LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 161 of 1672

ENGINE - TD5

12-1-22 DESCRIPTION AND OPERATION

The camshaft carrier and cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining

bolts which pass through the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the cylinder head

and will be damaged if the cylinder head is stored face down.

The camshaft is located between the cylinder head and the camshaft carrier, and the bearing journals are line bored

between the two components to form a matched pair.

CAUTION: Always fit plugs to open connections to prevent contamination.

The valve guides and valve seat inserts are sintered components which are interference fit to the cylinder head. The

cylinder head machining also provide the locations for the electronic unit injectors, glow plugs, hydraulic lash

adjusters, finger followers and low pressure fuel rail.

Cooling to the cylinder head is provided by coolant flow through a water jacket machined into the cylinder head.

Drillings through the block provide lubrication channels for pressurised oil supply to cylinder head components such

as the lash adjusters, finger followers, rocker arms and camshaft bearings.

A coolant outlet elbow is fitted to the front LH side of the cylinder head to allow flow of coolant from the cylinder head

back to the radiator. A metal gasket is used to seal the joint between the water outlet elbow and the cylinder head. A

coolant temperature sensor is located in a port in the side of the water outlet elbow for monitoring coolant temperature.

A stub pipe is connected at the front RH side of the cylinder block above the timing cover which connects a pipe to

supply oil to the vacuum pump. The timing chain tensioner adjuster is screwed in a thread in the cylinder head at a

location on the front RH side of the engine below the oil feed port for the vacuum pump.

An access hole for the camshaft gear is included at the front of the cylinder head which is sealed with a plastic plug

and rubber 'O'-ring. A press-fit core plug for the chain chest is located on the front face of the cylinder head.

A press-fit core plug for the cylinder head water jacket is located at the rear of the cylinder head and a threaded brass

plug for the water jacket is located on the LH side of the cylinder head beneath the exhaust manifold assembly.

Page 162 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-23

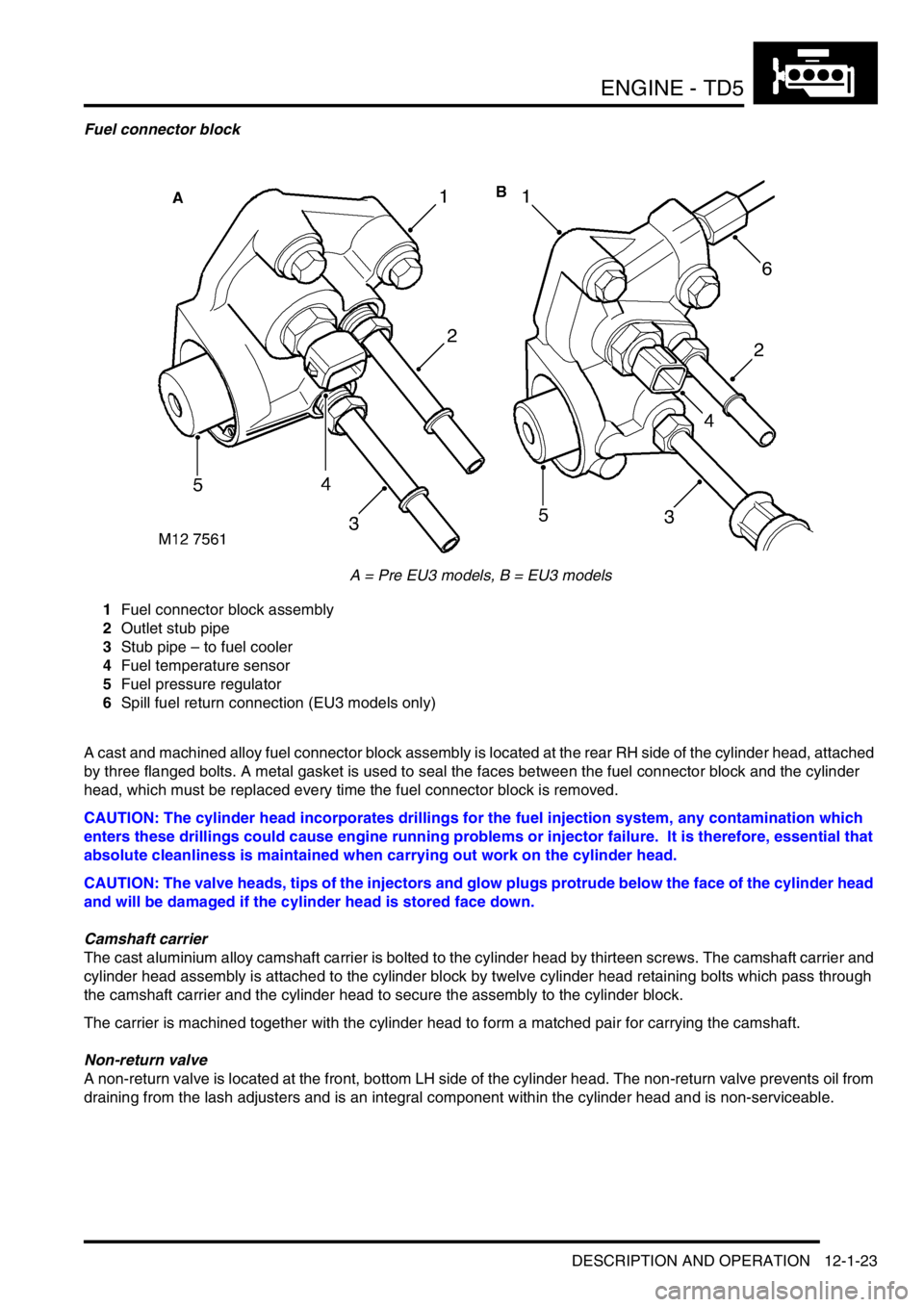

Fuel connector block

A = Pre EU3 models, B = EU3 models

1Fuel connector block assembly

2Outlet stub pipe

3Stub pipe – to fuel cooler

4Fuel temperature sensor

5Fuel pressure regulator

6Spill fuel return connection (EU3 models only)

A cast and machined alloy fuel connector block assembly is located at the rear RH side of the cylinder head, attached

by three flanged bolts. A metal gasket is used to seal the faces between the fuel connector block and the cylinder

head, which must be replaced every time the fuel connector block is removed.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any contamination which

enters these drillings could cause engine running problems or injector failure. It is therefore, essential that

absolute cleanliness is maintained when carrying out work on the cylinder head.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the cylinder head

and will be damaged if the cylinder head is stored face down.

Camshaft carrier

The cast aluminium alloy camshaft carrier is bolted to the cylinder head by thirteen screws. The camshaft carrier and

cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining bolts which pass through

the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

The carrier is machined together with the cylinder head to form a matched pair for carrying the camshaft.

Non-return valve

A non-return valve is located at the front, bottom LH side of the cylinder head. The non-return valve prevents oil from

draining from the lash adjusters and is an integral component within the cylinder head and is non-serviceable.

Page 163 of 1672

ENGINE - TD5

12-1-24 DESCRIPTION AND OPERATION

Camshaft

The camshaft is machined from cast steel and is located between the cylinder head and the camshaft carrier, and the

six bearing journals are line bored between the two components to form a matched pair. The machined camshaft has

15 lobes. Ten lobes operate the inlet and exhaust valves through hydraulic lash adjusters and finger followers which

are located below the camshaft. Five larger lobes activate the injector rockers which are located above the camshaft

on the rocker shaft and are used to generate fuel pressure in the EUI injectors.

The camshaft is sprocket driven via a duplex chain connected to the crankshaft sprocket at a speed ratio of 2:1. The

camshaft sprocket is fixed to the front end of the camshaft by three bolts.

Camshaft lubrication is splash and channel fed via pressurised oil flowing through galleries in the cylinder head.

Rocker shaft and Rocker Arms

A = Pre EU3 rocker arm, B = EU3 rocker arm

1Rocker shaft

2Rocker arm adjusting screw

3Rocker arm

4EUI pin and roller assembly

5Roller pin retention slug6Camshaft lobe

7Injector spring

8Injector push-rod

9Adjusting nut

The hollow rocker shaft is located in the camshaft carrier in six fixed mountings which sit above the camshaft. Six bolts

are used to lock the rocker shaft to the camshaft carrier. The front rocker shaft bearing has a ring dowel located at the

front rocker shaft mounting of the camshaft carrier for rocker shaft alignment. Two circlips hold each rocker arm in

position at the relevant positions on the rocker shaft.

The rocker shaft from a pre EU3 model must not be fitted to an EU3 engine. This is because the stroke of the

EU3 injector has increased which requires the rocker to articulate over a larger angle.

The camshaft end of each rocker arm features a roller which is free to rotate about a pin which passes through two

webs in the rocker arm, the roller pins are held in place by an interference fit retention slug passing through a hole in

the front web of each rocker arm.

To correctly function against the higher injection loads of the EU3 engine the geometry of the contact between the

injector pushrod and rocker arm adjusting screw has been modified. Both designs of adjusting screw are separately

available with the EU3 version being identified by an engraved dimple in the slotted end.

Rocker shaft and rocker arm lubrication is splash and channel fed via pressurised oil flowing through galleries in the

cylinder head and through the rocker shaft.

Page 164 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-25

Inlet and exhaust valves

The inlet and exhaust valves are mounted directly above the engine block cylinders.

Each valve is a forged and ground solid one-piece head and stem which is hardened by heat treatment. The stems

are chrome-plated then ground for improved heat transfer, wear resistance and smooth operation. It is not possible

to recut the valve's face angle, but the valves can be lapped to their seats using grinding paste.

The valve springs are made from spring steel and are of the parallel single-coil type. The bottom end of the spring

rests on the flange of a spring seal which has a centre bore that locates on a recess ground into the lower valve stem.

The top end of the spring is held in place by a spring retainer which is held in position at the top end of the valve stem

by split taper collets. The taper collets have grooves on the internal bore that locate to grooves ground into the upper

stems of the valves.

The valve seats and valve guides are sintered and are interference fit into the cylinder head. The valve seats and

guides are non-serviceable.

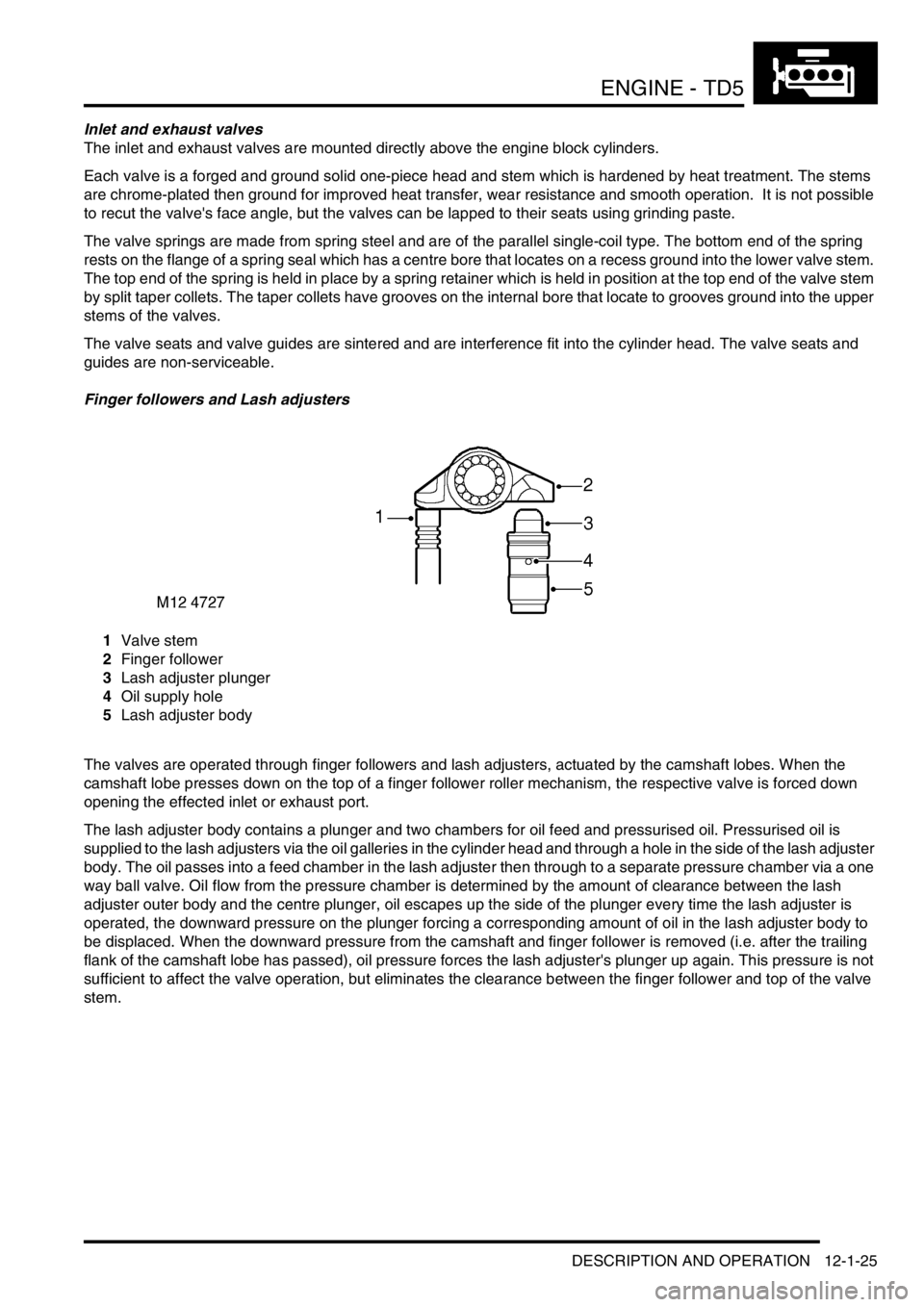

Finger followers and Lash adjusters

1Valve stem

2Finger follower

3Lash adjuster plunger

4Oil supply hole

5Lash adjuster body

The valves are operated through finger followers and lash adjusters, actuated by the camshaft lobes. When the

camshaft lobe presses down on the top of a finger follower roller mechanism, the respective valve is forced down

opening the effected inlet or exhaust port.

The lash adjuster body contains a plunger and two chambers for oil feed and pressurised oil. Pressurised oil is

supplied to the lash adjusters via the oil galleries in the cylinder head and through a hole in the side of the lash adjuster

body. The oil passes into a feed chamber in the lash adjuster then through to a separate pressure chamber via a one

way ball valve. Oil flow from the pressure chamber is determined by the amount of clearance between the lash

adjuster outer body and the centre plunger, oil escapes up the side of the plunger every time the lash adjuster is

operated, the downward pressure on the plunger forcing a corresponding amount of oil in the lash adjuster body to

be displaced. When the downward pressure from the camshaft and finger follower is removed (i.e. after the trailing

flank of the camshaft lobe has passed), oil pressure forces the lash adjuster's plunger up again. This pressure is not

sufficient to affect the valve operation, but eliminates the clearance between the finger follower and top of the valve

stem.

Page 165 of 1672

ENGINE - TD5

12-1-26 DESCRIPTION AND OPERATION

Camshaft cover and engine cover components

The camshaft cover and engine cover components are described below:

Camshaft cover

The camshaft cover is cast from aluminium alloy and is fixed to the camshaft carrier/cylinder head assembly by 13

bolts. The cover has spacers and sealing washers inserted into each of the thirteen bolt holes.

A breather hose is connected to a port at the top of the camshaft cover by means of a hose clip which vents crankcase

gases back to the air intake via a breather valve in the air intake tract, located forward of the turbocharger in the

flexible air intake duct.

A rubber seal is fitted between the camshaft cover.

An oil filler aperture is included in the top of the camshaft cover, which is sealed with a plastic cap with integral rubber

seal.

Camshaft timing chain components

The timing chain cover and timing chain components are described below:

Timing chain cover

The timing chain cover is cast and machined aluminium alloy and is attached to the cylinder head by a bolt at the RH

top of the cover and by a stud and nut at the LH top of the cover. Eight screws are used to attach the timing chain

cover to the front of the engine block. The timing cover is located to the cylinder block front face by two dowels.

A viscous fan is attached to an idler pulley at the front of the engine block. The fan bearing is located on a shaft and

held in place by a circlip and a bearing flange, the inner race of the fan bearing is an interference fit on the shaft. The

fan idler pulley is attached to the bearing hub by three bolts, and the fan itself is secured to the pulley and bearing

shaft by a left hand threaded nut.

+ COOLING SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

The front of the crankshaft passes through a hole in the lower part of the timing cover. An oil seal is pressed into a

recess in the front of the timing cover to seal the interface between the front of the crankshaft and the timing cover.

A stub pipe is fitted to the front RH side of the timing cover which is used to attach the oil drain pipe from the vacuum

pump by means of a hose and spring clip.

Timing chains

The timing chain between the camshaft and crankshaft sprockets is a duplex type, each chain having 56 links. The

timing chain is contained between a fixed plastic guide and an hydraulically adjustable plastic tensioner arm which

are attached to the front of the engine block.

To cope with higher injection loads of the EU3 engine, the timing drive between the camshaft and crankshaft has been

upgraded. This requires thicker chain links to be used, therefore, the individual pre EU3 and EU3 components are not

interchangeable.

To distinguish between the two timing chains the links are different colours. A pre EU3 chain has blue links and a EU3

chain has bronze links.

The oil pump timing chain is a single type and traverses the oil pump sprocket and the rear crankshaft sprocket.

The timing chains are oil lubricated, with oil being provided by a chain lubrication jet and from oil flow returning back

to the sump from the cylinder head. An oil hole is included at the front left hand side of the cylinder head which supplies

oil from the cylinder head oil galleries.

Page 166 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-27

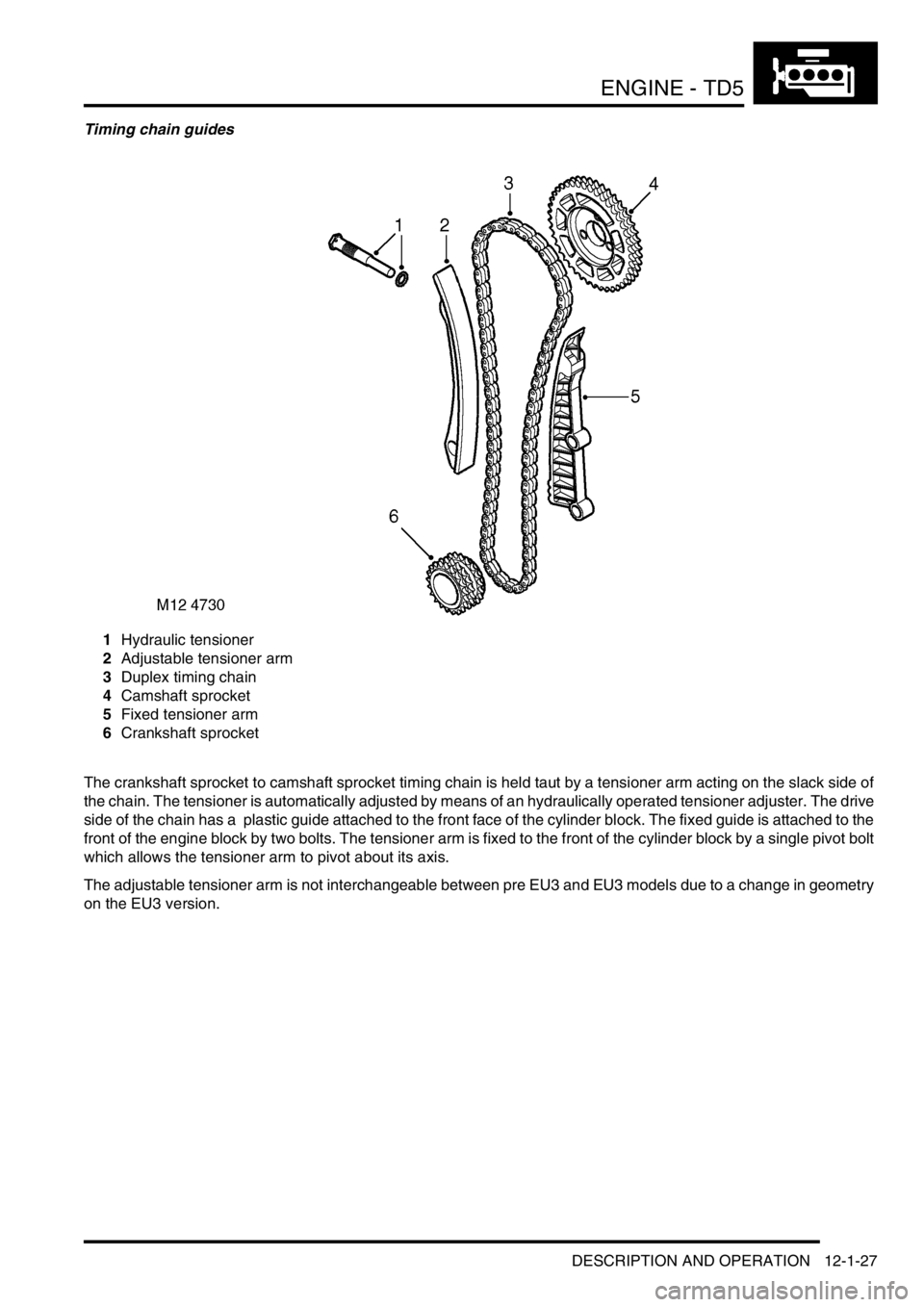

Timing chain guides

1Hydraulic tensioner

2Adjustable tensioner arm

3Duplex timing chain

4Camshaft sprocket

5Fixed tensioner arm

6Crankshaft sprocket

The crankshaft sprocket to camshaft sprocket timing chain is held taut by a tensioner arm acting on the slack side of

the chain. The tensioner is automatically adjusted by means of an hydraulically operated tensioner adjuster. The drive

side of the chain has a plastic guide attached to the front face of the cylinder block. The fixed guide is attached to the

front of the engine block by two bolts. The tensioner arm is fixed to the front of the cylinder block by a single pivot bolt

which allows the tensioner arm to pivot about its axis.

The adjustable tensioner arm is not interchangeable between pre EU3 and EU3 models due to a change in geometry

on the EU3 version.

Page 167 of 1672

ENGINE - TD5

12-1-28 DESCRIPTION AND OPERATION

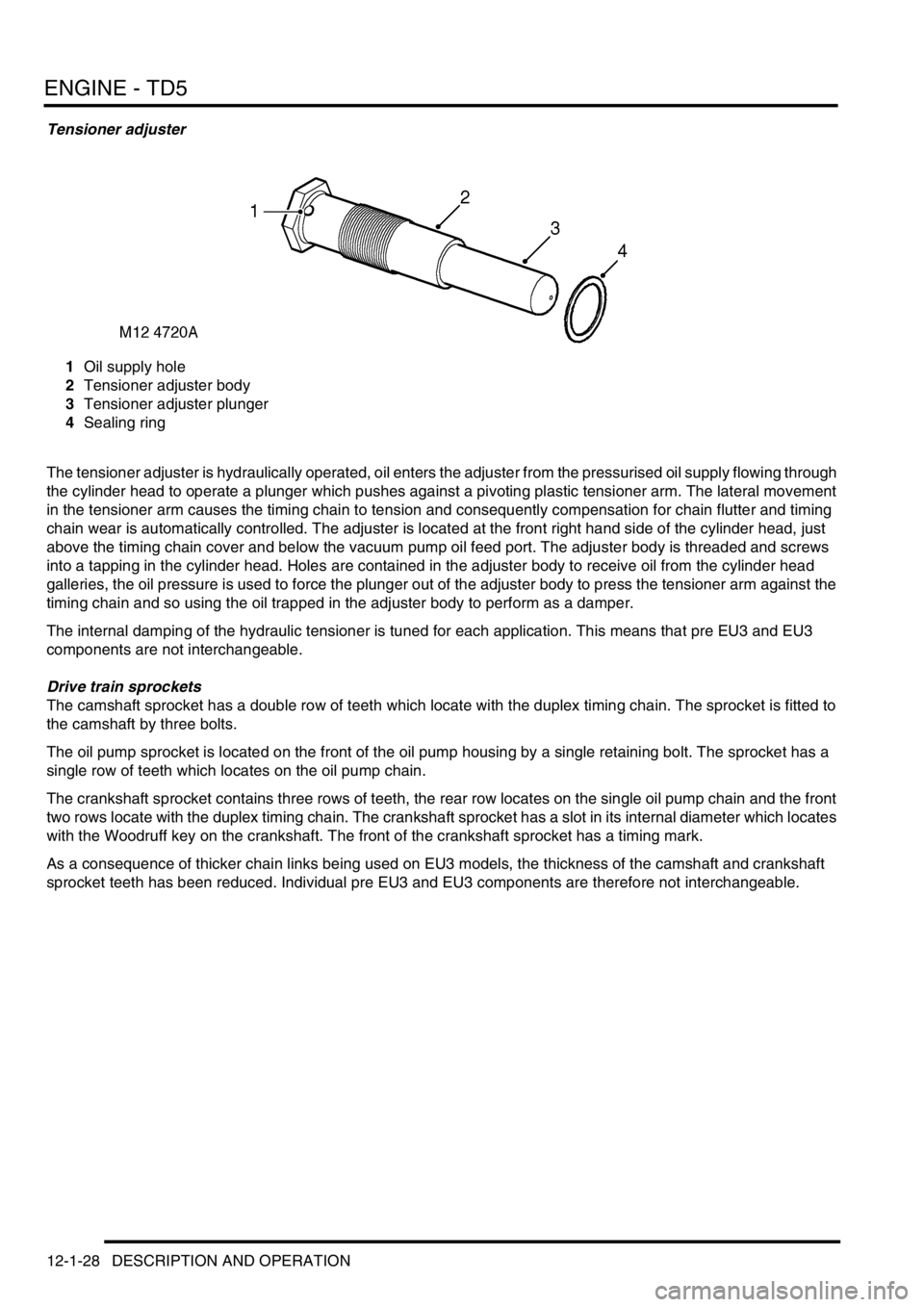

Tensioner adjuster

1Oil supply hole

2Tensioner adjuster body

3Tensioner adjuster plunger

4Sealing ring

The tensioner adjuster is hydraulically operated, oil enters the adjuster from the pressurised oil supply flowing through

the cylinder head to operate a plunger which pushes against a pivoting plastic tensioner arm. The lateral movement

in the tensioner arm causes the timing chain to tension and consequently compensation for chain flutter and timing

chain wear is automatically controlled. The adjuster is located at the front right hand side of the cylinder head, just

above the timing chain cover and below the vacuum pump oil feed port. The adjuster body is threaded and screws

into a tapping in the cylinder head. Holes are contained in the adjuster body to receive oil from the cylinder head

galleries, the oil pressure is used to force the plunger out of the adjuster body to press the tensioner arm against the

timing chain and so using the oil trapped in the adjuster body to perform as a damper.

The internal damping of the hydraulic tensioner is tuned for each application. This means that pre EU3 and EU3

components are not interchangeable.

Drive train sprockets

The camshaft sprocket has a double row of teeth which locate with the duplex timing chain. The sprocket is fitted to

the camshaft by three bolts.

The oil pump sprocket is located on the front of the oil pump housing by a single retaining bolt. The sprocket has a

single row of teeth which locates on the oil pump chain.

The crankshaft sprocket contains three rows of teeth, the rear row locates on the single oil pump chain and the front

two rows locate with the duplex timing chain. The crankshaft sprocket has a slot in its internal diameter which locates

with the Woodruff key on the crankshaft. The front of the crankshaft sprocket has a timing mark.

As a consequence of thicker chain links being used on EU3 models, the thickness of the camshaft and crankshaft

sprocket teeth has been reduced. Individual pre EU3 and EU3 components are therefore not interchangeable.

Page 168 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-29

Lubrication circuit

Cylinder block flow

1Oil squirt jets (5 off)

2Main oil delivery gallery

3Inflow from oil cooler housing

4Flow to oil cooler / filters (from oil pump via

cylinder block)

5Sump

6Oil pick-up pipe

7Flow from oil pump (relief-valve in housing)

8Oil pump9Cross-drilling supply to main and crankshaft

bearings

10To cylinder head

Page 169 of 1672

ENGINE - TD5

12-1-30 DESCRIPTION AND OPERATION

Oil from the sump is drawn up through a two-piece plastic pick-up which contains a mesh to siphon any relatively large

pieces of material which could cause damage to the pump. The head of the pick-up is centrally immersed in the sump

oil and oil is delivered to the inlet side of the eccentric rotor pump through a gallery in the stiffener plate.

Pressurised oil from the pump is passed through to the cylinder block where it is delivered to the centrifuge filter and

full-flow filter via a port in the RH cylinder block which interfaces with a port in the centre gallery of the oil cooler

housing. The oil pump contains an oil pressure relief valve which opens to allow oil to be recirculated back around the

pump if the oil pressure increases to a high enough level.

10% of the oil flow from the pump is diverted through the centrifuge filter and returned to the sump via the centrifuge

filter drain tube. The remaining 90% of the oil passes through the standard full-flow filter to the main oil gallery in the

cylinder block.

Page 170 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-31

Oil cooler / Filter flow (thermostat open)

1To cylinder block main gallery (from rear of oil

cooler housing)

2Oil cooler housing

3Oil pressure switch

4Full-flow filter

5Centrifuge filter6Return to sump

7Flow from oil pump (via cylinder block)

8Oil cooler matrix