Power steering pump JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 46 of 2490

Meter (measurement)m

Me

tric (screw thread, e.g.

M8)

M

MicrofaradMFDUni t

of electrical capacitance, one millionth of a farad

Mi

ll

imeter

mm

Mi

ll

imeter of mercury

mm

Hg

Mill

isecond

ms

Min

i

mum

mi

n.

Min u

te

minut

e

Model YearMY

ModuleMSelf

contained group of electrical/electronic components which is designed as

a single replaceable unit

Modulating signalMDA sh

ift process signal to the TCM on SC vehicles

Motorized In

-Car

AspiratorMIAD e

vice which constantly samples cabi

n temperature by passing air over a

sensor, and communicates with the A/ CCM to modify A/C system performance

to suit

Mult i Prot

ocol Adaptor

MPAAn i

n

terpreter for the various data

languages present on a vehicle

N

Nati

onal Institute of

Occupational Safety and

Health (US)

NIO S

H

Ne

wto

n

NSI unit of force. 1

N = 0.224

8 pounds force

Ne

wto

n meter

NmSI unit of torque. Must not be

co

nfused with nm (nanometer)

Ni

tr

ous Oxide

NO

xCompounds of nit rogen and oxygen fo rmed at high temperatures. Major

sourc

e of exhaust-gas air pollution

No

n

-Volatile Random

Access Memory

NVR A

M

R

A

M which retains memory even

if power supply is interrupted

Normal

ly aspirated

F

u

eling system using intake air at atmo

spheric pressure; not supercharged or

turbocharged

N ormal

ly Closed

NC

N

o

rmally Open

NO

No

r

th American

Specification

NASVehicles f or sal

e in the USA and Canadian markets

Nu

mbe

r

No

.

O

Oc

cupational Safety and

Health Administration

(US)

OS H

A

O

n

-Board Diagnostic

OB

DA system that moni

tors some or all co

mputer input and output control signals.

Signal(s) outside the pre-de termined limits imply a fault in the system or a

related system

O n

-Board Refueling

Vapor Recovery

OR V

R

O

riginal

Equipment

Manufacturer

OE M

Outp

ut

O/

PAn electrical o u

tput signal from a controlling device

Ou

ts

ide diameter

o.

d

ia

O

xides of

nitrogen

NO

x

Oxygen senso

r

O2

SA s

ensor which detects oxygen content in the exhaust gases

P

Parameter Identifi

erPIDAn in

dex number referring to a parame

ter within a module without knowledge

of its storage location

Park N e

utral Position

PN

P

Park N e

utral Position

Switch

PN PSIndic

ates the selected non-drive modes of the (automatic) transmission

Part numberpart no.

Portable Diag

nostic Un

it

PD

UCompre hen

sive electrical diagnosis system specific to Jaguar vehicles

Posi

ti

on

po

s'n

Power As si

sted Steering

PASHydraul

i

c pump-assisted steering system

Power Steer

i

ng Pressure

PSP

Programmable Elect

r

onic

Control Units System

PECU SProcess whereb y

a common ECM is progra

mmed on the production line to suit

the market requirements of a particular vehicle

Programmable Read-O

nly

PROMRO

M with some provision for setting

the stored data after manufacture

Page 453 of 2490

Stee

ring System - General Information -

S

teering Linkage Specifications

Power Steering Pump Specifications

Lubricants, Fluids, Sealers and Adhesives

S

teering Linkage Free Play

Meas

urement (mm)

Meas

urement (in)

F

ree play (measured at

the steering wheel rim)

0-

6

0

-0.24

It

em

S

pecification

Power steeri

ng pump relief pressure

10

6-114 bar

It

em

S

pecification

Power steeri

ng fluid

De

xtron 3

Page 455 of 2490

Steering System - General Inform

ation - Steering System

D

iagnosis and Testing

I

nspection and Verification

1.

1. Verify t

he customer concern by driving the vehicle.

2. 2. Visually inspect for obvious signs of mechanical or electrical damage.

Mec

hanical Inspection Chart

Electrical Inspection Chart

Mechanical Checks

Incorrect

tire pressure, loose whee

l nuts, incorrect wheel alignment

Loose ti

e-rods

Loose dam

per and spring assemblies or ball joint

Loose s

teering column shaft universal joints

Loose pinc

h bolts on steering column shaft

Loose steeri

ng gear assembly

Check f

or external damage to the steering gear.

- Damaged tie-rods

-

CAUTION: If a steering gear assemb ly is returned under warranty with leaking seals, but there is also

damage to the steering gear boot/boots the steering gear warranty will be invalid. This is due to the steering

gear seals being damaged due to fore ign materials entering the steering gear boot and damaging the steering

gear seals thereafter.

Damaged steering gear boot

Damaged accessory driv

e belt

Bin

ding or misaligned steering co

lumn, pump or steering gear

Incorrect fluid

level

Hose leaks o

r line restrictions

Hose fou

ling bodywork

El

ectrical Checks/Tests

Make sure all

connectors are in plac

e (steering gear Servotronic solenoid and steering control module (SCM) - if

applicable)

Make su

re all the fuses are in place and not blown

D

ISCONNECT the steering gear transducer

and the steering should become heavy

TEST e

lectrical values:

- Power Supply to the SCM = 12 Volts

- Steering gear transducer resist ance 7.0 to 7.5 Ohms is normal

(

limits: less than 5 Ohms and greater than 9 Ohms would

be declared unacceptable)

- Steeri

ng gear transducer voltage = 6 Volts

- Steering gear transducer cu rrent = 840 mA at 0 mph reducing to 0 mA at maximum speed

Page 457 of 2490

•

NOTE: The following steps must be carried out with assistance.

1. 1. With the wheels in the straight ahead po sition, gently turn the steering wheel to the left and the right to check for

free play.

2. 2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this

limit, either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear

is excessive.

CAUTION: DO NOT attempt to adjust the stee ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

3. 3. The backlash of the steering gear cannot be adjusted, in stall a new steering gear. For additional information,

REFER to Section 211

-0

2 Power Steering

.

4. 4. Grasp the steering wheel

firm

ly and move it up and down and to the left and right without turning the wheel to

check for column bearing wear, steering wheel or steering column. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Power Steering Fluid Condition Check

1.

1. R

un the engine for 2 minutes.

2. 2. Check the power steering fluid system level.

3. 3. Observe the color and the odor. The color under normal circumstances should be dark reddish, not brown or

black.

4. 4. Allow the fluid to drip onto a faci al tissue and examine the stain.

5. 5. If evidence of solid material is foun d, the power steering fluid system should be drained for further inspection.

6. 6. If fluid contamination or steering co mponent failure is confirmed by the se diment in the power steering fluid

system, REFER to Steering Fault Diagnosis by Symptom Charts in this section.

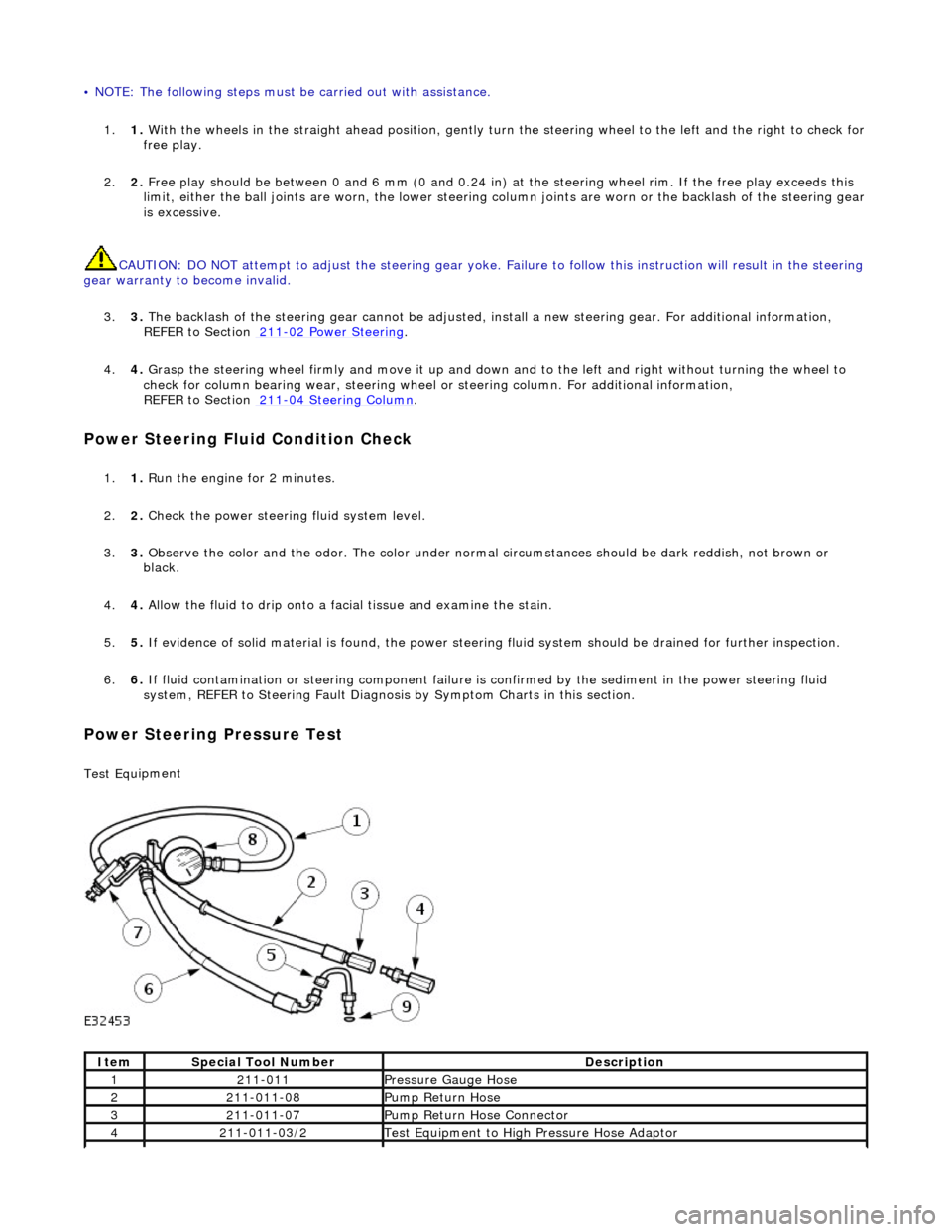

Power Steer

ing Pressure Test

Test Equ

ipment

It

em

S

pecial Tool Number

De

scription

12

11-011

Pres

sure Gauge Hose

221

1-011-08

Pump Return Hose

321

1-011-07

Pump Return Hose Connector

42

11-011-03/2

Test Equ

ipment to High

Pressure Hose Adaptor

Page 458 of 2490

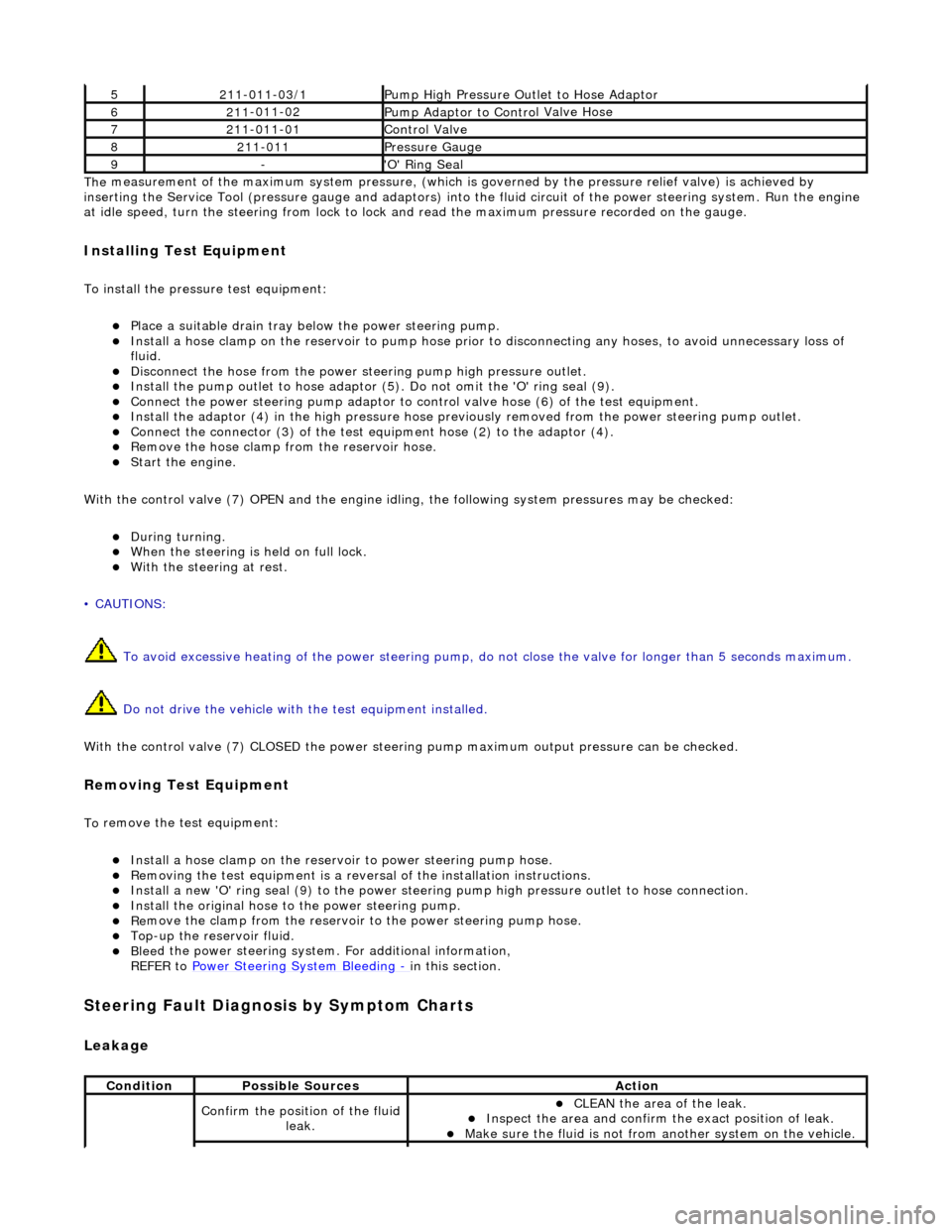

The

measurement of the maximum system pressure, (which is

governed by the pressure relief valve) is achieved by

inserting the Service Tool (pressure gauge and adaptors) into th e fluid circuit of the power steering system. Run the engine

at idle speed, turn the st eering from lock to lock and read the ma ximum pressure recorded on the gauge.

Installin

g Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray be

low the power steering pump.

Install a hose clamp on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Disc

onnect the hose from the power st

eering pump high pressure outlet.

Install the pu

mp outlet to hose adaptor (5

). Do not omit the 'O' ring seal (9).

Connect the power steering

pump

adaptor to control valve hose (6) of the test equipment.

Install th e adaptor (4) in th

e high

pressure hose previously removed from the power steering pump outlet.

Conn

ect the connector (3) of the test equipment hose (2) to the adaptor (4).

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve (7) OPEN and the engine idli ng, the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• CAUTIONS:

To avoid excessive heating of the po wer steering pump, do not close the valve for longer than 5 seconds maximum.

Do not drive the vehicle with the test equipment installed.

With the control valve (7) CLOSED the power steering pump maximum ou tput pressure can be checked.

Removing Test Equipment

To

remove the test equipment:

Install a hose clamp

on

the reservoir to power steering pump hose.

Re

movi

ng the test equipmen

t is a reversal of the in stallation instructions.

Install a new '

O

' ring seal (9) to the power steering pump high pressu

re outlet to hose connection.

Instal

l the original hose to

the power steering pump.

Re

move the clamp from the reservoir to

the power steering pump hose.

Top-up the reservoir flui

d.

Ble

e

d the power steerin

g system. For additional information,

REFER to Power Steering System Bleeding

- in thi

s section.

Stee

ring Fault Diagnosis by Sympt

om Charts

Leakage

52

11-0

11-03/1

Pump High Pressure Ou

tlet

to Hose Adaptor

621

1

-011-02

Pump Adaptor

to Contro

l Valve Hose

721

1

-011-01

Control Valve

82

11-

011

Pressure Gauge

9-'O

'

Ring Seal

Cond

iti

on

Possib

l

e Sources

Acti

o

n

Co

nfirm

the position of the fluid

leak.

CLEAN th

e area of the leak.

In

s

pect the area and confirm the exact position of leak.

Make sure the fluid

is not from anoth

er system on

the vehicle.

Page 459 of 2490

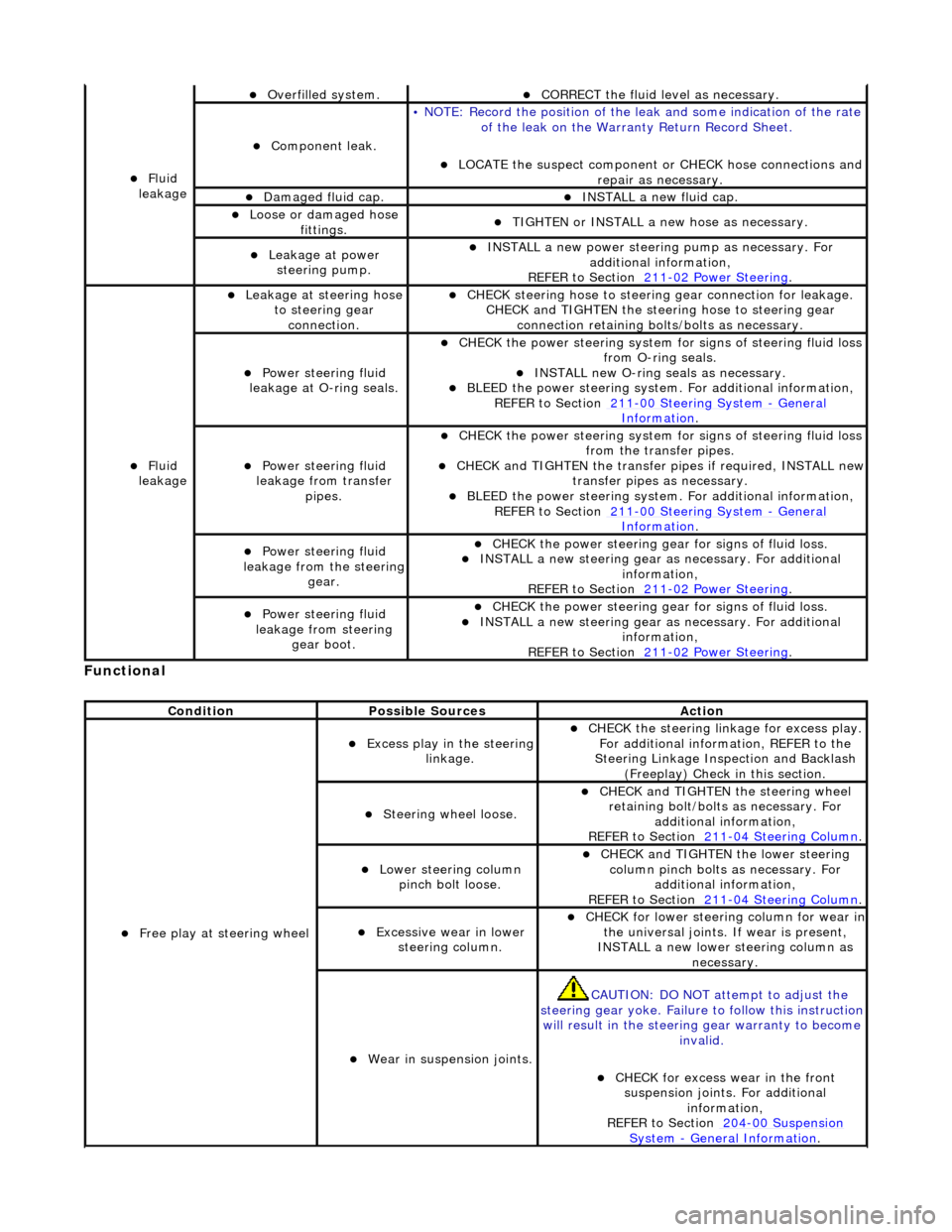

Function

al

Fl

uid

leakage

O

verfilled system.

CORRECT the

fluid leve

l as necessary.

Compon

ent leak.

•

NOTE: Record the position of the le

ak and some indication of the rate

of the leak on the Warra nty Return Record Sheet.

LOCATE

the suspect component or CHECK hose connections and

repair as necessary.

Damaged fluid cap. INST

ALL a new fluid cap.

Loose or damaged h

ose

fittings.

TI

GHTEN or INSTALL a new hose as necessary.

Leakage at

power

steering pump.

INST

ALL a new power steering

pump as necessary. For

additional information,

REFER to Section 211

-0

2 Power Steering

.

Fl

uid

leakage

Leakage

at steering hose

to steering gear connection.

CHECK

steering hose to

steering gear conn ection for leakage.

CHECK and TIGHTEN the steeri ng hose to steering gear

connection retaining bolt s/bolts as necessary.

Power steeri

ng fluid

leakage at O-ring seals.

CHECK

the power steering system fo

r signs of steering fluid loss

from O-ring seals.

INST

ALL new O-ring seals as necessary.

BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

Power steeri

ng fluid

leakage from transfer pipes.

CHECK

the power steering system fo

r signs of steering fluid loss

from the transfer pipes.

CHECK

and TIGHTEN the transfer pipes if required, INSTALL new

transfer pipes as necessary.

BLEE

D the power steering system.

For additional information,

REF

ER to Section 211

-0

0 Steering System

- Ge

neral

Informati

on

.

Power steeri

ng fluid

leakage from the steering

gear.

CHECK

the power steering gear for signs of fluid loss.

INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

Power steeri

ng fluid

leakage from steering gear boot.

CHECK

the power steering gear for signs of fluid loss.

INST

ALL a new steering gear as

necessary. For additional

information,

REFER to Section 211

-0

2 Power Steering

.

Cond

ition

Possib

le Sources

Acti

on

F

ree play at steering wheel

Exce

ss play in the steering

linkage.

CHECK

the steering linkage for excess play.

For additional information, REFER to the

Steering Linkage Inspection and Backlash (Freeplay) Check in this section.

S

teering wheel loose.

CHECK

and TIGHTEN the steering wheel

retaining bolt/bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Lower steeri

ng column

pinch bolt loose.

CHECK

and TIGHTEN the lower steering

column pinch bolts as necessary. For additional information,

REFER to Section 211

-0

4 Steering Column

.

Exce

ssive wear in lower

steering column.

CHECK

for lower steering column for wear in

the universal joints. If wear is present,

INSTALL a new lower steering column as necessary.

W

ear in suspension joints.

CAU

TION: DO NOT attempt to adjust the

steering gear yoke. Failure to follow this instruction

will result in the steering gear warranty to become

invalid.

CHECK

for excess wear in the front

suspension joints. For additional information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Page 462 of 2490

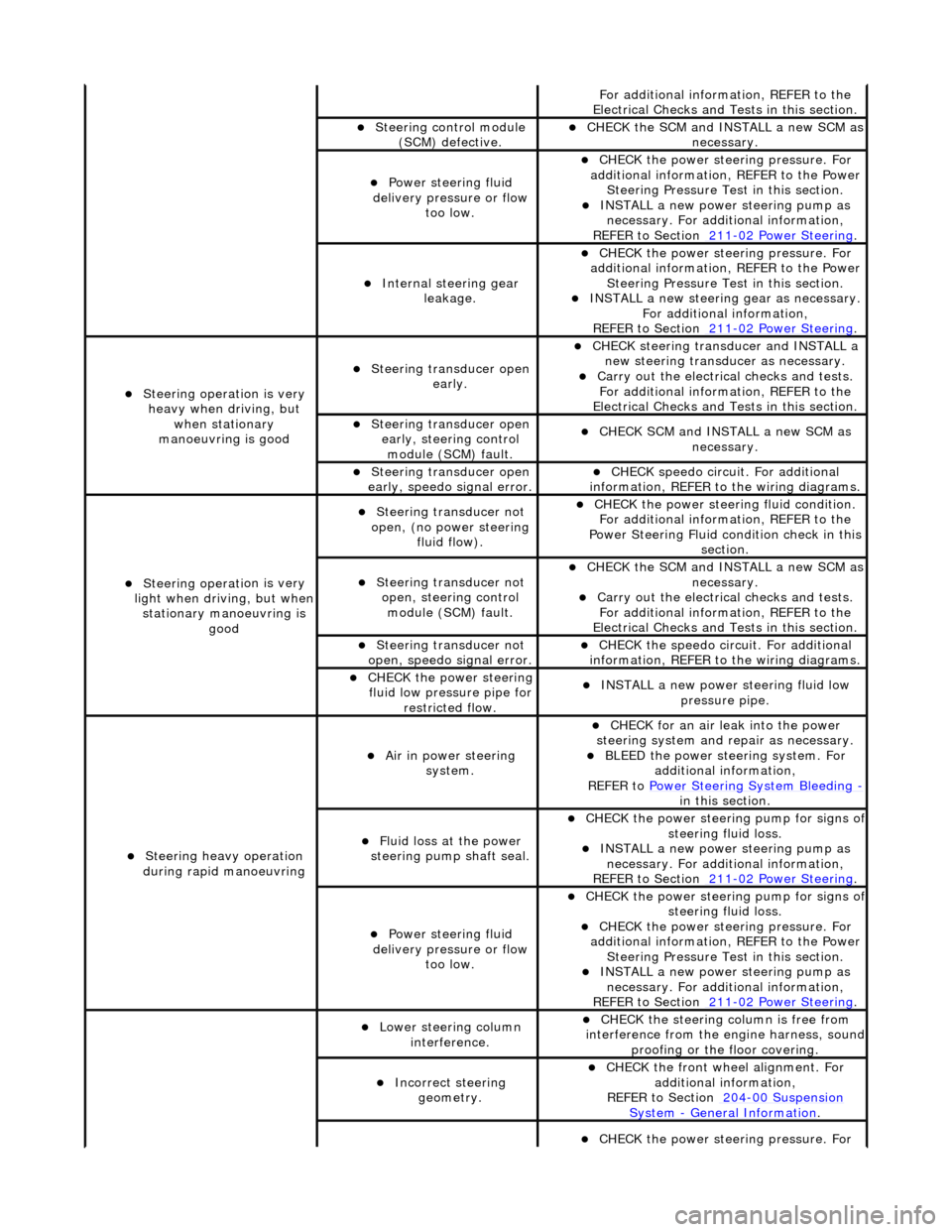

Fo

r additional information, REFER to the

Electrical Checks and Tests in this section.

Steering control

module

(SCM) defective.

CHECK

the SCM and INSTALL a new SCM as

necessary.

Power steeri ng f

luid

delivery pressure or flow too low.

CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

Internal steering gear

leakage.

CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

INSTALL a ne

w steering

gear as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

Steeri

ng operati

on is very

heavy when driving, but when stationary

manoeuvring is good

Steering transducer open earl

y.

CHECK

steering transducer and INSTALL a

new steering transducer as necessary.

Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steering transducer open

early,

steering control

module (SCM) fault.

CHECK

SCM and INSTALL a new SCM as

necessary.

Steering transducer open

earl

y, speedo signal error.

CHECK

speedo

circui

t. For additional

information, REFER to the wiring diagrams.

Steeri ng operati

on is very

light when driving, but when

stationary manoeuvring is good

Steering transducer not

o

pen, (no power steering

fluid flow).

CHECK

the power steering fluid condition.

For additional information, REFER to the

Power Steering Fluid condition check in this section.

Steering transducer not o

pen, steering control

module (SCM) fault.

CHECK

the SCM and INSTALL a new SCM as

necessary.

Carry out th

e electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steering transducer not

o

pen, speedo signal error.

CHECK

the speedo circ

uit. For additional

information, REFER to the wiring diagrams.

CHECK

the power steering

fluid low pressure pipe for restricted flow.

INSTALL a ne

w power steering fluid low

pressure pipe.

S t

eering heavy operation

during rapid manoeuvring

Ai r i

n power steering

system.

CHECK for an air l

eak into the power

steering system and re pair as necessary.

BLEED the

power steering system. For

additional information,

REFER to Power Steering System Bleeding

- in t hi

s section.

Fluid loss at the power

steering pump shaft seal.

CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

INST

ALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0 2

Power Steering

.

Power steeri

ng f

luid

delivery pressure or flow too low.

CHECK the power steer

ing pump for signs o

f steering fl

ui

d loss.

CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

INSTALL a ne

w power steering pump as

necessary. For additi onal information,

REFER to Section 211

-02

Power Steering

.

Lower steeri

ng col

umn

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorrect steering geometry. CHE

CK the front wheel alignment. For

additional information,

REFER to Section 204

-00 Sus

pension

Sy

ste

m

- General

Information

.

CHECK

the power stee

ring pressure. For

Page 463 of 2490

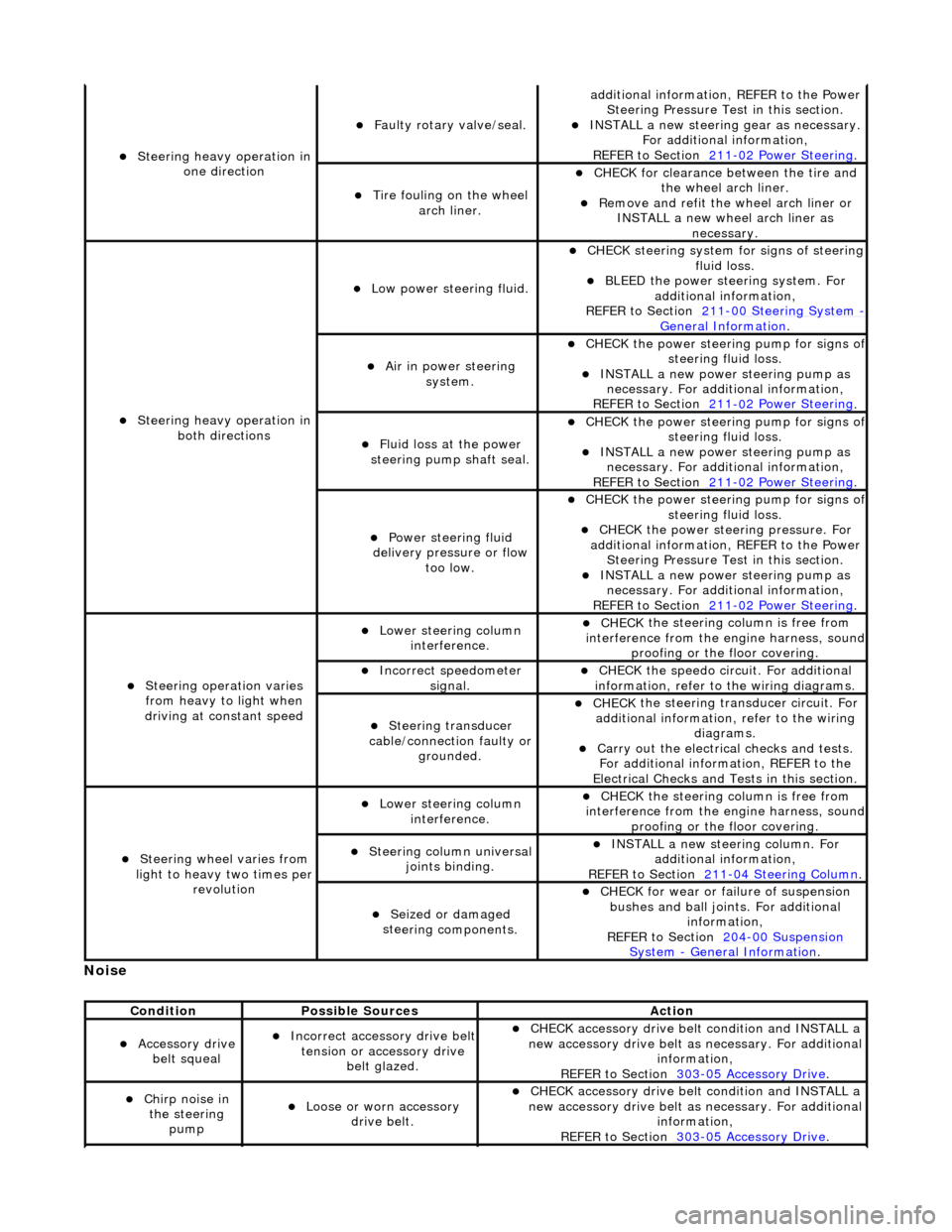

No

ise

S

teering heavy operation in

one direction

F

aulty rotary valve/seal.

addi

tional information, REFER to the Power

Steering Pressure Test in this section.

INST

ALL a new steering

gear as necessary.

For additional information,

REFER to Section 211

-0

2 Power Steering

.

Ti

re fouling on the wheel

arch liner.

CHECK for

clearance be

tween the tire and

the wheel arch liner.

R

emove and refit the wheel arch liner or

INSTALL a new wheel arch liner as necessary.

S

teering heavy operation in

both directions

Low power steer

ing fluid.

CHE

CK steering system

for signs of steering

fluid loss.

BLEE

D the power steering system. For

additional information,

REFER to Section 211

-0

0 Steering System

- General Informati

on

.

Ai

r in power steering

system.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Fluid loss at the power

steering pump shaft seal.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Power steeri

ng fluid

delivery pressure or flow too low.

CHECK

the power steering pump for signs o

f steering fl

uid loss.

CHECK

the power stee

ring pressure. For

additional information, REFER to the Power Steering Pressure Test in this section.

INST

ALL a new power steering pump as

necessary. For additi onal information,

REFER to Section 211

-0

2 Power Steering

.

Steeri

ng operation varies

from heavy to light when

driving at constant speed

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Incorre

ct sp

eedometer

signal.

CHECK

the speedo circ

uit. For additional

information, refer to the wiring diagrams.

Steeri

ng transducer

cable/connection faulty or grounded.

CHECK

the steering transducer circuit. For

additional information, refer to the wiring diagrams.

Carry ou

t the electrical checks and tests.

For additional information, REFER to the

Electrical Checks and Tests in this section.

Steeri

ng wheel varies from

light to heavy two times per revolution

Lower steeri

ng column

interference.

CHECK

the steering co

lumn is free from

interference from the en gine harness, sound

proofing or the floor covering.

Steeri

ng column universal

joints binding.

IN

STALL a new steering column. For

additional information,

REFER to Section 211

-0

4 Steering Column

.

Seized or damaged

ste

ering components.

CHECK

for wear or failure of suspension

bushes and ball join ts. For additional

information,

REFER to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Cond

ition

Possib

le Sources

Acti

on

Acce

ssory drive

belt squeal

Incorre

ct accessory drive belt

tension or accessory drive belt glazed.

CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

Chir

p noise in

the steering pump

Loose or worn accessory dr

ive belt.

CHECK

accessory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0

5 Accessory Drive

.

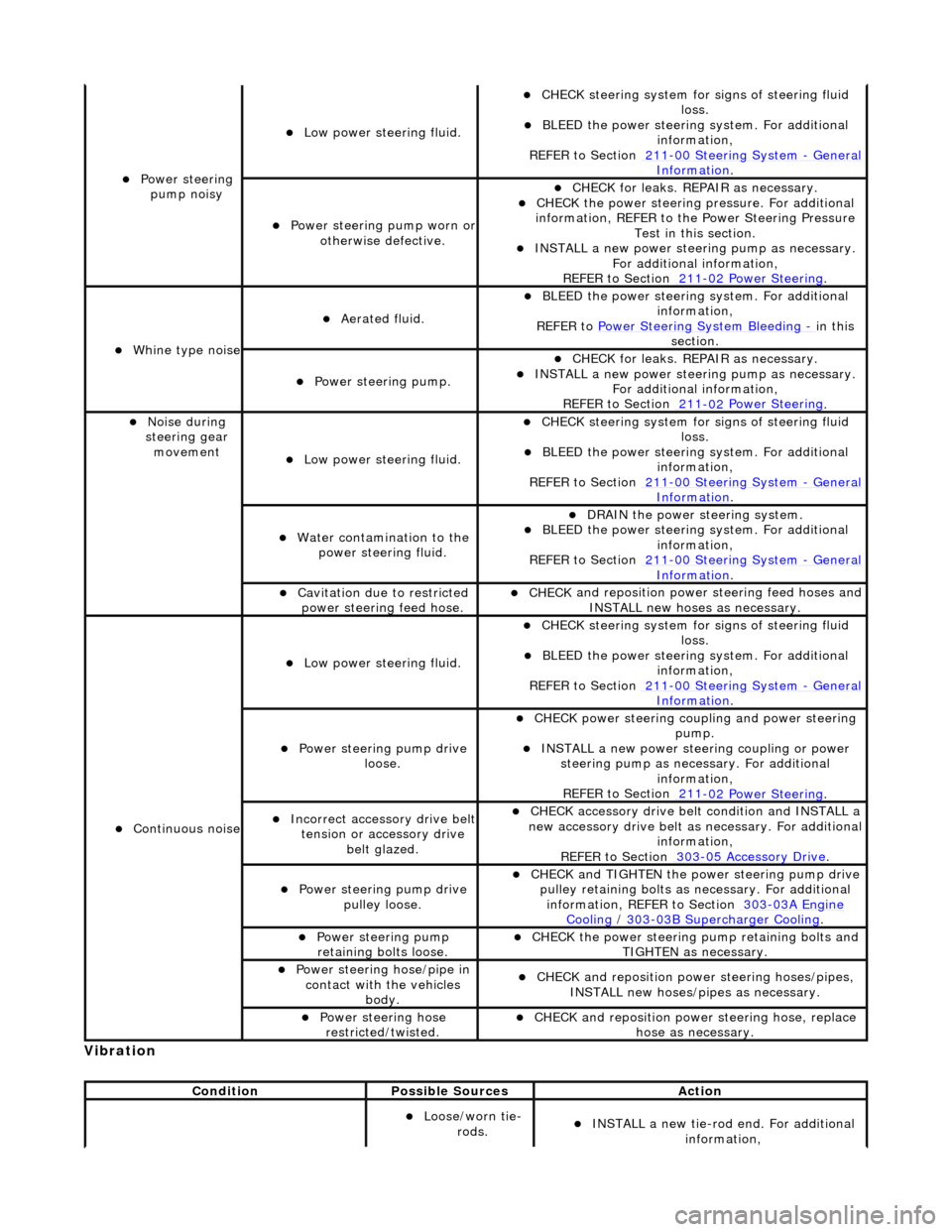

Page 464 of 2490

Vibrati

on

Power steeri

ng

pump noisy

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump wor

n or

otherwise defective.

CHECK for leaks. R

EPAIR as necessary.

CHECK

the power steering pressure. For additional

information, REFER to th e Power Steering Pressure

Test in this section.

INST ALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

Wh

in

e type noise

Aerated flui

d.

BLEE

D the

power steering system. For additional

information,

REFER to Power Steering System Bleeding

- in t h

is

section.

Power steering pump.

CHECK for leaks. R

EPAIR as necessary.

INSTALL a ne

w power steering pump as necessary.

For additional information,

REFER to Section 211

-0 2

Power Steering

.

No

i

se during

steering gear movement

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Water co

n

tamination to the

power steering fluid.

DR AIN

the power steering system.

BLEE

D the

power steering system. For additional

information,

REFER to Section 211

-00

Steering System

-

Gen

eral

Informati

o

n

.

Cavi

tation due to restricted

po

wer steering feed hose.

CHECK

and reposition power

steering feed hoses and

INSTALL new hoses as necessary.

Continu o

us noise

Low power steer i

ng fluid.

CHECK

steering system for s

igns of steering fluid

loss.

BLEE D the

power steering system. For additional

information,

REFER to Section 211

-0 0

Steering System

-

Ge n

eral

Informati

o

n

.

Power steeri

ng pump dri

ve

loose.

CHECK

power steering coupli

ng and power steering

pump.

IN ST

ALL a new power steering coupling or power

steering pump as nece ssary. For additional

information,

REFER to Section 211

-0 2

Power Steering

.

Incorre

ct

accessory drive belt

tension or accessory drive belt glazed.

CHECK acc

essory drive belt condition and INSTALL a

new accessory drive belt as necessary. For additional

information,

REFER to Section 303

-0 5 Ac

cessory Drive

.

Power steeri

ng pump dri

ve

pulley loose.

CHECK

and TIGHTEN the power steering pump drive

pulley retaining bolts as necessary. For additional

information, REFER to Section 303

-03A En

gine

Coo

ling / 30 3-03

B Supercharger Cooling

.

Power steeri

ng pump

r

etaining bolts loose.

CHECK

the power steering pump retaining bolts and

TIGHTEN as necessary.

Power steering hose/pipe in c

ontact with the vehicles

body.

CHECK

and reposition powe

r steering hoses/pipes,

INSTALL new hoses/pipes as necessary.

Power steeri ng hose

r

estricted/twisted.

CHECK

and reposition powe

r steering hose, replace

hose as necessary.

Conditi

on

Possibl

e Sources

Actio

n

Loose/worn tie-

ro

ds.

INST

ALL a new tie-r

od end. For additional

information,

Page 467 of 2490

High

-pitched sound like rubbing a clean window.

Squea

l

Continu

ous, high-pitched sound like runn

ing finger nails across a chalkboard.

Tap

Ligh

t, hammering sound like tapping pencil on edge

of table. May be rhythmic or intermittent.

Weep

Continu

ous mid-range sound (lower frequency

than squeal, higher frequency than groan).

Whir/

Whine

High

-pitched buzzing sound, like

an electric motor or drill.

Whistle

Sharp, shril

l sound, like wi

nd passing a small opening.

Description of Specific St eer

ing System Noise Types

Bel

t Squeal

Belt squea

l is a high frequency air-born

e noise generated by slippage of the ribbe d Vee belt on the power steering pump

pulley. Squeal increases with system loading and at the end of lock.

Clonk

Cl

onk is a structure-borne nois

e heard as a loose-sounding rattle or vibration coming from the steering column. Clonk can

be identified by driving and turning over cobblestones, rough roads, or high frequency bumps such as 25-50 mm tall tar

strips. Clonk requires a tie-rod load impact.

Column Knoc

k

Col

umn knock is a loose-sounding rattle or

vibration generated by the steering column shaft contacting other portions of the

column assembly. The noise is both audible and tactile. Column knock is generate d by driving over cobblestones or rough

pavement. It is not necessary to turn the steering wheel to create this noise.

Column Ra

ttle

Co

lumn rattle is a metallic sounding no

ise created when applying a highly impuls ive force to the steering wheel. Column

rattle is often used to combine the more general group of column noises includin g clonk and column knock. Column rattle

noises can be caused by clonk, knock, l oose column components, bonus parts etc. A series of parked, straight-line driving,

and cornering test should be carried out to isolate the source/sources.

Gr

inding/Scrape

Gr

inding is a low frequency noise in the column when the st

eering wheel is turned. Is generally caused by interference

between moving components such as the st eering wheel to steering column shroud.

Gr

unt (Squawk)

Grunt

is a "honking" sound elicited when coming off one of

the steering stops. Grunt is generally excited during parking

manoeuvres with a low to me dium speed steering input.

Squea

k