LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 191 of 1672

ENGINE - TD5

12-1-52 REPAIRS

5.Fit 2 upper bolts securing engine oil cooler pipe

and gearbox housing to engine and tighten to

50 Nm (37 lbf.ft) .

6.Lower engine onto mountings, and tighten nuts

to 85 Nm (63 lbf.ft) .

7.Remove tool LRT-12-138 from engine.

8.Fit and tighten bolt securing engine closing

panel to gearbox.

9.Raise vehicle on ramp.

10.Fit nuts and bolts securing engine LH and RH

mountings to chassis and tighten to 85 Nm (63

lbf.ft).

11.Fit remaining bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

12.Rotate crankshaft and align drive plate to

torque converter.

13.Using a magnetic socket, fit and tighten new

torque converter drive plate bolts to 50 Nm (37

lbf.ft) .

14.Fit front cross member and tighten bolts to 26

Nm (19 lbf.ft).

15.Align gearbox oil cooler pipes.

16.Fit oil cooler pipe clip and tighten bolts to 9 Nm

(7 lbf.ft).

17.Position gearbox oil cooler pipe clamps and

tighten nuts.

18.Position coolant rail and secure support bracket

in engine LH and RH mounting brackets.

19.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

20.Lower ramp.

21.Position coolant rail to front chassis member, fit

and tighten bolt to 10 Nm (7 lbf.ft).

22.Connect heater hose to coolant rail and secure

with clip.

23.Connect hose to coolant pump and secure with

clip.

24.Position PAS pump and tighten bolts to 25 Nm

(18 lbf.ft).

25.Position PAS pump pulley and lightly tighten

bolts.

26.Position ACE pump, fit bolts and tighten to 25

Nm (18 lbf.ft).

27.Position A/C compressor, fit bolts and tighten

to 25 Nm (18 lbf.ft).

28.Position ancillary drive belt, rotate tensioner

anti-clockwise and locate belt to pulleys.

29.Tighten PAS pump pulley bolts to 10 Nm (7

lbf.ft).

30.Position air intake hose to air cleaner and

secure clips.

31.Position engine harness and connect

multiplugs to compressor, MAF sensor,

turbocharger boost solenoid, AAP & IAT

sensor.

32.Position air inlet hose to turbocharger and

tighten clip. 33.Connect hoses to turbocharger boost solenoid

and secure clips.

34.Clean CKP sensor and mating face.

CAUTION: If originally fitted: Fit spacer to

CKP sensor.

35.Using new 'O' ring, fit CKP sensor, tighten CKP

sensor bolt to 9 Nm (7 lbf.ft) and connect

multiplug.

36.Connect multiplug to EGR modulator.

37.Connect engine earth lead to battery earth lead

and tighten bolt.

38.Connect engine harness multiplug to ECM and

main harness.

39.Connect engine harness multiplugs to fuse

box.

40.Position glow plug lead to fusebox and secure

with bolt.

41.Position battery and alternator leads to fusebox

and secure with bolts.

42.Fit engine compartment fuse box cover.

43.Connect vacuum hose to EGR valve.

44.Connect hose to vacuum pump and secure

vacuum pipe to fuel cooler.

45.Disconnect fuel hose from connector block and

connect to fuel cooler.

46.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

47.Position expansion tank, connect hose and

secure with clip. Secure tank to body mounting.

48.Connect coolant hoses to fuel cooler and

coolant rail and secure clips.

49.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

50. Fit radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

51.Fill engine with oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

52.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

53.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 192 of 1672

ENGINE - TD5

REPAIRS 12-1-53

Mounting - front - LH

$% 12.45.01

Remove

1.Remove centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

2.Remove 3 bolts, remove oil filter adaptor

housing and discard gasket.

3.Fit suitable lifting chains to support engine.

4.With assistance remove 2 bolts securing

engine mounting to chassis.

5.Remove 4 bolts securing engine mounting

bracket to cylinder block.

6.Remove nut securing mounting to mounting

bracket.

7.Remove mounting and mounting bracket.

8.Remove mounting shield.

Refit

1.Fit shield to mounting. 2.Fit mounting and mounting bracket.

3.Fit mounting bracket to cylinder block and

tighten – bolts securing front LH engine

mounting bracket to cylinder block to 48 Nm (35

lbf.ft).

4.With assistance, fit mounting to chassis and

tighten – bolts securing front LH engine

mounting to chassis to 85 Nm (63 lbf.ft).

5.Fit mounting to mounting bracket and tighten –

nut securing front LH mounting to mounting

bracket to 85 Nm (63 lbf.ft).

6.Remove engine support chains.

7.Clean oil filter adaptor housing and mating

face.

8.Fit oil filter adaptor housing to oil cooler

housing and tighten bolts to 25 Nm (18 lbf.ft).

9.Fit centrifuge assembly.

+ ENGINE - Td5, REPAIRS, Gasket -

centrifuge oil drain pipe.

Page 193 of 1672

ENGINE - TD5

12-1-54 REPAIRS

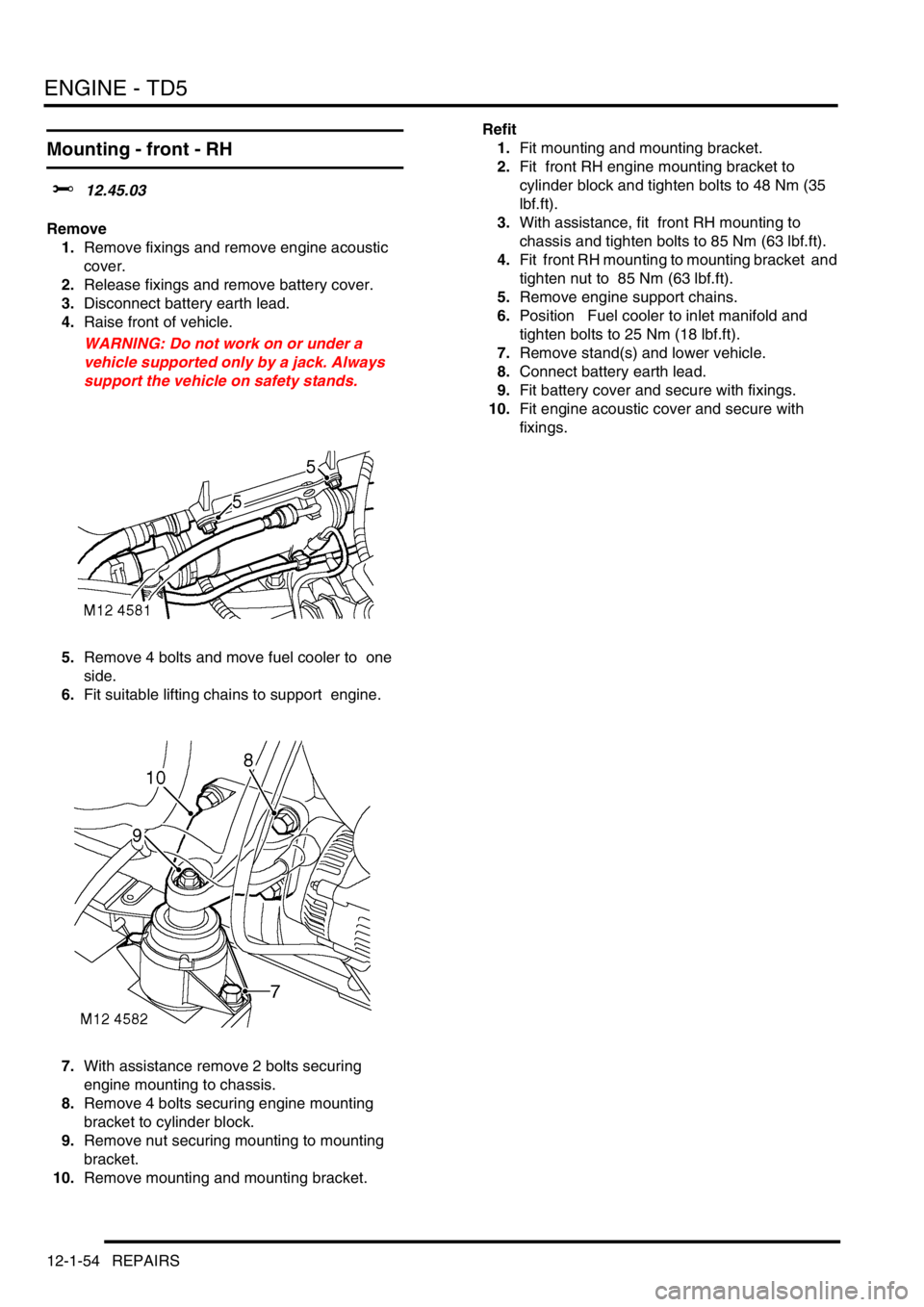

Mounting - front - RH

$% 12.45.03

Remove

1.Remove fixings and remove engine acoustic

cover.

2.Release fixings and remove battery cover.

3.Disconnect battery earth lead.

4.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

5.Remove 4 bolts and move fuel cooler to one

side.

6.Fit suitable lifting chains to support engine.

7.With assistance remove 2 bolts securing

engine mounting to chassis.

8.Remove 4 bolts securing engine mounting

bracket to cylinder block.

9.Remove nut securing mounting to mounting

bracket.

10.Remove mounting and mounting bracket. Refit

1.Fit mounting and mounting bracket.

2.Fit front RH engine mounting bracket to

cylinder block and tighten bolts to 48 Nm (35

lbf.ft).

3.With assistance, fit front RH mounting to

chassis and tighten bolts to 85 Nm (63 lbf.ft).

4.Fit front RH mounting to mounting bracket and

tighten nut to 85 Nm (63 lbf.ft).

5.Remove engine support chains.

6.Position Fuel cooler to inlet manifold and

tighten bolts to 25 Nm (18 lbf.ft).

7.Remove stand(s) and lower vehicle.

8.Connect battery earth lead.

9.Fit battery cover and secure with fixings.

10.Fit engine acoustic cover and secure with

fixings.

Page 194 of 1672

ENGINE - TD5

REPAIRS 12-1-55

Mounting - engine - rear - LH

$% 12.45.07

Remove

1.Raise vehicle on ramp.

2.Position jack to support gearbox.

3.Remove 2 nuts and remove mounting.

4.Remove heat shield from mounting.

Refit

1.Clean mounting and mating faces.

2.Position heat shield to mounting.

3.Position engine rear LH mounting and tighten

nuts to 48 Nm (35 lbf.ft).

4.Lower support jack.

5.Lower vehicle.

Mounting - engine - rear - RH

$% 12.45.09

Remove

1.Raise vehicle on ramp.

2.Position jack to support gearbox.

3.Remove 2 nuts and remove mounting.

Refit

1.Clean mounting and mating faces.

2.Position engine rear RH mounting and tighten

nuts to 48 Nm (35 lbf.ft).

3.Lower support jack.

4.Lower vehicle.

Page 195 of 1672

ENGINE - TD5

12-1-56 REPAIRS

Flywheel

$% 12.53.07

Remove

1.Remove clutch assembly.

+ CLUTCH - Td5, REPAIRS, Clutch

assembly.

2.Remove and discard 8 bolts securing flywheel

to crankshaft and remove flywheel.

Refit

1.Clean flywheel and mating face.

2.Position flywheel to crankshaft, fit new bolts

and working in a diagonal sequence tighten to

40 Nm (30 lbf.ft), then a further 90

°.

CAUTION: Do not carry out stages 1 and 2 in

one operation.

3.Fit clutch assembly.

+ CLUTCH - Td5, REPAIRS, Clutch

assembly.

Plate - drive - automatic

$% 12.53.13

Remove

1.Remove gearbox.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gearbox - convertor and

transfer gearbox - Diesel.

2.Remove and discard 8 bolts and remove

converter drive plate, spacer and starter ring

gear.

Refit

1.Clean drive plate, spacer and starter ring gear.

2.Fit starter ring gear, spacer and drive plate to

crankshaft, fit new bolts and working in a

diagonal sequence tighten to 40 Nm (30 lbf.ft),

then a further 90

°.

CAUTION: Do not carry out stages 1 and 2 in

one operation.

3.Refit gearbox.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gearbox - convertor and

transfer gearbox - Diesel.

Page 196 of 1672

ENGINE - TD5

REPAIRS 12-1-57

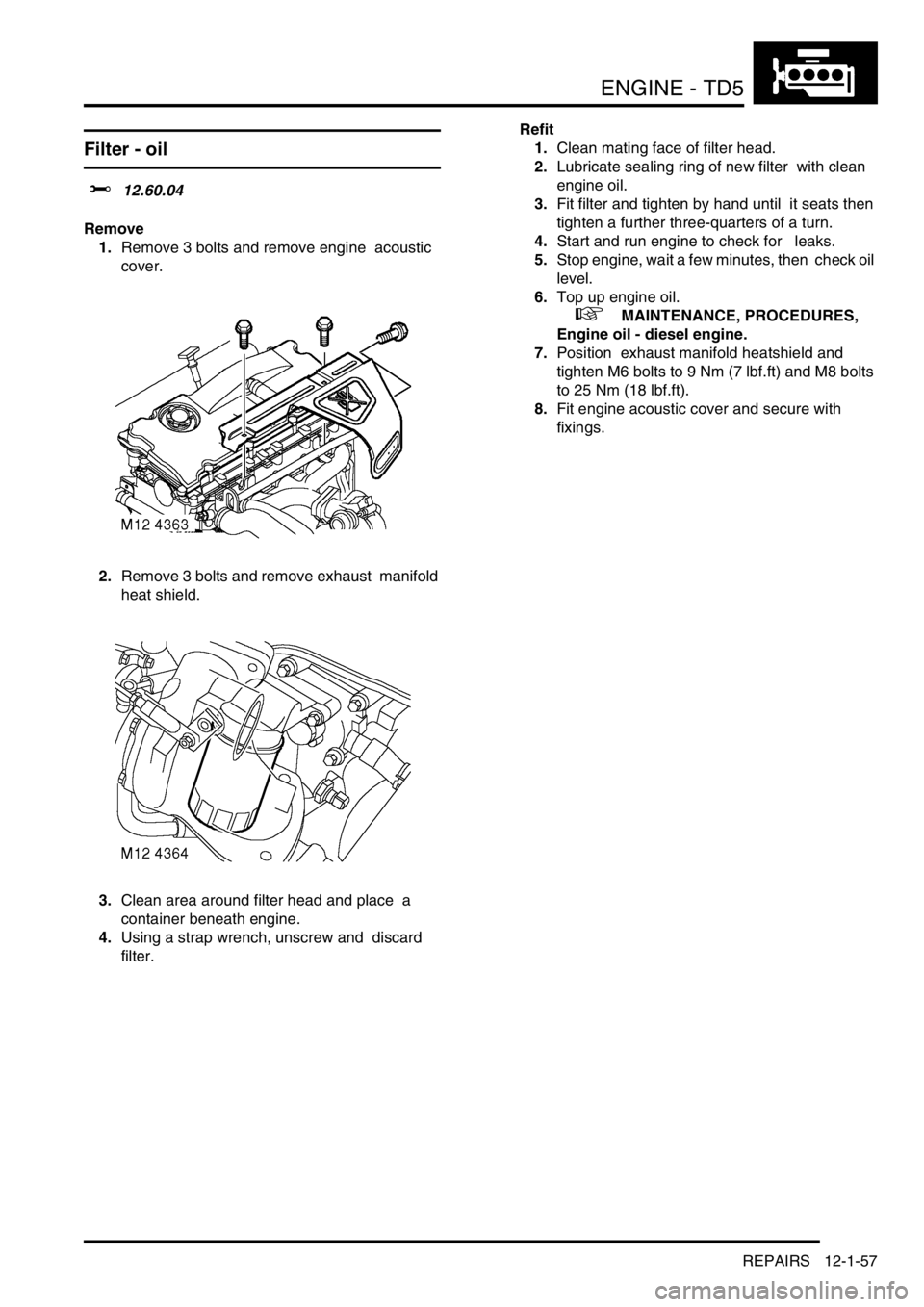

Filter - oil

$% 12.60.04

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Remove 3 bolts and remove exhaust manifold

heat shield.

3.Clean area around filter head and place a

container beneath engine.

4.Using a strap wrench, unscrew and discard

filter. Refit

1.Clean mating face of filter head.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit filter and tighten by hand until it seats then

tighten a further three-quarters of a turn.

4.Start and run engine to check for leaks.

5.Stop engine, wait a few minutes, then check oil

level.

6.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

7.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolts

to 25 Nm (18 lbf.ft).

8.Fit engine acoustic cover and secure with

fixings.

Page 197 of 1672

ENGINE - TD5

12-1-58 REPAIRS

Strainer - oil pick-up

$% 12.60.20

Remove

1.Remove sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

2.Remove 3 Torx screws securing oil pick- up

strainer.

3.Remove and discard 'O' ring.

Refit

1.Clean oil pick up strainer faces.

2.Fit new 'O' ring to oil pick-up strainer.

3.Clean threads of Torx screws.

4.Fit oil pick-up strainer, apply Loctite 242 to

threads of Torx screws, fit screws and tighten to

10 Nm (7 lbf.ft).

5.Fit new sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

Pump - oil

$% 12.60.26

Remove

1.Remove sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

2.Hold oil pump drive sprocket and remove

retaining bolt.

3.Remove sprocket from oil pump.

4.Remove 3 Torx screws securing oil pick-up

strainer.

5.Remove and discard 'O' ring.

Page 198 of 1672

ENGINE - TD5

REPAIRS 12-1-59

6.Using sequence shown, remove and discard 22

bolts securing oil pump and stiffener assembly.

7.Remove oil pump and stiffener assembly from

cylinder block.

8.Remove and discard 'O' ring.

Refit

1.Clean mating faces of oil pump and stiffener

assembly, main bearing caps and cylinder

block.

2.Fit new 'O' ring to oil pump housing.

3.Position oil pump and stiffener assembly onto

cylinder block ensuring 2 dowels are correctly

located. 4.Fit new bolts and using sequence shown,

tighten to 13 Nm (10 lbf.ft) .

5.Clean threads of oil pick-up strainer Torx

screws.

6.Fit new 'O' ring to oil pick-up strainer.

7.Fit oil pick-up strainer, apply Loctite 242 to

threads of Torx screws, fit screws and tighten to

10 Nm (7 lbf.ft).

8.Position oil pump drive sprocket and chain

onto oil pump ensuring that the 'D' shape on

the drive sprocket is located on the oil pump

shaft.

9.Clean oil pump drive sprocket retaining bolt

and apply Loctite 242 to bolt threads.

10.Fit oil pump drive sprocket and tighten bolt to

25 Nm (18 lbf.ft).

11.Fit new sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

Page 199 of 1672

ENGINE - TD5

12-1-60 REPAIRS

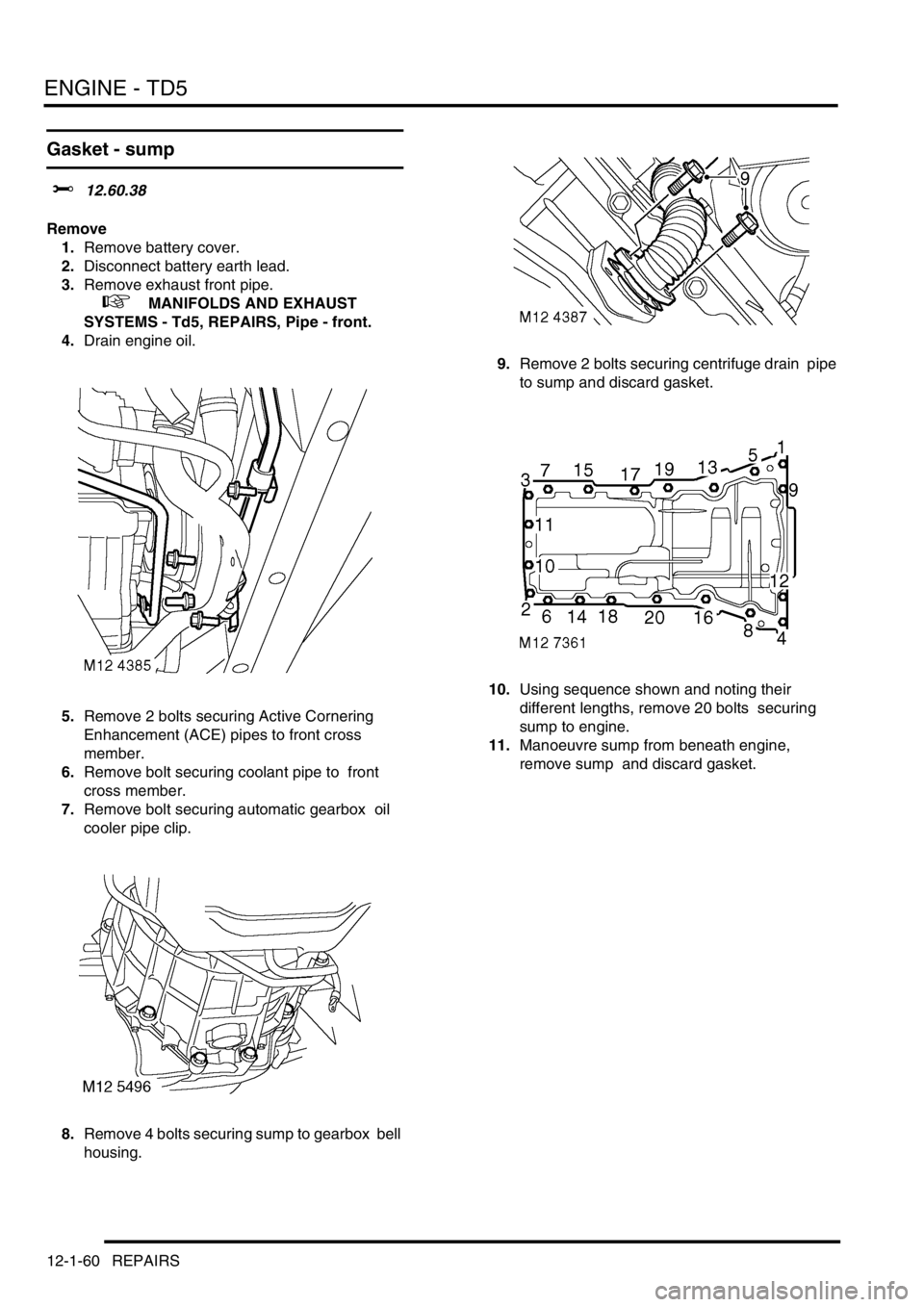

Gasket - sump

$% 12.60.38

Remove

1.Remove battery cover.

2.Disconnect battery earth lead.

3.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

4.Drain engine oil.

5.Remove 2 bolts securing Active Cornering

Enhancement (ACE) pipes to front cross

member.

6.Remove bolt securing coolant pipe to front

cross member.

7.Remove bolt securing automatic gearbox oil

cooler pipe clip.

8.Remove 4 bolts securing sump to gearbox bell

housing. 9.Remove 2 bolts securing centrifuge drain pipe

to sump and discard gasket.

10.Using sequence shown and noting their

different lengths, remove 20 bolts securing

sump to engine.

11.Manoeuvre sump from beneath engine,

remove sump and discard gasket.

Page 200 of 1672

ENGINE - TD5

REPAIRS 12-1-61

Refit

1.Clean sump and mating faces.

2.Apply sealant, Part No. STC 3254 to joint faces

of timing chain cover and crankshaft rear oil

seal housing.

CAUTION: Assembly and bolt tightening

must be completed within 20 minutes of

applying sealant.

3.Position new gasket.

CAUTION: Gasket must be fitted dry.

4.Position sump and, noting the positions of the

longer bolts, fit and lightly tighten bolts.

5.Fit and lightly tighten bolts securing sump to

gearbox bell housing. 6.Working in the sequence shown, tighten bolts

securing sump to 25 Nm (18 lbf.ft).

7.Tighten – sump to gearbox bell housing bolts

to 13 Nm (10 lbf.ft).

8.Fit new gasket to centrifuge drain pipe, fit to

sump and tighten bolts to 10 Nm (7 lbf.ft ) .

CAUTION: Gasket must be fitted dry.

9.Fit bolts securing oil cooler pipe to sump and

tighten to 9 Nm (7 lbf.ft).

10.Fit and tighten bolt securing coolant pipe to

cross member.

11.Fit and tighten bolts securing ACE pipes to front

cross member.

12.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

13.Refill engine with oil.

14.Connect battery earth lead.

15.Refit battery cover and secure fixings.