Can bus JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 53 of 3039

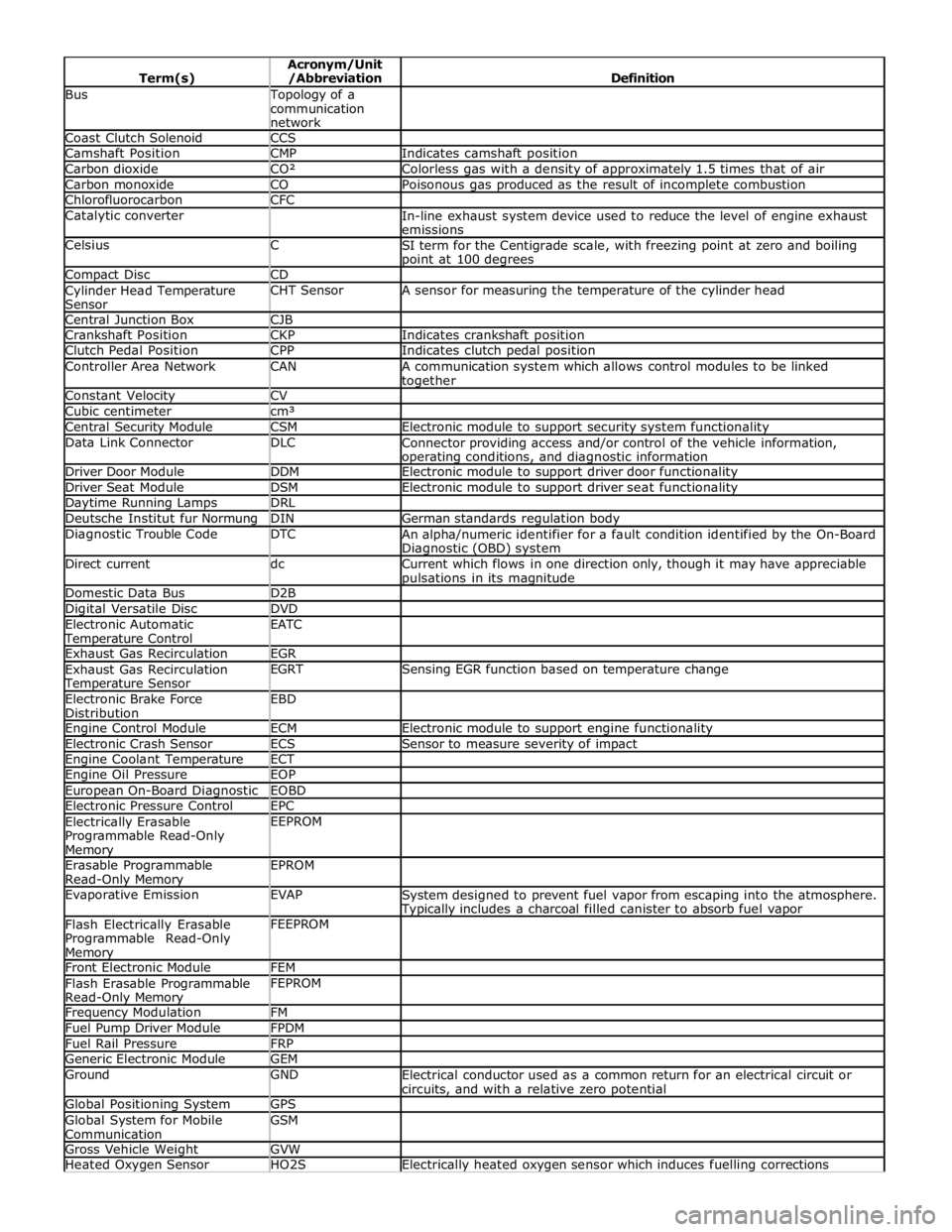

Bus Topology of a

communication

network Coast Clutch Solenoid CCS Camshaft Position CMP Indicates camshaft position Carbon dioxide CO² Colorless gas with a density of approximately 1.5 times that of air Carbon monoxide CO Poisonous gas produced as the result of incomplete combustion Chlorofluorocarbon CFC Catalytic converter

In-line exhaust system device used to reduce the level of engine exhaust

emissions Celsius C

SI term for the Centigrade scale, with freezing point at zero and boiling point at 100 degrees Compact Disc CD Cylinder Head Temperature

Sensor CHT Sensor A sensor for measuring the temperature of the cylinder head Central Junction Box CJB Crankshaft Position CKP Indicates crankshaft position Clutch Pedal Position CPP Indicates clutch pedal position Controller Area Network CAN

A communication system which allows control modules to be linked together Constant Velocity CV Cubic centimeter cm³ Central Security Module CSM Electronic module to support security system functionality Data Link Connector DLC

Connector providing access and/or control of the vehicle information, operating conditions, and diagnostic information Driver Door Module DDM Electronic module to support driver door functionality Driver Seat Module DSM Electronic module to support driver seat functionality Daytime Running Lamps DRL Deutsche Institut fur Normung DIN German standards regulation body Diagnostic Trouble Code DTC

An alpha/numeric identifier for a fault condition identified by the On-Board Diagnostic (OBD) system Direct current dc

Current which flows in one direction only, though it may have appreciable pulsations in its magnitude Domestic Data Bus D2B Digital Versatile Disc DVD Electronic Automatic Temperature Control EATC

Exhaust Gas Recirculation EGR Exhaust Gas Recirculation Temperature Sensor EGRT Sensing EGR function based on temperature change Electronic Brake Force

Distribution EBD

Engine Control Module ECM Electronic module to support engine functionality Electronic Crash Sensor ECS Sensor to measure severity of impact Engine Coolant Temperature ECT Engine Oil Pressure EOP European On-Board Diagnostic EOBD Electronic Pressure Control EPC Electrically Erasable

Programmable Read-Only Memory EEPROM

Erasable Programmable

Read-Only Memory EPROM

Evaporative Emission EVAP

System designed to prevent fuel vapor from escaping into the atmosphere. Typically includes a charcoal filled canister to absorb fuel vapor Flash Electrically Erasable

Programmable Read-Only Memory FEEPROM

Front Electronic Module FEM Flash Erasable Programmable

Read-Only Memory FEPROM

Frequency Modulation FM Fuel Pump Driver Module FPDM Fuel Rail Pressure FRP Generic Electronic Module GEM Ground GND

Electrical conductor used as a common return for an electrical circuit or

circuits, and with a relative zero potential Global Positioning System GPS Global System for Mobile

Communication GSM

Gross Vehicle Weight GVW Heated Oxygen Sensor HO2S Electrically heated oxygen sensor which induces fuelling corrections

Page 60 of 3039

Have a suitable fire extinguisher available when using welding or heating equipment.

First Aid

Apart from meeting any legal requirements it is desirable for someone in the workshop to be trained in First Aid procedures.

Splashes in the eye should be flushed carefully with clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

Individuals affected by inhalation of gases, fumes etc. should be removed to fresh air immediately. If effects persist, consult a

doctor.

If liquids are swallowed inadvertently, consult a doctor giving the information on the container or label. Do not induce vomiting

unless this action is indicated on the label.

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams used in seat and trim cushioning.

Follow manufacturer's instructions.

Unreacted components are irritating and may be harmful to the skin and eyes. Wear gloves and goggles.

Individuals with chronic respiratory diseases, asthma, bronchial medical problems, or histories of allergic diseases should not

work in or near uncured materials.

The components, vapors or spray mists can cause direct irritation, sensitivity reactions and may be toxic or harmful.

Vapors and spray mists must not be inhaled. These materials must be applied with adequate ventilation and respiratory

protection. Do not remove the respirator immediately after spraying, wait until the vapor/mists have cleared.

Burning of the uncured components and the cured foams can generate toxic and harmful fumes. Smoking, naked flames or the

use of electrical equipment during foaming operations and until vapors/mists have cleared should not be allowed. Any heat

cutting of cured foams or partially cured foams should be conducted with extraction ventilation.

Freon

See Air Conditioning Refrigerant.

Fuels

See also, Fire, Legal Aspects, Chemicals and Solvents.

Avoid skin contact with fuel where possible. Should contact occur, wash the affected skin with soap and water.

Gasoline (Petrol)

Highly flammable - observe No Smoking policy.

Swallowing can result in mouth and throat irritation and absorption from the stomach can result in drowsiness and

unconsciousness. Small amounts can be fatal to children. Aspiration of liquid into the lungs e.g. through vomiting, is a very

serious hazard.

Gasoline dries the skin and can cause irritation and dermatitis on prolonged or repeated contact. Liquid in the eye causes

severe pain.

Motor gasoline may contain appreciable quantities of benzene, which is toxic upon inhalation, and the concentration of

gasoline vapors must be kept very low. High concentrations will cause eye, nose and throat irritation, nausea, headache,

depression and symptoms of drunkenness. Very high concentrations will result in rapid loss of consciousness.

Ensure there is adequate ventilation when handling and using gasoline. Great care must be taken to avoid the serious

consequences of inhalation in the event of vapor build up arising from spillages in confined spaces.

Special precautions apply to cleaning and maintenance operations on gasoline storage tanks.

Gasoline should not be used as a cleaning agent. It must not be siphoned by mouth. See First Aid.

Gas - oil (Diesel Fuel)

See warnings and cautions in relevant manual sections.

Combustible.

www.JagDocs.com

Page 64 of 3039

Viton

In common with many other manufacturers' vehicles, some components installed to the Jaguar range have 'O' rings, seals or

gaskets which contain a material known as 'Viton'.

Viton is a fluoroelastomer, that is a synthetic rubber type which contains Fluorine. It is commonly used for 'O' rings, gaskets

and seals of all types. Although Viton is the most well known fluoroelastomer, there are others, including Fluorel and

Tecmoflon.

When used under design conditions fluoroelastomers are perfectly safe. If, however, they are exposed to temperatures in

excess of 400º C, the material will not burn, but will decompose, and one of the products formed is hydrofluoric acid.

This acid is extremely corrosive and may be absorbed directly, through contact, into the body.

'O' rings, seals or gaskets which have been exposed to very high temperatures will appear charred or as a black sticky

substance.

DO NOT, under any circumstances touch them or the attached components.

Enquiries should be made to determine whether Viton or any other fluoroelastomer has been used in the affected 'O' ring, seal

or gasket. If they are of natural rubber or nitrile there is no hazard. If in doubt, be cautious and assume that the material may

be Viton or any fluoroelastomer.

If Viton or any other fluoroelastomers have been used, the affected area should be decontaminated before the commencement

of work.

Disposable heavy duty plastic gloves should be worn at all times, and the affected area washed down using wire wool and a

limewater (calcium hydroxide) solution to neutralize the acid before disposing of the decomposed Viton residue and final

cleaning of the area. After use, the plastic gloves should be discarded carefully and safely.

Welding

See also Fire, Electric Shock, Gas Cylinders.

Welding processes include Resistance Welding (Spot Welding), Arc Welding and Gas Welding (and cutting).

Resistance Welding (Spot Welding)

This process may cause particles of molten metal to be emitted at a high velocity, and the eyes and skin must be protected.

Arc Welding

This process emits a high level of ultraviolet radiation which may cause arc-eye and skin burns to the operator and to other

persons nearby. Gas-shielded welding processes are particularly hazardous in this respect. Personal protection must be worn,

and screens used to shield other people.

CONTACT LENS WEARERS ARE ADVISED TO REVERT TO ORDINARY SPECTACLES WHEN ARC WELDING as the arc spectrum is

believed to emit microwaves which dry out the fluid between the lens and the eye. This may result in blindness when the lens

is removed from the eye.

Metal spatter will also occur, and appropriate eye and skin protection is necessary.

The heat of the welding arc will produce fumes and gases from the metals being welded, the rods and from any applied

coatings or contamination on the surfaces being worked on. These gases and fumes may be toxic and inhalation of these

should be avoided. The use of extraction ventilation to remove the fumes from the working area may be necessary particularly

in cases where the general ventilation is poor, or where considerable welding work is anticipated. In extreme cases or confined

spaces where adequate ventilation cannot be provided, air-fed respirators may be necessary.

Gas Welding (and Cutting)

Oxy-acetylene torches may be used for welding and cutting, and special care must be taken to prevent leakage of these gases,

with consequent risk of fire and explosion.

The process will produce metal spatter and eye and skin protection is necessary.

The flame is bright, and eye protection should be used, but the ultraviolet emission is much less than that from arc welding,

and lighter filters may be used.

The process itself produces few toxic fumes, but such fumes and gases may be produced from coatings on the work,

particularly during cutting away of damaged body parts, and inhalation of the fumes should be avoided.

In brazing, toxic fumes may be produced from the metals in the brazing rod, and a severe hazard may arise if brazing rods

containing cadmium are used. In this event particular care must be taken to avoid inhalation of fumes and expert advice may

be required.

SPECIAL PRECAUTIONS MUST BE TAKEN BEFORE ANY WELDING OR CUTTING TAKES PLACE ON VESSELS WHICH HAVE

CONTAINED COMBUSTIBLE MATERIALS, E.G. BOILING OR STEAMING OUT OF FUEL TANKS.

Warning Symbols on Vehicles

Decals showing warning symbols will be found on various vehicle components.

Page 71 of 3039

General Information - Solvents, Sealants and Adhesives

Description and Operation Published: 11-May-2011

WARNING: Always handle all solvents, sealers and adhesives with extreme care. Some contain chemicals or give off

fumes which can be dangerous to health. Always follow the manufacturers instructions. If in doubt about any substance,

particularly a solvent, DO NOT use it.

CAUTION: If in doubt about the suitability of any proprietary solvent or sealer for a particular application, contact the

manufacturer of the product for information regarding storage, handling and application.

The Solvents, Sealers and Adhesives subsection refers to some commonly used chemicals and materials, hazards associated

with their use, and safety measures to be taken.

Adhesives and Sealers

Highly flammable, flammable, combustible – observe No Smoking policy.

Generally should be stored in No Smoking' areas. Cleanliness and tidiness in use should be observed e.g. disposable paper

covering benches; should be dispensed from applicators where possible; containers, including secondary containers, should be

labelled appropriately.

Solvent - based Adhesives/Sealers - See Solvents

Follow manufacturer's instructions.

Water - based Adhesives/Sealers

Those based on polymer emulsions and rubber latexes may contain small amounts of volatile toxic and harmful chemicals. Skin

and eye contact should be avoided and adequate ventilation provided during use.

Hot Melt Adhesives

In the solid state, they are safe. In the molten state they may cause burns and health hazards may arise from the inhalation

of toxic fumes.

Use appropriate protective clothing and a thermostatically controlled heater with a thermal cut - out and adequate extraction.

Resin - based Adhesives/Sealers e.g. Epoxide and Formaldehyde Resin - based

Mixing should be carried out in well ventilated areas, as harmful or toxic volatile chemicals may be released.

Skin contact with uncured resins and hardeners can result in irritation, dermatitis, and absorption of toxic or harmful chemicals

through the skin. Splashes can damage the eyes.

Provide adequate ventilation and avoid skin and eye contact.

Anaerobic, Cyanoacrylate (Super - glues) and other Acrylic Adhesives Many are irritant, sensitizing or harmful to the skin and/or respiratory tract. Some are eye irritants.

Skin and eye contact should be avoided and the manufacturer's instructions followed.

Cyanoacrylate adhesives (super-glues) MUST NOT contact the skin or eyes. If skin or eye tissue is bonded, cover with a clean

moist pad and seek immediate medical attention. Do not attempt to pull tissue apart. Use in well ventilated areas as vapors

can cause irritation to the nose and eyes.

For two - pack systems see Resin - based and Isocyanate Adhesives/Sealers.

Isocyanate (Polyurethane) Adhesives/Sealers

See also Resin - based Adhesives

Individuals suffering from asthma or respiratory allergies should not work with or near these materials as sensitivity reactions

can occur.

Over exposure is irritating to the eyes and respiratory system. Excessive concentrations may produce effects on the nervous

system including drowsiness. In extreme cases, loss of consciousness may result. Long term exposure to vapor concentrations

may result in adverse health effects.

Prolonged contact with the skin may lead to skin irritation and, in some cases, dermatitis.

Splashes entering the eye will cause discomfort and possible damage.

Any spraying should preferably be carried out in exhaust ventilated booths removing vapors and spray droplets from the

breathing zone.

Wear appropriate gloves, eye and respiratory protection.

Page 100 of 3039

11

Cutting of fingers or hand 12

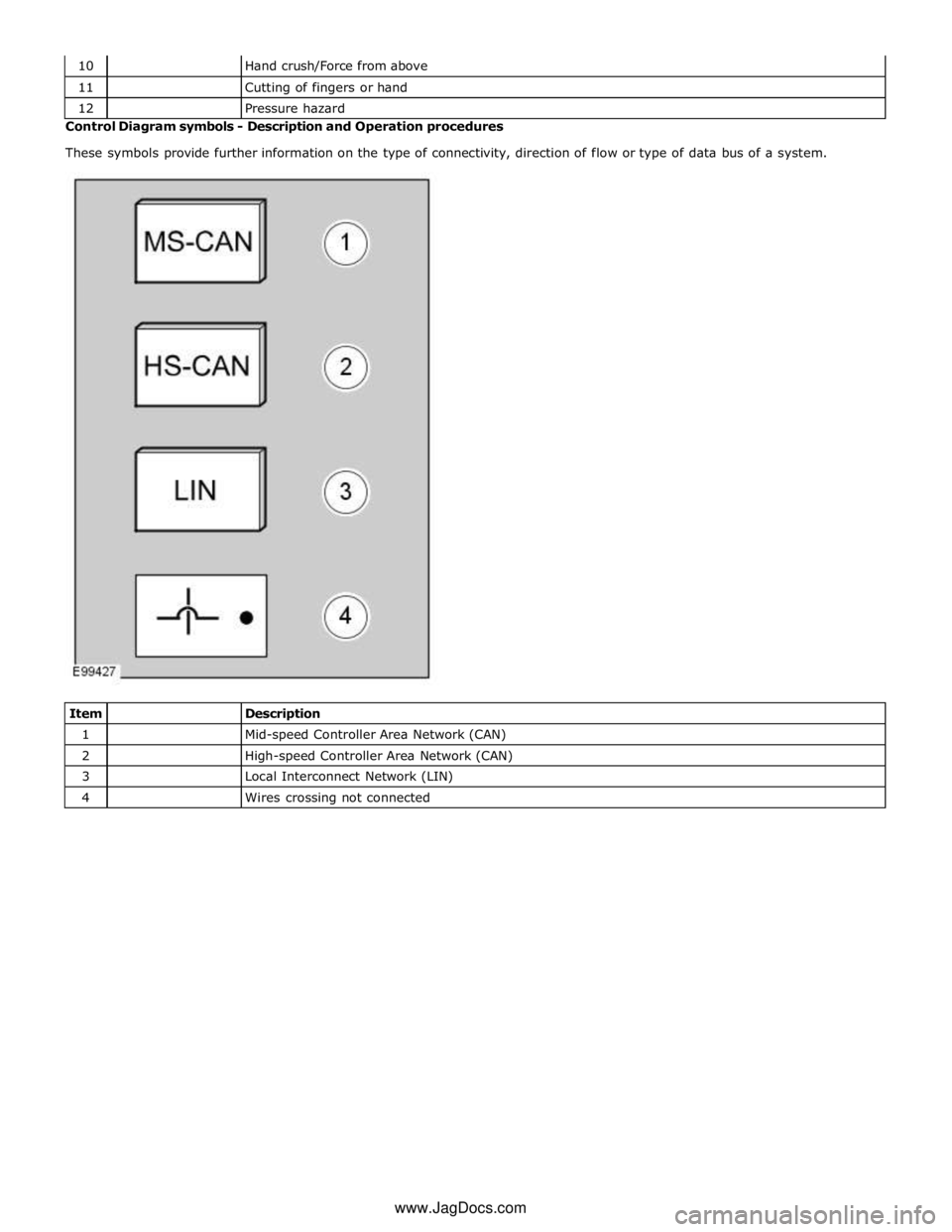

Pressure hazard Control Diagram symbols - Description and Operation procedures

These symbols provide further information on the type of connectivity, direction of flow or type of data bus of a system.

Item

Description 1

Mid-speed Controller Area Network (CAN) 2

High-speed Controller Area Network (CAN) 3

Local Interconnect Network (LIN) 4

Wires crossing not connected www.JagDocs.com

Page 104 of 3039

Avoid brake testing on busy roads where it can cause inconvenience or danger to other road users.

CAUTION: Brake testing which includes heavy brake applications should not be carried out with new brake pads/discs or

linings/drums until the components have bedded-in. New brake friction components will not reach full efficiency until the

bedding-in process is complete.

Test the brakes at several speeds within the normal operating range using both light and heavy pedal pressure. Note any

tendency to snatch, pull or drag, and any undue delay in application or release.

Allow the vehicle to coast and note any tendency to pull to one side, or evidence that the brakes are binding.

After stopping the vehicle (not immediately after a period of heavy braking), carefully check the brake temperature. A disc

which feels hot, or appreciably hotter than the others, indicates that the brake is binding.

After completion of the test, check for:

Oil, coolant, hydraulic, air and fuel leaks

Abnormal temperature of any moving components or assemblies, e.g. wheel hubs, transmission, axle etc., which might

indicate over tightness or lack of lubrication

Page 117 of 3039

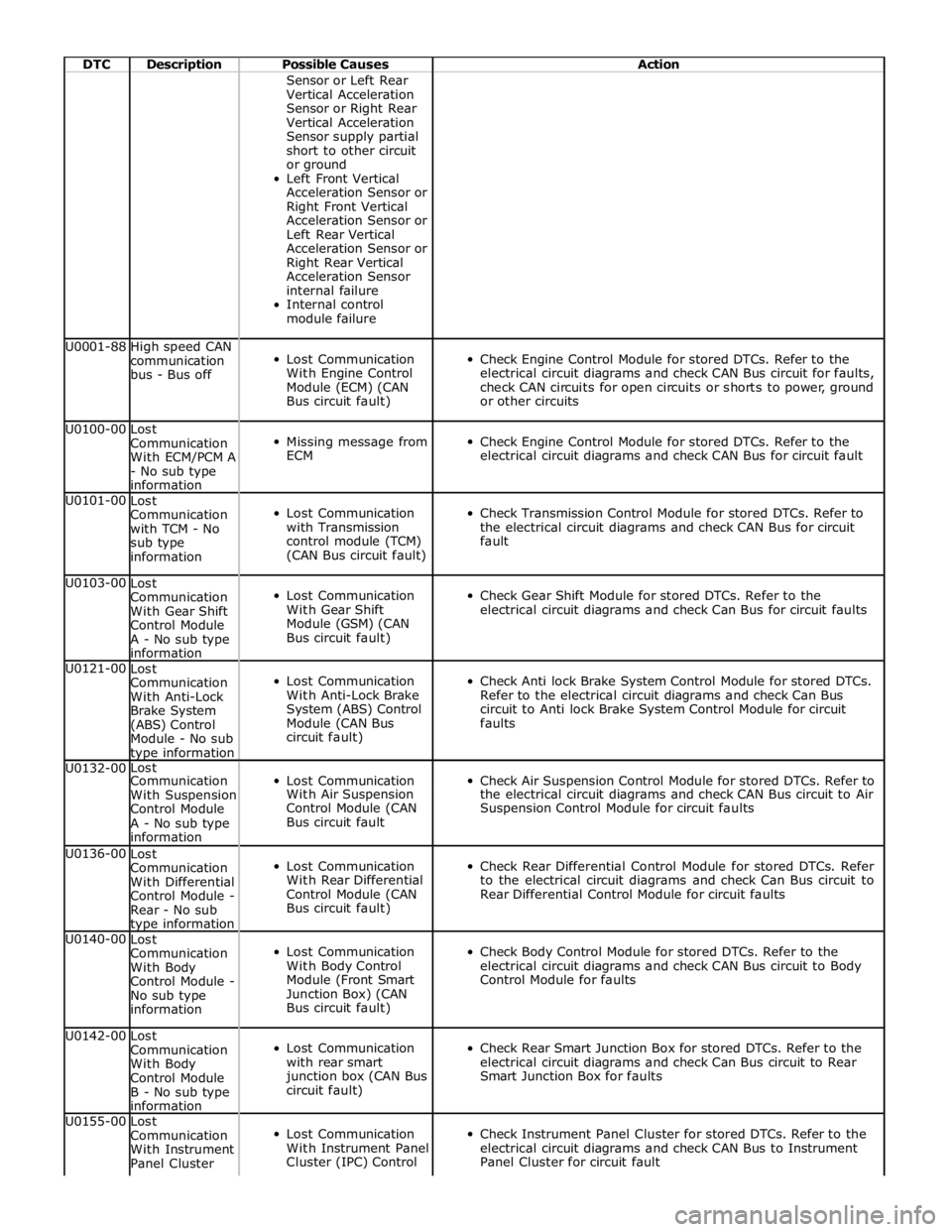

DTC Description Possible Causes Action Sensor or Left Rear

Vertical Acceleration

Sensor or Right Rear

Vertical Acceleration

Sensor supply partial

short to other circuit

or ground

Left Front Vertical

Acceleration Sensor or

Right Front Vertical

Acceleration Sensor or

Left Rear Vertical

Acceleration Sensor or

Right Rear Vertical

Acceleration Sensor

internal failure

Internal control

module failure U0001-88

High speed CAN

communication

bus - Bus off

Lost Communication

With Engine Control

Module (ECM) (CAN

Bus circuit fault)

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit for faults,

check CAN circuits for open circuits or shorts to power, ground

or other circuits U0100-00

Lost

Communication

With ECM/PCM A

- No sub type

information

Missing message from

ECM

Check Engine Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus for circuit fault U0101-00

Lost

Communication

with TCM - No

sub type

information

Lost Communication

with Transmission

control module (TCM)

(CAN Bus circuit fault)

Check Transmission Control Module for stored DTCs. Refer to

the electrical circuit diagrams and check CAN Bus for circuit

fault U0103-00

Lost

Communication

With Gear Shift

Control Module

A - No sub type

information

Lost Communication

With Gear Shift

Module (GSM) (CAN

Bus circuit fault)

Check Gear Shift Module for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus for circuit faults U0121-00

Lost

Communication

With Anti-Lock

Brake System

(ABS) Control

Module - No sub type information

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module (CAN Bus

circuit fault)

Check Anti lock Brake System Control Module for stored DTCs.

Refer to the electrical circuit diagrams and check Can Bus

circuit to Anti lock Brake System Control Module for circuit

faults U0132-00 Lost

Lost Communication

Check Air Suspension Control Module for stored DTCs. Refer to Communication With Suspension With Air Suspension the electrical circuit diagrams and check CAN Bus circuit to Air Control Module Control Module (CAN Suspension Control Module for circuit faults A - No sub type Bus circuit fault information U0136-00

Lost

Communication

With Differential

Control Module -

Rear - No sub type information

Lost Communication

With Rear Differential

Control Module (CAN

Bus circuit fault)

Check Rear Differential Control Module for stored DTCs. Refer

to the electrical circuit diagrams and check Can Bus circuit to

Rear Differential Control Module for circuit faults U0140-00

Lost

Communication

With Body

Control Module -

No sub type

information

Lost Communication

With Body Control

Module (Front Smart

Junction Box) (CAN

Bus circuit fault)

Check Body Control Module for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus circuit to Body

Control Module for faults U0142-00

Lost

Communication

With Body

Control Module

B - No sub type

information

Lost Communication

with rear smart

junction box (CAN Bus

circuit fault)

Check Rear Smart Junction Box for stored DTCs. Refer to the

electrical circuit diagrams and check Can Bus circuit to Rear

Smart Junction Box for faults U0155-00

Lost

Communication

With Instrument

Panel Cluster

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Check Instrument Panel Cluster for stored DTCs. Refer to the

electrical circuit diagrams and check CAN Bus to Instrument

Panel Cluster for circuit fault

Page 118 of 3039

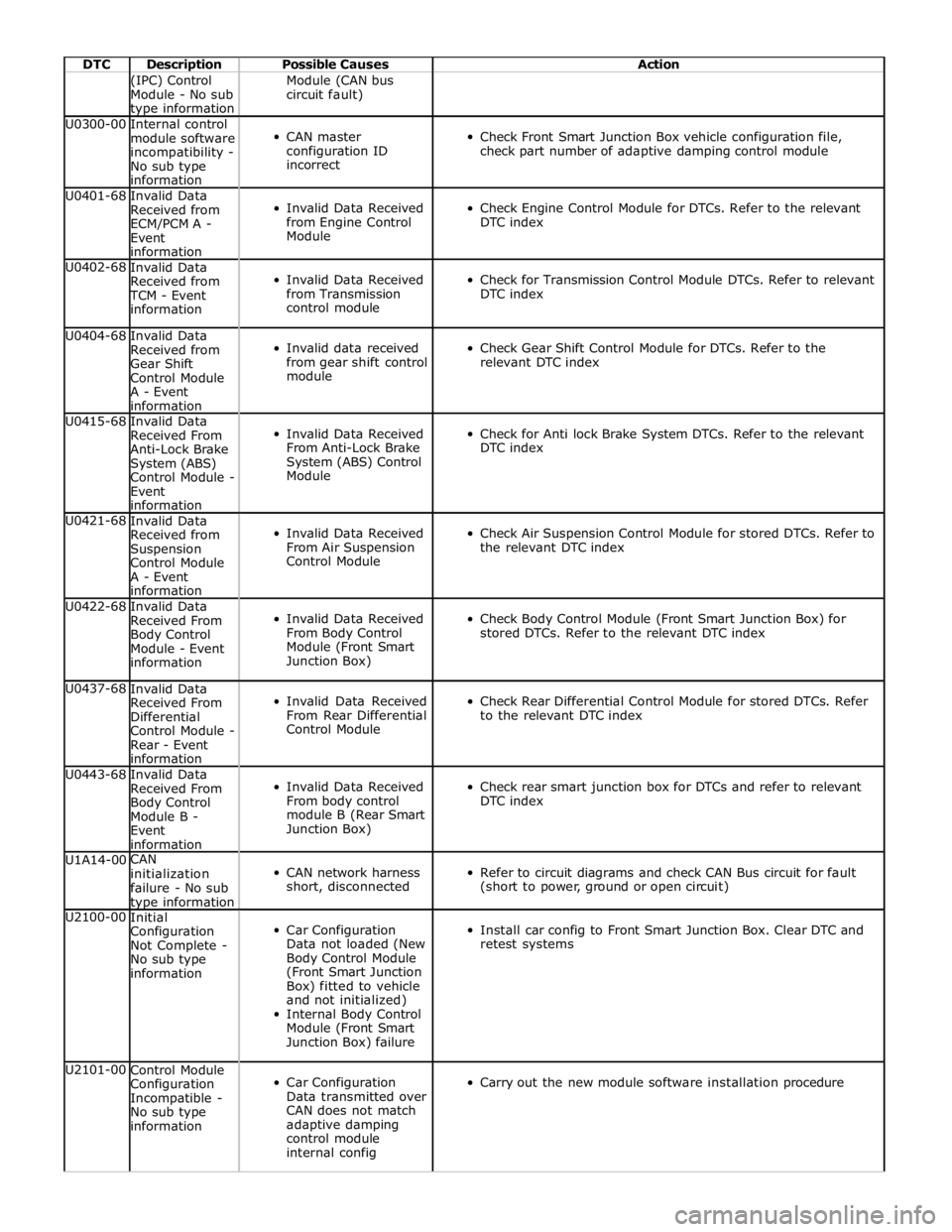

DTC Description Possible Causes Action (IPC) Control

Module - No sub

type information Module (CAN bus

circuit fault) U0300-00

Internal control

module software

incompatibility -

No sub type

information

CAN master

configuration ID

incorrect

Check Front Smart Junction Box vehicle configuration file,

check part number of adaptive damping control module U0401-68

Invalid Data

Received from

ECM/PCM A -

Event

information

Invalid Data Received

from Engine Control

Module

Check Engine Control Module for DTCs. Refer to the relevant

DTC index U0402-68

Invalid Data

Received from TCM - Event

information

Invalid Data Received

from Transmission

control module

Check for Transmission Control Module DTCs. Refer to relevant

DTC index U0404-68

Invalid Data

Received from

Gear Shift

Control Module

A - Event

information

Invalid data received

from gear shift control

module

Check Gear Shift Control Module for DTCs. Refer to the

relevant DTC index U0415-68

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module -

Event

information

Invalid Data Received

From Anti-Lock Brake

System (ABS) Control

Module

Check for Anti lock Brake System DTCs. Refer to the relevant

DTC index U0421-68

Invalid Data

Received from

Suspension

Control Module

A - Event

information

Invalid Data Received

From Air Suspension

Control Module

Check Air Suspension Control Module for stored DTCs. Refer to

the relevant DTC index U0422-68

Invalid Data

Received From

Body Control

Module - Event

information

Invalid Data Received

From Body Control

Module (Front Smart

Junction Box)

Check Body Control Module (Front Smart Junction Box) for

stored DTCs. Refer to the relevant DTC index U0437-68

Invalid Data

Received From

Differential

Control Module -

Rear - Event

information

Invalid Data Received

From Rear Differential

Control Module

Check Rear Differential Control Module for stored DTCs. Refer

to the relevant DTC index U0443-68

Invalid Data

Received From

Body Control

Module B -

Event

information

Invalid Data Received

From body control

module B (Rear Smart

Junction Box)

Check rear smart junction box for DTCs and refer to relevant

DTC index U1A14-00 CAN

initialization

failure - No sub type information

CAN network harness

short, disconnected

Refer to circuit diagrams and check CAN Bus circuit for fault

(short to power, ground or open circuit) U2100-00

Initial

Configuration

Not Complete -

No sub type

information

Car Configuration

Data not loaded (New

Body Control Module

(Front Smart Junction

Box) fitted to vehicle

and not initialized)

Internal Body Control

Module (Front Smart

Junction Box) failure

Install car config to Front Smart Junction Box. Clear DTC and

retest systems U2101-00

Control Module

Configuration

Incompatible -

No sub type

information

Car Configuration

Data transmitted over

CAN does not match

adaptive damping

control module

internal config

Carry out the new module software installation procedure

Page 129 of 3039

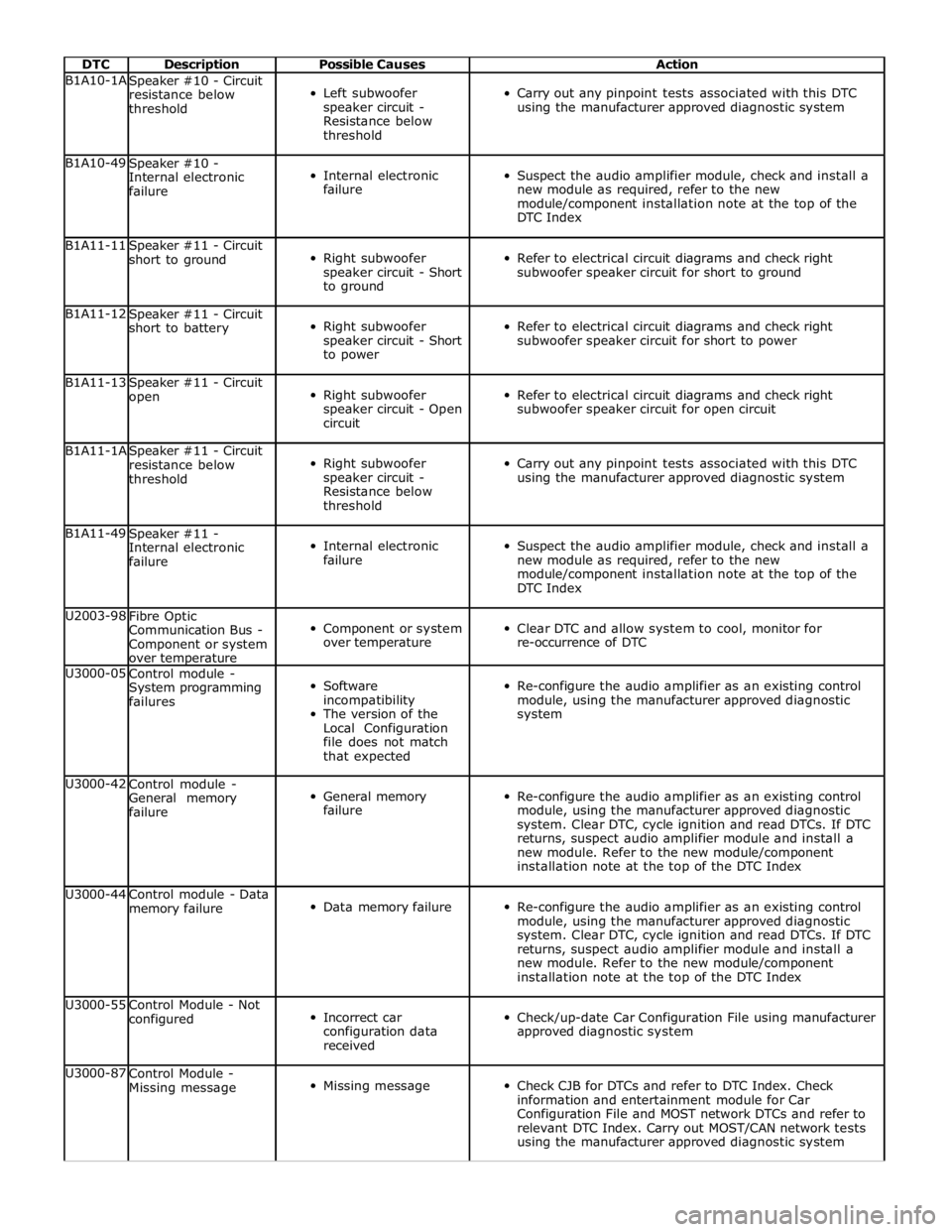

DTC Description Possible Causes Action B1A10-1A

Speaker #10 - Circuit

resistance below

threshold

Left subwoofer

speaker circuit -

Resistance below

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system B1A10-49

Speaker #10 -

Internal electronic

failure

Internal electronic

failure

Suspect the audio amplifier module, check and install a

new module as required, refer to the new

module/component installation note at the top of the

DTC Index B1A11-11

Speaker #11 - Circuit

short to ground

Right subwoofer

speaker circuit - Short

to ground

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for short to ground B1A11-12

Speaker #11 - Circuit

short to battery

Right subwoofer

speaker circuit - Short

to power

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for short to power B1A11-13

Speaker #11 - Circuit

open

Right subwoofer

speaker circuit - Open

circuit

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for open circuit B1A11-1A

Speaker #11 - Circuit

resistance below

threshold

Right subwoofer

speaker circuit -

Resistance below

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system B1A11-49

Speaker #11 -

Internal electronic

failure

Internal electronic

failure

Suspect the audio amplifier module, check and install a

new module as required, refer to the new

module/component installation note at the top of the

DTC Index U2003-98

Fibre Optic

Communication Bus -

Component or system

over temperature

Component or system

over temperature

Clear DTC and allow system to cool, monitor for

re-occurrence of DTC U3000-05

Control module -

System programming

failures

Software

incompatibility

The version of the

Local Configuration

file does not match

that expected

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system U3000-42

Control module -

General memory

failure

General memory

failure

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system. Clear DTC, cycle ignition and read DTCs. If DTC

returns, suspect audio amplifier module and install a

new module. Refer to the new module/component

installation note at the top of the DTC Index U3000-44

Control module - Data

memory failure

Data memory failure

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system. Clear DTC, cycle ignition and read DTCs. If DTC

returns, suspect audio amplifier module and install a

new module. Refer to the new module/component

installation note at the top of the DTC Index U3000-55

Control Module - Not

configured

Incorrect car

configuration data

received

Check/up-date Car Configuration File using manufacturer

approved diagnostic system U3000-87

Control Module -

Missing message

Missing message

Check CJB for DTCs and refer to DTC Index. Check

information and entertainment module for Car

Configuration File and MOST network DTCs and refer to

relevant DTC Index. Carry out MOST/CAN network tests

using the manufacturer approved diagnostic system

Page 131 of 3039

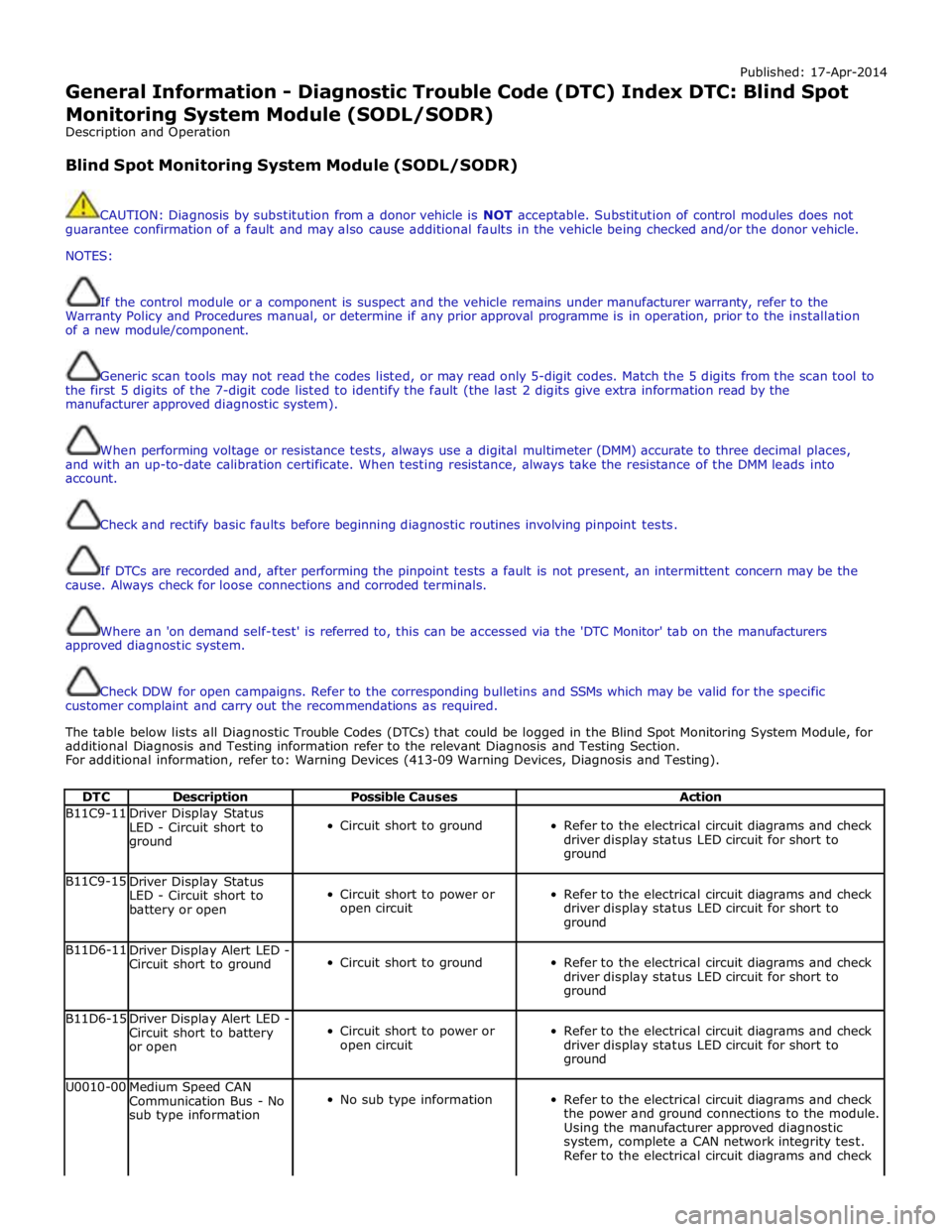

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Blind Spot Monitoring System Module (SODL/SODR)

Description and Operation

Blind Spot Monitoring System Module (SODL/SODR)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Blind Spot Monitoring System Module, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Warning Devices (413-09 Warning Devices, Diagnosis and Testing).

DTC Description Possible Causes Action B11C9-11

Driver Display Status

LED - Circuit short to

ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11C9-15

Driver Display Status

LED - Circuit short to

battery or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-11

Driver Display Alert LED -

Circuit short to ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-15

Driver Display Alert LED -

Circuit short to battery

or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground U0010-00

Medium Speed CAN

Communication Bus - No

sub type information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check