JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 101 of 3039

Published: 11-May-2011

General Information - Supplemental Restraint System (SRS) Health and

Safety Precautions

Description and Operation

WARNINGS:

Only qualified technicians are allowed to work on pyrotechnic components.

INHALED: Exposure to pyrotechnic residue may cause low blood pressure, severe headache, irritation of mucous

membranes, fainting, shortness of breath or rapid pulse. Move a victim to fresh air. Seek immediate medical attention.

EYE CONTACT: Exposure to unburned pyrotechnic residue may cause irritation, burning and etching of the eyes. Flush

immediately with plenty of cold running water for at least 15 minutes. Seek immediate medical attention.

EYE CONTACT: Exposure to burned pyrotechnic residue may cause irritation, burning and etching of the eyes. Flush

immediately with diluted boric acid solution. Seek immediate medical attention.

SKIN CONTACT: Unburned pyrotechnic residue may be rapidly absorbed through the skin in toxic quantities. Wash

immediately with plenty of soap and water. Seek medical attention.

SKIN CONTACT: Burned pyrotechnic residue may be rapidly absorbed through the skin in toxic quantities. Wash with

plenty of water. Do not use soap. Seek medical attention.

SWALLOWED: Unburned pyrotechnic residue is extremely toxic. If conscious drink plenty of water then induce vomiting.

Seek immediate medical attention. If unconscious, or in convulsions do not attempt to induce vomiting or give anything by

mouth. Seek immediate medical attention.

SWALLOWED: Burned pyrotechnic residue is extremely toxic. Drink plenty of water and seek immediate medical attention.

The deployment key must only be accessible to authorized personnel.

Make sure that the deployment key remains removed from the deployment equipment except during deployment.

If permenantly disabling or enabling the passenger air bag a new seat belt for vehicles without or with a passenger air

bag must be installed.

Undeployed pyrotechnic components must not be deployed in the vehicle.

Pyrotechnic components must be deployed following local regulations.

Check thoroughly that no loose objects can be spread during the deployment of pyrotechnic components.

Pyrotechnic components must be transported following local regulations.

Never carry out any electrical measurement on disconnected, undeployed pyrotechnic components.

Pyrotechnic components must not be disassembled.

Pyrotechnic components are not interchangeable between vehicles.

Always carry a live air bag module away from the body with the air bag or trim cover pointing upwards.

Page 102 of 3039

Live air bag modules must be placed in a suitable cage when removed from the vehicle. The air bag or trim cover must be

facing upwards.

Do not install a rearward facing child safety seat to the passenger seat with an activated passenger air bag.

CAUTIONS:

Pyrotechnic components must not be subjected to temperatures higher than 110°C.

Never install aftermarket accessories to the vehicle on or adjacent to the supplemental restraint system module.

Page 103 of 3039

General Information - Road/Roller Testing

Description and Operation Published: 11-May-2011

Road or roller testing may be carried out for various reasons and a procedure detailing pre-test checks, through engine starting

and stopping, pre-driving checks, on-test checks to final checks on completion of the test is given in this section.

Unless complete vehicle performance is being checked, the full road test procedure need not be carried out. Instead, those

items particularly relevant to the system/s being checked can be extracted.

Pre - Test Checks

WARNING: If the brake system hydraulic fluid level is low, pedal travel is excessive or a hydraulic leak is found, do not

attempt to road test the vehicle until the reason for the low fluid level, excessive pedal travel or hydraulic leak is found and

rectified.

It is suggested that pre-test checks, and functional tests of those systems/circuits which affect the safe and legal operations

of the vehicle, such as brakes, lights and steering, should always be carried out before the road or roller test.

Engine oil level

Engine coolant level

Tires, for correct pressure, compatible types and tread patterns, and wear within limits

There is sufficient fuel in the tank to complete the test

All around the engine, transmission and under the vehicle for oil, coolant, hydraulic and fuel leaks. Make a note of any

apparent leaks and wipe off the surrounding areas to make it easier to identify the extent of the leak on completion of

the test

Starting the Engine

CAUTION: On initial drive away from cold and within the first 1.5 km (1 mile), do not depress accelerator pedal beyond

half travel until the vehicle has attained a minimum speed of 25 km/h (15 miles/h). Never operate at high engine speed or

with the accelerator pedal at full travel whilst the engine is cold.

With the ignition switched off, check:

The parking brake is applied

The transmission selector lever is in Park

All instrument gauges (except fuel gauge) read zero

With the ignition switched on, check:

Ignition controlled warning lamps come on

Engine coolant temperature gauge registers a reading compatible with the engine coolant temperature

Fuel gauge registers a reading appropriate to the fuel level in the tank

The operation of the parking brake and brake fluid level warning lamps

On Road or Roller Test Check:

CAUTION: If road testing, check the brake operation while still travelling at low speed before continuing with the test. If

the brakes pull to one side, or appear to be otherwise faulty, do not continue with the road test until the fault has been found

and rectified.

Initial gear engagement is smooth

Parking brake control operates smoothly and the parking brake releases quickly and completely

Transmission takes up the drive smoothly, without judder

The engine power output is satisfactory, full power is achieved, acceleration is smooth and pedal operation not stiff or

heavy, and engine speed returns to idle correctly

There is no excessive or abnormally colored smoke from the engine under normal driving, heavy load or overrun

conditions

Steering operation, including power steering, is smooth, accurate, not excessively heavy or with excessive free play or

vibration. Does not pull to one side and self centres smoothly after cornering

Speedometer, oil pressure warning lamp, coolant temperature gauge and tachometer register the correct readings or

operate correctly

Switches and controls operate smoothly and positively, warning lamps operate correctly and the direction indicator

control self cancels when the steering is returned to the straight ahead position

Heating and ventilation systems work correctly and effectively

Brake operation and efficiency

Brake Testing

WARNING: When brake testing, avoid breathing the smoke or fumes from hot brakes, this may contain asbestos dust

which is hazardous to health, see Health and Safety Precautions.

Page 104 of 3039

Avoid brake testing on busy roads where it can cause inconvenience or danger to other road users.

CAUTION: Brake testing which includes heavy brake applications should not be carried out with new brake pads/discs or

linings/drums until the components have bedded-in. New brake friction components will not reach full efficiency until the

bedding-in process is complete.

Test the brakes at several speeds within the normal operating range using both light and heavy pedal pressure. Note any

tendency to snatch, pull or drag, and any undue delay in application or release.

Allow the vehicle to coast and note any tendency to pull to one side, or evidence that the brakes are binding.

After stopping the vehicle (not immediately after a period of heavy braking), carefully check the brake temperature. A disc

which feels hot, or appreciably hotter than the others, indicates that the brake is binding.

After completion of the test, check for:

Oil, coolant, hydraulic, air and fuel leaks

Abnormal temperature of any moving components or assemblies, e.g. wheel hubs, transmission, axle etc., which might

indicate over tightness or lack of lubrication

Page 105 of 3039

Published: 11-May-2011

General Information - Window Glass Health and Safety Precautions

Description and Operation

WARNINGS:

Cured polyurethane (PU) adhesive can degrade if subjected to high temperatures. Isocyanide compounds can be released

when grinding or welding in close proximity to cured PU adhesive.

SKIN CONTACT: Prolonged exposure to polyurethane (PU) adhesive may cause skin irritation. If PU adhesive comes into

contact with the skin, remove any contaminated clothing. Immediately wash the skin with soap and water. Seek medical

attention for any persistent skin irritation or abnormality.

EYE CONTACT: Polyurethane (PU) adhesive may cause severe irritation or damage. If PU adhesive comes into contact with

the eyes, immediately flush eyes with plenty of running water for at least 15 minutes. Seek immediate medical attention.

SWALLOWED: If polyurethane (PU) adhesive is swallowed, flush the mouth thoroughly. Do not induce vomiting. Provide

rest, warmth and fresh air. Seek immediate medical attention.

INHALED: Persons having a respiratory allergy may have an allergic reaction when handling polyurethane (PU) adhesive.

INHALED: Polyurethane (PU) adhesive can cause asthma like symptoms. Isocyanate vapor from primer or PU adhesive can

cause allergies in the respiratory tract.

INHALED: If polyurethane (PU) adhesive fumes are inhaled, move victim to fresh air. Provide oxygen if necessary. If

breathing stops, provide artificial respiration. Keep a victim warm and at rest. Seek immediate medical attention.

CAUTIONS:

Make sure that the direct glazing for bonded glass cutting blades are changed where the cutting depth changes to avoid

damage to the body and trim panels.

During the curing period of the PU adhesive, the door windows must be left open to avoid a build up of pressure when the

doors are opened and closed.

www.JagDocs.com

Page 106 of 3039

Published: 17-Apr-2014

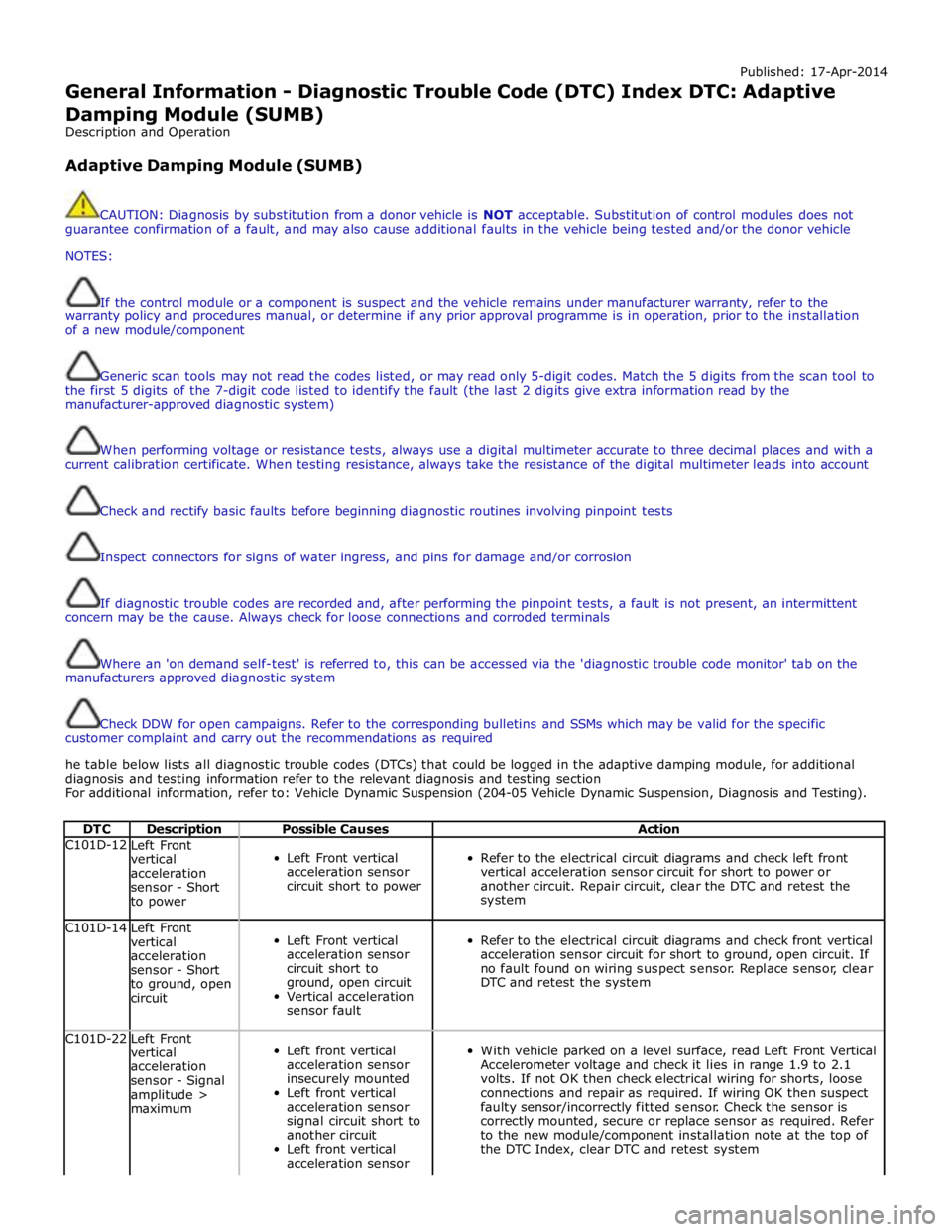

General Information - Diagnostic Trouble Code (DTC) Index DTC: Adaptive

Damping Module (SUMB)

Description and Operation

Adaptive Damping Module (SUMB)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

he table below lists all diagnostic trouble codes (DTCs) that could be logged in the adaptive damping module, for additional

diagnosis and testing information refer to the relevant diagnosis and testing section

For additional information, refer to: Vehicle Dynamic Suspension (204-05 Vehicle Dynamic Suspension, Diagnosis and Testing).

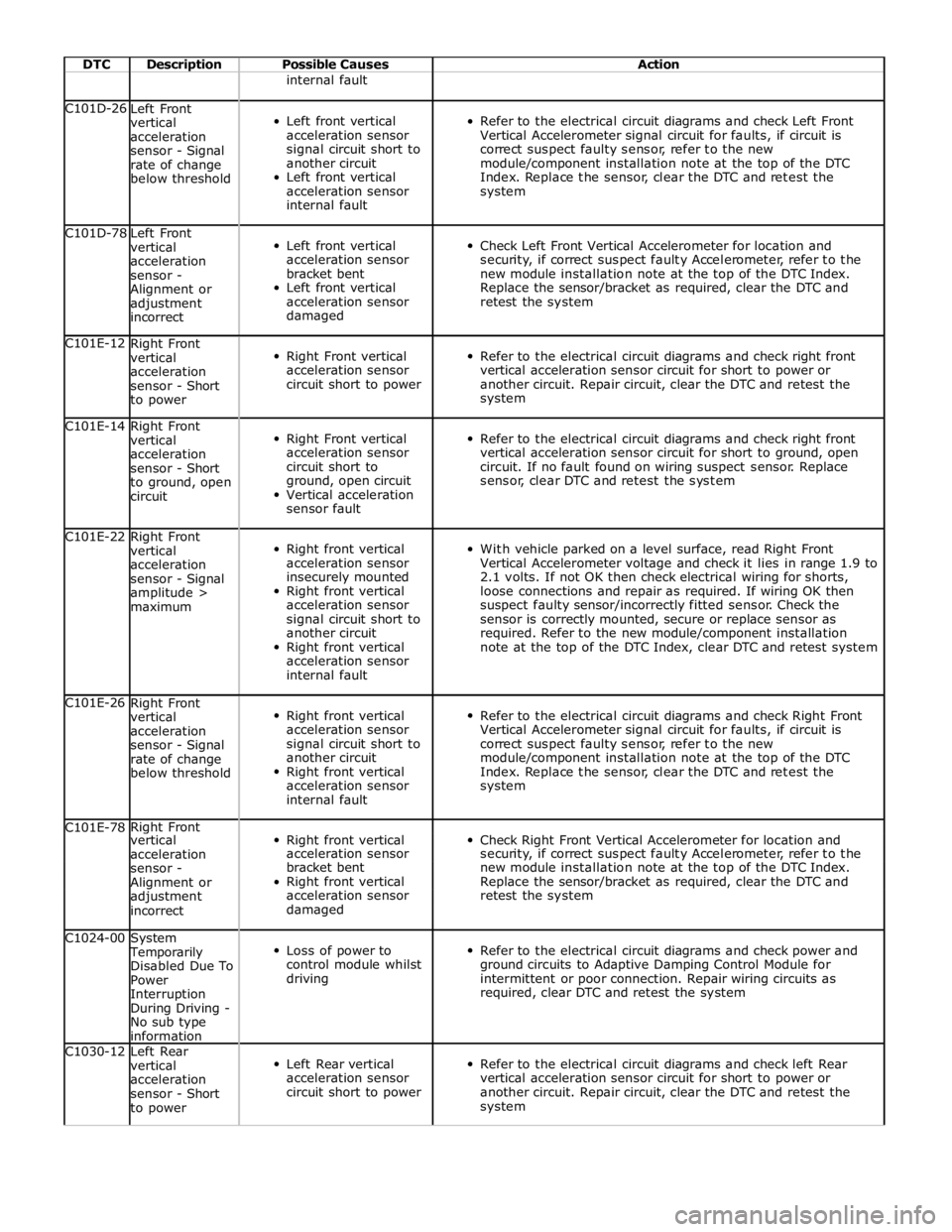

DTC Description Possible Causes Action C101D-12

Left Front

vertical

acceleration

sensor - Short

to power

Left Front vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check left front

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system C101D-14

Left Front

vertical

acceleration

sensor - Short

to ground, open

circuit

Left Front vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check front vertical

acceleration sensor circuit for short to ground, open circuit. If

no fault found on wiring suspect sensor. Replace sensor, clear

DTC and retest the system C101D-22

Left Front

vertical

acceleration

sensor - Signal

amplitude >

maximum

Left front vertical

acceleration sensor

insecurely mounted

Left front vertical

acceleration sensor

signal circuit short to

another circuit

Left front vertical

acceleration sensor

With vehicle parked on a level surface, read Left Front Vertical

Accelerometer voltage and check it lies in range 1.9 to 2.1

volts. If not OK then check electrical wiring for shorts, loose

connections and repair as required. If wiring OK then suspect

faulty sensor/incorrectly fitted sensor. Check the sensor is

correctly mounted, secure or replace sensor as required. Refer

to the new module/component installation note at the top of

the DTC Index, clear DTC and retest system

Page 107 of 3039

DTC Description Possible Causes Action internal fault

C101D-26

Left Front

vertical

acceleration

sensor - Signal

rate of change

below threshold

Left front vertical

acceleration sensor

signal circuit short to

another circuit

Left front vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Left Front

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C101D-78

Left Front

vertical

acceleration

sensor -

Alignment or

adjustment

incorrect

Left front vertical

acceleration sensor

bracket bent

Left front vertical

acceleration sensor

damaged

Check Left Front Vertical Accelerometer for location and

security, if correct suspect faulty Accelerometer, refer to the

new module installation note at the top of the DTC Index.

Replace the sensor/bracket as required, clear the DTC and

retest the system C101E-12

Right Front

vertical

acceleration

sensor - Short

to power

Right Front vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check right front

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system C101E-14

Right Front

vertical

acceleration

sensor - Short

to ground, open

circuit

Right Front vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check right front

vertical acceleration sensor circuit for short to ground, open

circuit. If no fault found on wiring suspect sensor. Replace

sensor, clear DTC and retest the system C101E-22

Right Front

vertical

acceleration

sensor - Signal

amplitude >

maximum

Right front vertical

acceleration sensor

insecurely mounted

Right front vertical

acceleration sensor

signal circuit short to

another circuit

Right front vertical

acceleration sensor

internal fault

With vehicle parked on a level surface, read Right Front

Vertical Accelerometer voltage and check it lies in range 1.9 to

2.1 volts. If not OK then check electrical wiring for shorts,

loose connections and repair as required. If wiring OK then

suspect faulty sensor/incorrectly fitted sensor. Check the

sensor is correctly mounted, secure or replace sensor as

required. Refer to the new module/component installation

note at the top of the DTC Index, clear DTC and retest system C101E-26

Right Front

vertical

acceleration

sensor - Signal

rate of change

below threshold

Right front vertical

acceleration sensor

signal circuit short to

another circuit

Right front vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Right Front

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C101E-78 Right Front

Right front vertical

Check Right Front Vertical Accelerometer for location and vertical acceleration acceleration sensor security, if correct suspect faulty Accelerometer, refer to the sensor - bracket bent new module installation note at the top of the DTC Index. Alignment or Right front vertical Replace the sensor/bracket as required, clear the DTC and adjustment acceleration sensor retest the system incorrect damaged C1024-00

System Temporarily

Disabled Due To

Power

Interruption

During Driving -

No sub type

information

Loss of power to

control module whilst

driving

Refer to the electrical circuit diagrams and check power and

ground circuits to Adaptive Damping Control Module for

intermittent or poor connection. Repair wiring circuits as

required, clear DTC and retest the system C1030-12

Left Rear

vertical

acceleration

sensor - Short

to power

Left Rear vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check left Rear

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system

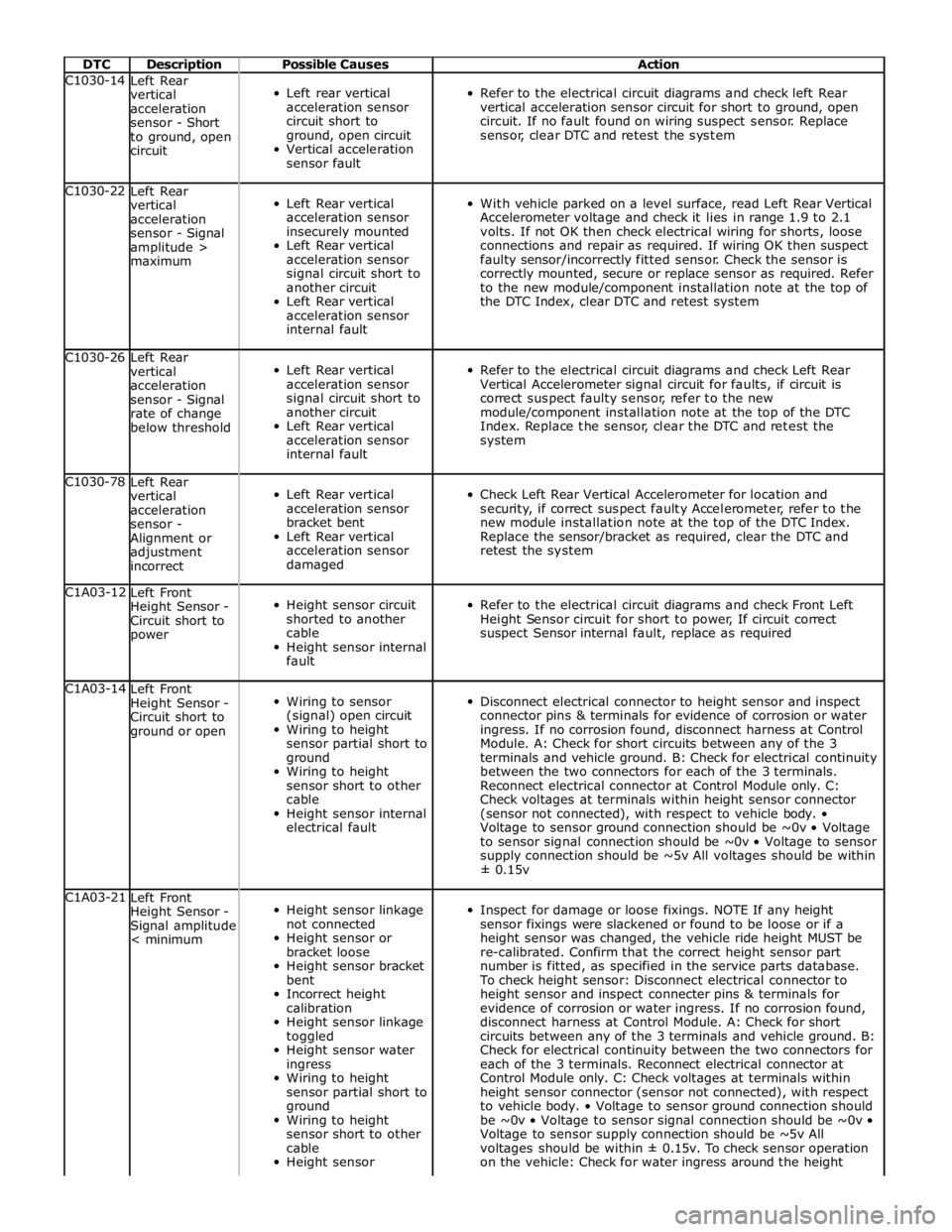

Page 108 of 3039

DTC Description Possible Causes Action C1030-14

Left Rear

vertical

acceleration

sensor - Short

to ground, open

circuit

Left rear vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check left Rear

vertical acceleration sensor circuit for short to ground, open

circuit. If no fault found on wiring suspect sensor. Replace

sensor, clear DTC and retest the system C1030-22

Left Rear

vertical

acceleration

sensor - Signal

amplitude >

maximum

Left Rear vertical

acceleration sensor

insecurely mounted

Left Rear vertical

acceleration sensor

signal circuit short to

another circuit

Left Rear vertical

acceleration sensor

internal fault

With vehicle parked on a level surface, read Left Rear Vertical

Accelerometer voltage and check it lies in range 1.9 to 2.1

volts. If not OK then check electrical wiring for shorts, loose

connections and repair as required. If wiring OK then suspect

faulty sensor/incorrectly fitted sensor. Check the sensor is

correctly mounted, secure or replace sensor as required. Refer

to the new module/component installation note at the top of

the DTC Index, clear DTC and retest system C1030-26

Left Rear

vertical

acceleration

sensor - Signal

rate of change

below threshold

Left Rear vertical

acceleration sensor

signal circuit short to

another circuit

Left Rear vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Left Rear

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C1030-78

Left Rear

vertical

acceleration

sensor -

Alignment or

adjustment

incorrect

Left Rear vertical

acceleration sensor

bracket bent

Left Rear vertical

acceleration sensor

damaged

Check Left Rear Vertical Accelerometer for location and

security, if correct suspect faulty Accelerometer, refer to the

new module installation note at the top of the DTC Index.

Replace the sensor/bracket as required, clear the DTC and

retest the system C1A03-12

Left Front

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Front Left

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A03-14

Left Front

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A03-21

Left Front

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

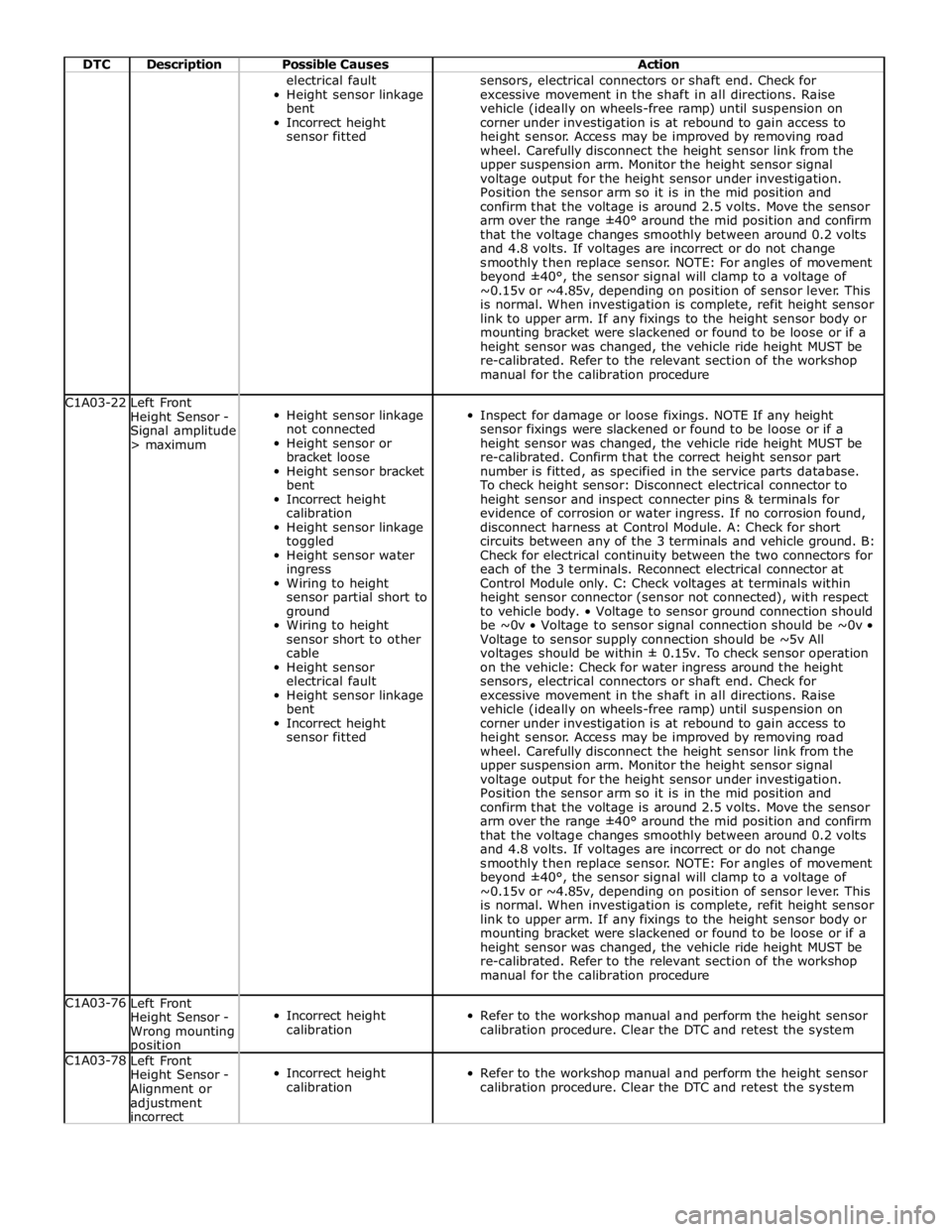

Page 109 of 3039

DTC Description Possible Causes Action electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-22

Left Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-76

Left Front

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A03-78

Left Front

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system

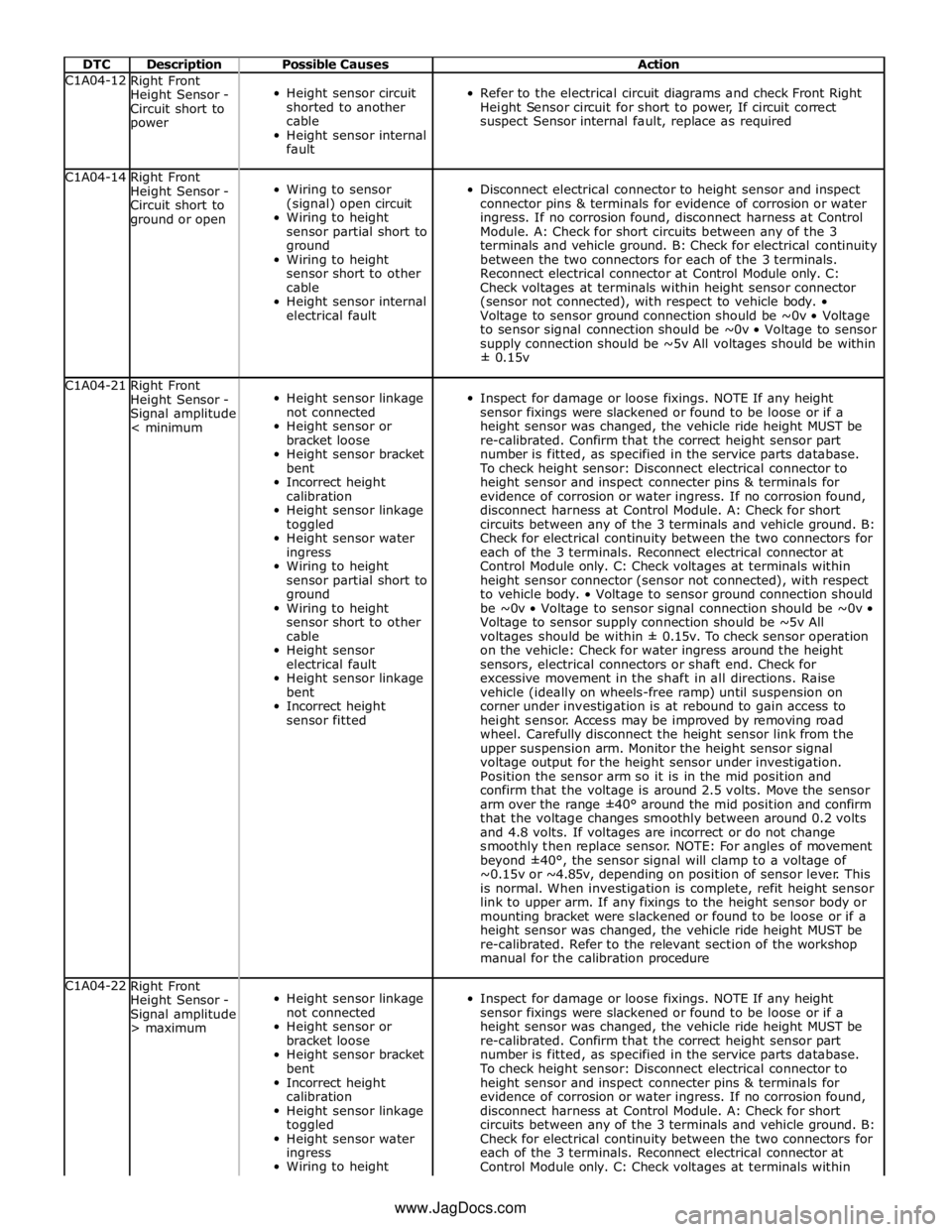

Page 110 of 3039

DTC Description Possible Causes Action C1A04-12

Right Front

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Front Right

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A04-14

Right Front

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A04-21

Right Front

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A04-22

Right Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within www.JagDocs.com