fuse JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 811 of 3039

Engine System - General Information - Engine 5.0L

Diagnosis and Testing

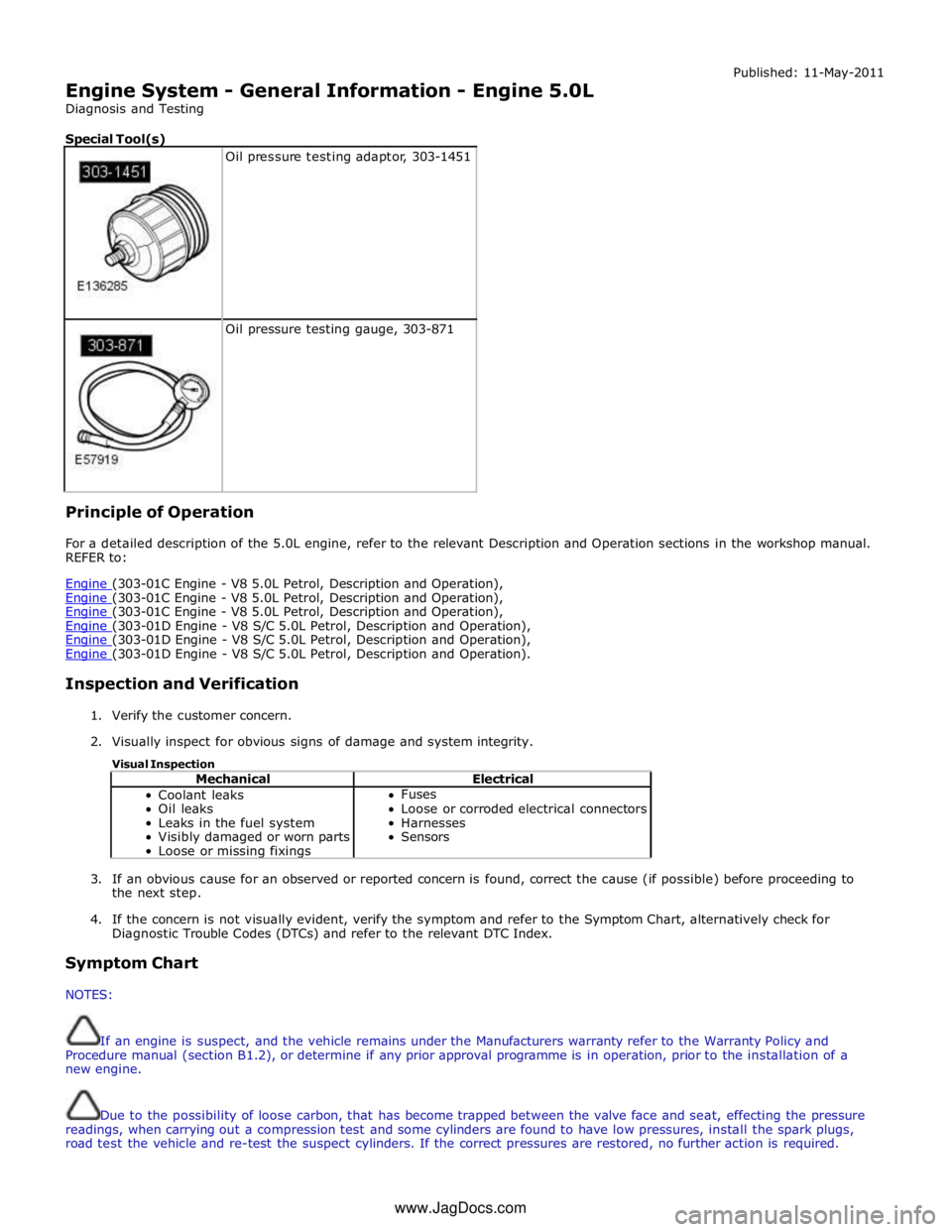

Special Tool(s)

Oil pressure testing adaptor, 303-1451

Oil pressure testing gauge, 303-871 Principle of Operation Published: 11-May-2011

For a detailed description of the 5.0L engine, refer to the relevant Description and Operation sections in the workshop manual.

REFER to:

Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical Coolant leaks

Oil leaks

Leaks in the fuel system

Visibly damaged or worn parts

Loose or missing fixings Fuses

Loose or corroded electrical connectors

Harnesses

Sensors

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index.

Symptom Chart

NOTES:

If an engine is suspect, and the vehicle remains under the Manufacturers warranty refer to the Warranty Policy and

Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new engine.

Due to the possibility of loose carbon, that has become trapped between the valve face and seat, effecting the pressure

readings, when carrying out a compression test and some cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required. www.JagDocs.com

Page 813 of 3039

Component Tests

Engine Oil Leaks

NOTE: Before installing new gaskets or oil seals, make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual inspection, carry out an Ultraviolet test:

Fluorescent Oil Additive Method

1. Clean the engine with a suitable cleaning fluid (brake cleaner).

2. Drain the engine oil and refill with recommended oil, premixed with Diesel Engine Oil Dye or equivalent. Use a minimum

14.8 ml (0.5 ounce) to a maximum 29.6 ml (1 ounce) of fluorescent additive to all engines. If oil is not premixed,

fluorescent additive must first be added to the crankcase.

3. Run engine for 15 minutes. Stop the engine and inspect all seal and gasket areas for leaks using a 12 Volt Master UV

Diagnostic Inspection Kit or equivalent. A clear bright yellow or orange area will identify leak. For extremely small

leaks, several hours may be required for the leak to appear.

4. As necessary, pressurize the main oil gallery system to locate leaks due to incorrectly sealed, loose or cocked plugs. If

the flywheel bolts leak oil, look for sealer on the threads.

5. Repair all leaks as necessary.

Compression Test General Remarks

NOTES:

Removing fuses and disconnecting electrical components may cause the Engine Control Module (ECM) to log Diagnostic

Trouble Codes (DTCs). After the measurements have been carried out, DTCs should be cleared from memory by connecting to

the Manufacturer Approved Diagnostic System.

Only check the compression pressure with the valves set to the prescribed clearance (if this can be adjusted).

The compression pressure should be checked with the engine at normal operating temperature.

Check the Compression Pressure

WARNING: Move gear selector lever to 'P' position. Failure to follow this instruction may result in personal injury.

1. Remove the fuel pump relay.

2. Start the engine - the engine will start, run for a few seconds then stall.

3. Remove the spark plugs.

4. Install the compression tester.

5. Install an auxiliary starter switch in the starting circuit. With the ignition switch OFF, using the auxiliary starter switch,

crank the engine a minimum of five compression strokes and record the highest reading. Note the approximate number

of compression strokes required to obtain the highest reading.

6. Repeat the test on each cylinder, cranking the engine approximately the same number of compression strokes.

7. Install the removed components in reverse order, observing the specified tightening torques.

8. Clear all DTCs from the ECM.

Interpretation of the Results

NOTE: Due to the possibility of loose carbon that has become trapped between the valve face and seat effecting the

pressure readings, when carrying out a compression test and cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required.

The indicated compression pressures are considered within specification if the lowest reading cylinder is within 75% of the

highest reading.

If the cylinder pressures are found to be low, carry out a leakdown test to determine the location of the fault (if any leakback

can be heard through the engine breather system suspect the piston rings, if any leakback can be heard through the inlet

system suspect the inlet valve or seat, if any leakback can be heard through the exhaust manifold suspect the exhaust valve

or seat. If the measurements for two cylinders next to each other are both too low then it is very likely that the cylinder head

gasket between them is burnt through. This can also be recognized by traces of engine oil in the coolant and/or coolant in the

Page 1112 of 3039

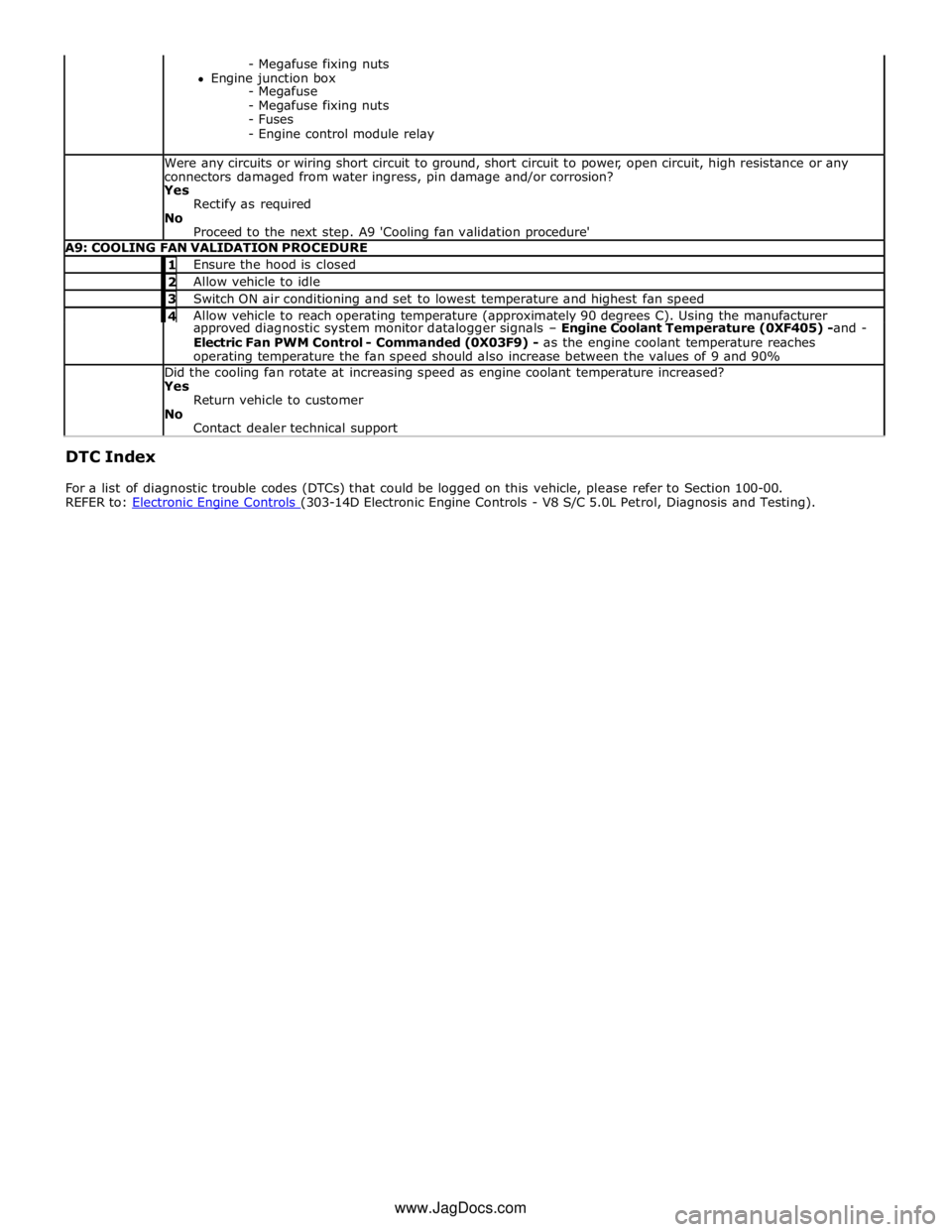

Published: 11-May-2011

Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Cooling - System

Operation and Component Description

Description and Operation

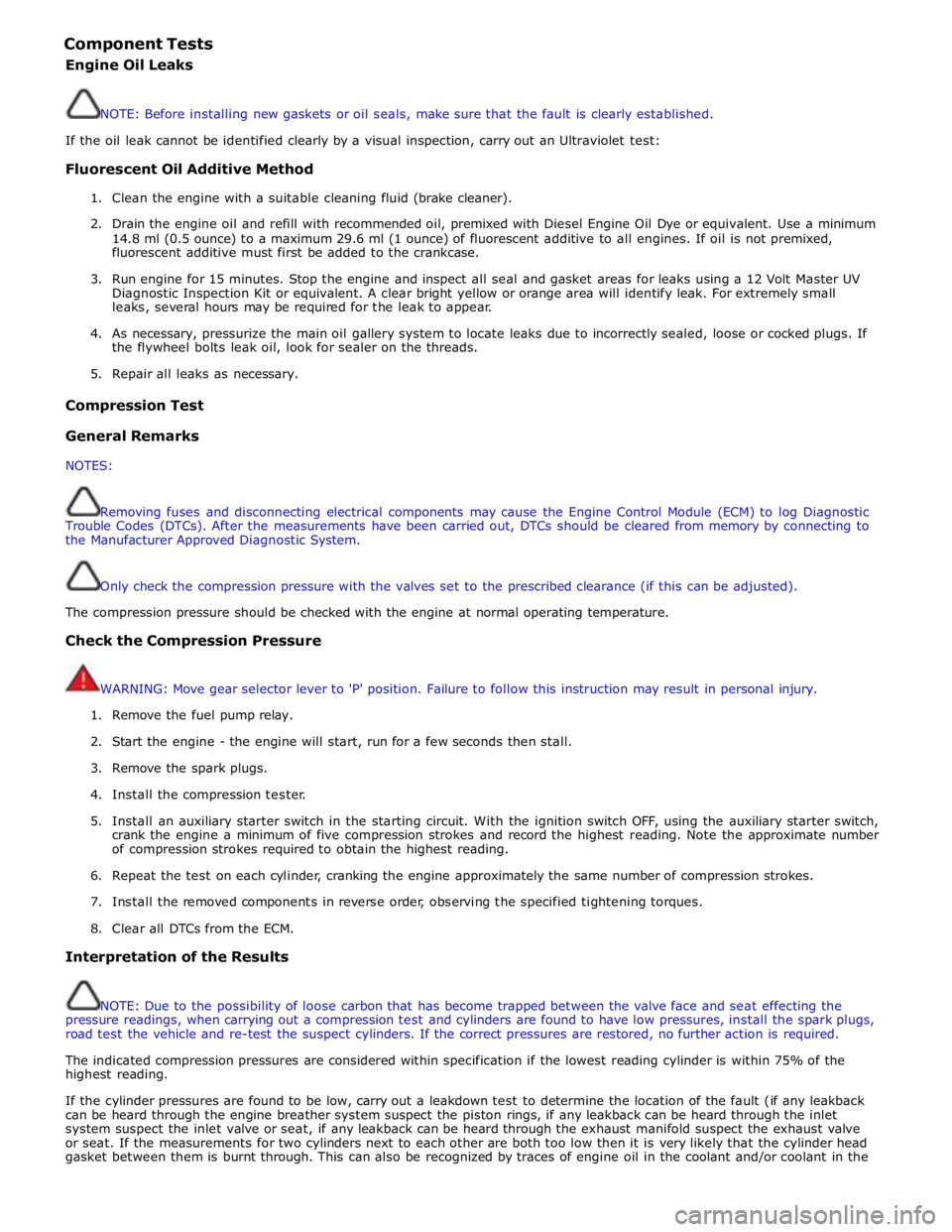

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 Cooling fan 5 ECM (engine control module) www.JagDocs.com

Page 1122 of 3039

Published: 17-Apr-2014

Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Cooling V8 5.0L

Petrol/V8 S/C 5.0L Petrol

Diagnosis and Testing

Principle of Operation

For a detailed description of the engine cooling system and operation, refer to the relevant description and operation section of

the workshop manual. Engine Cooling, Section - 303-03

Inspection and Verification

WARNING: Moving parts can cause severe injury, keep clear of moving parts, never place your hands or any part of your

body near to moving parts

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTES:

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

1. Verify the customer concern

2. Visually inspect for obvious signs of mechanical or electrical damage

Visual Inspection

Mechanical Electrical

Coolant leaks

Coolant hoses

Coolant expansion tank

Radiator

Heater core

Accessory drive belt

Cooling fan

Fuses

Harnesses

Loose or corroded connector(s)

Engine coolant temperature sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the symptom chart, alternatively check for

diagnostic trouble codes (DTCs) and refer to the DTC Index

Symptom Chart

Symptom Possible Causes Action Coolant loss

Hoses

Hose connections

Radiator

Water pump

Heater core

Gaskets

Engine casting cracks

Engine block core

plugs Carry out a visual inspection. If there are no obvious leaks, carry out a

cooling system pressure test. Rectify any leaks as necessary Overheating

Low/contaminated

coolant

Thermostat

Cooling fan Check the coolant level and condition. Carry out a cooling system pressure

test. Rectify any leaks as necessary. Check the thermostat and rectify as

necessary. Check the cooling fan operation, make sure the cooling fan

rotates freely. Check for obstructions to the air flow over the radiator.

Rectify as necessary

Page 1123 of 3039

Symptom Possible Causes Action Engine coolant

temperature sensor

Restricted air flow

over the radiator Engine not reaching

normal temperature

Thermostat

Cooling fan

Thermostat

Fan speed module Check the thermostat operation. Check the cooling fan operation, make

sure the cooling fan is not seized. Rectify as necessary Engine NOT running.

Cooling fan is

maximum speed

Circuit reference PWM

- Duty cycle is

implausible

Circuit reference PWM

- Frequency out

of range

Circuit reference PWM

- Circuit is open

circuit

Circuit reference PWM

- Circuit is short

circuit to power

Circuit reference PWM

- Circuit is short

circuit to

ground Refer to the electrical circuit diagrams and check the PWM circuit for short

circuit to ground, short circuit to power, open circuit, high resistance Engine IS running.

Cooling fan is

stationary

Circuit reference - IGN

-

- Circuit is open

circuit

Circuit reference - IGN

-

- Circuit is short

circuit to

ground

- EMS fuse

failure

- EMS relay

failure Refer to the electrical circuit diagrams and check the IGN circuit for short

circuit to ground, open circuit, high resistance. Check and install a new EMS

relay and fuse

PINPOINT TEST A : TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK FOR COOLING FAN RELATED DTCS

NOTE: For a complete list of all diagnostic trouble codes that could be logged on this vehicle, please refer

to section 100-00. Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the

5 digits from the scan tool to the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits

give extra information read by the manufacturer-approved diagnostic system). 1 Using the manufacturer approved diagnostic system check the engine control module for DTCs 2 P0480-00 & P0480 with any other different last 2 digits in the DTC 3 P0481-00 & P0481 with any other different last 2 digits in the DTC 4 P0483-00 & P0483 with any other different last 2 digits in the DTC Are any of the cooling fan related DTCs listed, logged in the engine control module?

Yes

Please refer to section 100-00 and refer to the relevant DTC index and carry out repair procedure

Using the manufacturer approved diagnostic system clear all stored diagnostic trouble codes from the

diagnosis menu tab

Proceed to the test step A9 'Cooling fan validation procedure'

No

Proceed to the next step. A2 'Check for other DTCs' A2: CHECK FOR OTHER DTCS 1 Using the manufacturer approved diagnostic system check the engine control module for DTCs Are any other DTCs listed, logged in the engine control module?

Yes

Please refer to section 100-00 and refer to the relevant DTC index and carry out repair procedure

Using the manufacturer approved diagnostic system clear all stored diagnostic trouble codes from the

diagnosis menu tab

No

Page 1124 of 3039

Proceed to the next step. A3 'Cooling fan is operating permanently' A3: COOLING FAN IS OPERATING PERMANENTLY 1 The cooling fan is operating permanently Is the customer reported symptom that the cooling fan is operating permanently at maximum speed?

Yes

The cooling fan is operating permanently

Proceed to the test step A5 'Cooling fan is operating permanently'

No

The cooling fan is NOT operating permanently

Proceed to the next step. A4 'Cooling fan is NOT operating' A4: COOLING FAN IS NOT OPERATING 1 The cooling fan is NOT operating Is the cooling fan NOT operating?

Yes

The cooling fan is NOT operating

Proceed to the test step A6 'Cooling fan is NOT operating'

No

No fault found. Verify customer concern of cooling fan operation A5: COOLING FAN IS OPERATING PERMANENTLY

WARNING: Moving parts can cause severe injury, keep clear of moving parts, never place your hands or any part of your

body near to moving parts 1 Using the manufacturer approved diagnostic system check datalogger signal – Electric Fan PWM Control - Commanded (0X03F9) - 2 Record the value of the datalogger signal – Electric Fan PWM Control - Commanded (0X03F9) - Is the value of the datalogger signal – Electric Fan PWM Control - Commanded (0X03F9) -between 5% &

16% whilst the cooling fan is operating?

Yes

The cooling fan should not be rotating in this PWM range

Refer to the electrical circuit diagrams and check the following circuit's for short circuit to ground, short

circuit to power, open circuit, high resistanceRefer to the electrical circuit diagrams and check the following

connectors for signs of water ingress, and pins for damage and/or corrosionEngine control module,

connector and wiringCircuit reference - ECFC -Cooling fan motor control unit connector and wiringCircuit

reference - VBATT -Circuit reference - IGN -Circuit reference - PWM -Circuit reference - GND -Battery

junction box, connector and wiringEngine junction box, connector and wiringCheck and install a new cooling

fan

No

Proceed to the next step. A6 'Cooling fan is NOT operating' A6: COOLING FAN IS NOT OPERATING

CAUTION: Ensure hood is closed and there are not any loose objects in front of the vehicle 1 Using the manufacturer approved diagnostic system command datalogger signal – Electric Fan PWM Control - Commanded (0X03F9) -to 30% Did the cooling fan start rotating?

Yes

Proceed to the next step. A7 'Electric Fan PWM Control'

No

Proceed to the step. A8 'Wiring check' A7: ELECTRIC FAN PWM CONTROL 1 Using the manufacturer approved diagnostic system command datalogger signal – Electric Fan PWM Control - Commanded (0X03F9) -to 90% Did the cooling fan rotating speed increase?

Yes

Using the manufacturer approved diagnostic system disable output state control function for this signal

and allow the cooling fan to stop rotating

No fault found. Verify customer concern of cooling fan operation

Proceed to the test step A9 'Cooling fan validation procedure'

No

Proceed to the step. A8 'Wiring check' A8: WIRING CHECK 1 Refer to the electrical circuit diagrams and check the following circuit's for short circuit to ground, short circuit to power, open circuit, high resistance 2 Refer to the electrical circuit diagrams and check the following connectors for signs of water ingress, and pins for damage and/or corrosion

Engine control module, connector and wiring

- Circuit reference - ECFC -

Cooling fan motor control unit connector and wiring

- Circuit reference - VBATT -

- Circuit reference - IGN -

- Circuit reference - PWM -

- Circuit reference - GND -

Battery junction box, connector and wiring

- Megafuses

Page 1125 of 3039

- Megafuse fixing nuts

Engine junction box

- Megafuse

- Megafuse fixing nuts

- Fuses

- Engine control module relay Were any circuits or wiring short circuit to ground, short circuit to power, open circuit, high resistance or any

connectors damaged from water ingress, pin damage and/or corrosion?

Yes

Rectify as required

No

Proceed to the next step. A9 'Cooling fan validation procedure' A9: COOLING FAN VALIDATION PROCEDURE 1 Ensure the hood is closed 2 Allow vehicle to idle 3 Switch ON air conditioning and set to lowest temperature and highest fan speed 4 Allow vehicle to reach operating temperature (approximately 90 degrees C). Using the manufacturer approved diagnostic system monitor datalogger signals – Engine Coolant Temperature (0XF405) -and -

Electric Fan PWM Control - Commanded (0X03F9) - as the engine coolant temperature reaches

operating temperature the fan speed should also increase between the values of 9 and 90% Did the cooling fan rotate at increasing speed as engine coolant temperature increased?

Yes

Return vehicle to customer

No

Contact dealer technical support DTC Index

For a list of diagnostic trouble codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing). www.JagDocs.com

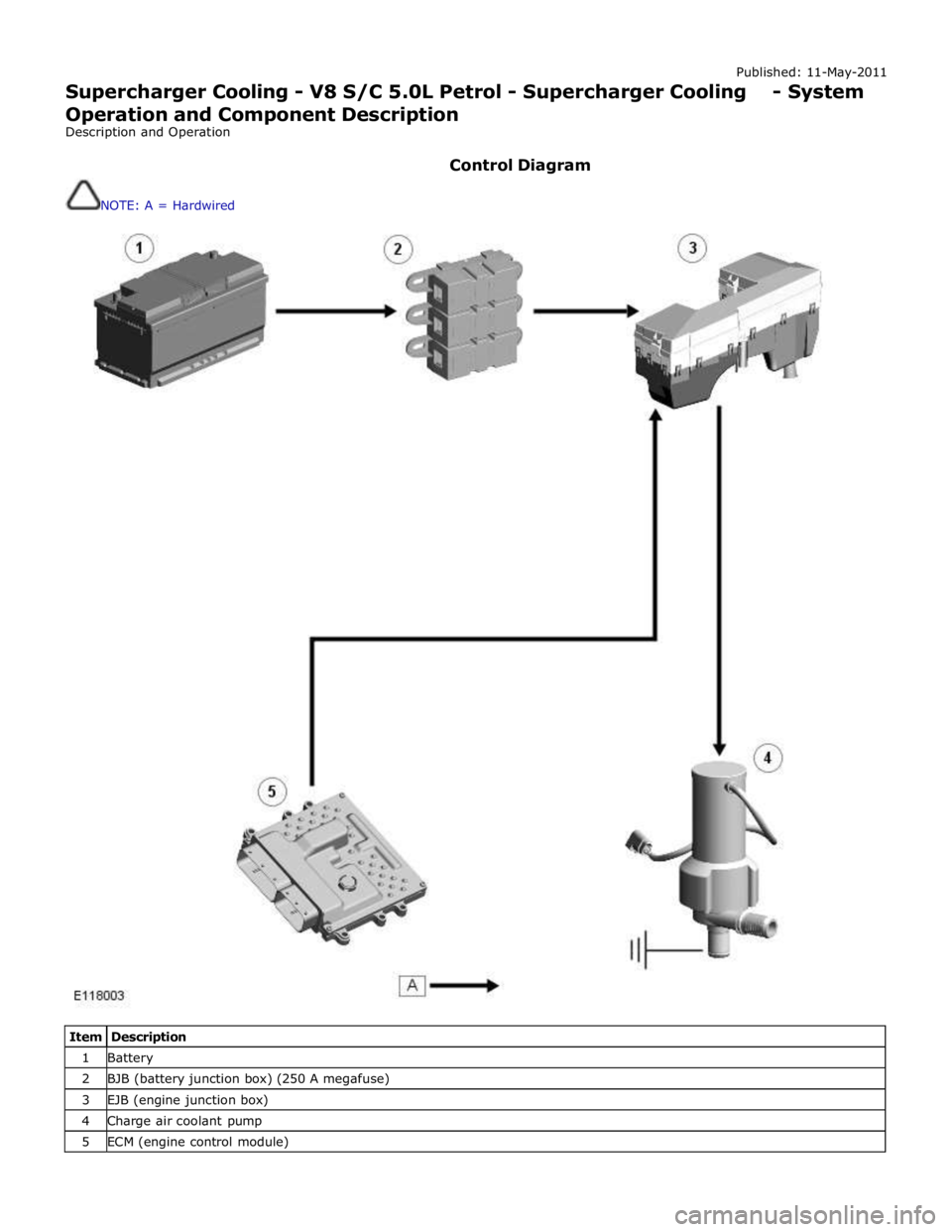

Page 1169 of 3039

Published: 11-May-2011

Supercharger Cooling - V8 S/C 5.0L Petrol - Supercharger Cooling - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 Charge air coolant pump 5 ECM (engine control module)

Page 1180 of 3039

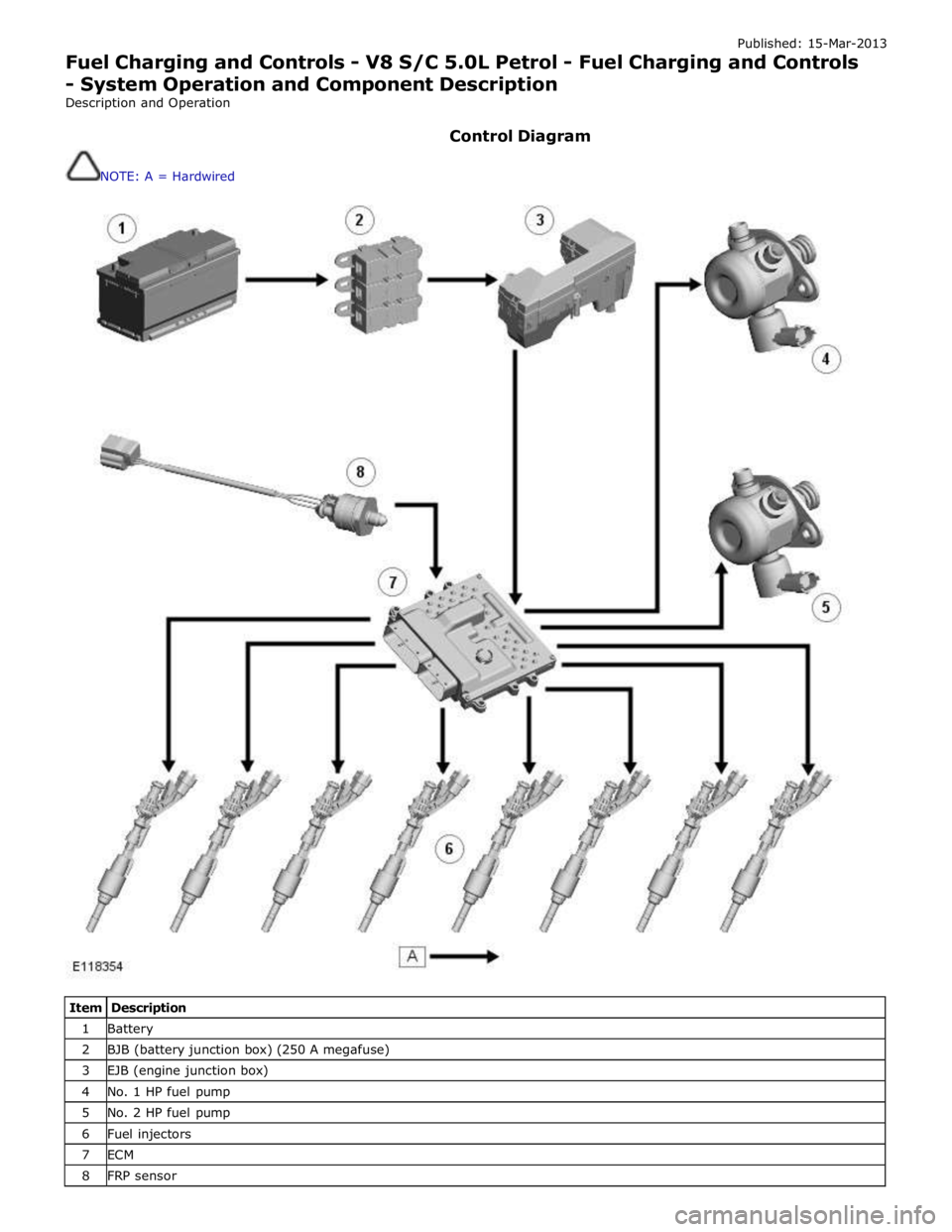

Published: 15-Mar-2013

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Charging and Controls

- System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 No. 1 HP fuel pump 5 No. 2 HP fuel pump 6 Fuel injectors 7 ECM 8 FRP sensor

Page 1187 of 3039

Published: 11-May-2011

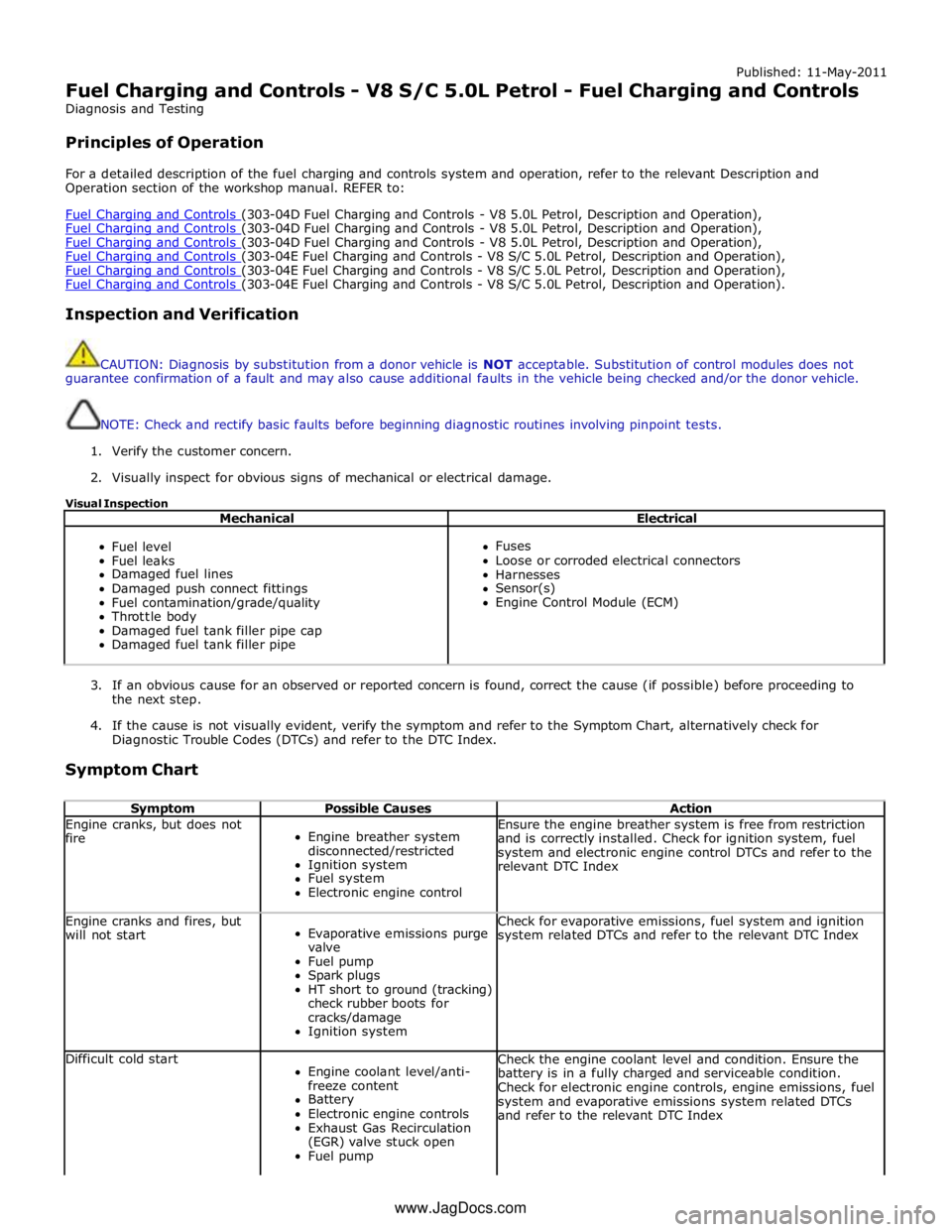

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Charging and Controls

Diagnosis and Testing

Principles of Operation

For a detailed description of the fuel charging and controls system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to:

Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Fuel level

Fuel leaks

Damaged fuel lines

Damaged push connect fittings

Fuel contamination/grade/quality

Throttle body

Damaged fuel tank filler pipe cap

Damaged fuel tank filler pipe

Fuses

Loose or corroded electrical connectors

Harnesses

Sensor(s)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control Ensure the engine breather system is free from restriction

and is correctly installed. Check for ignition system, fuel

system and electronic engine control DTCs and refer to the

relevant DTC Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system Check for evaporative emissions, fuel system and ignition

system related DTCs and refer to the relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel pump Check the engine coolant level and condition. Ensure the

battery is in a fully charged and serviceable condition.

Check for electronic engine controls, engine emissions, fuel

system and evaporative emissions system related DTCs

and refer to the relevant DTC Index www.JagDocs.com