LAND ROVER DISCOVERY 2002 Owner's Guide

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 31 of 1672

INTRODUCTION

01-2

Specifications

Land Rover are constantly seeking to improve the

specification, design and production of their vehicles

and alterations take place accordingly. While every

effort has been made to ensure the accuracy of this

Manual, it should not be regarded as an infallible

guide to current specifications of any particular

vehicle.

This Manual does not constitute an offer for sale of

any particular vehicle. Land Rover Dealers are not

agents of Land Rover and have no authority to bind

the manufacturer by any expressed or implied

undertaking or representation.

Page 32 of 1672

INTRODUCTION

01-3

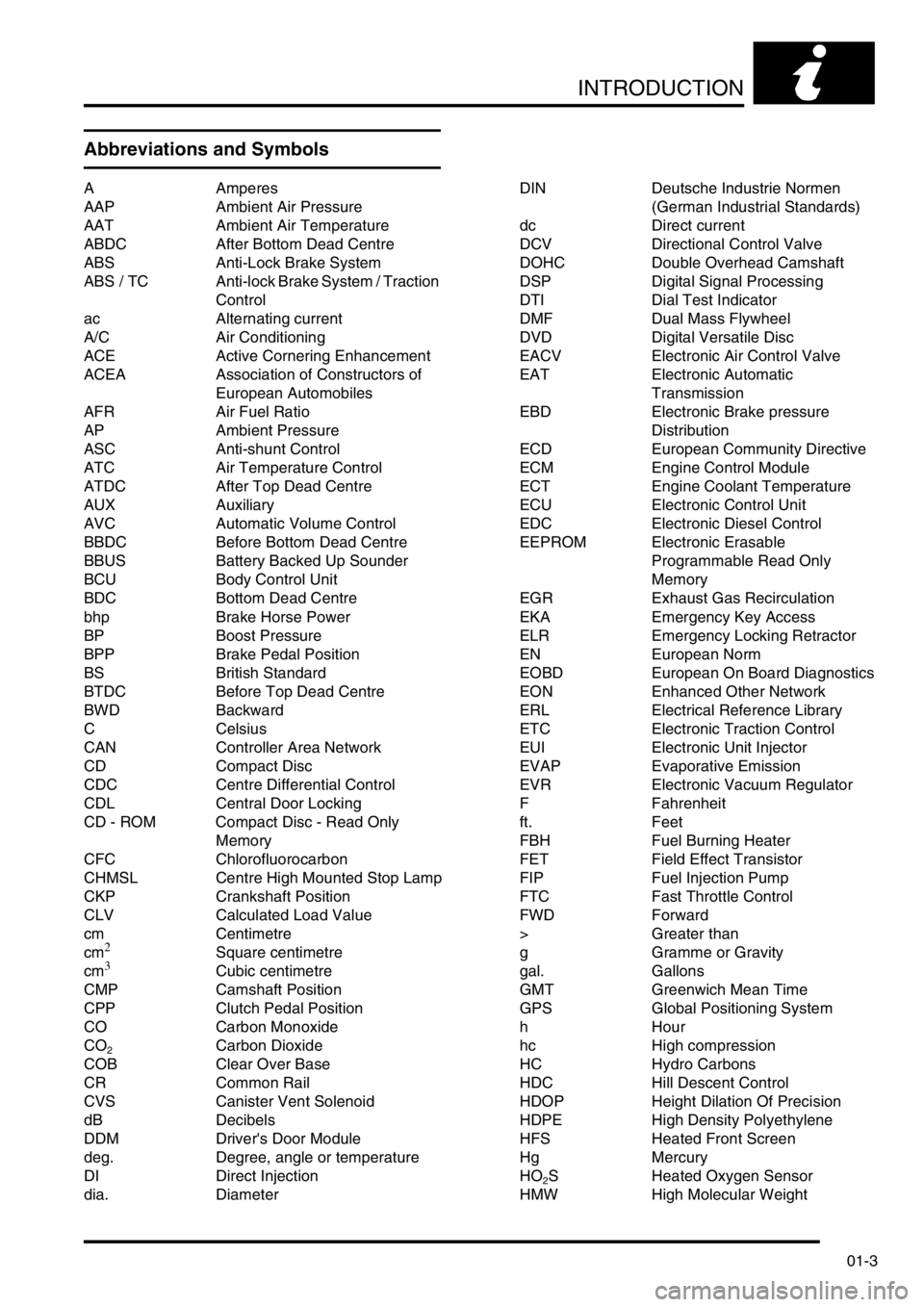

Abbreviations and Symbols

A Amperes

AAP Ambient Air Pressure

AAT Ambient Air Temperature

ABDC After Bottom Dead Centre

ABS Anti-Lock Brake System

ABS / TC Anti-lock Brake System / Traction

Control

ac Alternating current

A/C Air Conditioning

ACE Active Cornering Enhancement

ACEA Association of Constructors of

European Automobiles

AFR Air Fuel Ratio

AP Ambient Pressure

ASC Anti-shunt Control

ATC Air Temperature Control

ATDC After Top Dead Centre

AUX Auxiliary

AVC Automatic Volume Control

BBDC Before Bottom Dead Centre

BBUS Battery Backed Up Sounder

BCU Body Control Unit

BDC Bottom Dead Centre

bhp Brake Horse Power

BP Boost Pressure

BPP Brake Pedal Position

BS British Standard

BTDC Before Top Dead Centre

BWD Backward

C Celsius

CAN Controller Area Network

CD Compact Disc

CDC Centre Differential Control

CDL Central Door Locking

CD - ROM Compact Disc - Read Only

Memory

CFC Chlorofluorocarbon

CHMSL Centre High Mounted Stop Lamp

CKP Crankshaft Position

CLV Calculated Load Value

cm Centimetre

cm

2Square centimetre

cm3Cubic centimetre

CMP Camshaft Position

CPP Clutch Pedal Position

CO Carbon Monoxide

CO

2Carbon Dioxide

COB Clear Over Base

CR Common Rail

CVS Canister Vent Solenoid

dB Decibels

DDM Driver's Door Module

deg. Degree, angle or temperature

DI Direct Injection

dia. DiameterDIN Deutsche Industrie Normen

(German Industrial Standards)

dc Direct current

DCV Directional Control Valve

DOHC Double Overhead Camshaft

DSP Digital Signal Processing

DTI Dial Test Indicator

DMF Dual Mass Flywheel

DVD Digital Versatile Disc

EACV Electronic Air Control Valve

EAT Electronic Automatic

Transmission

EBD Electronic Brake pressure

Distribution

ECD European Community Directive

ECM Engine Control Module

ECT Engine Coolant Temperature

ECU Electronic Control Unit

EDC Electronic Diesel Control

EEPROM Electronic Erasable

Programmable Read Only

Memory

EGR Exhaust Gas Recirculation

EKA Emergency Key Access

ELR Emergency Locking Retractor

EN European Norm

EOBD European On Board Diagnostics

EON Enhanced Other Network

ERL Electrical Reference Library

ETC Electronic Traction Control

EUI Electronic Unit Injector

EVAP Evaporative Emission

EVR Electronic Vacuum Regulator

F Fahrenheit

ft. Feet

FBH Fuel Burning Heater

FET Field Effect Transistor

FIP Fuel Injection Pump

FTC Fast Throttle Control

FWD Forward

> Greater than

g Gramme or Gravity

gal. Gallons

GMT Greenwich Mean Time

GPS Global Positioning System

hHour

hc High compression

HC Hydro Carbons

HDC Hill Descent Control

HDOP Height Dilation Of Precision

HDPE High Density Polyethylene

HFS Heated Front Screen

Hg Mercury

HO

2S Heated Oxygen Sensor

HMW High Molecular Weight

Page 33 of 1672

INTRODUCTION

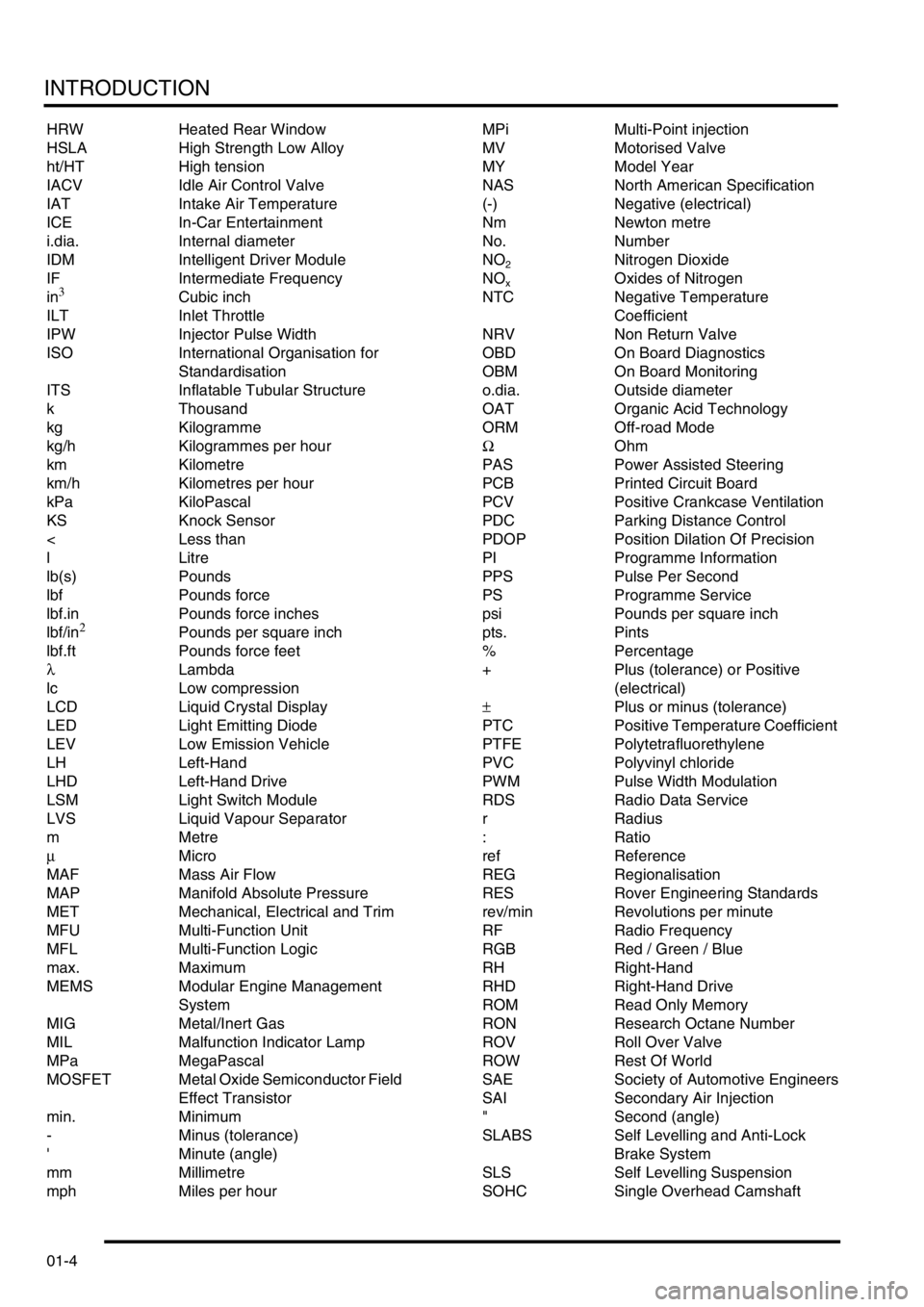

01-4

HRW Heated Rear Window

HSLA High Strength Low Alloy

ht/HT High tension

IACV Idle Air Control Valve

IAT Intake Air Temperature

ICE In-Car Entertainment

i.dia. Internal diameter

IDM Intelligent Driver Module

IF Intermediate Frequency

in

3Cubic inch

ILT Inlet Throttle

IPW Injector Pulse Width

ISO International Organisation for

Standardisation

ITS Inflatable Tubular Structure

k Thousand

kg Kilogramme

kg/h Kilogrammes per hour

km Kilometre

km/h Kilometres per hour

kPa KiloPascal

KS Knock Sensor

lb(s) Pounds

lbf Pounds force

lbf.in Pounds force inches

lbf/in

2Pounds per square inch

lbf.ft Pounds force feet

λLambda

lc Low compression

LCD Liquid Crystal Display

LED Light Emitting Diode

LEV Low Emission Vehicle

LH Left-Hand

LHD Left-Hand Drive

LSM Light Switch Module

LVS Liquid Vapour Separator

mMetre

µMicro

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MET Mechanical, Electrical and Trim

MFU Multi-Function Unit

MFL Multi-Function Logic

max. Maximum

MEMS Modular Engine Management

System

MIG Metal/Inert Gas

MIL Malfunction Indicator Lamp

MPa MegaPascal

MOSFET Metal Oxide Semiconductor Field

Effect Transistor

min. Minimum

- Minus (tolerance)

' Minute (angle)

mm Millimetre

mph Miles per hour MPi Multi-Point injection

MV Motorised Valve

MY Model Year

NAS North American Specification

(-) Negative (electrical)

Nm Newton metre

No. Number

NO

2Nitrogen Dioxide

NO

xOxides of Nitrogen

NTC Negative Temperature

Coefficient

NRV Non Return Valve

OBD On Board Diagnostics

OBM On Board Monitoring

o.dia. Outside diameter

OAT Organic Acid Technology

ORM Off-road Mode

ΩOhm

PAS Power Assisted Steering

PCB Printed Circuit Board

PCV Positive Crankcase Ventilation

PDC Parking Distance Control

PDOP Position Dilation Of Precision

PI Programme Information

PPS Pulse Per Second

PS Programme Service

psi Pounds per square inch

pts. Pints

% Percentage

+ Plus (tolerance) or Positive

(electrical)

±Plus or minus (tolerance)

PTC Positive Temperature Coefficient

PTFE Polytetrafluorethylene

PVC Polyvinyl chloride

PWM Pulse Width Modulation

RDS Radio Data Service

rRadius

:Ratio

ref Reference

REG Regionalisation

RES Rover Engineering Standards

rev/min Revolutions per minute

RF Radio Frequency

RGB Red / Green / Blue

RH Right-Hand

RHD Right-Hand Drive

ROM Read Only Memory

RON Research Octane Number

ROV Roll Over Valve

ROW Rest Of World

SAE Society of Automotive Engineers

SAI Secondary Air Injection

" Second (angle)

SLABS Self Levelling and Anti-Lock

Brake System

SLS Self Levelling Suspension

SOHC Single Overhead Camshaft

Page 34 of 1672

INTRODUCTION

01-5

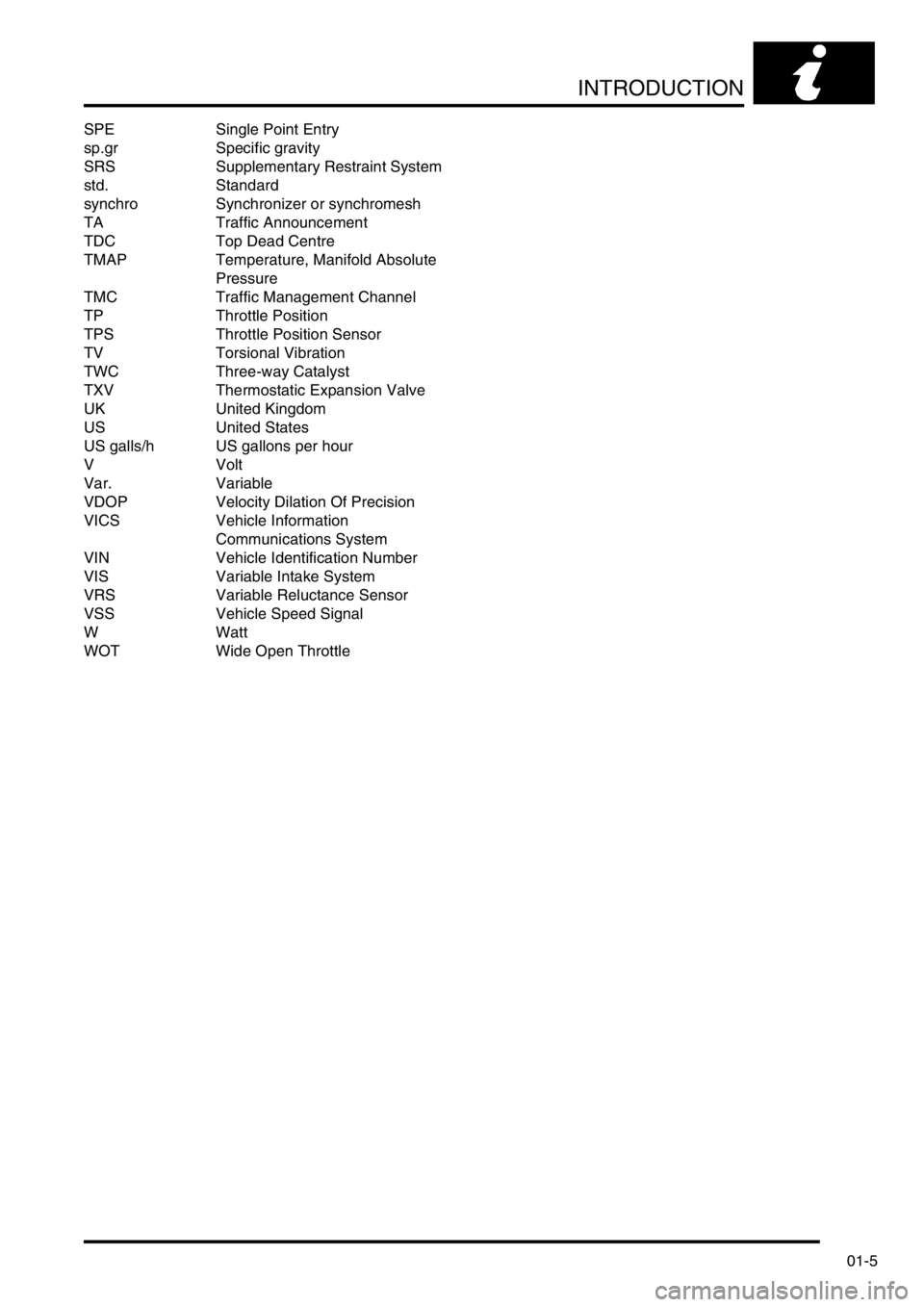

SPE Single Point Entry

sp.gr Specific gravity

SRS Supplementary Restraint System

std. Standard

synchro Synchronizer or synchromesh

TA Traffic Announcement

TDC Top Dead Centre

TMAP Temperature, Manifold Absolute

Pressure

TMC Traffic Management Channel

TP Throttle Position

TPS Throttle Position Sensor

TV Torsional Vibration

TWC Three-way Catalyst

TXV Thermostatic Expansion Valve

UK United Kingdom

US United States

US galls/h US gallons per hour

V Volt

Var. Variable

VDOP Velocity Dilation Of Precision

VICS Vehicle Information

Communications System

VIN Vehicle Identification Number

VIS Variable Intake System

VRS Variable Reluctance Sensor

VSS Vehicle Speed Signal

WWatt

WOT Wide Open Throttle

Page 35 of 1672

INTRODUCTION

01-6

Page 36 of 1672

GENERAL INFORMATION

03-1

GENERAL INFORMATION

General Precautions

Dangerous substances

Modern vehicles contain many materials and liquids

which if not handled with care can be hazardous to

both personal health and the environment.

WARNING: Many liquids and other substances

used in motor vehicles are poisonous and should

under no circumstances be consumed and

should, as far as possible, be kept from contact

with the skin. These liquids and substances

include acid, anti-freeze, asbestos, brake fluid,

fuel, windscreen washer additives, lubricants,

refrigerants and various adhesives.

Always read carefully the instructions printed on

labels or stamped on components and obey them

implicitly. Such instructions are included for

reasons of your health and personal safety.

Never disregard them.

Synthetic rubber

Many 'O' rings, seals, hoses, flexible pipes and other

similar items which appear to be natural rubber, are

in fact, made of synthetic materials called

Fluoroelastomers. Under normal operating

conditions this material is safe and does not present

a health hazard. However, if the material is damaged

by fire or excessive heating, it can break down and

produce highly corrosive Hydrofluoric acid.

Contact with Hydrofluoric acid can cause serious

burns on contact with skin. If skin contact does occur:

lRemove any contaminated clothing

immediately.

lIrrigate effected area of skin with a copious

amount of cold water or limewater for 15 to 60

minutes.

lObtain medical assistance immediately.

Should any material be in a burnt or overheated

condition, handle with extreme caution and wear

protective clothing (seamless industrial gloves,

protective apron etc.).

Decontaminate and dispose of gloves immediately

after use.Lubricating oils

Avoid excessive skin contact with used lubricating

oils and always adhere to the health protection

precautions.

WARNING: Avoid excessive skin contact with

used engine oil. Used engine oil contains

potentially harmful contaminants which may

cause skin cancer or other serious skin

disorders.

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Health protection precautions

The following precautions should be observed at all

times.

lWear protective clothing, including impervious

gloves where practicable.

lAvoid prolonged and repeated contact with oils,

particularly used engine oils.

lDo not put oily rags in pockets.

lAvoid contaminating clothes (particularly those

next to the skin) with oil.

lOveralls must be cleaned regularly. Discard

heavily soiled clothing and oil impregnated

footwear.

lFirst aid treatment should be obtained

immediately for open cuts and wounds.

lApply barrier creams before each work period to

help prevent lubricating oil from contaminating

the skin.

lWash with soap and water to ensure all oil is

removed (proprietary skin cleansers and nail

brushes will help).

lUse moisturisers after cleaning; preparations

containing lanolin help replace the skin's natural

oils which have been removed.

lDo not use petrol/gasoline, kerosene, diesel

fuel, oil, thinners or solvents for cleaning skin.

lWhere practicable, degrease components prior

to handling.

lIf skin disorders develop, obtain medical advice

without delay.

lWear eye protection (e.g. goggles or face

shield) if there is a risk of eye contamination.

Eye wash facilities should be provided in close

vicinity of the work area.

Page 37 of 1672

GENERAL INFORMATION

03-2

Safety Instructions

Whenever possible, use a lift or pit when working

beneath vehicle, in preference to jacking. Chock

wheels as well as applying parking brake.

Jacking

Always use the recommended jacking points.

Always ensure that any lifting apparatus has

sufficient load capacity for the weight to be lifted.

Ensure the vehicle is standing on level ground prior

to lifting or jacking.

Apply the handbrake and chock the wheels.

WARNING: Do not work on or under a vehicle

supported only by a jack. Always support the

vehicle on safety stands.

Do not leave tools, lifting equipment, spilt oil, etc.

around or on the work bench area. Always keep a

clean and tidy work area.

Brake shoes and pads

Always fit the correct grade and specification of

brake linings. When renewing brake pads and brake

shoes, always replace as complete axle sets.Brake hydraulics

Observe the following recommendations when

working on the brake system:

lAlways use two spanners when loosening or

tightening brake pipe or hose connections.

lEnsure that hoses run in a natural curve and are

not kinked or twisted.

lFit brake pipes securely in their retaining clips

and ensure that the pipe cannot contact a

potential chafing point.

lContainers used for brake fluid must be kept

absolutely clean.

lDo not store brake fluid in an unsealed

container, it will absorb water and in this

condition would be dangerous to use due to a

lowering of its boiling point.

lDo not allow brake fluid to be contaminated with

mineral oil, or put new brake fluid in a container

which has previously contained mineral oil.

lDo not re-use brake fluid removed from the

system.

lAlways use clean brake fluid or a recommended

alternative to clean hydraulic components.

lAfter disconnection of brake pipes and hoses,

immediately fit suitable blanking caps or plugs to

prevent the ingress of dirt.

lOnly use the correct brake fittings with

compatible threads.

lObserve absolute cleanliness when working

with hydraulic components.

Cooling system caps and plugs

Extreme care is necessary when removing

expansion tank caps and coolant drain or bleed

screws when the engine is hot, especially if it is

overheated. To avoid the possibility of scalding,

allow the engine to cool before attempting removal.

Page 38 of 1672

GENERAL INFORMATION

03-3

Environmental Precautions

General

This section provides general information which can

help to reduce the environmental impacts from the

activities carried out in workshops.

Emissions to air

Many of the activities that are carried out in

workshops emit gases and fumes which contribute to

global warming, depletion of the ozone layer and/or

the formation of photochemical smog at ground

level. By considering how the workshop activities are

carried out, these gases and fumes can be

minimised, thus reducing the impact on the

environment.

Exhaust fumes

Running car engines is an essential part of workshop

activities and exhaust fumes need to be ventilated to

atmosphere. However, the amount of time engines

are running and the position of the vehicle should be

carefully considered at all times, to reduce the

release of poisonous gases and minimise the

inconvenience to people living nearby.

Solvents

Some of the cleaning agents used are solvent based

and will evaporate to atmosphere if used carelessly,

or if cans are left unsealed. All solvent containers

should be firmly closed when not needed and

solvent should be used sparingly. Suitable

alternative materials may be available to replace

some of the commonly used solvents. Similarly,

many paints are solvent based and the spray should

be minimised to reduce solvent emissions.

Refrigerant

It is illegal to release any refrigerants into the

atmosphere. Discharge and replacement of these

materials from air conditioning units should only be

carried out using the correct equipment.

Checklist

Always adhere to the following.

Engines:

ldon't leave engines running unnecessarily;

lminimise testing times and check where the

exhaust fumes are being blown.

Materials:

lkeep lids on containers of solvents;

lonly use the minimum quantity;

lconsider alternative materials;

lminimise over-spray when painting. Gases:

luse the correct equipment for collecting

refrigerants;

ldon't burn rubbish on site.

Discharges to water

Most sites will have two systems for discharging

water: storm drains and foul drains. Storm drains

should only receive clean water, foul drains will take

dirty water.

The foul drain will accept many of the normal waste

waters such as washing water, detergents and

domestic type wastes, but oil, petrol, solvent, acids,

hydraulic oil, antifreeze and other such substances

should never be poured down the drain. If in any

doubt speak to the Water Company first.

Every precaution must be taken to prevent spillage of

oil, fuel, solvents etc. reaching the drains. All

handling of such materials must take place well away

from the drains and preferably in an area with a kerb

or wall around it, to prevent discharge into the drain.

If a spillage occurs it should be soaked up

immediately. Having a spill kit available will make

this easier.

Additional precautions

Check whether the surface water drains are

connected to an oil water separator, this could

reduce the pollution if an incident was to occur. Oil

water separators do need regular maintenance to

ensure effectiveness.

Checklist

Always adhere to the following.

Disposal:

lnever pour anything down a drain without first

checking that it is environmentally safe to do so,

and that it does not contravene any local

regulations or bye-laws;

l have oil traps emptied regularly.

Spillage prevention:

lstore liquids in a walled area;

lmake sure that taps on liquid containers are

secure and cannot be accidentally turned on;

lprotect bulk storage tanks from vandalism by

locking the valves;

ltransfer liquids from one container to another in

an area away from open drains;

lensure lids are replaced securely on containers;

lhave spill kits available near to points of storage

and handling of liquids.

Page 39 of 1672

GENERAL INFORMATION

03-4

Spill kits

Special materials are available to absorb a number of

different substances. They can be in granular form,

ready to use and bought in convenient containers for

storage. Disposal of used spill-absorbing material is

dealt with in 'Waste Management' section.

Land contamination

Oils, fuels and solvents etc. can contaminate any soil

that they are allowed to contact. Such materials

should never be disposed of by pouring onto soil and

every precaution must be taken to prevent spillage

reaching soil. Waste materials stored on open

ground could also leak, or have polluting substances

washed off them that would contaminate the land.

Always store these materials in suitable skips or

other similarly robust containers.

Checklist

Always adhere to the following.

lDon't pour or spill anything onto the soil or bare

ground;

ldon't store waste materials on bare ground, see

'Spillage prevention' list.

Legal compliance

Some sites may have a discharge consent for

effluent discharge to the foul drain for a car wash etc.

It is important to know what materials are allowed in

the drain and to check the results of any monitoring

carried out by the Water Company.

Where paint-spraying operations are carried out it

may be necessary to apply to the Local Authority for

an air emissions licence to operate the plant. If such

a licence is in operation, additional precautions will

be necessary to comply with the requirements, and

the results of any air quality monitoring must be

checked regularly.

Checklist

Always adhere to the following.

lKnow what legal consents and licences apply to

the operations;

lcheck that the emissions and discharges

comply with legal requirements.

Local issues

A number of environmental issues will be of

particular concern to residents and other neighbours

close to the site. The sensitivity of these issues will

depend on the proximity of the site and the layout

and amount of activity carried on at the site.

Noise is a major concern and therefore

consideration should be given to the time spent

carrying out noisy activities and the location of those

activities that can cause excessive noise. Car alarm testing, panel beating, hammering and

other such noisy activities should, whenever

possible, be carried out indoors with doors and

windows shut or as far away from houses as

possible.

Running vehicle engines may be an outside activity

which could cause nuisance to neighbours because

of both noise and smell.

Be sensitive to the time of day when these activities

are carried out and minimise the time of the noisy

operation, particularly in the early morning and late

evening.

Another local concern will be the smell from the

various materials used. Using less solvent, paint

and petrol could help prevent this annoyance.

Local residents and other business users will also be

concerned about traffic congestion, noise and

exhaust fumes, be sensitive to these concerns and

try to minimise inconvenience from deliveries,

customers and servicing operations.

Checklist

Always adhere to the following.

lIdentify where the neighbours who are likely to

be affected are situated;

lminimise noise, smells and traffic nuisance;

lprevent litter by putting waste in the correct

containers;

lhave waste skips emptied regularly.

Use of resource

Another environmental concern is the waste of

materials and energy that can occur in day to day

activities.

Electricity for heating, lighting and compressed air

uses resources and releases pollution during its

generation.

Fuel used for heating, running cars or vans and

mobile plant is another limited resource which

consumes large amounts of energy during its

extraction and refining processes.

Water has to be cleaned, piped to site and disposed

of; all of which creates more potential pollution.

Oil, spares, paint etc., have all produced pollution in

the process of manufacture and they become a

waste disposal problem if discarded.

Checklist

Always adhere to the following.

Page 40 of 1672

GENERAL INFORMATION

03-5

Electricity and heating:

lkeep doors and windows closed in the winter;

lswitch off machinery or lights when not needed;

luse energy efficient heating systems;

lswitch off computers and photocopiers when

not needed.

Fuel:

ldon't run engines unnecessarily;

lthink about whether journeys are necessary and

drive to conserve fuel.

Water:

ldon't leave taps and hose pipes running;

lmend leaks quickly, don't be wasteful.

Compressed air:

ldon't leave valves open;

lmend leaks quickly;

ldon't leave the compressor running when not

needed.

Use of environmentally damaging materials:

lcheck whether a less toxic material is available.

Handling and storage of materials:

lhave the correct facilities available for handling

liquids to prevent spillage and wastage as listed

above;

lprovide suitable locations for storage to prevent

frost damage or other deterioration.

Waste Management

One of the major ways that pollution can be reduced

is by the careful handling, storage and disposal of all

waste materials that occur on sites. Legislation

makes it illegal to dispose of waste materials other

than to licensed waste carriers and disposal sites.

This means that it is necessary to not only know what

the waste materials are, but also to have the

necessary documentation and licenses.

Handling and storage of waste

Ensure that waste materials are not poured down the

drain or onto soils. They should be stored in such a

way as to prevent the escape of the material to land,

water or air.

They must also be segregated into different types of

waste e.g. oil, metals, batteries, used vehicle

components. This will prevent any reaction between

different materials and assist in disposal.

Disposal of waste

Disposal of waste materials must only be to waste

carriers who are licensed to carry those particular

waste materials and all the necessary

documentation must be completed. The waste

carrier is responsible for ensuring that the waste is

taken to the correct disposal sites.Dispose of waste in accordance with the following

guidelines.

lFuel, hydraulic fluid, anti-freeze and oil: keep

separate and dispose of to specialist contractor.

lRefrigerant: collect in specialist equipment and

reuse.

lDetergents: safe to pour down the foul drain if

diluted.

lPaint, thinners: keep separate and dispose of

to specialist contractor.

lComponents: send back to supplier for

refurbishment, or disassemble and reuse any

suitable parts. Dispose of the remainder in

ordinary waste.

lSmall parts: reuse any suitable parts, dispose

of the remainder in ordinary waste.

lMetals: can be sold if kept separate from

general waste.

lTyres: keep separate and dispose of to

specialist contractor.

lPackaging: compact as much as possible and

dispose of in ordinary waste.

lAsbestos-containing: keep separate and

dispose of to specialist contractor.

lOily and fuel wastes (e.g. rags, used spill kit

material): keep separate and dispose of to

specialist contractor.

lAir filters: keep separate and dispose of to

specialist contractor.

lRubber/plastics: dispose of in ordinary waste.

lHoses: dispose of in ordinary waste.

lBatteries: keep separate and dispose of to

specialist contractor.

lAirbags - explosives: keep separate and

dispose of to specialist contractor.

lElectrical components: send back to supplier

for refurbishment, or disassemble and reuse

any suitable parts. Dispose of the remainder in

ordinary waste.

lElectronic components: send back to supplier

for refurbishment, or disassemble and reuse

any suitable parts. Dispose of the remainder in

ordinary waste.

lCatalysts: can be sold if kept separate from

general waste

lUsed spill-absorbing material: keep separate

and dispose of to specialist contractor.

lOffice waste: recycle paper and toner and ink

cartridges, dispose of the remainder in ordinary

waste.