JEEP CJ 1953 Service Manual

Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 261 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Jl

1—

Blocking

Rir

2—

Direct

and 1

3—

Snap

Ring

4—

Spring

5—

Shifting

Plat

6—

Direct

and 1 7—

Third

Speed

J1-3

4-Speed Transmission Disassembly

•

Refer to Fig. Jl-1.

Note;

The

models

T-98 and T-18 four-speed

transmission are similar in design with exception of

the second

speed

gear-to-mainshaft arrangement.

In

the model T-18 transmission, the second

speed

gear is a slide fit on the mainshaft, whereas in the

model T-98 transmission roller bearings and a

spacer are required in this area. Refer to Figs. Jl-3

and

Jl-4.

a.

Remove the transmission to transfer case adapter plate and gasket. Remove the oil seal from

the plate and, if damaged, discard the seal.

b. Remove the transmission control housing as

sembly. Refer to paragraph Jl-4 for its dis

assembly.

c. To make certain the two blocking rings, direct-

and-third

clutch hub, and direct-and-third clutch

sleeve

will

be assembled in their original relation

ship,

mark them with a quick drying lacquer or an

electric pencil. Also mark the blocking ring, low-

and-second clutch hub, and the low-and-second

speed

gear.

d.

Slide the low-and-second

speed

gear toward the rear of the transmission case.

e.

Disengage

the reverse shifting arm and reverse shifting

shoe

from the reverse idler gear. Remove

the arm from the reverse shifting arm pivot.

f. Move the low-and-second

speed

gear

into

neutral position.

g. Remove the bearing retainer and gasket.

Remove the snap rings from the main drive gear

and

the outer race of the ball bearing.

h.

With a bearing puller, remove the main drive

gear ball bearing. 1436S

i

Hub

Gear

izer

Assembly

ironizer

Assembly

i.

Remove the oil slinger.

j.

Remove the snap ring from the outer bearing

race

of the transmission mainshaft ball bearing.

k. With a bearing puller, remove the mainshaft

ball

bearing.

Note:

It may be necessary to drive the mainshaft

rearward

by striking the end of the main drive gear with a lead hammer to get sufficient clearance

to install the bearing puller plates.

I.

Slide the direct-and-third clutch

sleeve

to the

rear

(third

speed)

position. Separate the mainshaft

assembly from the main drive gear. Be careful

not to

lose

any of the mainshaft pilot bearing

rollers.

m.

Lift

the mainshaft assembly out of the top

of the transmission case.

n.

Remove the main drive gear from the trans

mission case.

o. Remove the mainshaft bearing rollers from the gear.

p.

Mark

relationship

between

synchronizer hubs

and

the splines on the mainshaft.

q. Begin disassembly of the main shaft assembly by removing the snap ring which holds the direct

and

third synchronizer assembly on the mainshaft,

r.

Remove the front blocking ring from the front

of the shaft.

s. Slide the direct-and-third-synchronizer assembly

and

the third-speed-gear assembly off the main-shaft.

t. Remove the snap ring at the rear of the main-

shaft. Slide the second synchronizer assembly and the blocking ring off the mainshaft.

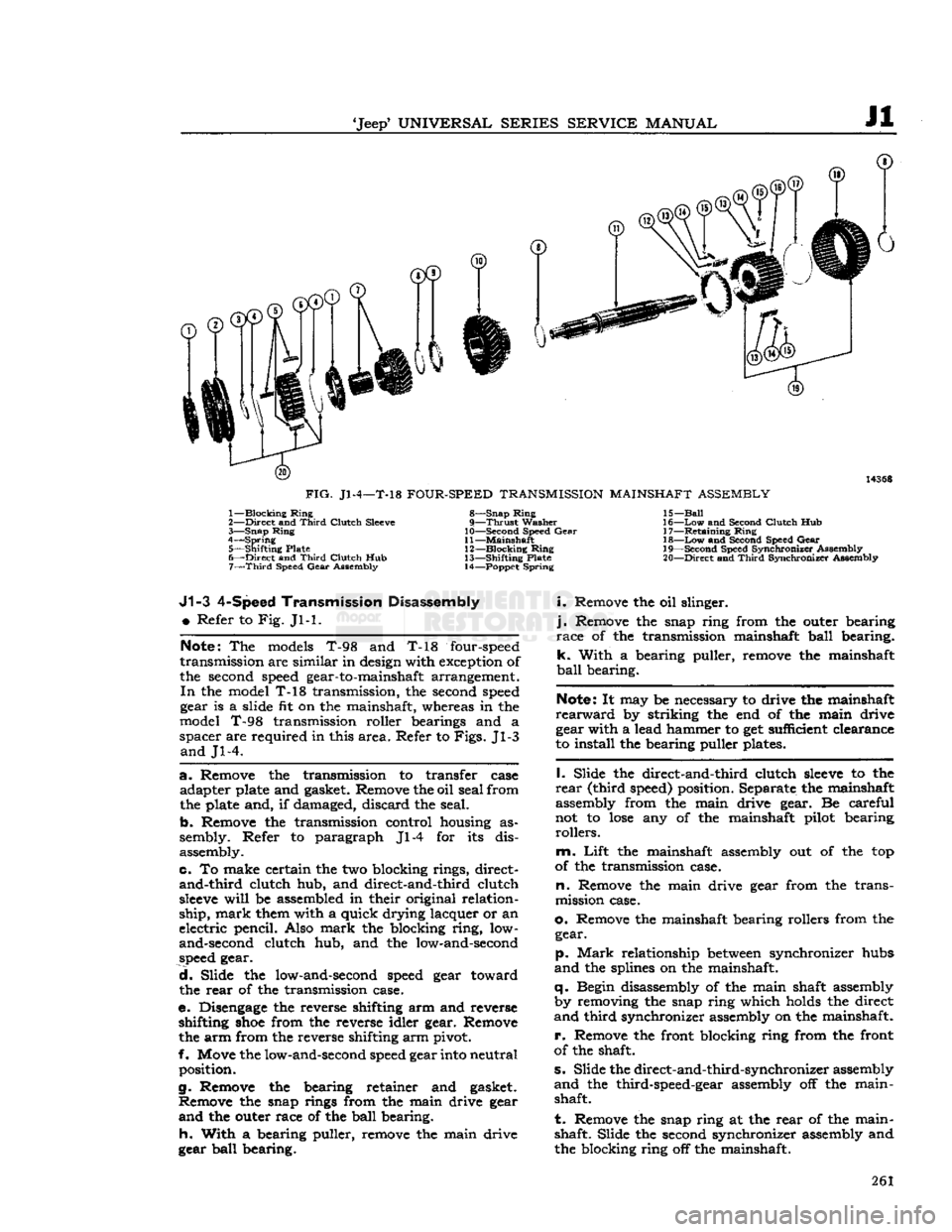

FIG.

Jl-4—T-18

FOUR-SPEED TRANSMISSION MAINSHAFT ASSEMBLY

ng 8—Snap

Ring

15—Ball

third

Clutch

Sleeve

9—Thrust

Washer 16—Low and Second

Clutch

10—

Second

Speed

Gear

17—Retaining

Ring

11—

Mainshaft

18—Low and Second Speed

te 12—Blocking

Ring

19—Second Speed

Synchroni

rhird

Clutch

Hub 13—Shifting Plate 20—Direct and

Third

Synch

Gear

Assembly 14—Poppet

Spring

261

Page 262 of 376

Jl

FOUR-SPEED

TRANSMISSION

U.

On the T-98 transmission remove the snap rings

holding the thrust washer, bearing rollers, second-

speed

gear, and spacer on the mainshaft. Slide

these

components

off the shaft. Refer to Fig. Jl-3.

Note:

The second

speed

gear in the T-18 trans

mission is a slide fit

onto

the mainshaft and

does

not contain roller bearings or a spacer.

v. If the synchronizer assemblies are to be dis

assembled and serviced proceed as follows:

Wrap

the

second-speed

synchronizer assembly in a cloth

to prevent losing the lock balls and springs. Push the clutch hub out of the low-and-second-speed

gear in a direction

opposite

the shift fork

groove.

Remove the cloth.

Lift

the balls, springs, and

plates out of the hub.

w. Remove the lockplate for the countershaft and

reverse idler gear shaft.

x.

Use a pry bar in the

slot

of the reverse idler gear

shaft to

loosen

the shaft.

Then,

slip the reverse

idler

gear shaft out of the housing and gear.

Lift

the reverse idler gear assembly from the transmission case.

y. To remove the countershaft, use a heavy brass

drift

and drive the countershaft toward the

rear

of

the transmission case. When the countershaft end

is just about even with the inside of the trans mission case, use a dummy shaft to force it the

remainder of the way. (Since a dummy shaft is a

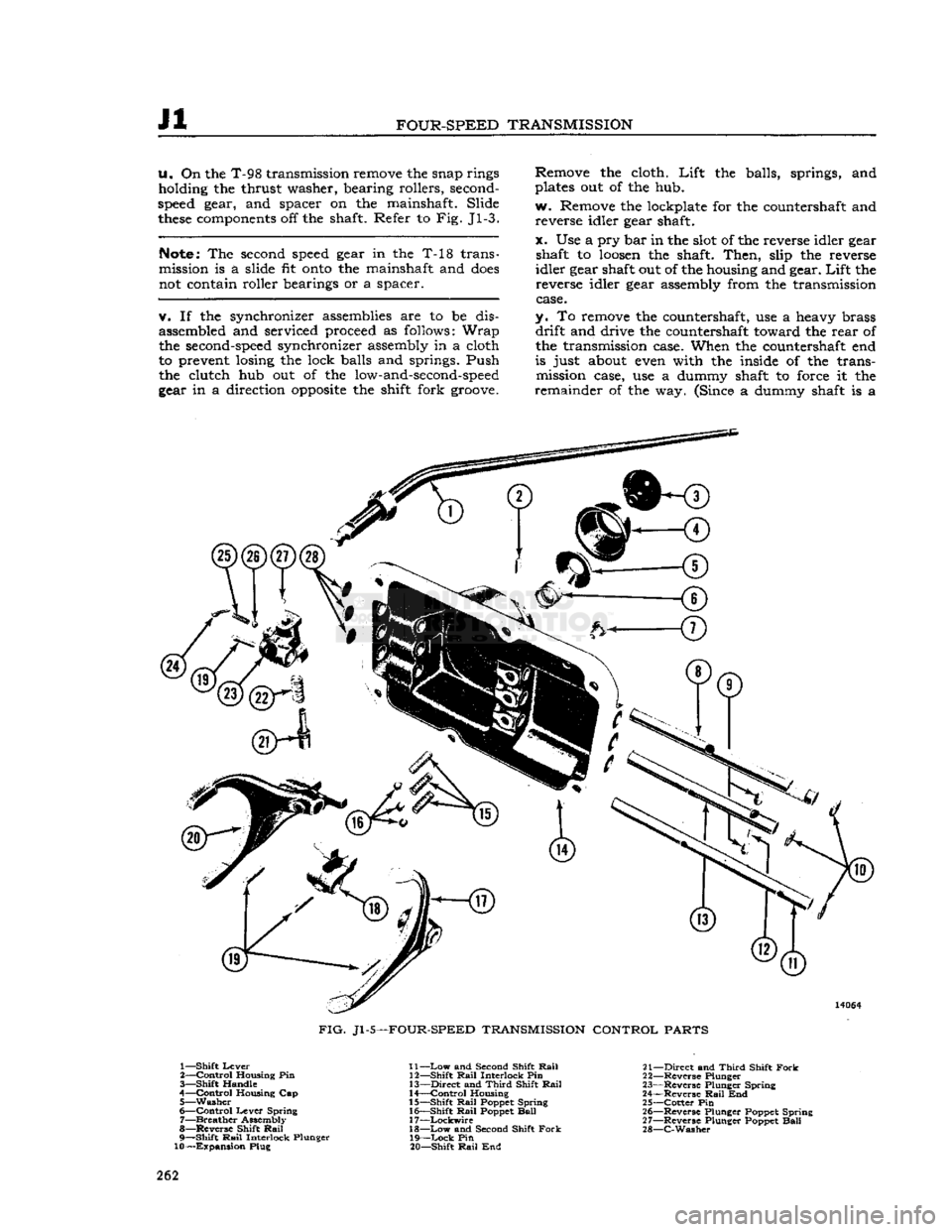

FIG.

Jl -5—FOUR-SPEED TRANSMISSION CONTROL PARTS

1—

Shift

Lever

2—

Control

Housing Pin

3—

Shift

Handle

4—

Control

Housing Cap 5—

Washer

6—

Control

Lever

Spring

7—

Breather

Assembly

8— Reverse Shift

Rail

9—

Shift

Rail

Interlock Plunger

10—Expansion

Plug 11—

Low

and Second Shift

Rail

12—

Shift

Rail

Interlock Pin

13—

Direct

and

Third

Shift

Rail

14—

Control

Housing

15—

Shift

Rail

Poppet Spring

16—

Shift

Rail

Poppet

Ball

17—

Lockwire

18—

Low

and Second Shift

Fork

19—

Lock

Pin

20—

Shift

Rail

End 21—

Direct

and

Third

Shift

Fork

22— Reverse Plunger

23— Reverse Plunger Spring

24— Reverse

Rail

End

25—

Cotter

Pin

26— Reverse Plunger Poppet Spring

27— Reverse Plunger Poppet

Ball

28—

C-Washer

262

Page 263 of 376

![JEEP CJ 1953 Service Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut JEEP CJ 1953 Service Manual

Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut](/img/16/57040/w960_57040-262.png)

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Jl

necessity for assembly, one should be made at this

time to assist on disassembly. One can be made by

using a \Y%N [2,86 cm.] diameter steel rod cut to

9.850*

{25,02

cm.] long.

Break

sharp

edges

with a

mill

file.) Keep the dummy shaft in contact with

the countershaft at all times to prevent dropping

the bearing rollers or thrust washers,

z.

With

the dummy shaft in position, place the

transmission

case on its side and carefully

roll

the countershaft gear cluster out of the case,

aa.

Complete the disassembly by removing the dummy shaft, thrust washers, four

sets

of bearing

rollers,

and spacers.

bb.

To disassemble the reverse idler gear assembly,

remove one of the snap rings and tap out the

washers,

both

sets

of bearing rollers, center spacer,

and

sleeve.

Remove the remaining snap

ring.

J1-4.

4-Speed

Transmission

Control

Housing

Disassembly

•

Refer to Fig. Jl-5.

The

gearshift lever, spring, and spring seat were previously removed for removal of the transmission

from

the vehicle.

a.

Remove the lock pins from the gearshift forks

and

gearshift rod ends. Remove the expansion plugs

from

the front and

rear

of the gearshift lever base. Remove back-up light switch.

b.

Remove the center (third and high) gearshift

rod

first. Drive this gearshift rod out the

rear

of the gearshift lever base. As the gearshift rod is

withdrawn

from the center section of the gearshift base, remove the interlock pin from the cross

over

hole

in the gearshift rod. Before the gearshift

rod

is removed from the center section of the gear

shift base, place a finger over the

hole

to prevent

loss

of the

ball

and spring.

Then

remove the rod.

c»

Remove the low- and second-speed gearshift rod

in

the same manner.

d.

Remove the gearshift rod lock balls and springs

and.

with a piece of

wire,

push the two gearshift rod

interlock

plungers out of the pockets in the center

section of the gearshift base.

In

the reverse gearshift rod end is a spring-loaded

plunger which prevents the

driver

from accidentally

shifting into reverse gear. Should this part require

servicing,

proceed as follows:

Remove the cotter key from the rod end assembly

and

at the same time hold a finger over the

hole

to prevent

loss

of the spring.

Then

shake out the

spring

and

ball.

Compress the plunger and spring

until

the C-washer

groove

just clears the end of

the casting. Remove the C-washer.

J1-5.

4-speed

Transmission Reassembly •

Refer to Fig. Jl-1.

Assemble the unit in the reverse order of dis

assembly noting the following points:

a.

Assemble the countershaft assembly with the

fabricated

dummy shaft. The bronze front thrust

washer

and the steel backed bronze

rear

thrust

washer

should be coated with stiff lubricant and

installed

with the lugs

engaged

in the notches

in

the end of the gear cluster. Place the assembly

in

the transmission case and install the counter

shaft from the

rear,

keeping the countershaft and

dummy shaft in contact to prevent dropping

bearing

rollers or washers. Tap the countershaft

lightly into position in the front of the case but

do not seat it until the reverse idler gear assembly

and

shaft have been installed in the case.

b.

Install

the reverse idler gear shaft in the case

until

the lock plate slot is adjacent to the slot in

the countershaft. Insert the lock plate in the

slots

of the shafts making sure the plate ends are square

with

the slots.

Install

the lock plate screw and

lockwasher

to act as a pilot while tapping the

shafts alternately into position in the case. Tighten

the lock plate screw securely.

c.

Begin assembly of the second speed synchronizer assembly (see

Fig.

Jl-6) by installing the low-and

-

second-speed clutch hub in the low-and-second-

speed gear.

Install

the retaining ring in the speed gear.

Install

the retaining ring in the low and

FIG.

Jl

-6—ASSEMBLING

SECOND-SPEED

SYNCHRONIZER

1—

Low

and Second

Clutch

Gear

2—

Ball

3—

Low

and Second

Clutch

Hub

4—

Shifting

Plate

second speed gear. Slide the hub out of the gear

in

the direction

opposite

the shift fork

groove

until

the

holes

in the hub are clear of the gear.

Install

the shifter plates and springs. Push the

hub back into the gear until the springs touch the

internal

teeth

of the gear. Push one of the shifter

plates toward the center of the gear while installing

ball.

See

Fig.

Jl-6 .

This

will

hold the

ball

in position.

Install

the other two balls in the same manner.

Be

careful when rotating the assembly to prevent the hub from slipping out of the gear. When the

balls

are installed, push the hub into the gear

until

the balls snap into the neutral position.

d.

Assemble the

direct

-

and

-

third

synchronizer as

sembly in accordance with the instructions given

in

Section J, Par.

J-lle.

e.

Start

assembly of the mainshaft assembly by 263

Page 264 of 376

Jl

FOUR-SPEED TRANSMISSION

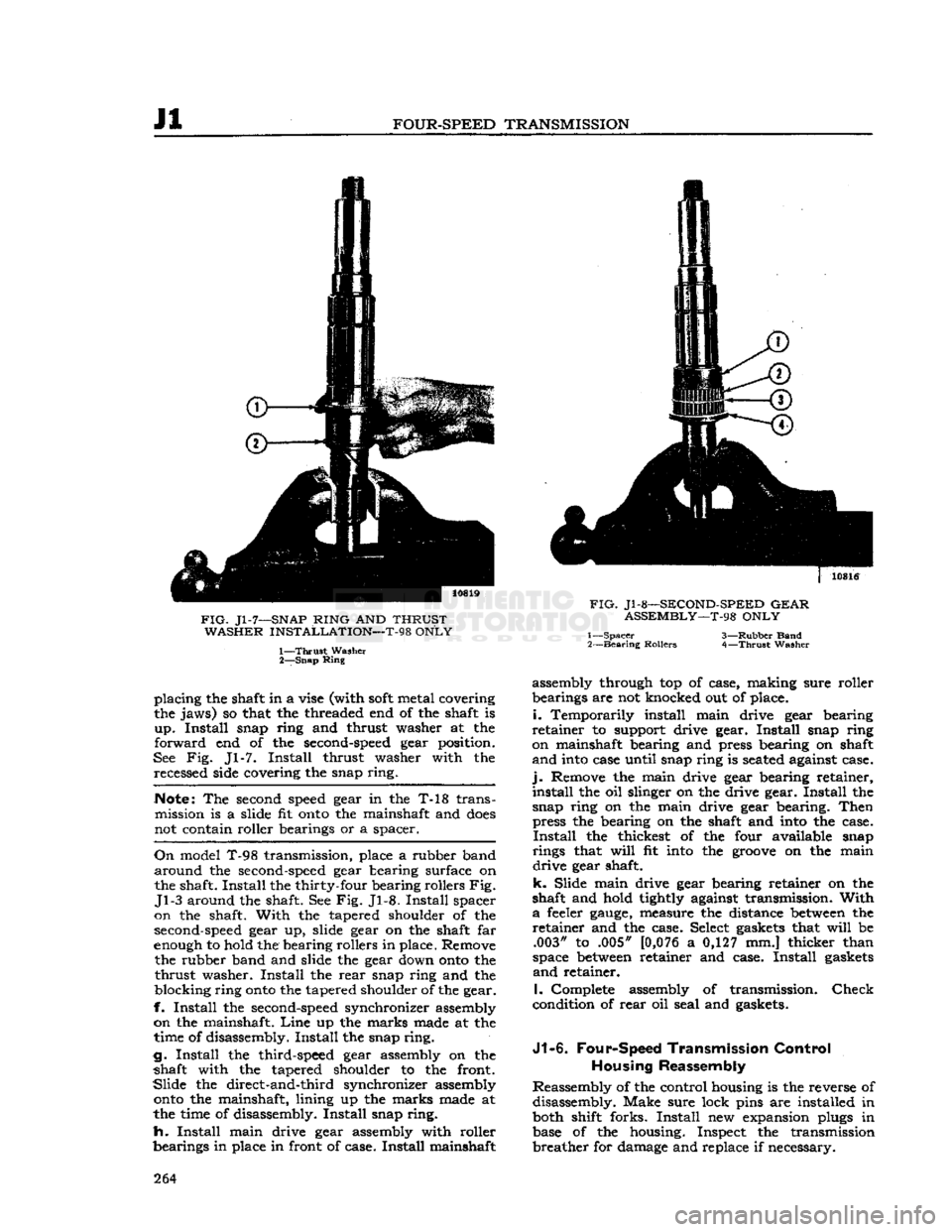

FIG.

Jl-7—SNAP

RING

AND

THRUST WASHER INSTALLATION—T-98 ONLY

1—

Thrust

Washer

2—

Snap

Ring

placing

the shaft in a vise (with

soft

metal covering the jaws) so that the threaded end of the shaft is

up.

Install

snap ring and thrust washer at the

forward

end of the

second-speed

gear position.

See Fig. Jl-7.

Install

thrust washer with the recessed side covering the snap

ring.

Note:

The second

speed

gear in the T-18 trans mission is a slide fit

onto

the mainshaft and

does

not contain roller bearings or a spacer.

On

model T-98 transmission, place a rubber band

around

the

second-speed

gear bearing surface on

the shaft.

Install

the thirty-four bearing rollers Fig.

Jl-3

around the shaft. See Fig. Jl-8.

Install

spacer on the shaft.

With

the tapered shoulder of the

second-speed

gear up, slide gear on the shaft far

enough

to hold the bearing rollers in place. Remove the rubber band and slide the gear down

onto

the

thrust

washer.

Install

the

rear

snap ring and the

blocking ring

onto

the tapered shoulder of the gear.

f.

Install

the

second-speed

synchronizer assembly

on the mainshaft.

Line

up the marks made at the

time of disassembly.

Install

the snap

ring.

g.

Install

the third-speed gear assembly on the

shaft with the tapered shoulder to the front.

Slide

the direct-and-third synchronizer assembly

onto

the mainshaft, lining up the marks made at

the time of disassembly.

Install

snap

ring.

h.

Install

main drive gear assembly with roller

bearings in place in front of case.

Install

mainshaft

FIG.

Jl-8—SECOND-SPEED

GEAR

ASSEMBLY—T-98 ONLY

1—

Spacer

3—Rubber

Band

2—

Bearing

Rollers

4—Thrust

Washer

assembly through top of case, making sure roller

bearings are not knocked out of place,

i.

Temporarily install main drive gear bearing

retainer

to support drive gear.

Install

snap ring on mainshaft bearing and press bearing on shaft

and

into case until snap ring is seated against case,

j-

Remove the main drive gear bearing retainer,

install

the oil slinger on the drive gear.

Install

the snap ring on the main drive gear bearing.

Then

press the bearing on the shaft and into the case.

Install

the thickest of the four available snap

rings that

will

fit into the

groove

on the main

drive

gear shaft.

k.

Slide main drive gear bearing retainer on the

shaft and hold tightly against transmission.

With

a

feeler

gauge,

measure the distance

between

the

retainer

and the case. Select gaskets that

will

be .003" to .005"

[0,076

a 0,127 mm.] thicker than

space

between

retainer and case.

Install

gaskets

and

retainer.

I.

Complete assembly of transmission.

Check

condition of

rear

oil seal and gaskets.

J1-6. Four-Speed

Transmission Control

Housing Reassembly

Reassembly of the control housing is the reverse of disassembly. Make sure lock pins are installed in

both shift forks.

Install

new expansion plugs in base of the housing. Inspect the transmission

breather

for damage and replace if necessary. 264

Page 265 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Jl

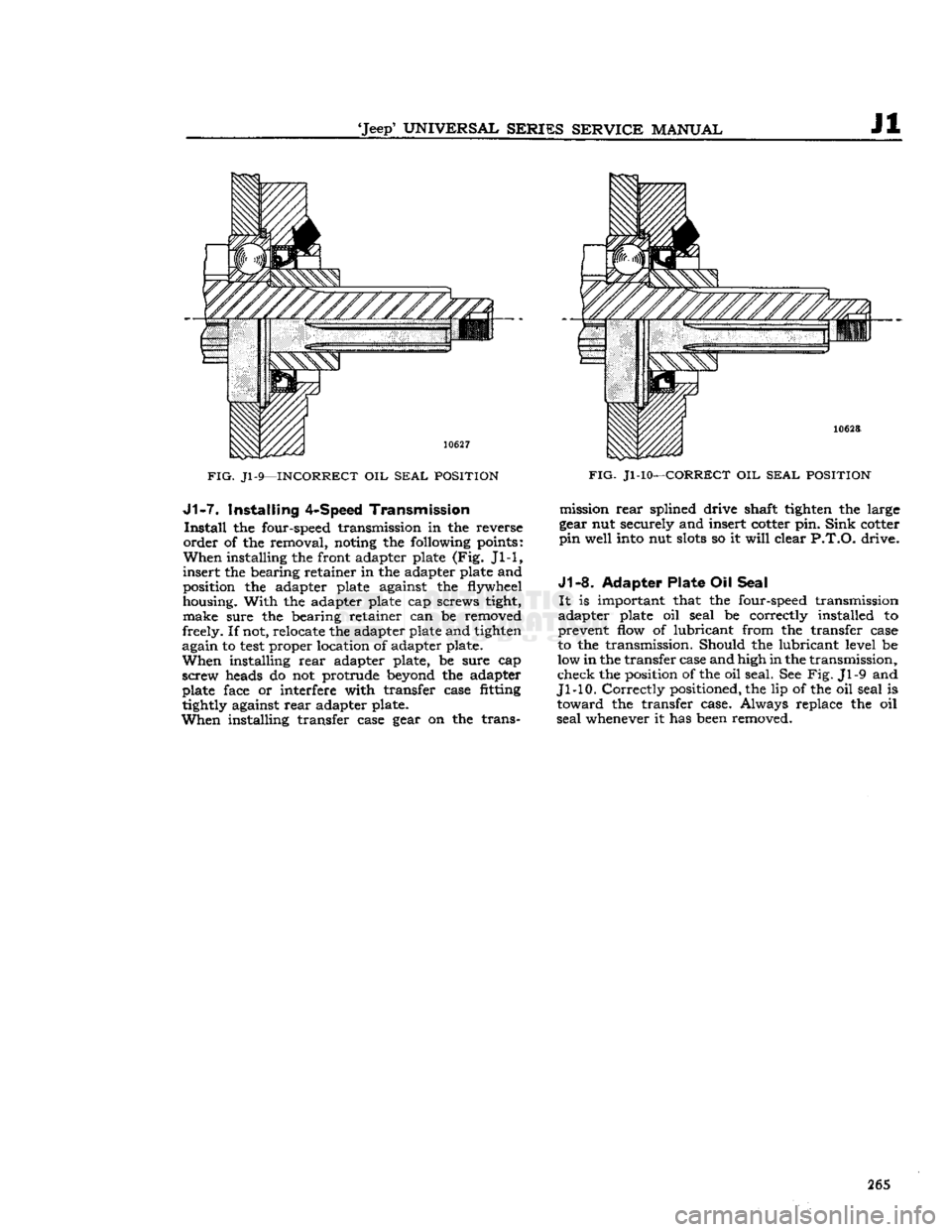

FIG.

Jl-9—INCORRECT

OIL

SEAL POSITION J1-7.

Installing

4-Speed

Transmission

Install

the four-speed transmission in the reverse

order

of the removal, noting the following points:

When

installing the front adapter plate (Fig. Jl-1,

insert

the bearing retainer in the adapter plate and

position the adapter plate against the flywheel

housing.

With

the adapter plate cap screws tight, make sure the bearing retainer can be removed

freely. If not, relocate the adapter plate and tighten

again to

test

proper location of adapter plate.

When

installing

rear

adapter plate, be sure cap

screw heads do not protrude beyond the adapter

plate face or interfere with transfer case fitting

tightly against

rear

adapter plate.

When

installing transfer case gear on the trans-

FIG.

Jl-10—CORRECT

OIL

SEAL POSITION

mission

rear

splined drive shaft tighten the large

gear nut securely and insert cotter pin.

Sink

cotter

pin

well into nut

slots

so it

will

clear

P.T.O.

drive.

J1-8.

Adapter Plate

Oil

Seal

It

is important that the four-speed transmission

adapter plate oil seal be correctly installed to

prevent flow of lubricant from the transfer case

to the transmission. Should the lubricant level be

low in the transfer case and high in the transmission,

check the position of the oil seal. See Fig. Jl-9 and

Jl-10.

Correctly

positioned, the lip of the oil seal is

toward

the transfer case. Always replace the oil

seal

whenever it has been removed. 265

Page 266 of 376

Jl

FOUR-SPEED

TRANSMISSION

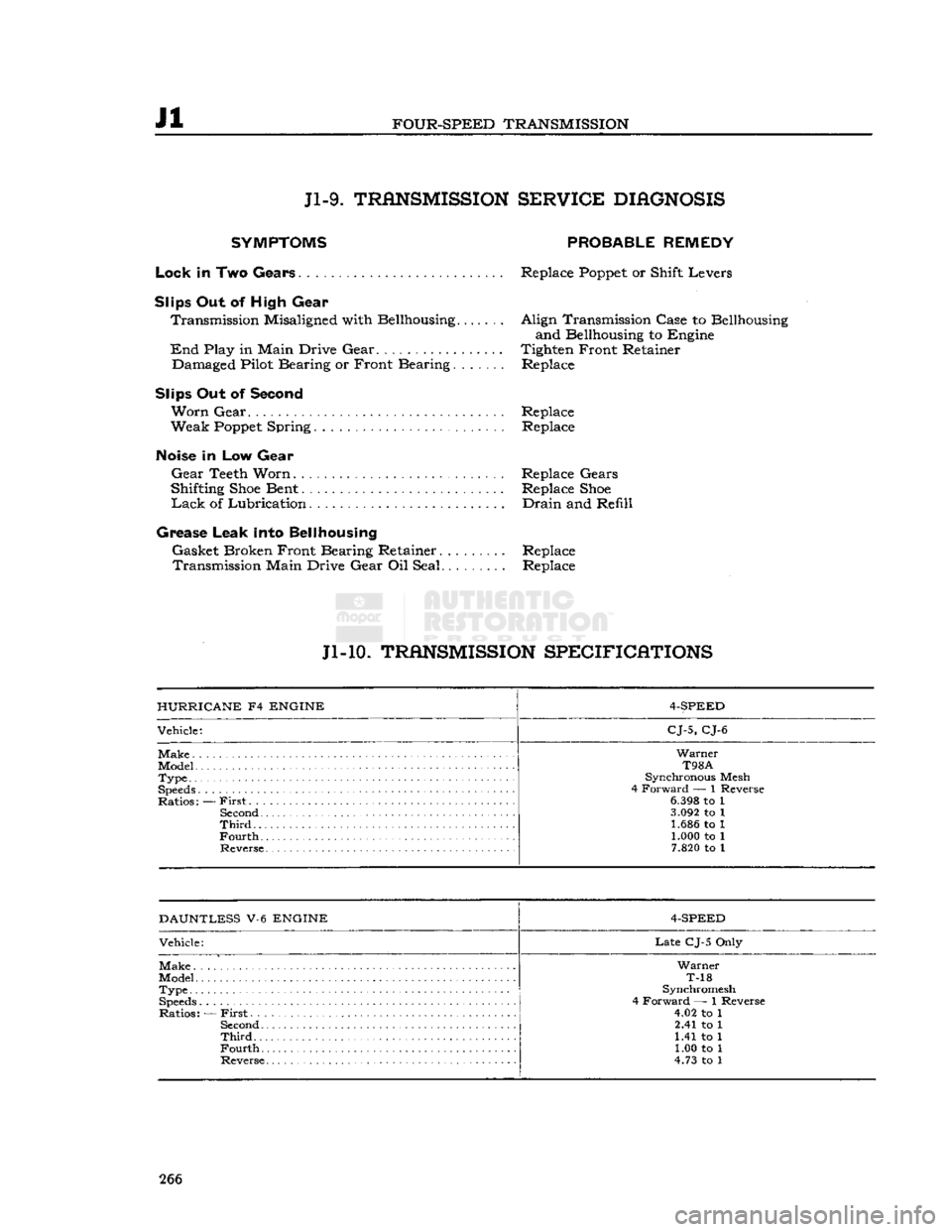

Jl-9.

TRANSMISSION

SER¥ICE

DIAGNOSIS

SYMPTOMS

Lock

In Two Gears

Slips

Out of High Gear Transmission Misaligned with Bellhousing

End

Play in Main Drive Gear Damaged Pilot Bearing or Front Bearing.

Slips Out of

Second

Worn

Gear

Weak

Poppet

Spring

PROBABLE

REMEDY

Replace

Poppet

or Shift Levers

Align Transmission Case to Bellhousing and Bellhousing to Engine

Tighten Front Retainer Replace

Replace Replace

Noise

in Low Gear

Gear

Teeth Worn. Replace Gears

Shifting

Shoe

Bent Replace

Shoe

Lack

of Lubrication Drain and Refill

Grease

Leak into Bellhousing Gasket Broken Front Bearing Retainer......... Replace Transmission Main Drive Gear Oil Seal Replace

Jl-10.

TRANSMISSION

SPECIFICATIONS

HURRICANE

F4

ENGINE

4-SPEED

Vehicle:

CJ-5,

CJ-6

Warner

T98A

Type..

• Synchronous Mesh

4 Forward — 1 Reverse

Ratios: —

First

. .

6.398

to 1

Second

3.092

to 1

Third

1.686 to 1

Fourth

1.000 to 1

7.820

to 1

DAUNTLESS

V-6

ENGINE

4-SPEED

Vehicle:

Late

CJ-5 Only

Warner

Model T-18

Type Synchromesh

4 Forward — 1 Reverse

Ratios: —

First

4.02 to 1

Second

2.41 to 1

Third

1.41 to 1

Fourth

1.00 to 1

Reverse 4.73 to 1 266

Page 267 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

ft

TRANSFER CASE

Contents

SUBJECT

PAR.

GENERAL

. . .K-1

TRANSFER CASE REMOVAL

K-2

TRANSFER CASE DISASSEMBLY

K-3

Front

Bearing Cap K-4

Rear

Bearing Cap K-5

TRANSFER CASE REASSEMBLY.

. .K-6

TRANSFER CASE INSTALLATION

K-7

TRANSFER CASE LINKAGE

ADJUSTMENT

K-8

SERVICE

DIAGNOSIS

K-9

SPECIFICATIONS

.K-10

K-1. GENERAL

All

4-wheel-drive models are equipped with a

transfer

case to connect the power to the front

axle.

It is essentially a

two-speed

transmission

located at the

rear

of the standard transmission

and

provides a low and direct gear.

The

transfer case gears are controlled by the

driver

through

one shift lever.

Early

'Jeep'

Universal

Models with the F4-134

Hurricane

engine

are equipped with two transfer case shift control levers.

a.

On vehicles equipped with one transfer case

shift

lever, the transfer case shift lever has four

positions: 2WD

High,

4WD

High,

Neutral, and

4WD

low. The forward position of the lever 2WD

High

allows the

rear

wheels only to drive. The

first

rear

position (4WD High)

engages

the 4- wheel drive and provides high range 4-wheel drive.

The

second

rear

position (Neutral)

disengages

all power to the wheels and is used for stationary

power take-off operations. The last

rear

position

(4WD

Low) provides low range 4-wheel drive.

b.

On vehicles equipped with two transfer case

shift

levers, the transfer case front axle drive lever (left hand lever)

gives

a choice of 2-wheel or 4-

wheel drive. In the forward (out) position the

vehicle is in 2-wheel drive. Move the lever to the

rear

(in) position for 4-wheel drive operation.

The

4-wheel-drive

auxiliary-range

shift lever (right

hand

lever) has three positions; low, neutral, and

high.

The forward position (low)

gives

low-range

4-wheel drive. The center position (neutral) dis

engages

all power to the wheels and is used for

stationary

power take-off operations. A built-in in

terlock

prevents shifting into low range, 2-wheel

drive.

This

feature protects the

rear

axle from over

load.

K-2.

Removal of

Transfer

Case

The

transfer case may be removed from the vehicle

without removing the transmission. Where both

transmission

and transfer case are to be removed

together,

refer to Section J. To remove only the

transfer

case from the vehicle, proceed as follows:

a.

Drain

transmission

and transfer case and replace

drain

plugs.

b.

Disconnect the brake cable.

c.

Disconnect front and

rear

propeller shafts at

the transfer case. See "Propeller Shafts and

Uni

versal

Joints."

d.

Disconnect

speedometer

cable at transfer case. e. Disconnect the transfer case shift levers. On

vehicles equipped with two shift levers

loosen

set screw and remove pivot pin. Use a screw

driver

to pry shift lever springs away from shift levers.

Lift

levers from transfer case. On models equipped

with

a single shift lever remove pivot pin cotter

key,

and the adjusting rod attaching nut to remove

shift

lever. See Fig. K-4.

f. Remove cover plate on

rear

face of transfer case.

Remove

cotter key, nut and washer from trans

mission

main shaft.

g. If possible, at this point remove the transfer case main drive gear from the transmission main

shaft.

If not possible, see

step

j below.

h.

Remove transfer case torque reaction support

bracket

bolt and nut.

i.

Remove transmission to transfer case bolts.

j.

Remove transfer case. If the transfer case main

drive

gear has not been removed in

step

g above,

proceed as follows:

Brace

the end of the trans

mission

main shaft so that it cannot

move

in the

transmission,

pull

the transfer case to the

rear

to 267

Page 268 of 376

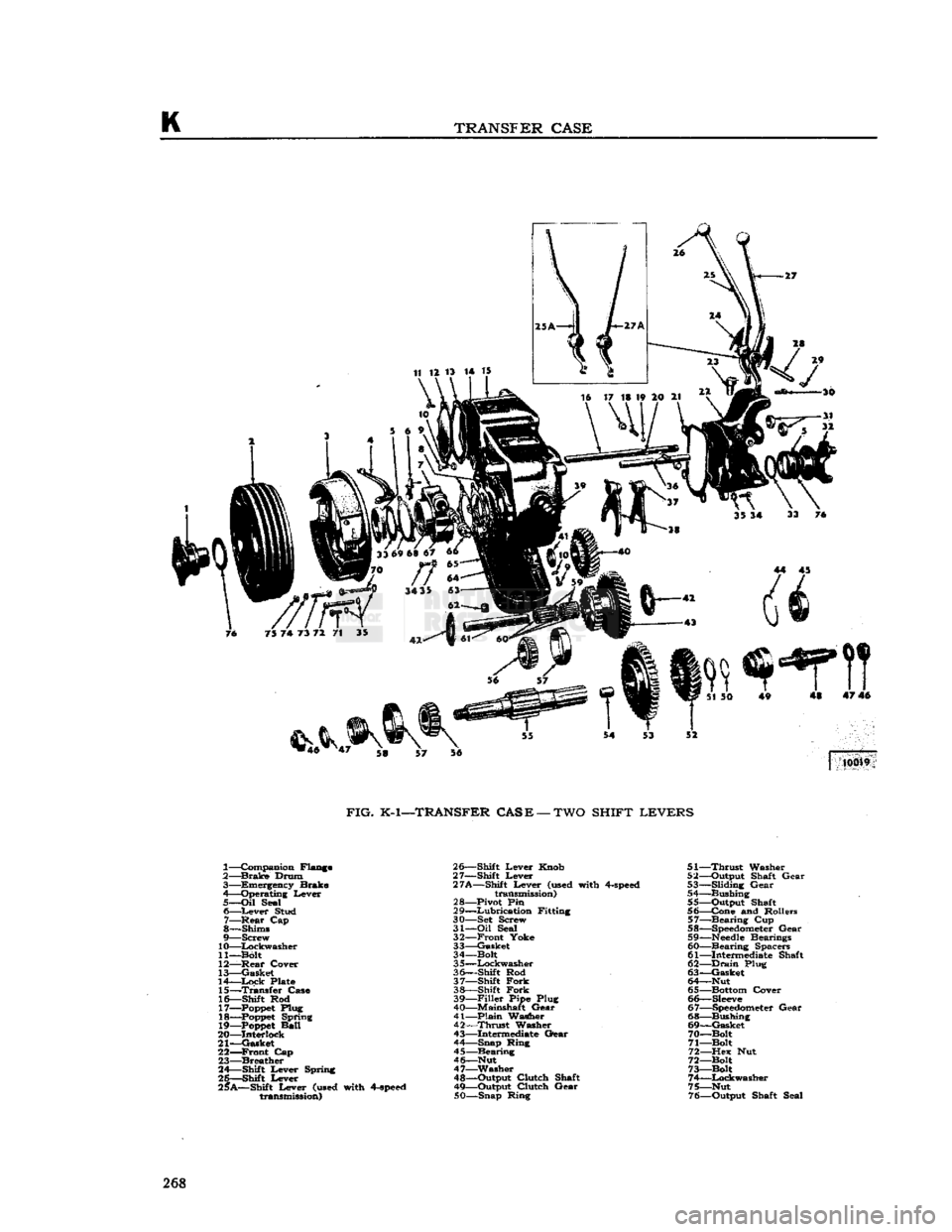

TRANSFER

CASE

FIG.

K-1—TRANSFER

CASE

—

TWO

SHIFT

LEVERS

1— Companion Flange

2—

Brake

Drum 3— Emergency Brake

4—Operating Lever

5—

Oil

Seal 6—

Lever

Stud 7—

-Rear

Cap

8— Shims

9—

Screw

10—

Lockwasher

11— Bolt

12—

-Rear

Cover

13—

Gasket

14—

Lock

Plate

15—

Transfer

Case

16— Shift Rod 17—

Poppet

Plug

18—Poppet

Spring 19—

Poppet

Ball

20— Interlock

21—Gasket 22—

Front

Cap

23—

Breather

24— Shift Lever Spring

26—Shift

Lever

25*A—Shift Lever

(used

with

4-speed

transmission) 26— Shift Lever Knob

27— Shift Lever

27A—Shift Lever

(used

with

4-speed

transmission)

28—

Pivot

Pin

29—

Lubrication

Fitting

30— Set Screw

31—

Oil

Seal 32—

Front

Yoke

33—

Gasket

34— Bolt

3

5—Lockwasher

36— Shift Rod

37—

Shift

Fork

38— Shift

Fork

39—

Filler

Pipe Plug

40—Mainshaft Gear 41— plain Washer

42—

Thrust

Washer

43—

Intermediate

Gear

44—

Snap Ring

45—

Bearing

46—

Nut 47— Washer

48— Output Clutch Shaft

49—

Output Clutch Gear

50— Snap Ring 51—

Thrust

Washer

52— Output Shaft Gear

53— Sliding Gear

54— Bushing

55— Output Shaft

56— Cone and Rollers

57—

Bearing

Cup

58—

Speedometer

Gear 59—

Needle

Bearings 60—Bearing Spacers

61—

Intermediate

Shaft

62—

Drain

Plug 63—

Gasket

64—Nut

65—

Bottom

Cover

66—

Sleeve

67—

Speedometer

Gear 68— Bushing

69—

Gasket

70— Bolt

71—Bolt

72—

Hex Nut

72— Bolt

73— Bolt

74—

Lockwasher

75— Nut

76— Output Shaft Seal 268

Page 269 of 376

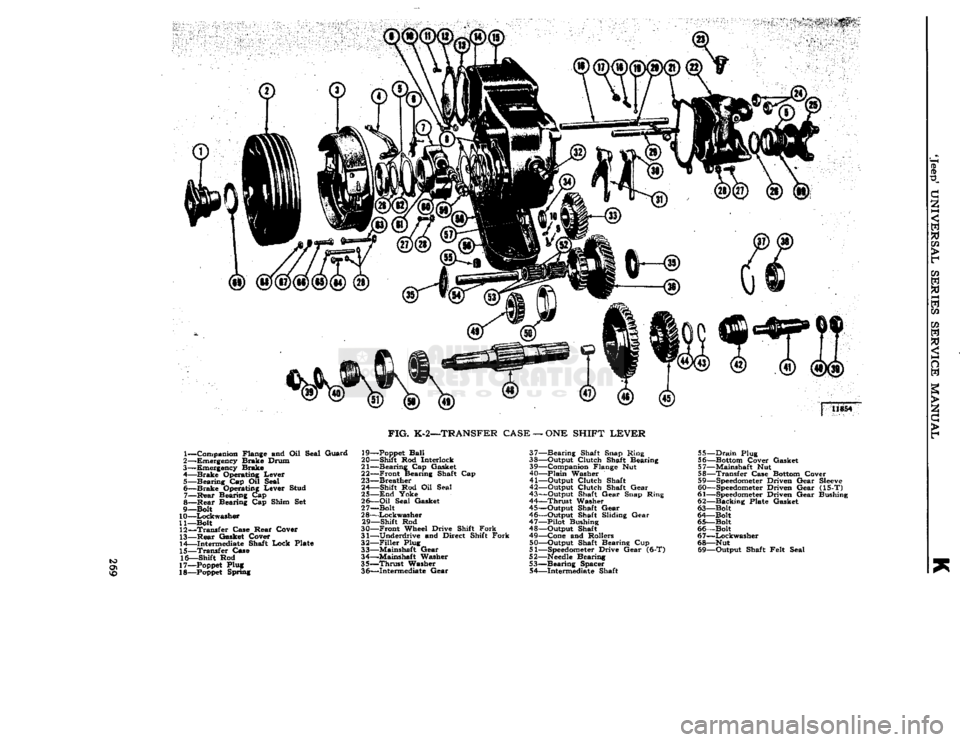

FIG.

K-2—TRANSFER CASE

— ONE

SHIFT

LEVER

1— Companion Flange and Oil Seal

Guard

2— Emergency Brake Drum

3— Emergency Brake 4—

Brake

Operating Lever

5—

Bearing

Cap Ofl Seal 6—

Brake

Operating Lever Stud 7—

Rear

Bearing Cap

8—

Rear

Bearing Cap Shim Set

9— Bolt

10—

Lockwasher

11— Bolt 12—

Transfer

Case Hear Cover

13—

Rear

Gasket Cover 14—

Intermediate

Shaft

Lock

Plate

15—

Transfer

Case

1G—Shift

Rod

17—

Poppet

Plug

18—

Poppet

Spring 19—

Poppet

Ball

20— Shift Rod Interlock

21—

Bearing

Cap Gasket

22—

Front

Bearing Shaft Cap

23—

Breather

24— Shift Rod Oil Seal

25—

End

Yoke

26—

Oil

Seal Gasket

27— Bolt

2 8—Lockwasher 29— Shift Rod

30—

Front

Wheel Drive Shift

Fork

31— Underdrive and Direct Shift

Fork

32—

Filler

Plug 33— Mainshaft

Gear

34— Mainshaft Washer 35—

Thrust

Washer

36—

Intermediate

Gear

37—

Bearing

Shaft Snap Ring

38— Output Clutch Shaft Bearing

39— Companion Flange Nut

40—

Plain

Washer

41— Output Clutch Shaft

42— Output Clutch Shaft

Gear

43— Output Shaft

Gear

Snap Ring

44—

Thrust

Washer

45— Output Shaft

Gear

46— Output Shaft Sliding

Gear

47—

Pilot

Bushing

48— Output Shaft

49— Cone and Rollers 50— Output Shaft Bearing Cup

51—

Speedometer

Drive

Gear

(6-T)

52—

Needle

Bearing 53—

Bearing

Spacer 54—

Intermediate

Shaft 55—

Drain

Plug

56—

Bottom

Cover Gasket

57— Mainshaft Nut

58—

Transfer

Case

Bottom

Cover

59—

Speedometer

Driven

Gear

Sleeve

60—

Speedometer

Driven

Gear

(15-T)

61—

Speedometer

Driven

Gear

Bushing

62—

Backing

Plate

Gasket

63— Bolt

64— Bolt

65— Bolt

66— Bolt

67—

Lockwasher

68— Nut 69— Output Shaft Felt Seal

Page 270 of 376

K

TRANSFER

CASE

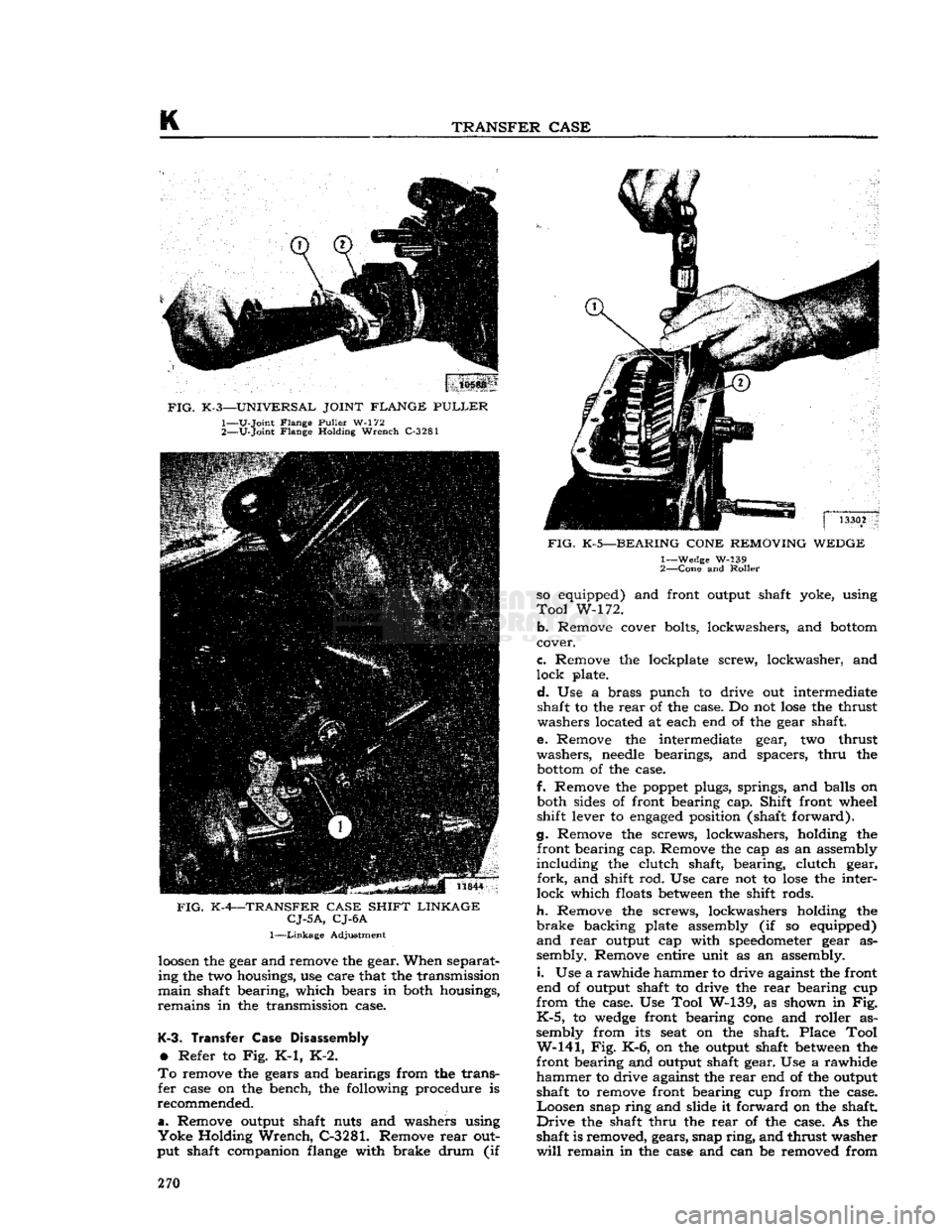

FIG.

K-3—UNIVERSAL JOINT FLANGE

PULLER

1—

U-Joint

Flange

Puller

W-172

2—

V-Joint

Flange Holding

Wrench

C-3281

FIG.

K-4—TRANSFER CASE SHIFT LINKAGE

CJ-5A,

CJ-6A

1—Linkage

Adjustment

loosen

the gear and remove the gear. When separat

ing the two housings, use care that the transmission

main

shaft bearing, which bears in both housings,

remains

in the transmission case.

K-3.

Transfer

Case

Disassembly

•

Refer to Fig. K-1, K-2.

To

remove the gears and bearings from the trans

fer

case on the bench, the following procedure is

recommended.

a.

Remove output shaft nuts and washers using

Yoke

Holding

Wrench,

C-3281. Remove

rear

out

put shaft companion flange with brake drum (if

FIG.

K-5—BEARING CONE REMOVING WEDGE

1— Wedge W-139

2—

Cone

and

Roller

so equipped) and front output shaft yoke, using

Tool

W-172.

b.

Remove cover bolts, lockwashers, and

bottom

cover.

c.

Remove the lockplate screw, lockwasher, and

lock

plate.

d.

Use a brass punch to drive out intermediate shaft to the

rear

of the case. Do not

lose

the thrust

washers located at each end of the gear shaft.

e. Remove the intermediate gear, two thrust

washers,

needle

bearings, and spacers,

thru

the

bottom

of the case.

f. Remove the

poppet

plugs, springs, and balls on both sides of front bearing cap. Shift front wheel

shift lever to

engaged

position (shaft forward).

g. Remove the screws, lockwashers, holding the front bearing cap. Remove the cap as an assembly

including

the clutch shaft, bearing, clutch gear,

fork,

and shift rod. Use care not to

lose

the inter

lock

which floats

between

the shift rods.

h.

Remove the screws, lockwashers holding the

brake

backing plate assembly (if so equipped)

and

rear

output cap with

speedometer

gear as

sembly. Remove entire unit as an assembly.

i.

Use a rawhide hammer to drive against the front

end of output shaft to drive the

rear

bearing cup

from

the case. Use Tool W-139, as shown in Fig.

K-5,

to

wedge

front bearing

cone

and roller as

sembly from its seat on the shaft. Place Tool

W-141,

Fig. K-6, on the output shaft

between

the

front bearing and output shaft gear. Use a rawhide

hammer

to drive against the

rear

end of the output shaft to remove front bearing cup from the case.

Loosen

snap ring and slide it forward on the shaft.

Drive

the shaft

thru

the

rear

of the case. As the shaft is removed, gears, snap

ring,

and thrust washer

will

remain in the case and can be removed from 270