LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1331 of 1672

CORROSION PREVENTION AND SEALING

77-4-16 SEALING

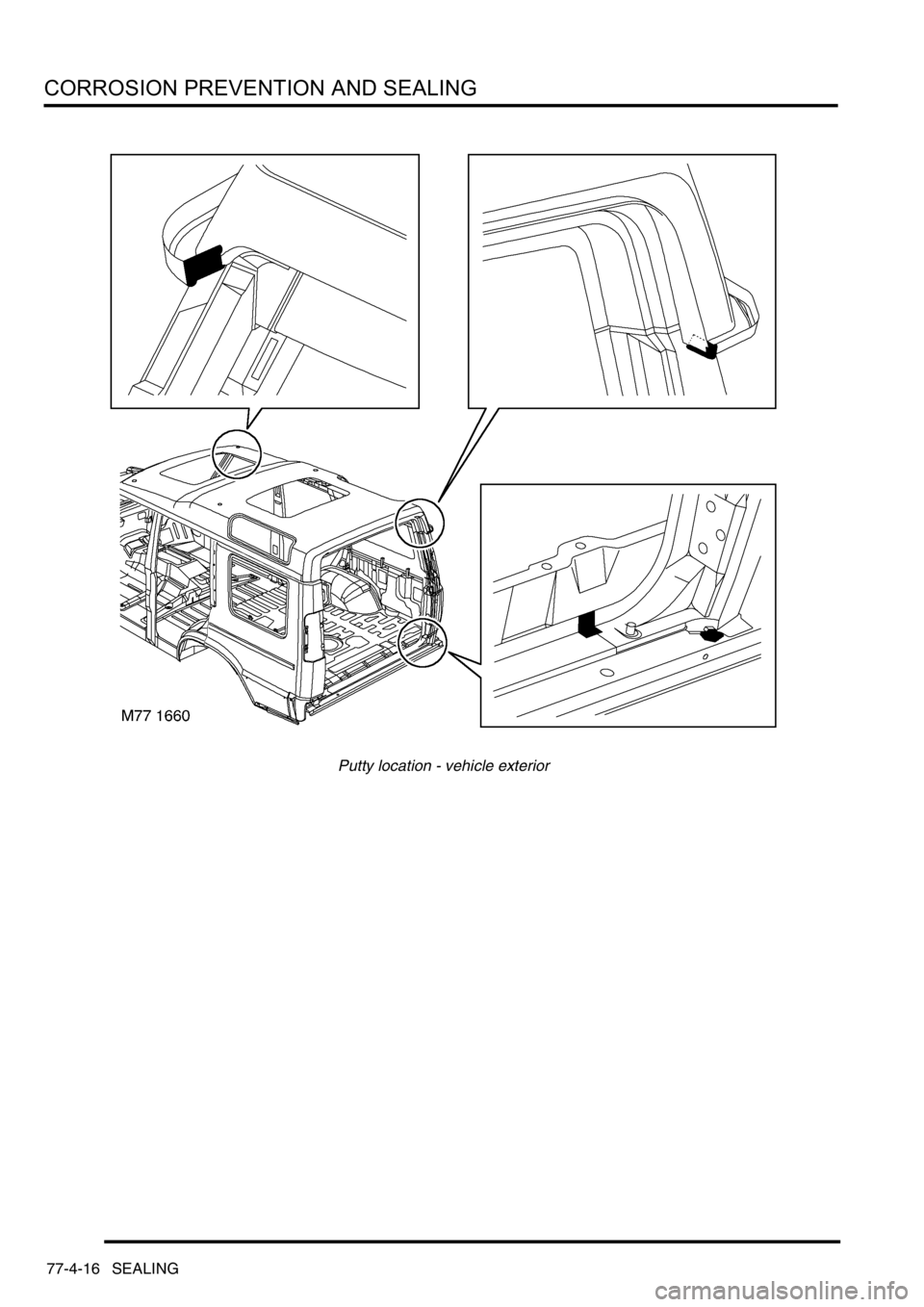

Putty location - vehicle exterior

Page 1332 of 1672

CORROSION PREVENTION AND SEALING

SEALING 77-4-17

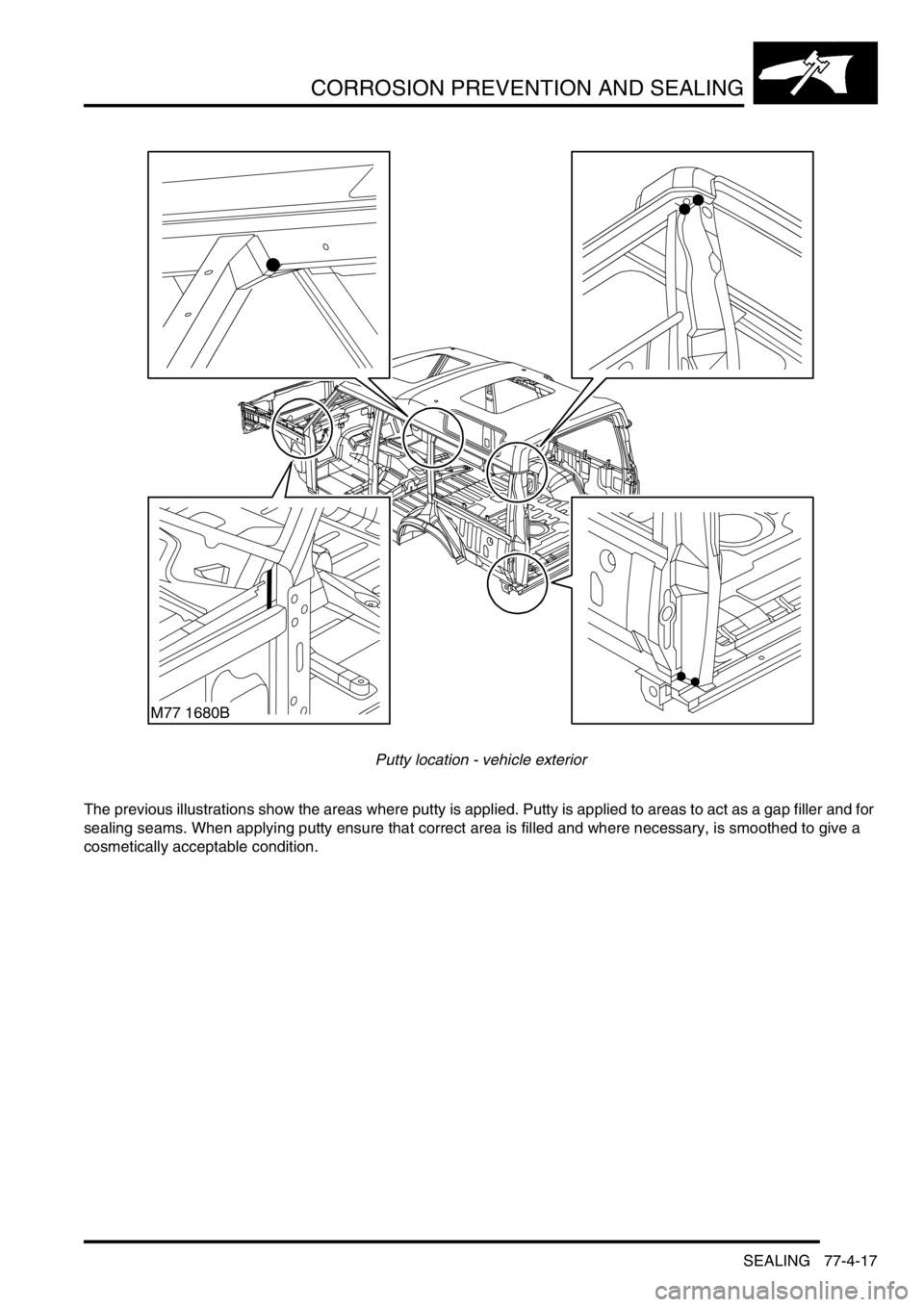

Putty location - vehicle exterior

The previous illustrations show the areas where putty is applied. Putty is applied to areas to act as a gap filler and for

sealing seams. When applying putty ensure that correct area is filled and where necessary, is smoothed to give a

cosmetically acceptable condition.

M77 1680B

Page 1333 of 1672

CORROSION PREVENTION AND SEALING

77-4-18 SEALING

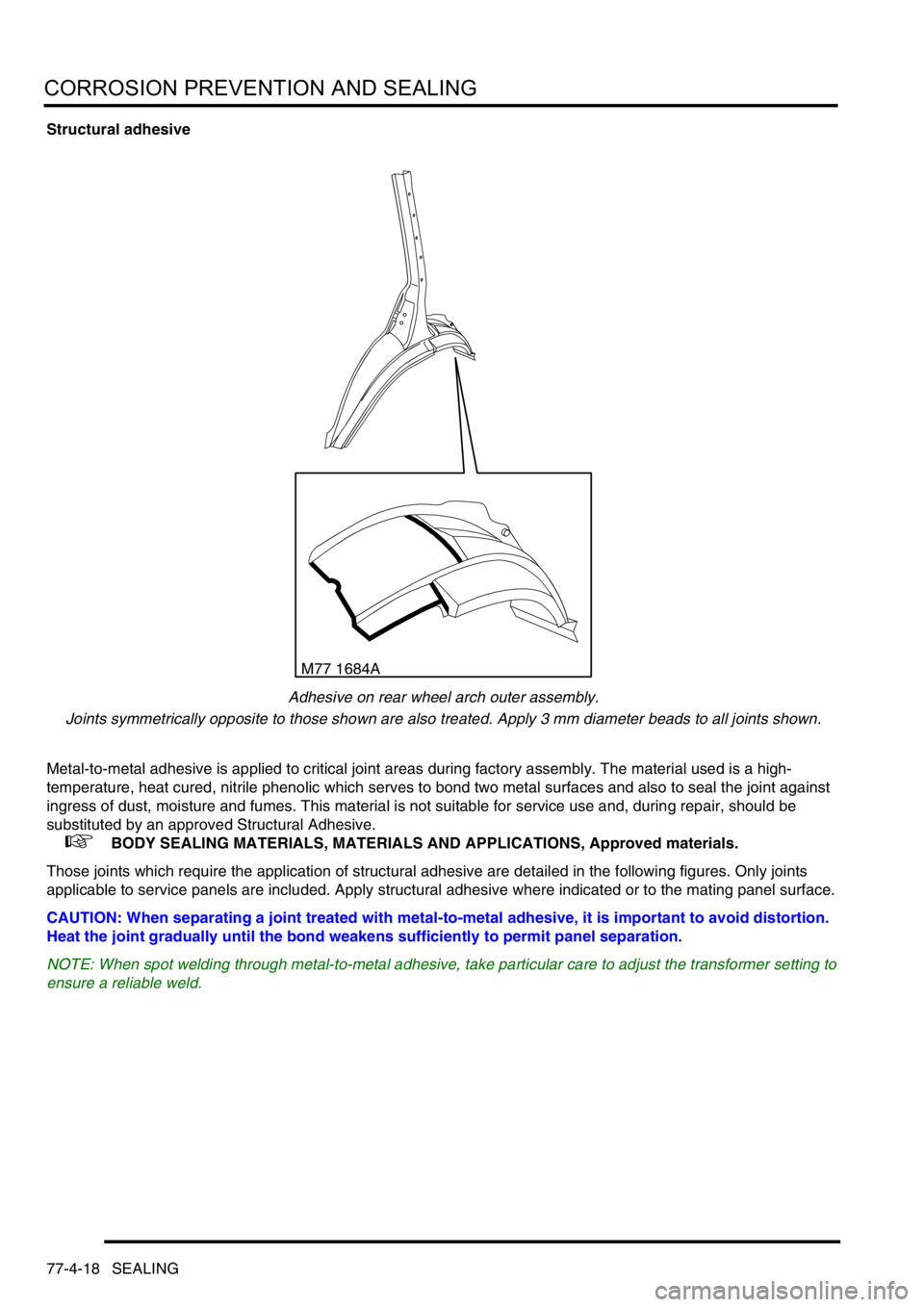

Structural adhesive

Adhesive on rear wheel arch outer assembly.

Joints symmetrically opposite to those shown are also treated. Apply 3 mm diameter beads to all joints shown.

Metal-to-metal adhesive is applied to critical joint areas during factory assembly. The material used is a high-

temperature, heat cured, nitrile phenolic which serves to bond two metal surfaces and also to seal the joint against

ingress of dust, moisture and fumes. This material is not suitable for service use and, during repair, should be

substituted by an approved Structural Adhesive.

+ BODY SEALING MATERIALS, MATERIALS AND APPLICATIONS, Approved materials.

Those joints which require the application of structural adhesive are detailed in the following figures. Only joints

applicable to service panels are included. Apply structural adhesive where indicated or to the mating panel surface.

CAUTION: When separating a joint treated with metal-to-metal adhesive, it is important to avoid distortion.

Heat the joint gradually until the bond weakens sufficiently to permit panel separation.

NOTE: When spot welding through metal-to-metal adhesive, take particular care to adjust the transformer setting to

ensure a reliable weld.

M77 1684A

Page 1334 of 1672

CORROSION PREVENTION AND SEALING

SEALING 77-4-19

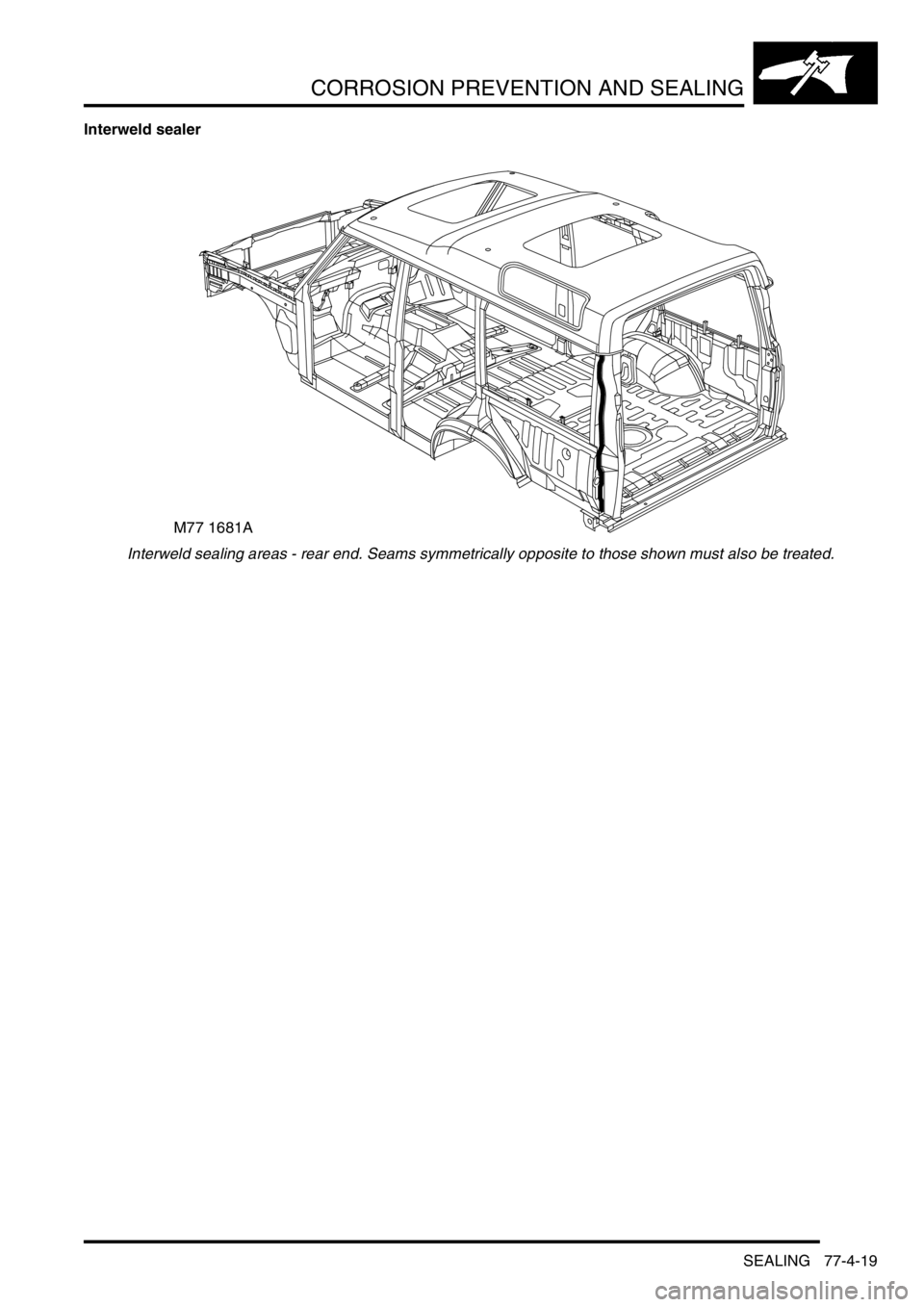

Interweld sealer

Interweld sealing areas - rear end. Seams symmetrically opposite to those shown must also be treated.

M77 1681A

Page 1335 of 1672

CORROSION PREVENTION AND SEALING

77-4-20 SEALING

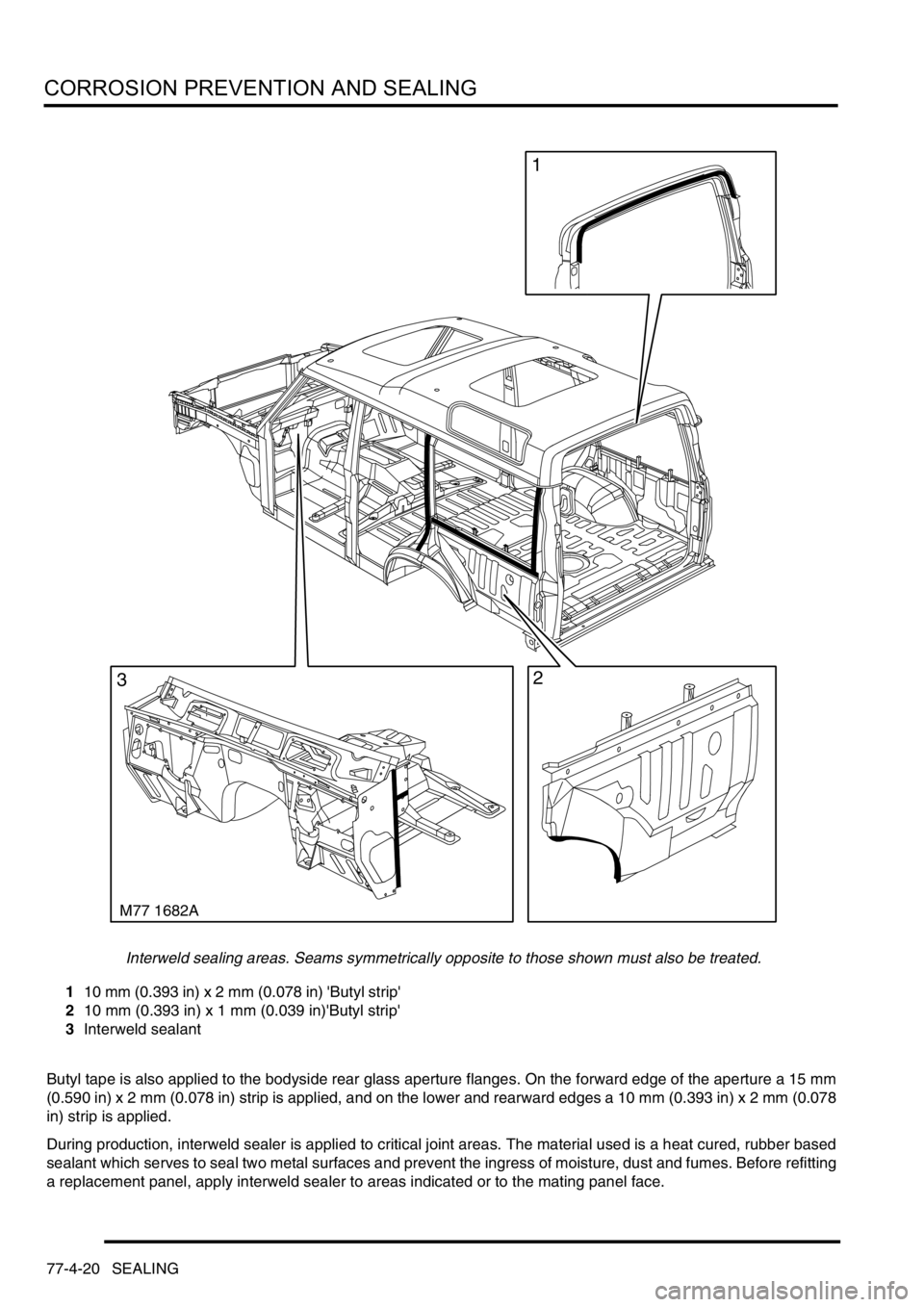

Interweld sealing areas. Seams symmetrically opposite to those shown must also be treated.

110 mm (0.393 in) x 2 mm (0.078 in) 'Butyl strip'

210 mm (0.393 in) x 1 mm (0.039 in)'Butyl strip'

3Interweld sealant

Butyl tape is also applied to the bodyside rear glass aperture flanges. On the forward edge of the aperture a 15 mm

(0.590 in) x 2 mm (0.078 in) strip is applied, and on the lower and rearward edges a 10 mm (0.393 in) x 2 mm (0.078

in) strip is applied.

During production, interweld sealer is applied to critical joint areas. The material used is a heat cured, rubber based

sealant which serves to seal two metal surfaces and prevent the ingress of moisture, dust and fumes. Before refitting

a replacement panel, apply interweld sealer to areas indicated or to the mating panel face.

M77 1682A

1

23

Page 1336 of 1672

CORROSION PREVENTION AND SEALING

SEALING 77-4-21

Those joints which require the application of interweld sealers are detailed in the previous illustrations. Only joints

applicable to service panels are included.

Page 1337 of 1672

CORROSION PREVENTION AND SEALING

77-4-22 SEALING

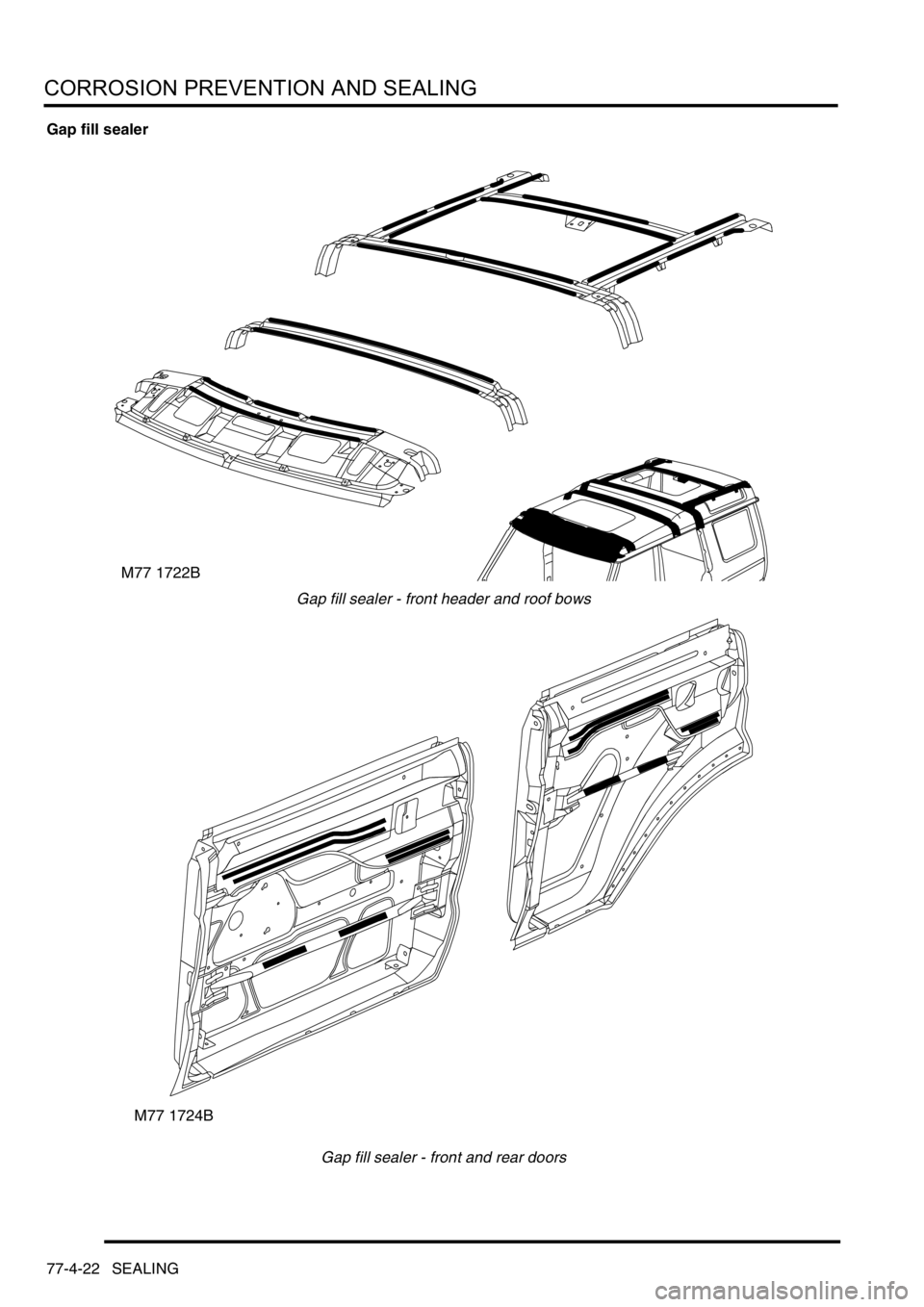

Gap fill sealer

Gap fill sealer - front header and roof bows

Gap fill sealer - front and rear doors

M77 1722B

M77 1724B

Page 1338 of 1672

CORROSION PREVENTION AND SEALING

SEALING 77-4-23

The previous illustrations show the areas where gap-fill (anti-flutter) sealer is applied. The material bonds two surfaces

together but allows for a certain amount of movement between the two bonded surfaces.

Page 1339 of 1672

CORROSION PREVENTION AND SEALING

77-4-24 SEALING

Water leaks

Where water leakage is involved, always adopt a logical approach to the problem using a combination of skill,

experience and intuition. Do not reach a conclusion based only on visual evidence, such as assuming that a wet

footwell is caused by a leak emanating from the windscreen. It will often be found that the source of the leak is

elsewhere. Use of the correct procedure will increase the chance of locating a leak, however obscure it may seem.

Tools and equipment

The following tools and equipment are recommended for the purpose of detection and rectification of water leaks:

1Garden sprayer (hand-operated)

2Wet/dry vacuum cleaner

3Dry, absorbent cloths

4Battery torch

5Small mirror

6Weatherstrip locating tool

7Trim panel remover

8Small wooden or plastic wedges

9Dry compressed air supply

10Hot air blower

11Sealer applicators

12Ultrasonic leak detector

During leak detection, the vehicle should be considered in three basic sections:

lThe front interior space;

lThe rear passenger space;

lThe loadspace or boot.

Testing

From the information supplied by the customer it should be possible for the bodyshop operator to locate the starting

point from which the leak may be detected. After the area of the leak has been identified, find the actual point of entry

into the vehicle.

A simple and effective means in the first instance is an ordinary garden spray with provision for pressure and jet

adjustment, which will allow water to be directed in a jet or turned into a fine spray. Use a mirror and a battery-powered

torch (NOT a mains voltage inspection lamp) to see into dark corners.

The sequence of testing is particularly important. Start at the lowest point and work slowly upwards, to avoid testing

in one area while masking the leak in another. For example, if testing started at the level of the windscreen, any water

cascading into the plenum chamber could leak through a bulkhead grommet and into the footwells. Even at this point

it could still be wrongly assumed that the windscreen seal was at fault.

Another important part of identifying a water leak is by visual examination of door aperture seals, grommets and

weatherstrips for damage, deterioration or misalignment, together with the fit of the door itself against the seals.

Sealing

When the point of the leak has been detected, it will then be necessary to rectify it using the following procedure:

1Renew all door aperture seals and weatherstrips which have suffered damage, misalignment or deterioration

2Check all body seals to ensure that they are correctly located on their mounting flanges/faces using a lipping

tool if necessary

3Dry out body seams to be treated using compressed air and/or a hot air blower as necessary

4Apply sealant on the outside of the joint wherever possible to ensure the exclusion of water

5When rectifying leaks between a screen glass and it's weatherstrip (or in the case of direct glazing, between the

glass and bodywork), avoid removing the glass if possible. Apply the approved material at the appropriate

location (i.e. glass to weatherstrip or glass to body)

Page 1340 of 1672

PAINTING

PROCEDURES 77-5-1

PAINTING PROCEDURES

Panel preparation

General

Replacement panels are supplied with a cathodic primer coating as part of the panel protection and in compliance

with the vehicle's Corrosion Warranty, where applicable. DO NOT remove the primer before paint refinishing. In

the event of localised surface damage or imperfections, ensure that only the minimum of primer is removed

during rectification work for effective repair.

Rectify damage as far as possible by panel beating or straightening. To remove corrosion or paint runs on outer

surfaces, abrade the primer coat in the affected area as necessary, then follow the procedure below:

1Clean the panel using a solvent wipe

2Treat exposed areas of metal with an etch phosphate process

3Re-treat the affected area using either a separate acid-etch primer and two-pack surfacer, or an integrated etch

primer/filler

Panel preparation

The following procedures should be followed when repairing panels.

Welded panels

When replacing welded panels the following procedure must be observed:

1Remove primer from the immediate vicinity of new and existing panel flanges, cleaning to bright metal finish

2On joints to be spot welded, apply weld-through zinc rich primer to joint faces of both flanges. Make spot welds

while primer is still wet or according to the manufacturer's instructions

3Dress accessible weld joints

4Clean panel using solvent wipe

5Treat bare metal with an etch phosphate process

6Re-treat repaired areas

Sectioned panels

When replacing part or sectioned panels, the basic procedure is the same as for welded panels described above, with

the following variations:

1Remove primer from both new and existing joint faces, cleaning to a bright metal finish

2Where an overlap joint with the existing panel is to be spot welded, apply weld-through, zinc rich primer to both

joint faces and spot weld while the primer is still wet, or according to the manufacturer's instructions

3MIG weld butt joints where applicable

4Dress weld joints

5Clean the panel with a solvent wipe.

6Treat bare metal areas using an etch phosphate process

7Re-treat the affected area using either a separate acid-etch primer and two-pack surfacer, or an integrated etch

primer/filler

8Treat the inner faces of lap or butt joints with a suitable cavity wax

+ PANEL REPAIRS, PROCEDURES, Panel replacement procedure.

Clinched panels

When replacing clinched panels the following procedure must be observed:

1Abrade primer on new and existing panel joint faces, and clean using a solvent wipe

2Apply metal-to-metal adhesive where applicable

3Where joints are to be spot welded, apply suitable weld-through, zinc rich primer to weld areas

4Where joints are to be MIG, arc or gas welded, apply zinc rich primer in adjacent areas but leave the welded

area untreated

5To retain the panel while clinching the flanges, tack spot weld or plug weld as appropriate

6Clean the panel with a solvent wipe

7Treat bare metal areas with a suitable etch phosphate process

8Re-treat the affected area using either a separate acid-etch primer and two-pack surfacer, or an integrated etch

primer/filler