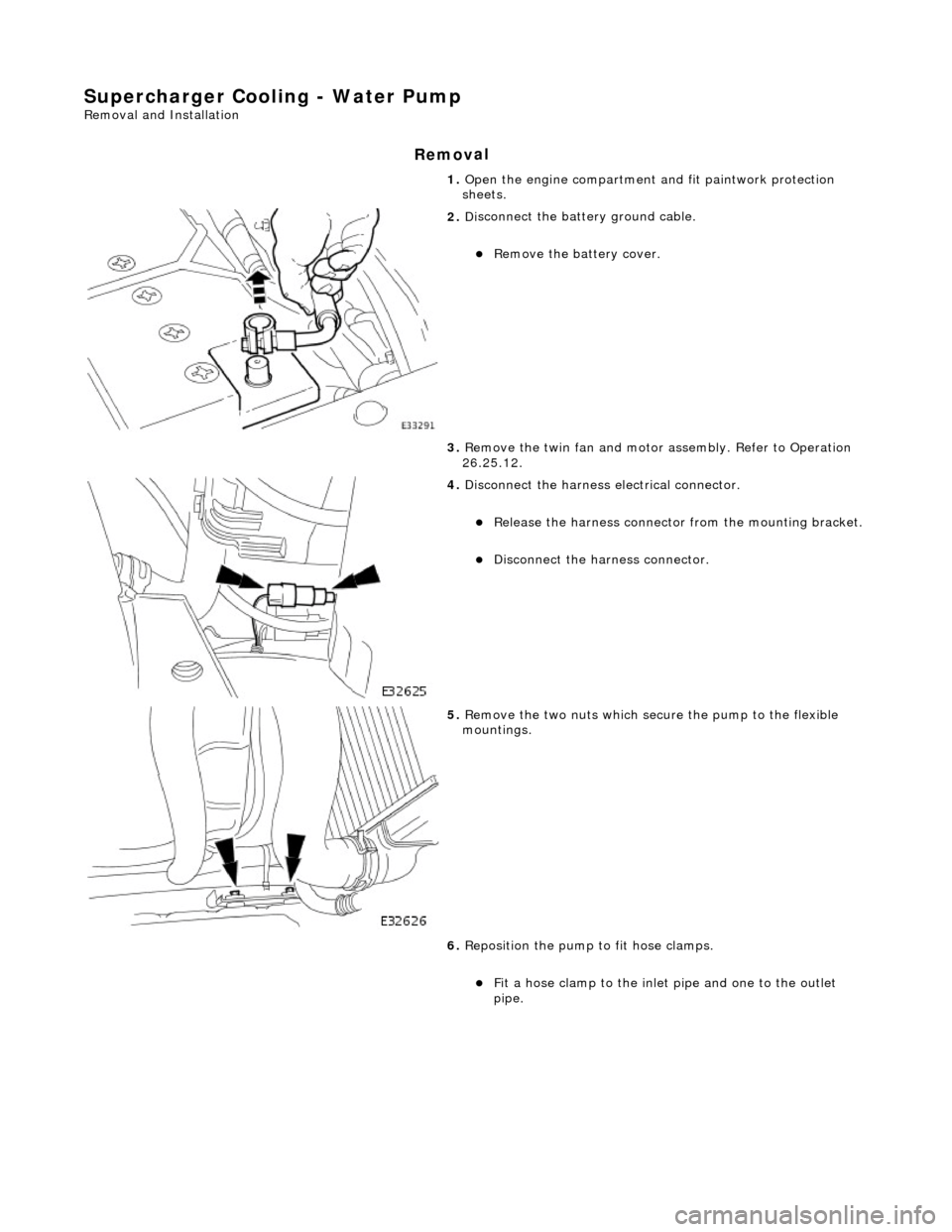

Supercharger Cooling - Water Pump

Re

moval and Installation

Remov

al

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Di

sconnect the batt

ery ground cable.

пЃ¬R

emove the battery cover.

3. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

4. Disc

onnect the harness electrical connector.

пЃ¬R

elease the harness connector from the mounting bracket.

пЃ¬Disc

onnect the harness connector.

5. R

emove the two nuts which secure the pump to the flexible

mountings.

6. Reposition the pump to fit hose clamps.

пЃ¬Fi

t a hose clamp to the inlet pipe and one to the outlet

pipe.

Page 1015 of 2490

Fuel D

istribution

Fuel is supplied to th

e engine

via eight fuel injectors (one pe r cylinder). The injectors are located in two fuel rails which r un

the length of each cylinder bank and ar e integral with the air intake manifold.

Fuel pumped from the tank enters a feed pipe at the rear of bank 2. Fuel flow is along bank 2 fuel rail, across the top front

of the engine (cross-over pipe) and through bank 1 fuel rail, the unused fuel re turning to the tank via a pressure regulator.

The fuel injectors are each controlled electrically from the engine control module (ECM).

A test valve is fitted to the cross-over pipe connecting the fu el rails at the front of the intake manifold. This valve allows the

fuel system to be depr essurized during servicin g and troubleshooting.

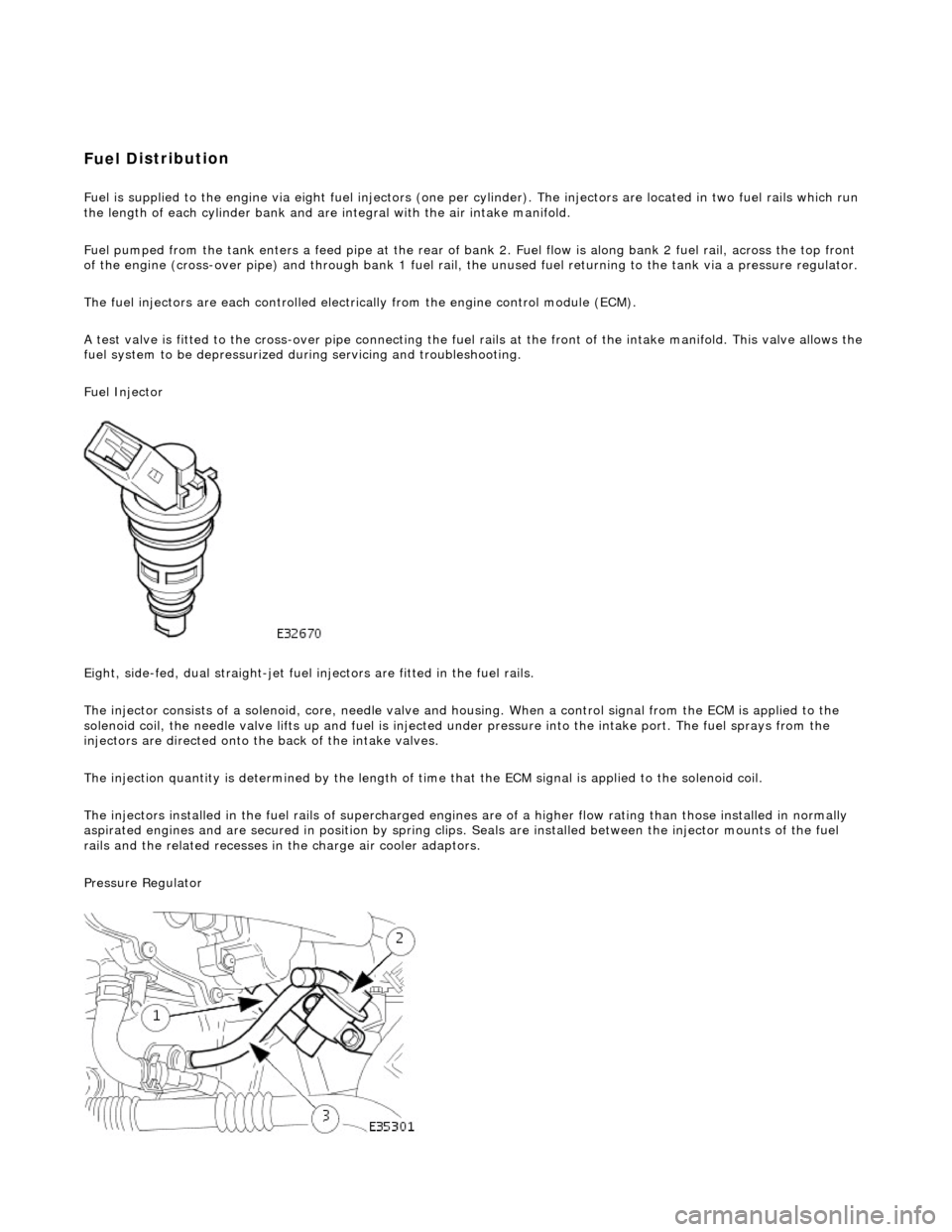

Fuel Injector

Eight, side-fed, dual straight-jet fuel injectors are fi tted in the fuel rails.

The injector consists of a solenoid, core, needle valve and ho using. When a control signal from the ECM is applied to the

solenoid coil, the needle valve lifts up and fuel is injected under pressure into the intake port. The fuel sprays from the

injectors are directed onto the back of the intake valves.

The injection quantity is determined by the length of time that the ECM signal is applied to the solenoid coil.

The injectors installed in the fuel rails of supercharged engines are of a higher flow rating than those installed in normally

aspirated engines and are secured in position by spring clips. Seals are instal led between the injector mounts of the fuel

rails and the related re cesses in the charge air cooler adaptors.

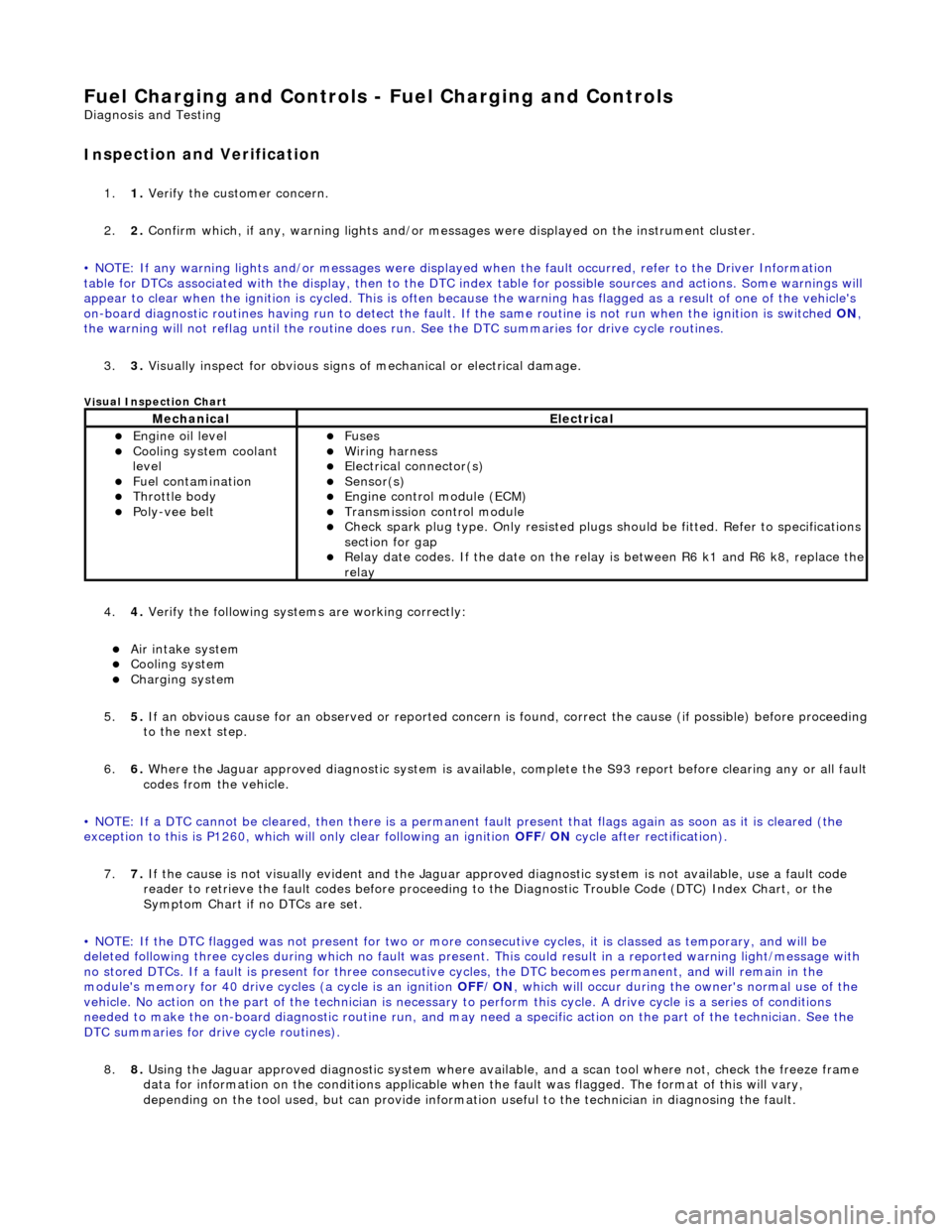

Pressure Regulator

Page 1020 of 2490

Fuel Char

ging and Controls - Fuel Charging and Controls

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Confi

rm which, if any, warning li

ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

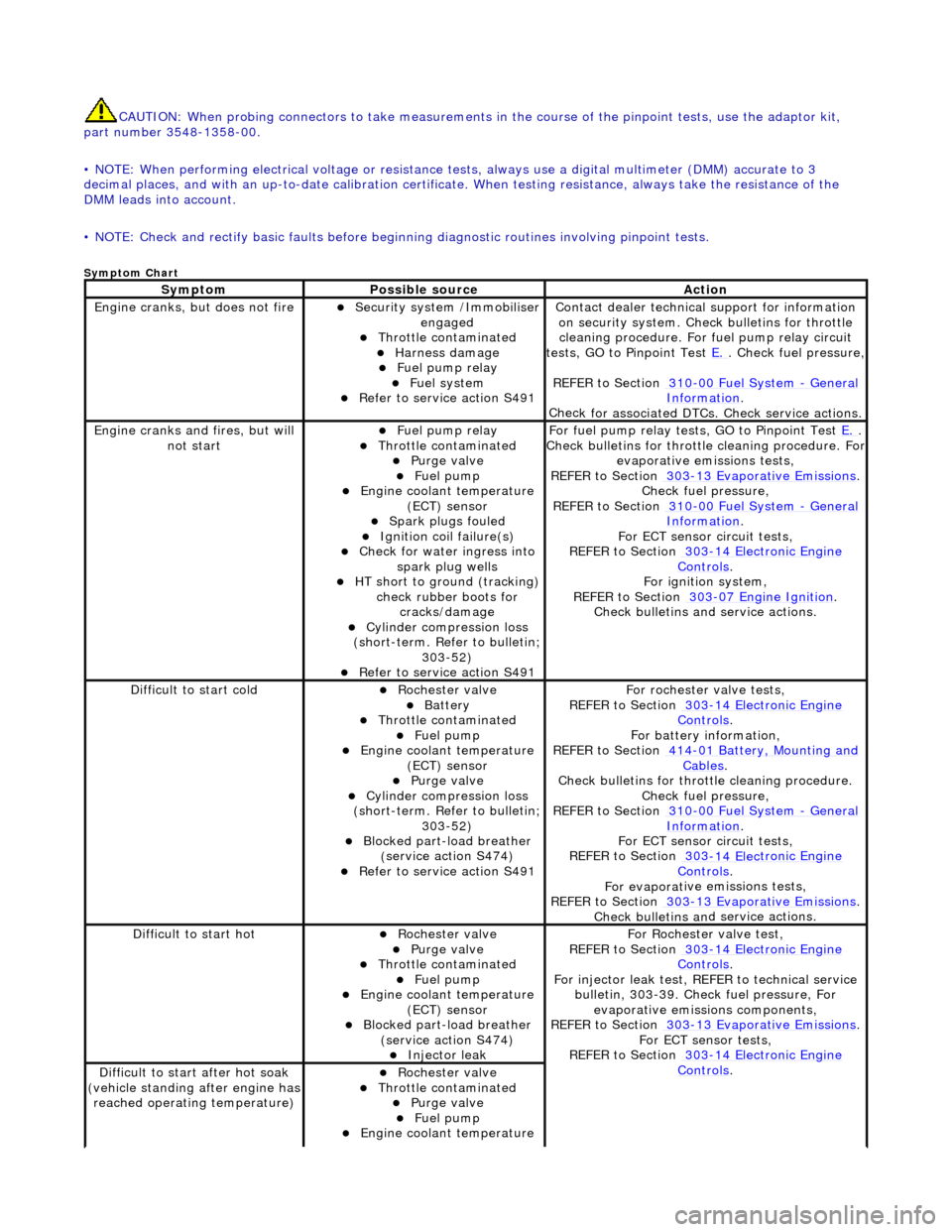

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

Vi

sual Inspection Chart

4.

4. Veri fy the foll

owing syst

ems are working correctly:

пЃ¬Air intake

system

пЃ¬Cooling system

пЃ¬Charging system

5. 5. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycl es (a cycle is an ignition OFF/ON, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for drive cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

MechanicalElectrical

пЃ¬Engine

oil level

пЃ¬Coo

ling system coolant

lev

el

пЃ¬Fuel contamination

пЃ¬Throttle body пЃ¬Poly-ve

e belt

пЃ¬Fu

ses

пЃ¬W

i

ring harness

пЃ¬E

l

ectrical connector(s)

пЃ¬Sens

o

r(s)

пЃ¬Engine

control module (E

CM)

пЃ¬Tran

s

mission control module

пЃ¬Check spark plu

g type. Only r

e

sisted plugs should be fitted. Refer to specifications

section for gap

пЃ¬Relay date codes. I

f the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1021 of 2490

CAUTI

ON: When probing connectors to take

measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

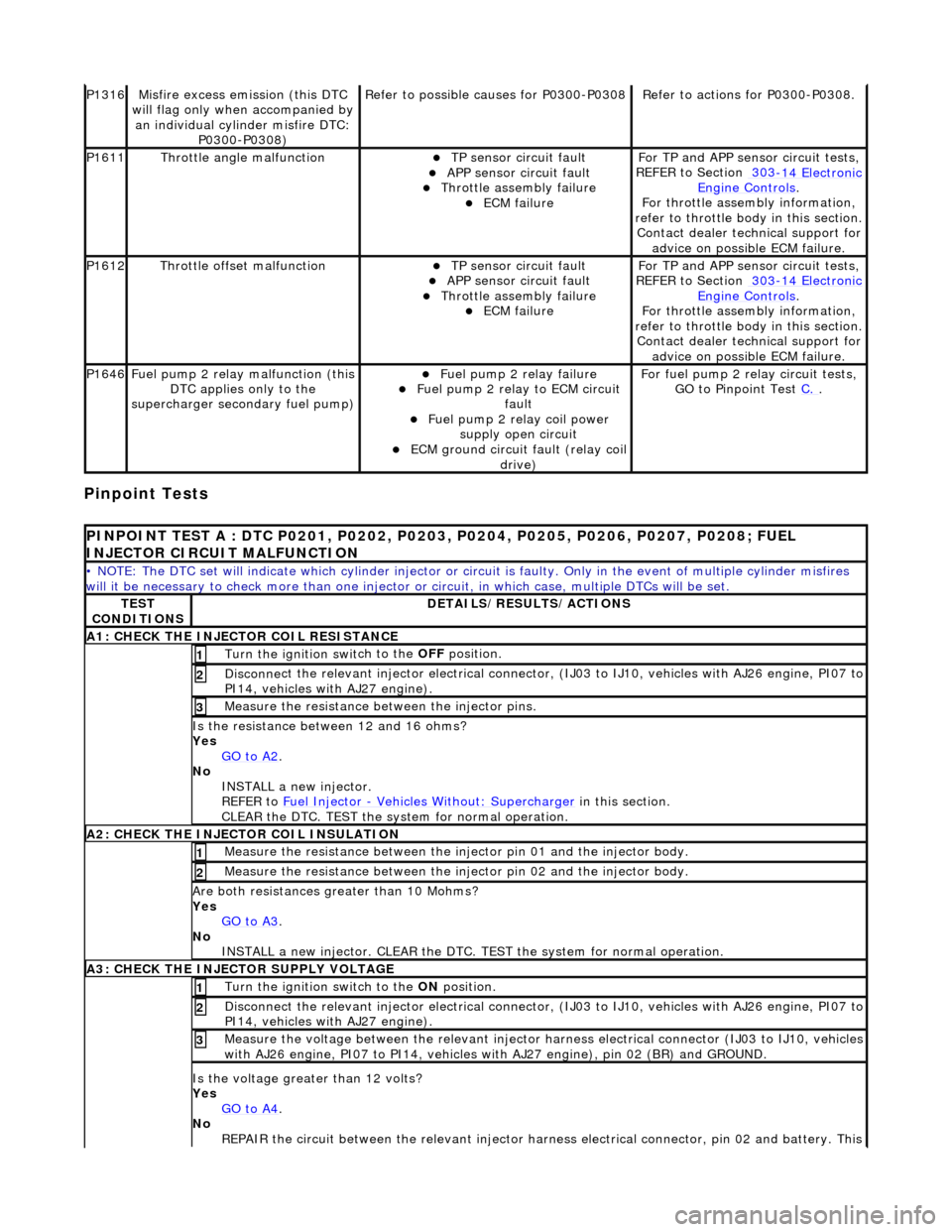

Sy

mptom Chart

Sy

mptom

Possib

le source

Acti

on

Engine

cranks, but does not fire

пЃ¬Secu

rity system /Immobiliser

engaged

пЃ¬Thr

ottle contaminated

пЃ¬Harness damage

пЃ¬F

uel pump relay

пЃ¬Fue

l system

пЃ¬R

efer to service action S491

Contact dealer techn

ical

support for information

on security system. Chec k bulletins for throttle

cleaning procedure. For fuel pump relay circuit

tests, GO to Pinpoint Test E.

.

Check fuel pressure,

REFER to Section 310

-00

Fuel System

- Gen

eral

Informati

on

.

Chec

k for associated DTCs

. Check service actions.

Engine

cranks and fires, but will

not start

пЃ¬F

uel pump relay

пЃ¬Thr

ottle contaminated

пЃ¬Purge

valve

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Spark plugs

fouled

пЃ¬Ignition coil

failure(s)

пЃ¬Check f

or water ingress into

spark plug wells

пЃ¬HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

пЃ¬Cyl

inder compression loss

(short-term. Refer to bulletin;

303-52)

пЃ¬R

efer to service action S491

F

or fuel pump relay tests,

GO to Pinpoint Test E.

.

Check bull

etins for throttle cleaning procedure. For

evaporative emissions tests,

REFER to Section 303

-1

3 Evaporative Emissions

. Chec

k fuel pressure,

REFER to Section 310

-00

Fuel System

- Ge

neral

Informati

on

.

F

or ECT sensor circuit tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

For ign

ition system,

REFER to Section 303

-07

Engine Ignition

.

Check bulletins an d service

actions.

D

ifficult to start cold

пЃ¬Roc

hester valve

пЃ¬Batt

ery

пЃ¬Thr

ottle contaminated

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Purge

valve

пЃ¬Cyl

inder compression loss

(short-term. Refer to bulletin;

303-52)

пЃ¬Blocked part-load breather (

service action S474)

пЃ¬R

efer to service action S491

F

or rochester valve tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure,

REFER to Section 310

-00

Fuel System

- Ge

neral

Informati

on

.

F

or ECT sensor circuit tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

For evaporat

ive emissions tests,

REFER to Section 303

-1

3 Evaporative Emissions

. Check bulletins an

d

service actions.

D

ifficult to start hot

пЃ¬Roc

hester valve

пЃ¬Purge

valve

пЃ¬Thr

ottle contaminated

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

(ECT) sensor

пЃ¬Blocked part-load breather (

service action S474)

пЃ¬Injec

tor leak

F

or Rochester

valve test,

REFER to Section 303

-14 Elec

tronic Engine

Controls.

Fo

r injector leak test, REFER to technical service

bulletin, 303-39. Check fuel pressure, For evaporative emissions components,

REFER to Section 303

-1

3 Evaporative Emissions

. F

or ECT sensor tests,

REFER to Section 303

-14 Elec

tronic Engine

Controls. D

ifficult to start after hot soak

(vehicle standing after engine has

reached operating temperature)

пЃ¬Roc

hester valve

пЃ¬Thr

ottle contaminated

пЃ¬Purge

valve

пЃ¬Fue

l pump

пЃ¬Engine coolan

t temperature

Page 1028 of 2490

Pinpoint Tests

P1316Mi

sfire excess emission (this DTC

will flag only when accompanied by an individual cylinder misfire DTC: P0300-P0308)

Re

fer to possible causes for P0300-P0308

R

e

fer to actions for P0300-P0308.

P1611Thr

o

ttle angle malfunction

пЃ¬TP sensor

ci

rcuit fault

пЃ¬APP sensor circuit faul

t пЃ¬Throttle

assembly failure

пЃ¬ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1612Throttl e

offset malfunction

пЃ¬TP sensor

ci

rcuit fault

пЃ¬APP sensor circuit faul

t пЃ¬Throttle

assembly failure

пЃ¬ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1646Fu

el pump 2 relay malfunction (this

DTC applies only to the

supercharger secondary fuel pump)

пЃ¬Fu

el pump 2 relay failure

пЃ¬Fu

el pump 2 relay to ECM circuit

fault

пЃ¬Fu

el pump 2 relay coil power

supply open circuit

пЃ¬ECM ground circuit faul t (relay coil

drive)

For fuel pump 2 r

elay circuit tests,

GO to Pinpoint Test C.

.

PI

NPOINT TEST A : DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208; FUEL

INJECTOR CIRCUIT MALFUNCTION

• NOTE

: The DTC set will indicate which cylinder injector or circ

uit is faulty. Only in the event of multiple cylinder misfires

will it be necessary to chec k more than one injector or circuit, in which case, multiple DTCs will be set.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK THE INJECTOR COIL RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he resistance between the injector pins.

3

Is

t

he resistance between 12 and 16 ohms?

Yes GO to A2

.

No

INST

ALL a new injector.

REFER to Fuel Injector

- Ve hicles With

out: Supercharger

in this

section.

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK

THE INJECTOR COIL INSULATION

Meas

ure t

he resistance between the inje

ctor pin 01 and the injector body.

1

Measure t

he resistance between the inje

ctor pin 02 and the injector body.

2

Are both re

sistances greater than 10 Mohms?

Yes GO to A3

.

No

INST

ALL a new injector. CLEAR the DTC. TE

ST the system for normal operation.

A3: CHECK THE INJECTOR

SUPPLY VOLTAGE

Turn the ignition swi

t

ch to the ON

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI 14, vehicles with AJ27 engine), pin 02 (BR) and GROUND.

3

Is the volt

age greater than 12 volts?

Yes GO to A4

.

No

R

EPAIR the circuit between the relevant injector harn

ess electrical connector, pin 02 and battery. This

Page 1029 of 2490

ci

rcuit includes the EMS fuse box,

fuse 05, and the fuel injection relay. For additional information,

refer to the wiring diagrams. CLEAR DTC. TEST the system for normal operation.

A4: CHECK

THE INJECTOR GROUND

CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, (EM15, vehi

cles with AJ26 engine, EM84, vehicles with AJ27

engine).

3

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and the ECM electrical

connector, pins as follows -

Vehicles with AJ26 engine:

пЃ¬Cy

l 1 IJ03, pin 01 (BU) and EM15, pin 07

пЃ¬Cy

l 2 IJ07, pin 01 (BU) and EM15, pin 18

пЃ¬Cy

l 3 IJ04, pin 01 (BN) and EM15, pin 17

пЃ¬Cy

l 4 IJ08, pin 01 (BN) and EM15, pin 05

пЃ¬Cy

l 5 IJ05, pin 01 (BG) and EM15, pin 16

пЃ¬Cy

l 6 IJ09, pin 01 (BG) and EM15, pin 04

пЃ¬Cy

l 7 IJ06, pin 01 (BW) and EM15, pin 06

пЃ¬Cy

l 8 IJ10, pin 01 (BW) and EM15, pin 15

Vehicles with AJ27 engine:

пЃ¬Cy

l 1 PI07, pin 01 (B

G) and EM84, pin 02

пЃ¬Cy

l 2 PI11, pin 01 (BW) and EM84, pin 06

пЃ¬Cy

l 3 PI08, pin 01 (BO) and EM84, pin 21

пЃ¬Cy

l 4 PI12, pin 01 (BW) and EM84, pin 04

пЃ¬Cy

l 5 PI09, pin 01 (B

G) and EM84, pin 14

пЃ¬Cy

l 6 PI13, pin 01 (BO) and EM84, pin 03

пЃ¬Cy

l 7 PI10, pin 01 (BW) and EM84, pin 05

пЃ¬Cy

l 8 PI14, pin 01 (BR) and EM84, pin 13

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit between the relevant injector harness electrical connector pin 01 and the engine

control module electrical connecto r. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO BATTERY

R

econnect the battery negative terminal.

1

Meas

ure the voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO GROUND

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

1

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

P

INPOINT TEST B : DTC P0460; FUEL

LEVEL SENSE SIGNAL PERFORMANCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE FUEL LEVEL SENSOR REFERENCE GROUND

Di

sconnect the fuel level sensor electrical connector, BT15.

1

Page 1030 of 2490

Measure t

he resistance

between BT15 and GROUND.

2

Is the res

istance greater than 5 ohms?

Yes GO to B2

.

No

GO to B3

.

B2: CHECK THE FUEL

LEVEL SENSOR REFERE

NCE GROUND CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the instrument cluster electrical connector, FC25.

1

Meas

ure t

he resistance between FC25, pin 14 (RW) and BT15 (RW).

2

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B3

.

B3: CHECK THE FUEL

LEVEL SENSOR (EMPTY)

Di

sc

onnect the fuel level sensor electrical connectors, BT14 and BT15.

1

Empty the fuel

tank. 2

Measure t

he resistance between the

fuel level sensor connections.

3

Is t

he resistance 900 ohms?

Yes GO to B4

.

No

INST

ALL a new fuel level sensor.

REFER to Section 310

-0 1

Fuel Tank and Lines

.

CLEAR t h

e DTC. TEST the system for normal operation.

B4:

CHECK

THE FUEL LEVEL SENSOR (FULL)

Fi

ll

the fuel tank.

1

Meas

ure t

he resistance between the

fuel level sensor connections.

2

Is

the resistance 80 ohms?

Yes GO to B5

.

No

INST

ALL a new fuel level sensor.

REFER to Section 310

-0 1

Fuel Tank and Lines

.

CLEAR t h

e DTC. TEST the system for normal operation.

B

5

: CHECK THE FUEL LEVEL SENSOR SIGNAL WIRE FOR HIGH RESISTANCE

Di

sc

onnect the instrument cluster electrical connector, FC25.

1

Meas

ure t

he resistance between FC25, pin 13 (BW) and BT14 (BW).

2

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new instrument cluster.

REFER to Section 413

-01

Instrume

nt Cluster

.

CLEAR t h

e DTC. TEST the system for normal operation.

P

INPOINT TEST C : DTC P1646; FU

EL PUMP 2 (SC) RELAY MALFUNCTION

•

NO

TE: This DTC applies only to the

supercharged system fuel pump 2.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C

1

: CHECK THE FUEL PUMP 2 RELAY POWER SUPPLY

R

e

move the fuel pump 2 relay.

1

Turn the ignition swi

t

ch to the

ON position.

2

Meas

ure t

he voltage between the

relay base, pin 01 and GROUND.

3

Is the volt

age less than 10 volts?

Yes REPAIR the circuit between the rela y base, pin 01 and battery. This circuit includes the trunk fuse

box, the ignition positive relay, and the high power protection module. For additional information,

refer to the wiring diagrams. CLEAR the DTC. TEST the system for normal operation.

No GO to C2

.