electrical JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 461 of 2490

sus

pension components

and for damaged coil springs in the front suspension.

as necessary. For addi tional information,

REF

ER to Section 204

-0

2 Rear Suspension

. пЃ¬I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

пЃ¬Chec

k the rear suspension

for loose or worn

suspension components.

пЃ¬TIGHTE

N or INSTALL new components as

necessary. For additi onal information,

REFER to Section 204

-0

2 Rear Suspension

.

пЃ¬Incorre

ct underbody

alignment.

пЃ¬CHECK

underbody alignment. For additional

information,

REFER to Section 502

-00

Uni

-Body, Subframe and M

ounting System

.

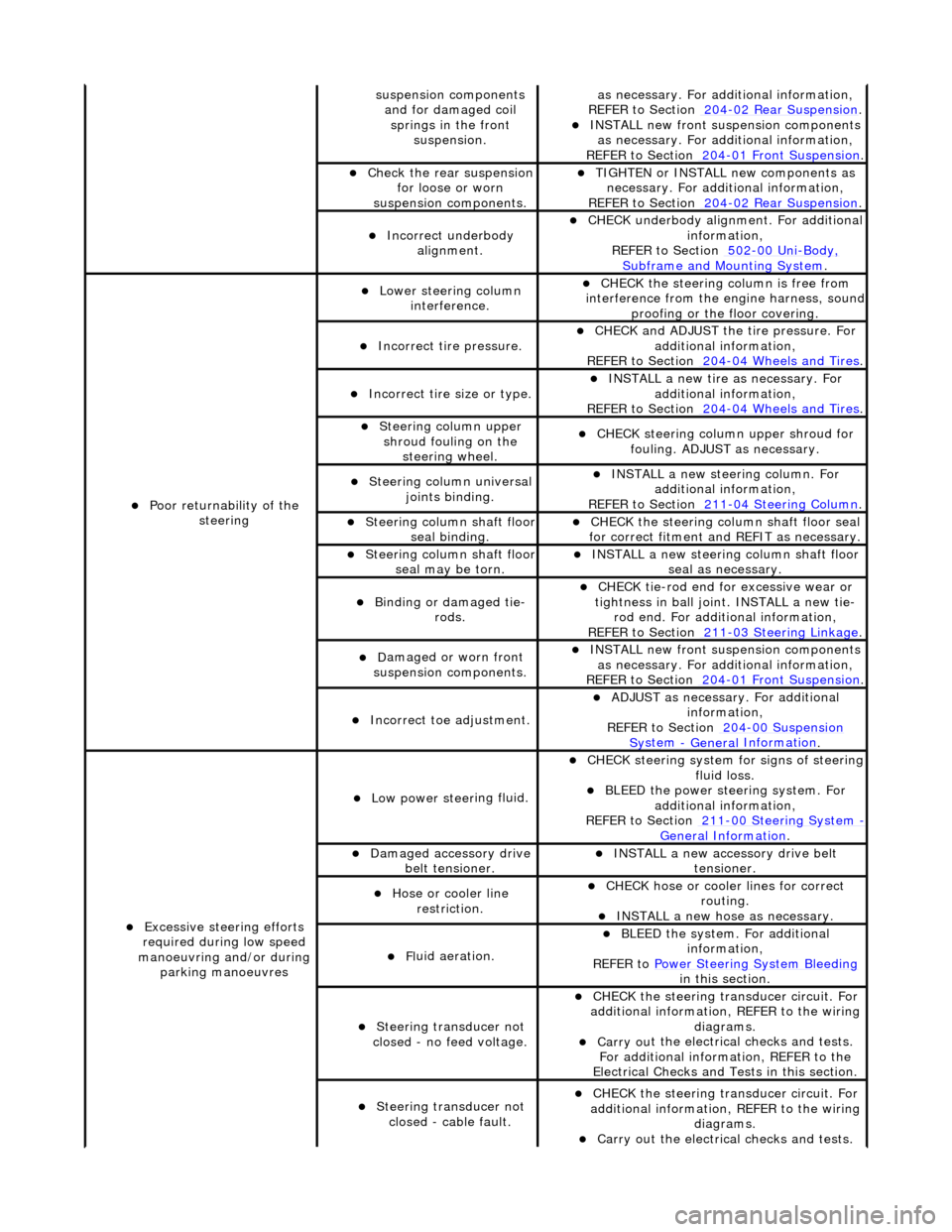

пЃ¬Poor r

eturnability of the

steering

пЃ¬Lower steeri

ng column

interference.

пЃ¬CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

пЃ¬Incorrect

tire pressure.

пЃ¬CHECK

and ADJUST the tire pressure. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

пЃ¬Incorrect

tire size or type.

пЃ¬IN

STALL a new tire as necessary. For

additional information,

REFER to Section 204

-0

4 Wheels and Tires

.

пЃ¬Steeri

ng column upper

shroud fouling on the steering wheel.

пЃ¬CHECK

steering column upper shroud for

fouling. ADJUST as necessary.

пЃ¬Steeri

ng column universal

joints binding.

пЃ¬IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

пЃ¬Steeri

ng column shaft floor

seal binding.

пЃ¬CHE

CK the steering column shaft floor seal

for correct fitm ent and REFIT as necessary.

пЃ¬Steeri

ng column shaft floor

seal may be torn.

пЃ¬IN

STALL a new steering column shaft floor

seal as necessary.

пЃ¬Bin

ding or damaged tie-

rods.

пЃ¬CHECK

tie-rod end for excessive wear or

tightness in ball joint. INSTALL a new tie- rod end. For additional information,

REFER to Section 211

-0

3 Steering Linkage

.

пЃ¬D

amaged or worn front

suspension components.

пЃ¬I

NSTALL new front suspension components

as necessary. For addi tional information,

REFER to Section 204

-01

Front Suspension

.

пЃ¬Incorre

ct toe adjustment.

пЃ¬AD

JUST as necessary. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

пЃ¬Excessive steeri

ng efforts

required during low speed

manoeuvring and/or during parking manoeuvres

пЃ¬Low power steer

ing fluid.

пЃ¬CHE

CK steering system

for signs of steering

fluid loss.

пЃ¬BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

пЃ¬Damaged accessory driv

e

belt tensioner.

пЃ¬INST

ALL a new accessory drive belt

tensioner.

пЃ¬Hose or cooler li

ne

restriction.

пЃ¬CHECK

hose or cooler lines for correct

routing.

пЃ¬INST

ALL a new hose as necessary.

пЃ¬Fl

uid aeration.

пЃ¬BLEE

D the system. For additional

information,

REFER to Power Steering System Bleeding

in t

his section.

пЃ¬Steeri

ng transducer not

closed - no feed voltage.

пЃ¬CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

пЃ¬Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steeri

ng transducer not

closed - cable fault.

пЃ¬CHECK

the steering transducer circuit. For

additional information, REFER to the wiring diagrams.

пЃ¬Carry ou

t the electrical checks and tests.

Page 462 of 2490

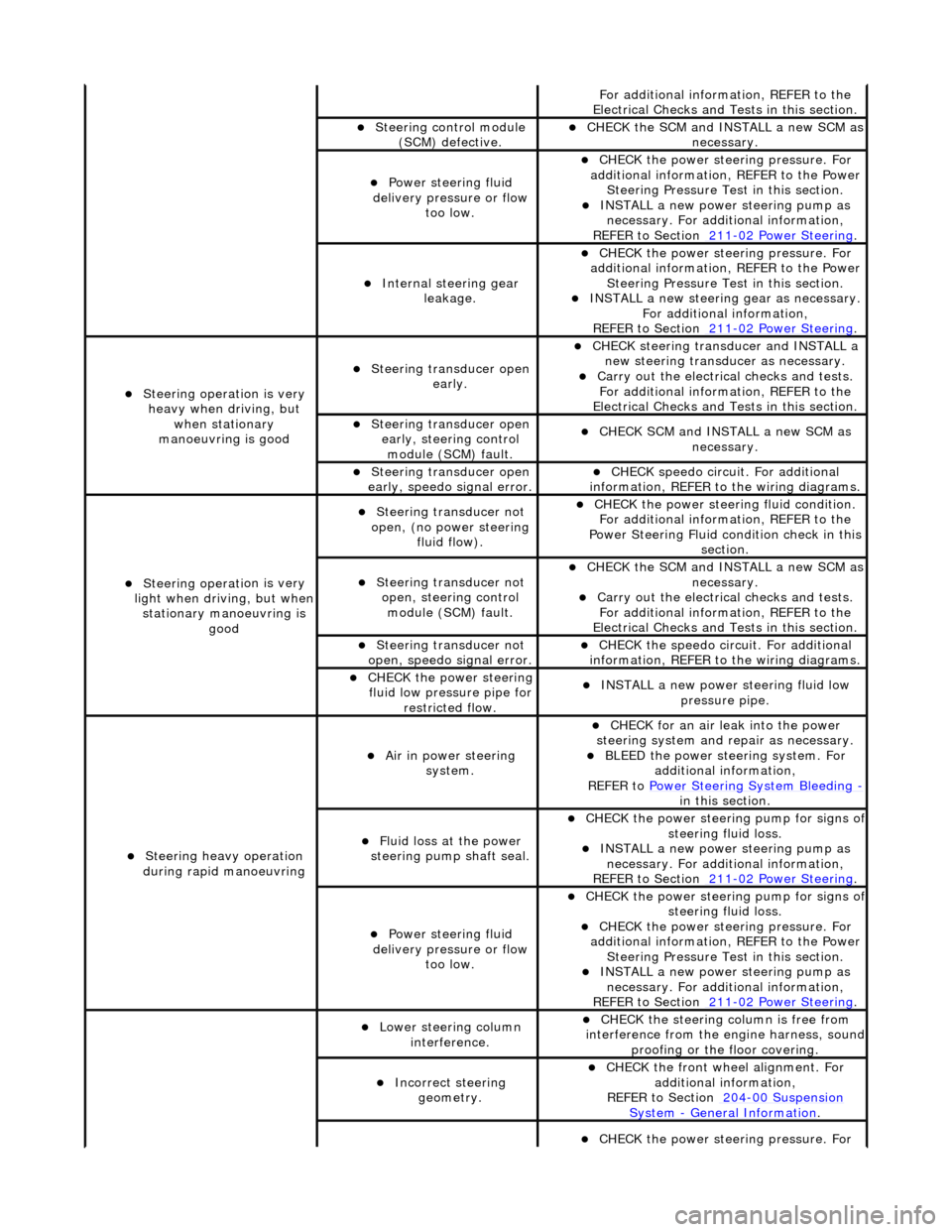

Fo

r additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering control

module

(SCM) defective.

пЃ¬CHECK

the SCM and INSTALL a new SCM as

necessary.

пЃ¬Power steeri ng f

luid

delivery pressure or flow too low.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Internal steering gear

leakage.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w steering

gear as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Steeri

ng operati

on is very

heavy when driving, but when stationary

manoeuvring is good

пЃ¬Steering transducer open earl

y.

пЃ¬CHECK

steering transducer and INSTALL a

new steering transducer as necessary.

пЃ¬Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering transducer open

early,

steering control

module (SCM) fault.

пЃ¬CHECK

SCM and INSTALL a new SCM as

necessary.

пЃ¬Steering transducer open

earl

y, speedo signal error.

пЃ¬CHECK

speedo

circui

t. For additional

information, REFER to the wiring diagrams.

пЃ¬Steeri ng operati

on is very

light when driving, but when

stationary manoeuvring is good

пЃ¬Steering transducer not

o

pen, (no power steering

fluid flow).

пЃ¬CHECK

the power steering fluid condition.

For additional information, REFER to the

Power Steering Fluid condition check in this section.

пЃ¬Steering transducer not o

pen, steering control

module (SCM) fault.

пЃ¬CHECK

the SCM and INSTALL a new SCM as

necessary.

пЃ¬Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steering transducer not

o

pen, speedo signal error.

пЃ¬CHECK

the speedo circ

uit. For additional

information, REFER to the wiring diagrams.

пЃ¬CHECK

the power steering

fluid low pressure pipe for restricted flow.

пЃ¬INSTALL a ne

w power steering fluid low

pressure pipe.

пЃ¬S t

eering heavy operation

during rapid manoeuvring

пЃ¬Ai r i

n power steering

system.

пЃ¬CHECK for an air l

eak into the power

steering system and re pair as necessary.

пЃ¬BLEED the

power steering system. For

additional information,

REFER to Power Steering System Bleeding

- in t hi

s section.

пЃ¬Fluid loss at the power

steering pump shaft seal.

пЃ¬CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

пЃ¬INST

ALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

пЃ¬Power steeri

ng f

luid

delivery pressure or flow too low.

пЃ¬CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-02

Power Steering

.

пЃ¬Lower steeri

ng col

umn

interference.

пЃ¬CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

пЃ¬Incorrect steering geometry. пЃ¬CHE

CK the front wheel alignment. For

additional information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

пЃ¬CHECK

the power stee

ring pressure. For

Page 463 of 2490

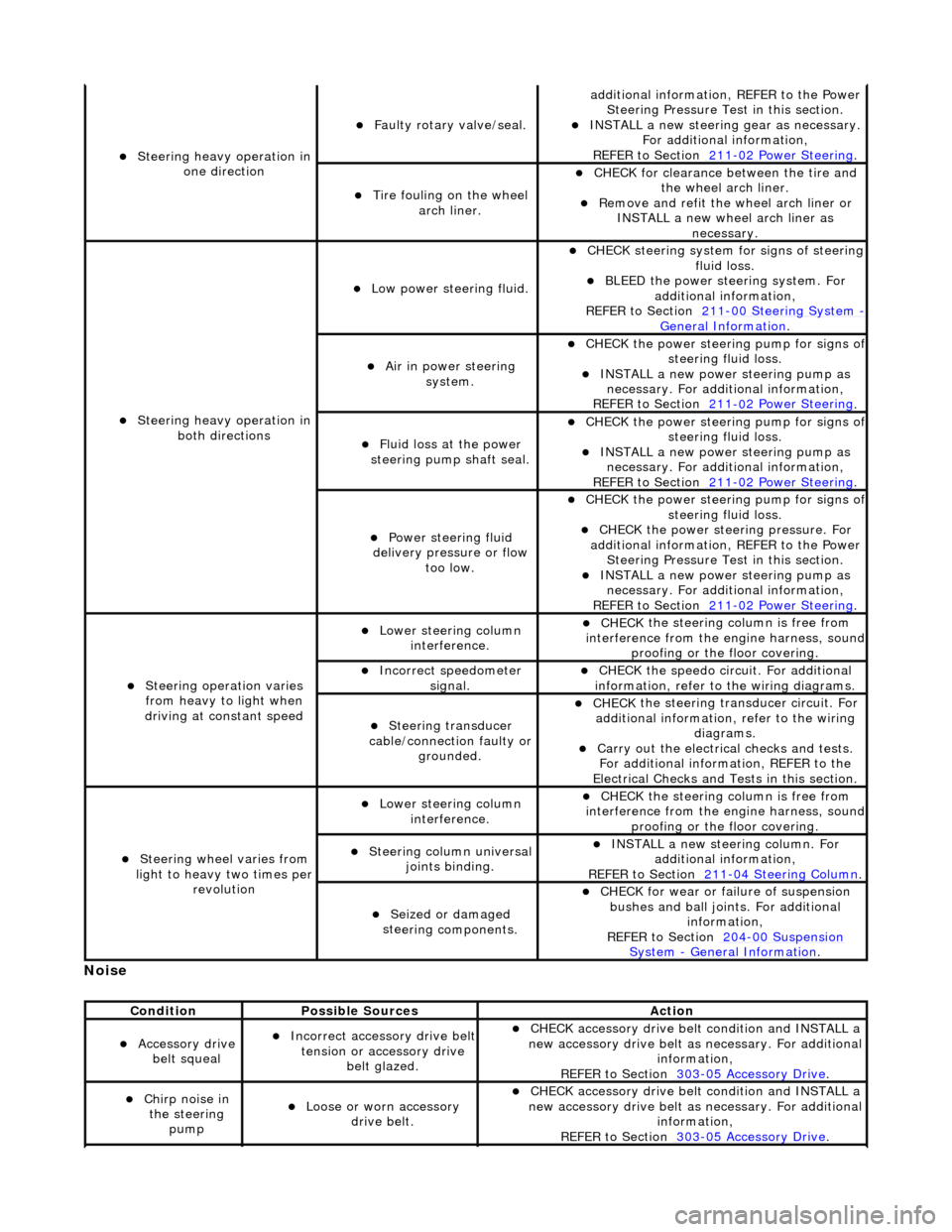

No

ise

пЃ¬S

teering heavy operation in

one direction

пЃ¬F

aulty rotary valve/seal.

addi

tional information, REFER to the Power

Steering Pressure Test in this section.

пЃ¬INST

ALL a new steering

gear as necessary.

For additional information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Ti

re fouling on the wheel

arch liner.

пЃ¬CHECK for

clearance be

tween the tire and

the wheel arch liner.

пЃ¬R

emove and refit the wheel arch liner or

INSTALL a new wheel arch liner as necessary.

пЃ¬S

teering heavy operation in

both directions

пЃ¬Low power steer

ing fluid.

пЃ¬CHE

CK steering system

for signs of steering

fluid loss.

пЃ¬BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

пЃ¬Ai

r in power steering

system.

пЃ¬CHECK

the power steering pump for signs o

f steering fl

uid loss.

пЃ¬INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Fluid loss at the power

steering pump shaft seal.

пЃ¬CHECK

the power steering pump for signs o

f steering fl

uid loss.

пЃ¬INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Power steeri

ng fluid

delivery pressure or flow too low.

пЃ¬CHECK

the power steering pump for signs o

f steering fl

uid loss.

пЃ¬CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

пЃ¬INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

пЃ¬Steeri

ng operation varies

from heavy to light when

driving at constant speed

пЃ¬Lower steeri

ng column

interference.

пЃ¬CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

пЃ¬Incorre

ct sp

eedometer

signal.

пЃ¬CHECK

the speedo circ

uit. For additional

information, refer to the wiring diagrams.

пЃ¬Steeri

ng transducer

cable/connection faulty or grounded.

пЃ¬CHECK

the steering transducer circuit. For

additional information, refer to the wiring diagrams.

пЃ¬Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

пЃ¬Steeri

ng wheel varies from

light to heavy two times per revolution

пЃ¬Lower steeri

ng column

interference.

пЃ¬CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

пЃ¬Steeri

ng column universal

joints binding.

пЃ¬IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

пЃ¬Seized or damaged

ste

ering components.

пЃ¬CHECK

for wear or failure of suspension

bushes and ball join ts. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Cond

ition

Possib

le Sources

Acti

on

пЃ¬Acce

ssory drive

belt squeal

пЃ¬Incorre

ct accessory drive belt

tension or accessory drive belt glazed.

пЃ¬CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

пЃ¬Chir

p noise in

the steering pump

пЃ¬Loose or worn accessory dr

ive belt.

пЃ¬CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

Page 491 of 2490

DO NOT DRIVE THE VEHICLE WITH THE TEST EQUIPMENT INSTALLED.

With the control valve CLOSED the pump maximum output pressure can be checked.

Remov

ing Test Equipment

T

o remove the test equipment:

пЃ¬Install a hose clamp

on the

reservoir to pump hose.

пЃ¬Re

moving the test equipmen

t is a reversal of the installation instructions.

пЃ¬Install a new O-r

ing to the PAS pump high

pressure outlet to hose connection.

пЃ¬Inst

all the original hose to the PAS pump.

пЃ¬R

emove the clamp from the reservoir to pump hose.

пЃ¬Top-up the reservoi

r fluid.

пЃ¬B

leed the PAS system; refe

r to this section.

Refer to PDU

User Guide

T

he PDU will diagnose all electrical components of the system.

Before changing a component, chec k fuse No. 12 (10A) in the left-hand heelboard fu se box. However, if this fuse is faulty a

number of other components wi ll also fail to function.

Page 493 of 2490

Righ

t-hand drive vehicles

All vehicles

7. De

tach the steering

column lower shaft.

1. Loosen the steering column lower shaft retaining bolt.

2. Remove and discard the st eering column lower shaft

retaining bolt.

3. Detach the steering column lower shaft.

8. Di

sconnect the steering gear transducer electrical connector.

9. Cut an

d discard the stee

ring gear transducer harness tie-strap.

10

.

Cut and discard the power steeri ng return pipe tie-strap.

11. Detach the power steering re turn pipe from the mounting

rubber.

Page 496 of 2490

Right

-hand drive vehicles

All vehicles

only

).

8. Install a new power st ee

ring return

pipe tie-strap.

9. Install a new steering gear transducer harness tie-strap.

10 . Conne

ct the steering gear transducer electrical connector.

пЃ¬On righ

t-hand drive vehicles

, position the steering gear

transducer harness behind th e power steering return pipe.

11

. NOTE

: Right-hand shown, left-hand similar.

Attach the tie rod end.

Page 708 of 2490

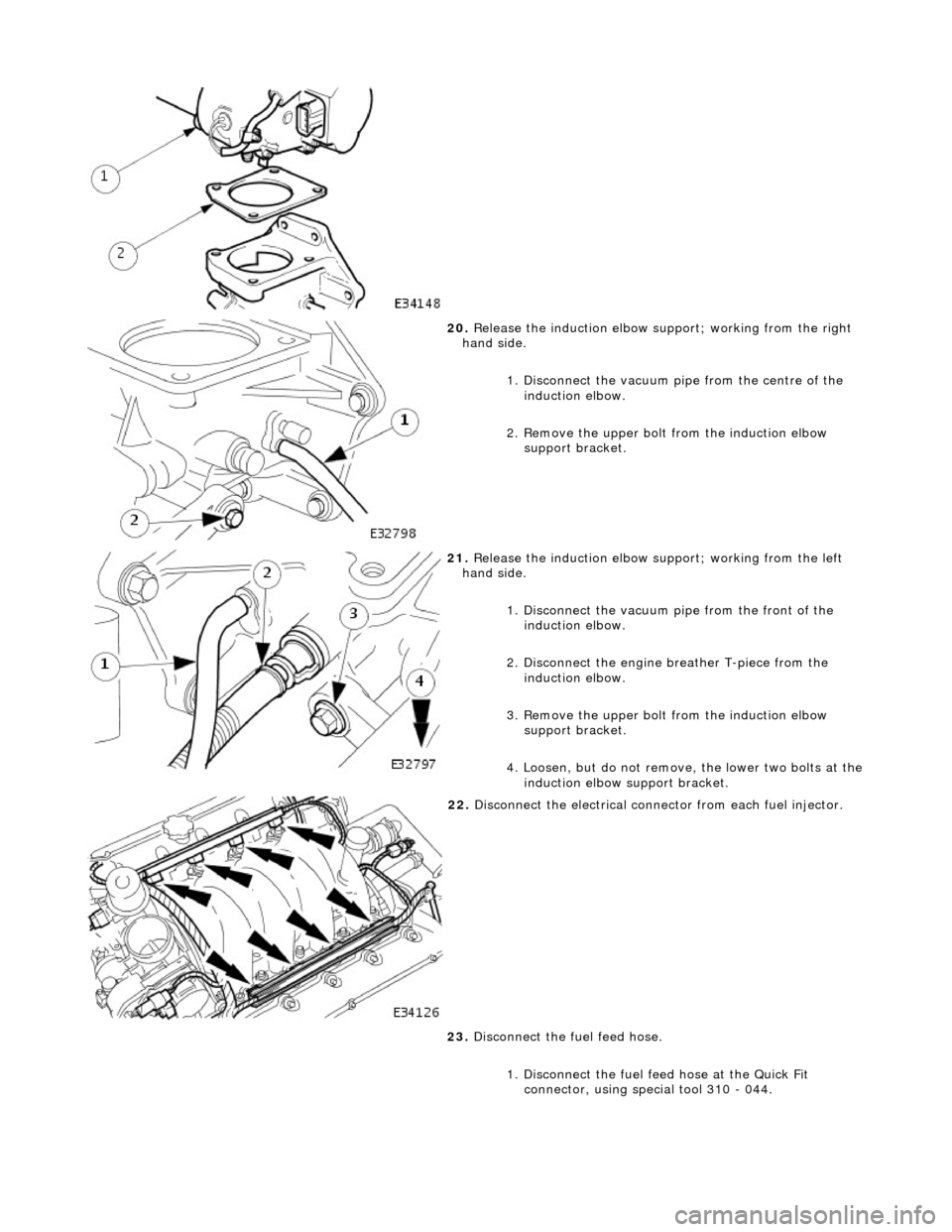

20. Release the induction elbow su pport; working from the right

hand side.

1. Disconnect the vacuum pi pe from the centre of the

induction elbow.

2. Remove the upper bolt from the induction elbow support bracket.

21. Release the induction elbow su pport; working from the left

hand side.

1. Disconnect the vacuum pipe from the front of the

induction elbow.

2. Disconnect the engine breather T-piece from the induction elbow.

3. Remove the upper bolt from the induction elbow support bracket.

4. Loosen, but do not remove , the lower two bolts at the

induction elbow support bracket.

22. Disconnect the electrical conne ctor from each fuel injector.

23. Disconnect the fuel feed hose.

1. Disconnect the fuel f eed hose at the Quick Fit

connector, using special tool 310 - 044.

Page 714 of 2490

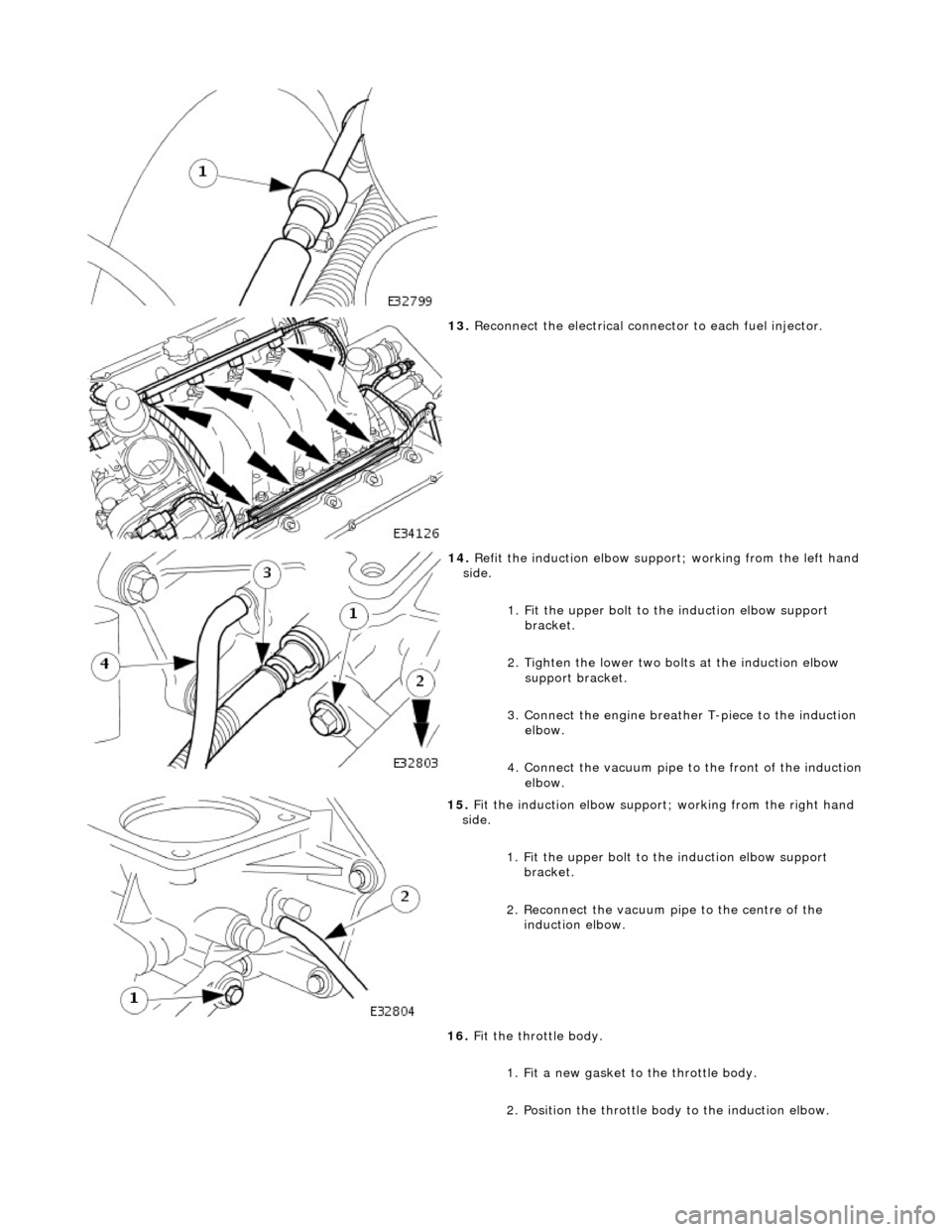

13. Reconnect the electrical connector to each fuel injector.

14. Refit the induction elbow support ; working from the left hand

side.

1. Fit the upper bolt to the induction elbow support

bracket.

2. Tighten the lower two bolts at the induction elbow support bracket.

3. Connect the engine breather T-piece to the induction elbow.

4. Connect the vacuum pipe to the front of the induction

elbow.

15. Fit the induction elbow support; working from the right hand

side.

1. Fit the upper bolt to the induction elbow support

bracket.

2. Reconnect the vacuum pi pe to the centre of the

induction elbow.

16. Fit the throttle body.

1. Fit a new gasket to the throttle body.

2. Position the throttle body to the induction elbow.

Page 722 of 2490

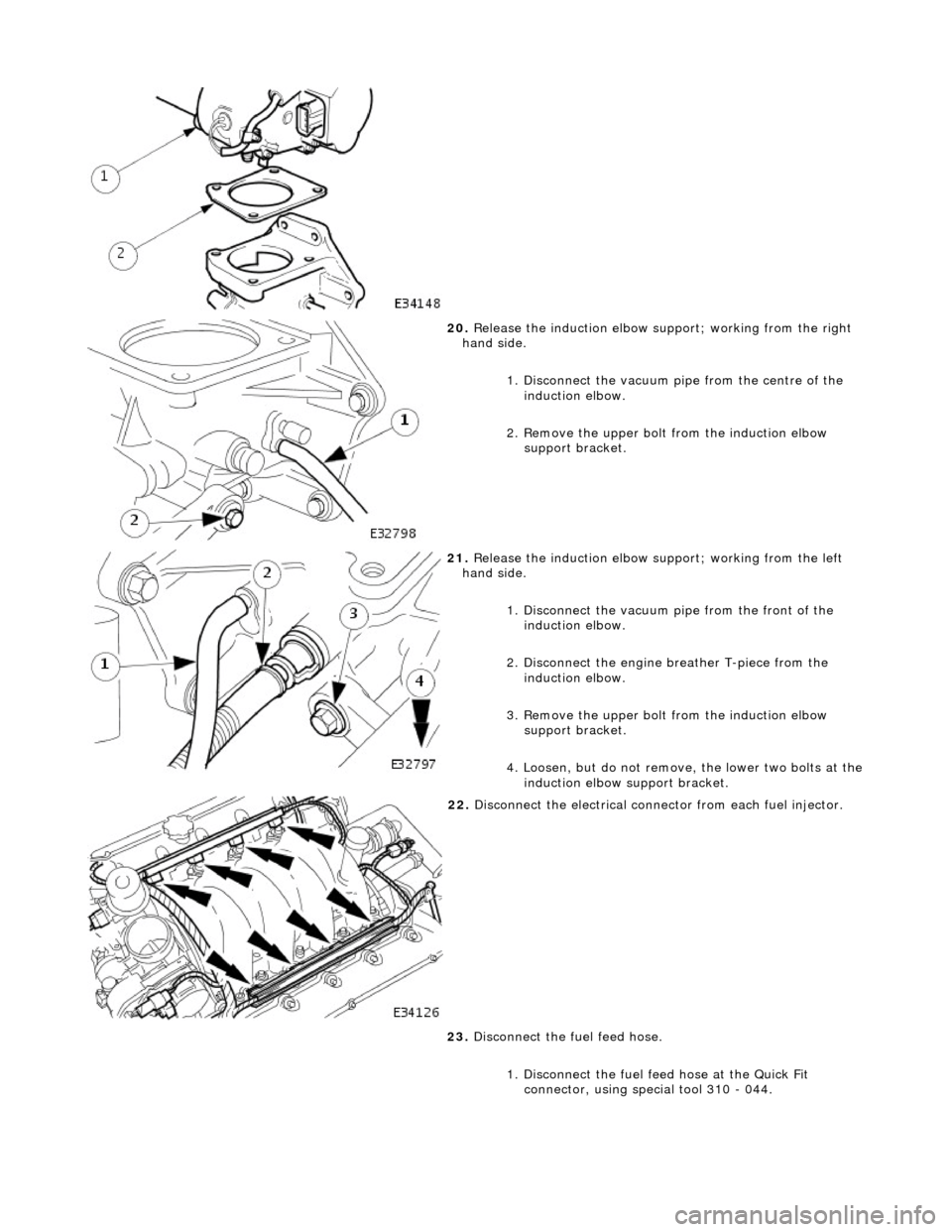

20. Release the induction elbow su pport; working from the right

hand side.

1. Disconnect the vacuum pi pe from the centre of the

induction elbow.

2. Remove the upper bolt from the induction elbow support bracket.

21. Release the induction elbow su pport; working from the left

hand side.

1. Disconnect the vacuum pipe from the front of the

induction elbow.

2. Disconnect the engine breather T-piece from the induction elbow.

3. Remove the upper bolt from the induction elbow support bracket.

4. Loosen, but do not remove , the lower two bolts at the

induction elbow support bracket.

22. Disconnect the electrical conne ctor from each fuel injector.

23. Disconnect the fuel feed hose.

1. Disconnect the fuel f eed hose at the Quick Fit

connector, using special tool 310 - 044.

Page 724 of 2490

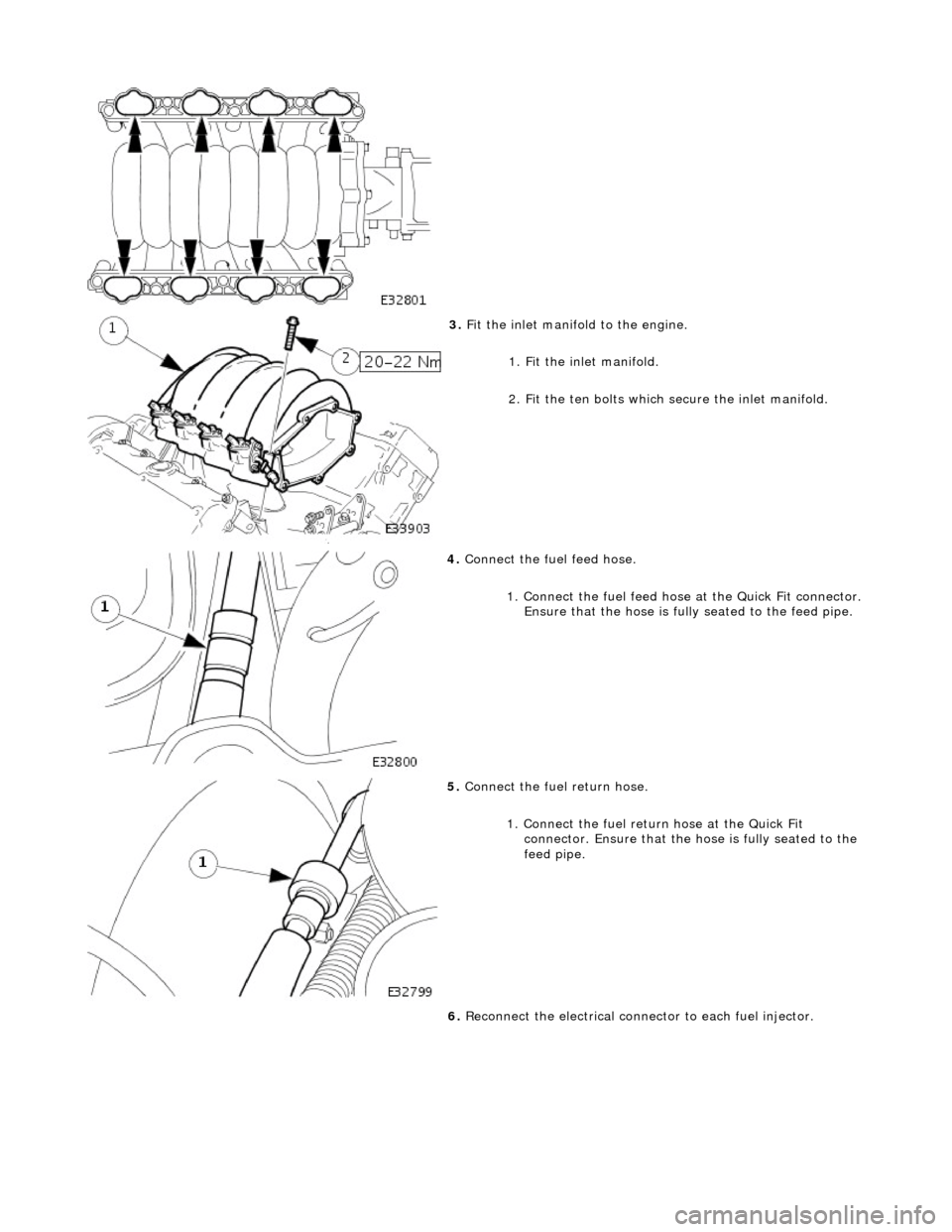

3. Fit the inlet manifold to the engine.

1. Fit the inlet manifold.

2. Fit the ten bolts which secure the inlet manifold.

4. Connect the fuel feed hose.

1. Connect the fuel feed hose at the Quick Fit connector. Ensure that the hose is fully seated to the feed pipe.

5. Connect the fuel return hose.

1. Connect the fuel return hose at the Quick Fit

connector. Ensure th at the hose is fully seated to the

feed pipe.

6. Reconnect the electrical connector to each fuel injector.