LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 221 of 1007

ENGINE - K SERIES KV6

12-3-44 REPAIRS

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm.

39.Stake nuts to drive shafts

40.Fit front road wheels, fit and tighten nuts to 115

Nm.

41.Lower vehicle on lift.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket.

48.Connect hose to purge valve.

49.Fit purge hose into clip.

50.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

51.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

52.Connect Lucar connector to starter solenoid.

53.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm.

54.Position engine harness to 'E' box mounting

bracket and secure with clips.

55.Connect earth header multiplug.

56.Connect multiplug to under bonnet fuse box.

57.Position battery and starter motor lead to under

bonnet fuse box, fit and tighten bolts to 8 Nm.

58.Fit under bonnet fuse box cover.

59.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm.

60.Fit carrier to 'E' box.

61.Fit air ducting to 'E' box.

62.Fit body harness to 'E' box, secure grommet

and harness clip.

63.Connect 'E' box cooling fan multiplug.

64.Connect multiplug to 'E' box temperature

sensor.

65.Connect multiplug to gearbox ECU.

66.Position engine harness to 'E' box and secure

grommet.67.Fit engine harness clamp and secure with

screws.

68.Connect engine harness multiplug to body

harness multiplug and fit multiplug to 'E' box.

69.Fit heated front screen harness to battery

positive cable and tighten bolt to 15 Nm (11

lbf.ft).

70.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - fuel - NAS.

71.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

72.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

73.Connect the battery earth lead.

74.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

75.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

76.Untie and close bonnet.

Page 222 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-45

Arm assembly - engine mounting RH

$% 12.45.06

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

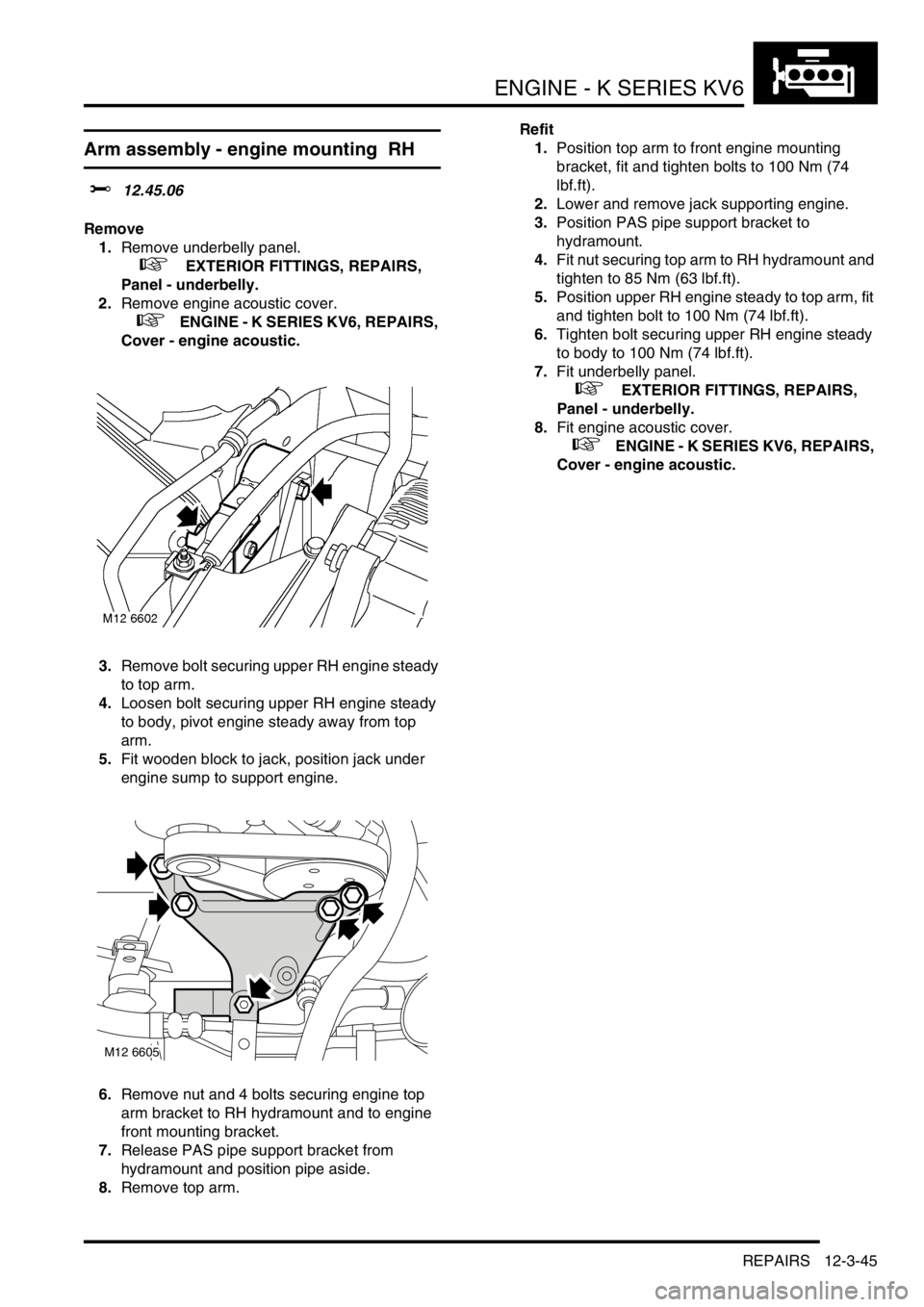

3.Remove bolt securing upper RH engine steady

to top arm.

4.Loosen bolt securing upper RH engine steady

to body, pivot engine steady away from top

arm.

5.Fit wooden block to jack, position jack under

engine sump to support engine.

6.Remove nut and 4 bolts securing engine top

arm bracket to RH hydramount and to engine

front mounting bracket.

7.Release PAS pipe support bracket from

hydramount and position pipe aside.

8.Remove top arm.Refit

1.Position top arm to front engine mounting

bracket, fit and tighten bolts to 100 Nm (74

lbf.ft).

2.Lower and remove jack supporting engine.

3.Position PAS pipe support bracket to

hydramount.

4.Fit nut securing top arm to RH hydramount and

tighten to 85 Nm (63 lbf.ft).

5.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

6.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M12 6605

Page 223 of 1007

ENGINE - K SERIES KV6

12-3-46 REPAIRS

Engine mounting - LH

$% 12.45.11

Remove

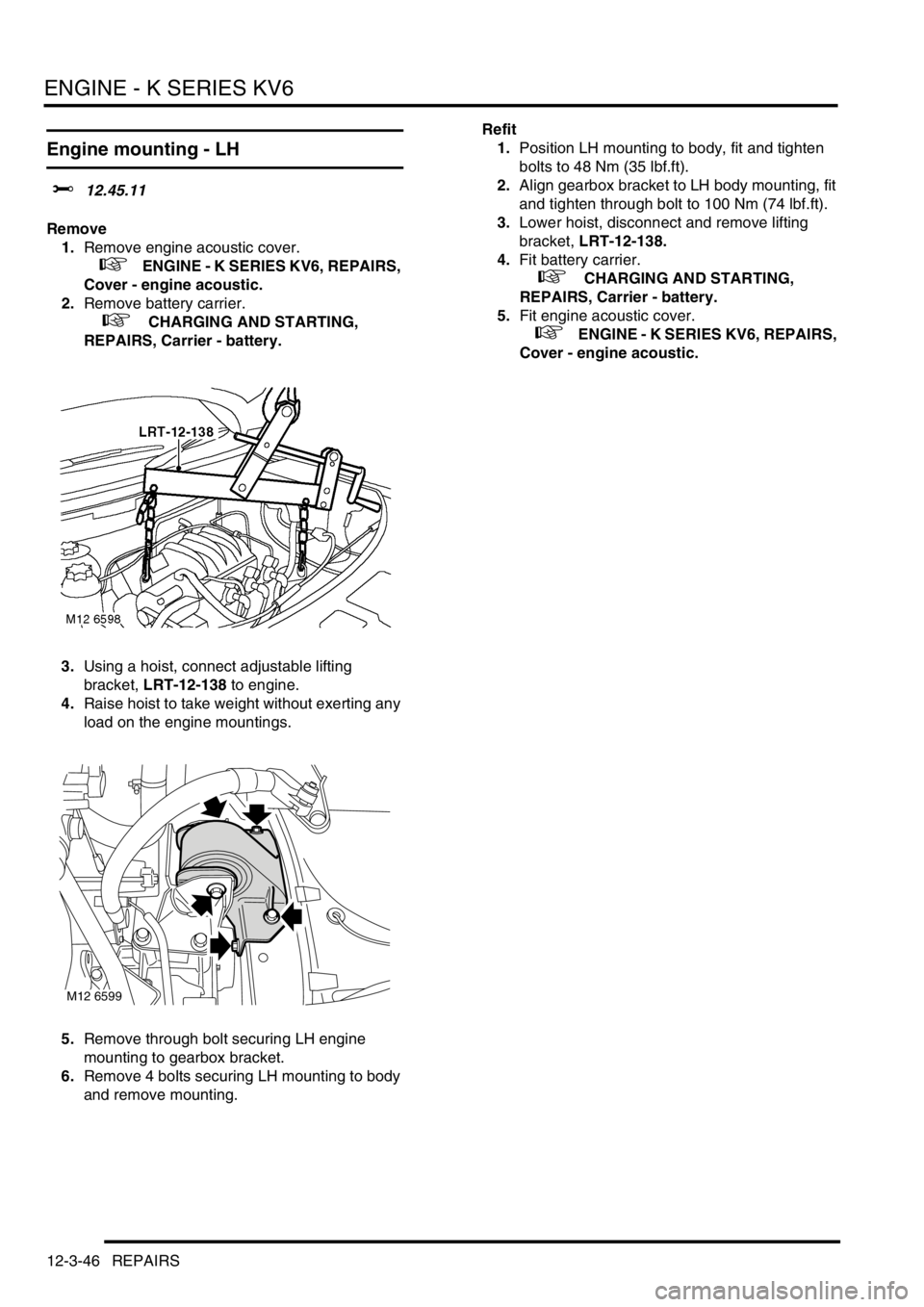

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

3.Using a hoist, connect adjustable lifting

bracket, LRT-12-138 to engine.

4.Raise hoist to take weight without exerting any

load on the engine mountings.

5.Remove through bolt securing LH engine

mounting to gearbox bracket.

6.Remove 4 bolts securing LH mounting to body

and remove mounting.Refit

1.Position LH mounting to body, fit and tighten

bolts to 48 Nm (35 lbf.ft).

2.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

3.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

4.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

5.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M12 6599

Page 224 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-47

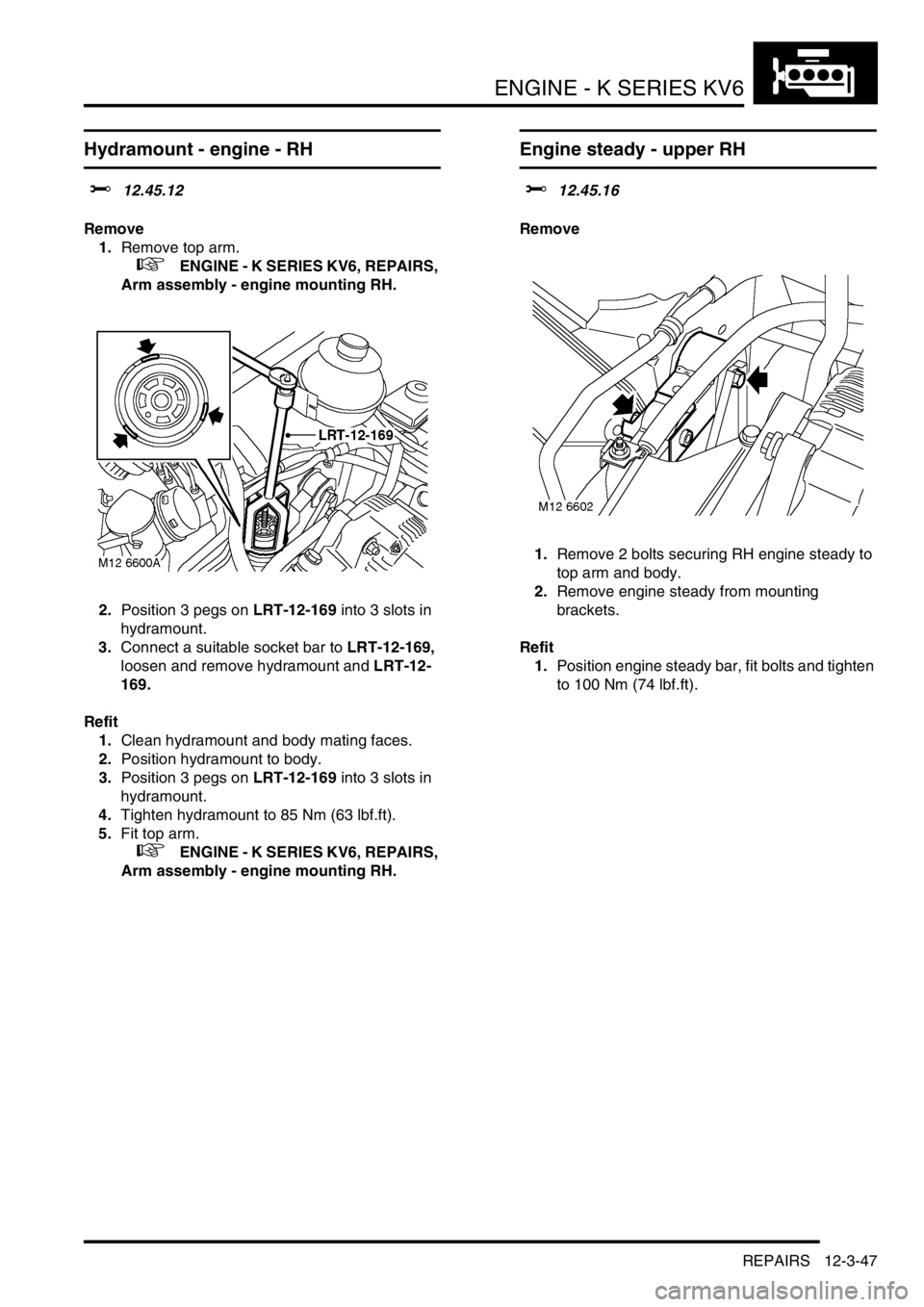

Hydramount - engine - RH

$% 12.45.12

Remove

1.Remove top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

2.Position 3 pegs on LRT-12-169 into 3 slots in

hydramount.

3.Connect a suitable socket bar to LRT-12-169,

loosen and remove hydramount and LRT-12-

169.

Refit

1.Clean hydramount and body mating faces.

2.Position hydramount to body.

3.Position 3 pegs on LRT-12-169 into 3 slots in

hydramount.

4.Tighten hydramount to 85 Nm (63 lbf.ft).

5.Fit top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

Engine steady - upper RH

$% 12.45.16

Remove

1.Remove 2 bolts securing RH engine steady to

top arm and body.

2.Remove engine steady from mounting

brackets.

Refit

1.Position engine steady bar, fit bolts and tighten

to 100 Nm (74 lbf.ft).

Page 225 of 1007

ENGINE - K SERIES KV6

12-3-48 REPAIRS

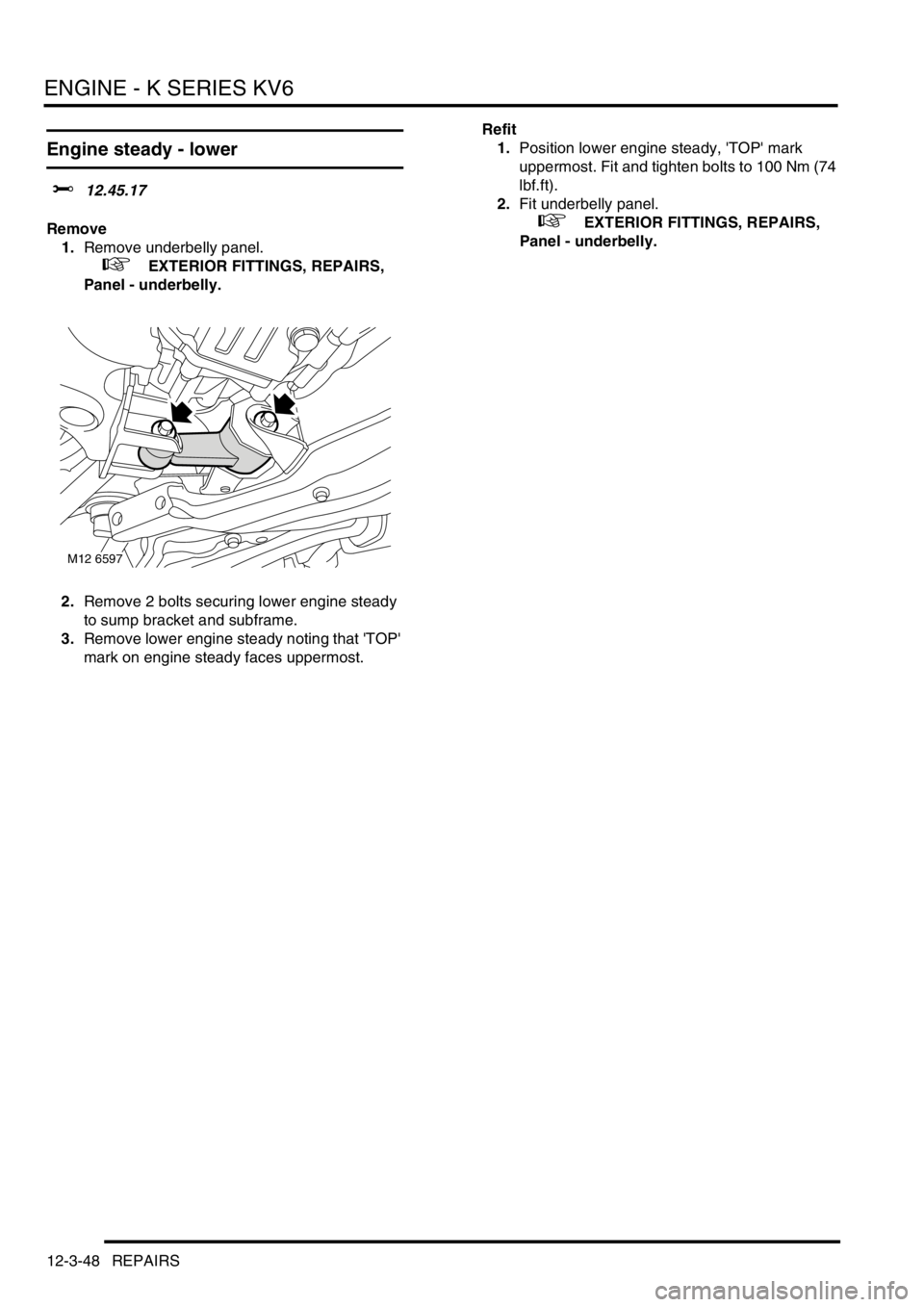

Engine steady - lower

$% 12.45.17

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Remove 2 bolts securing lower engine steady

to sump bracket and subframe.

3.Remove lower engine steady noting that 'TOP'

mark on engine steady faces uppermost.Refit

1.Position lower engine steady, 'TOP' mark

uppermost. Fit and tighten bolts to 100 Nm (74

lbf.ft).

2.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M12 6597

Page 226 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-49

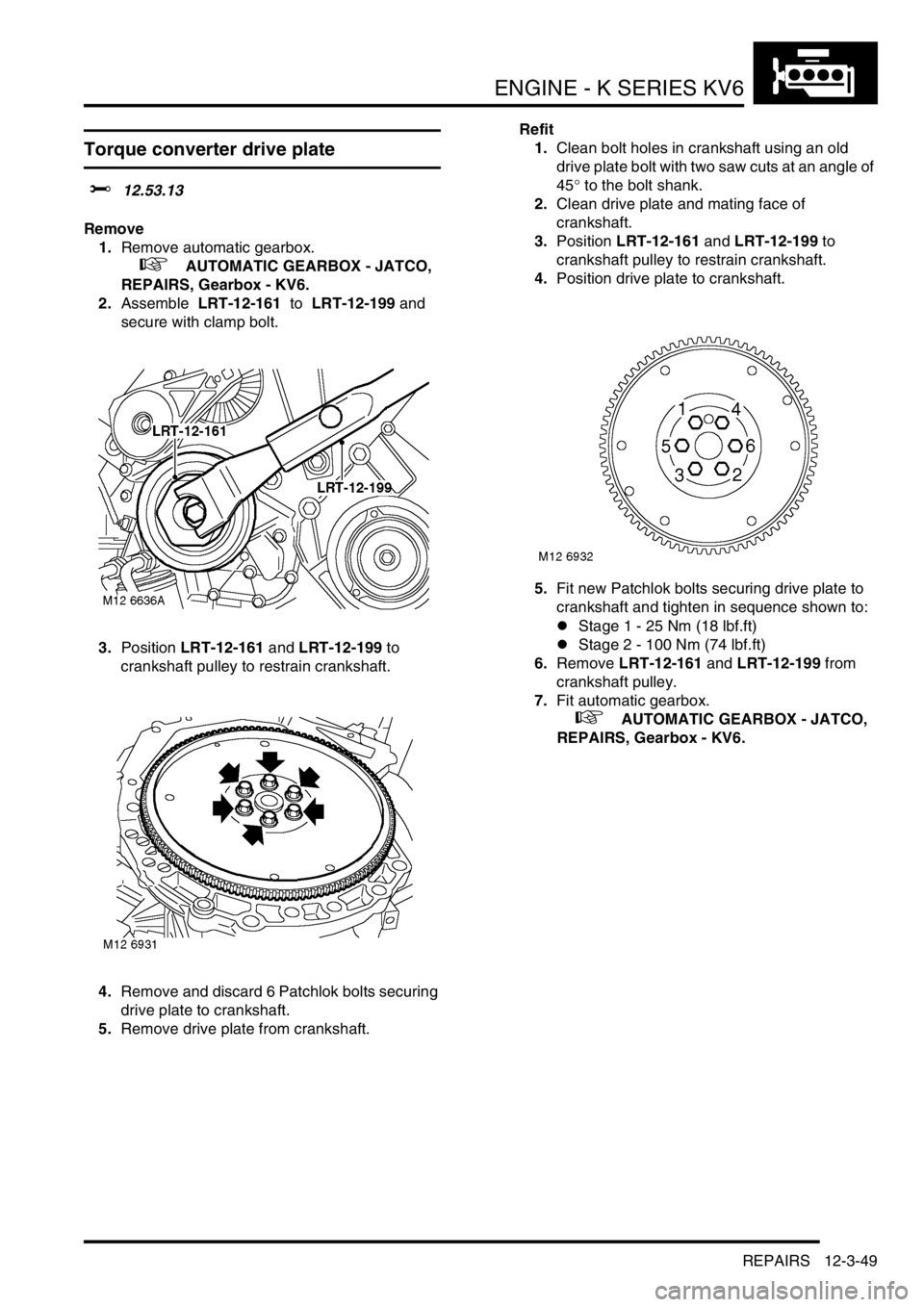

Torque converter drive plate

$% 12.53.13

Remove

1.Remove automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

2.Assemble LRT-12-161 to LRT-12-199 and

secure with clamp bolt.

3.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

4.Remove and discard 6 Patchlok bolts securing

drive plate to crankshaft.

5.Remove drive plate from crankshaft.Refit

1.Clean bolt holes in crankshaft using an old

drive plate bolt with two saw cuts at an angle of

45° to the bolt shank.

2.Clean drive plate and mating face of

crankshaft.

3.Position LRT-12-161 and LRT-12-199 to

crankshaft pulley to restrain crankshaft.

4.Position drive plate to crankshaft.

5.Fit new Patchlok bolts securing drive plate to

crankshaft and tighten in sequence shown to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - 100 Nm (74 lbf.ft)

6.Remove LRT-12-161 and LRT-12-199 from

crankshaft pulley.

7.Fit automatic gearbox.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Gearbox - KV6.

Page 227 of 1007

ENGINE - K SERIES KV6

12-3-50 REPAIRS

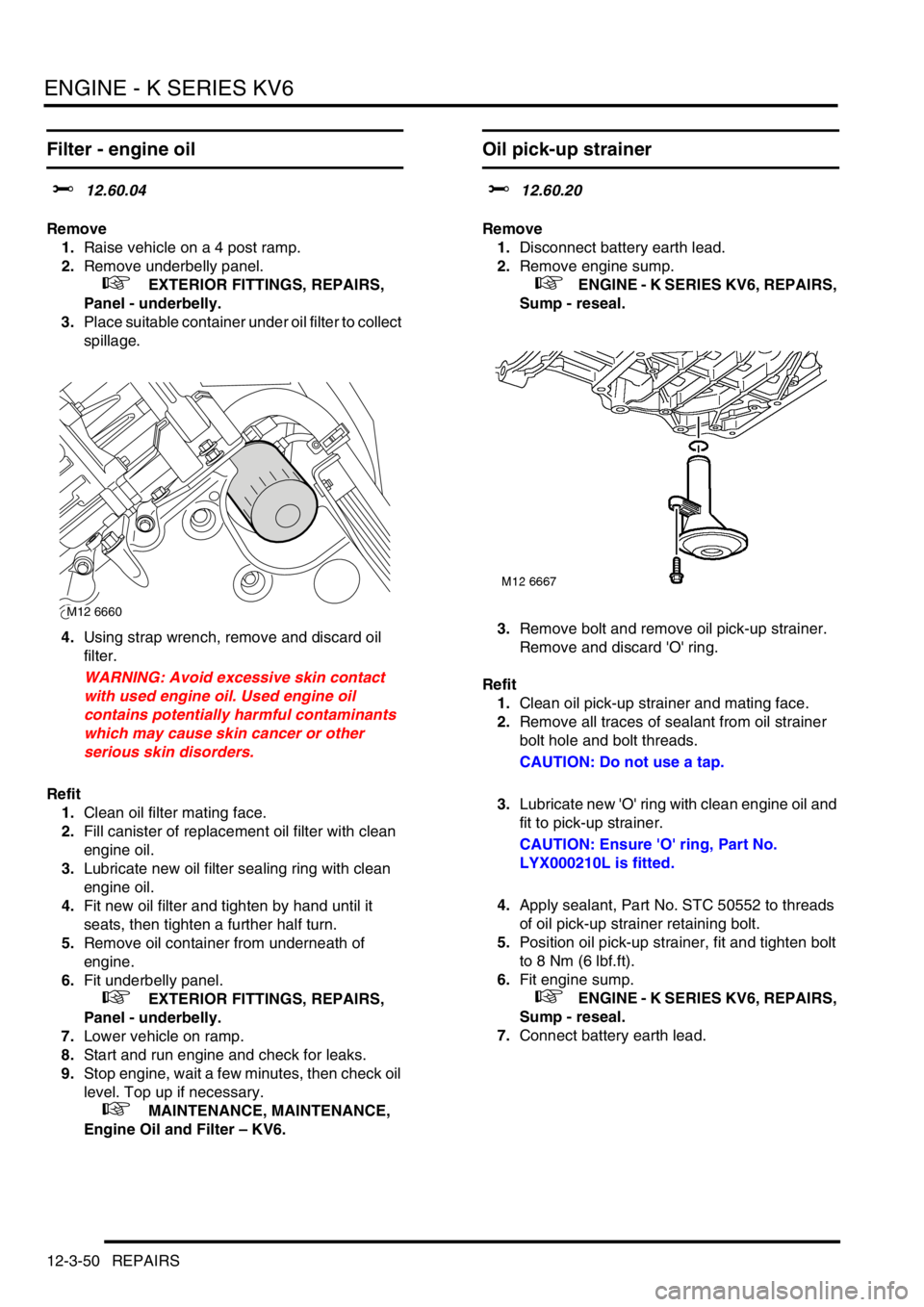

Filter - engine oil

$% 12.60.04

Remove

1.Raise vehicle on a 4 post ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place suitable container under oil filter to collect

spillage.

4.Using strap wrench, remove and discard oil

filter.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

Refit

1.Clean oil filter mating face.

2.Fill canister of replacement oil filter with clean

engine oil.

3.Lubricate new oil filter sealing ring with clean

engine oil.

4.Fit new oil filter and tighten by hand until it

seats, then tighten a further half turn.

5.Remove oil container from underneath of

engine.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Lower vehicle on ramp.

8.Start and run engine and check for leaks.

9.Stop engine, wait a few minutes, then check oil

level. Top up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Oil pick-up strainer

$% 12.60.20

Remove

1.Disconnect battery earth lead.

2.Remove engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

3.Remove bolt and remove oil pick-up strainer.

Remove and discard 'O' ring.

Refit

1.Clean oil pick-up strainer and mating face.

2.Remove all traces of sealant from oil strainer

bolt hole and bolt threads.

CAUTION: Do not use a tap.

3.Lubricate new 'O' ring with clean engine oil and

fit to pick-up strainer.

CAUTION: Ensure 'O' ring, Part No.

LYX000210L is fitted.

4.Apply sealant, Part No. STC 50552 to threads

of oil pick-up strainer retaining bolt.

5.Position oil pick-up strainer, fit and tighten bolt

to 8 Nm (6 lbf.ft).

6.Fit engine sump.

+ ENGINE - K SERIES KV6, REPAIRS,

Sump - reseal.

7.Connect battery earth lead.

M12 6660

Page 228 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-51

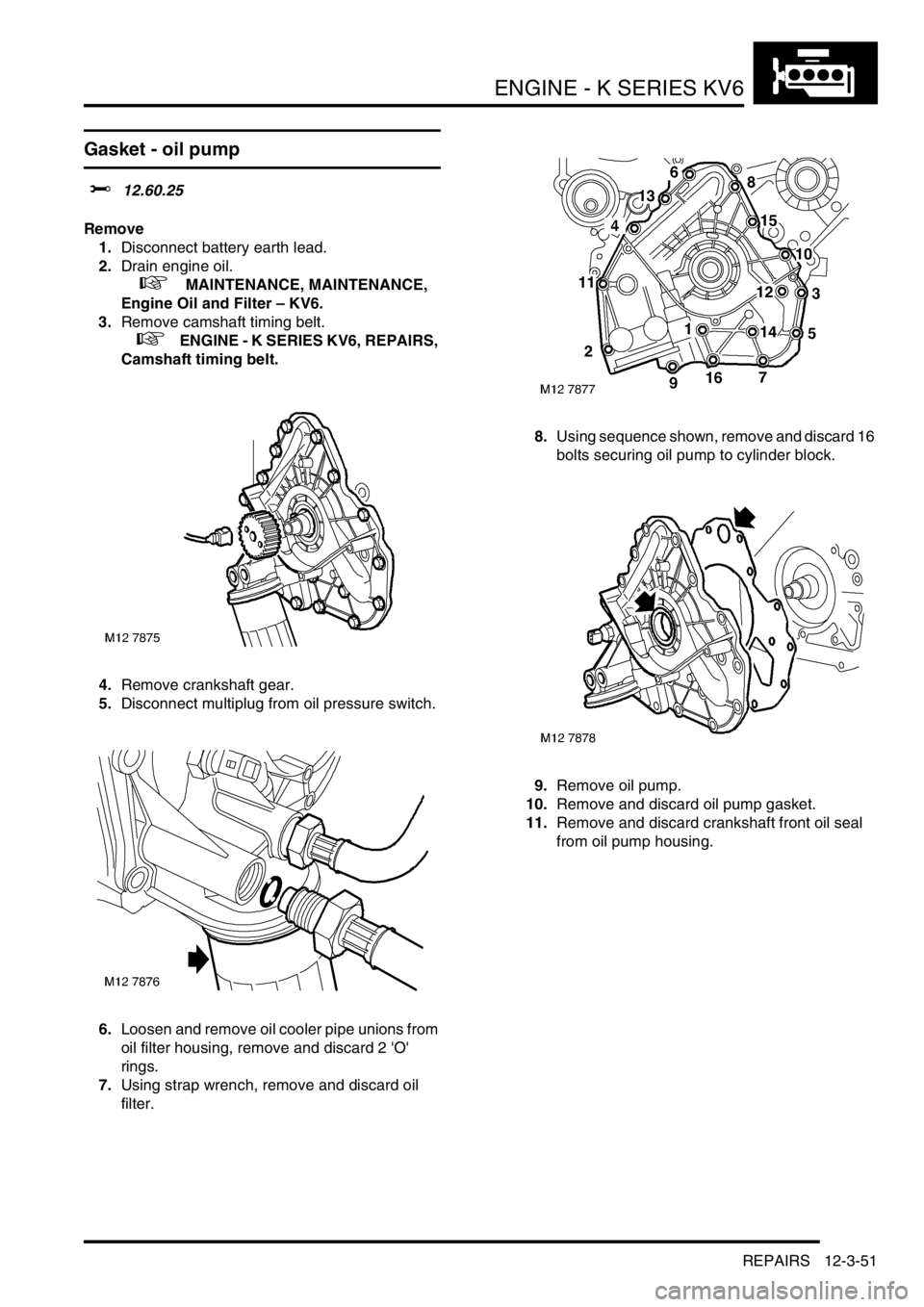

Gasket - oil pump

$% 12.60.25

Remove

1.Disconnect battery earth lead.

2.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

3.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

4.Remove crankshaft gear.

5.Disconnect multiplug from oil pressure switch.

6.Loosen and remove oil cooler pipe unions from

oil filter housing, remove and discard 2 'O'

rings.

7.Using strap wrench, remove and discard oil

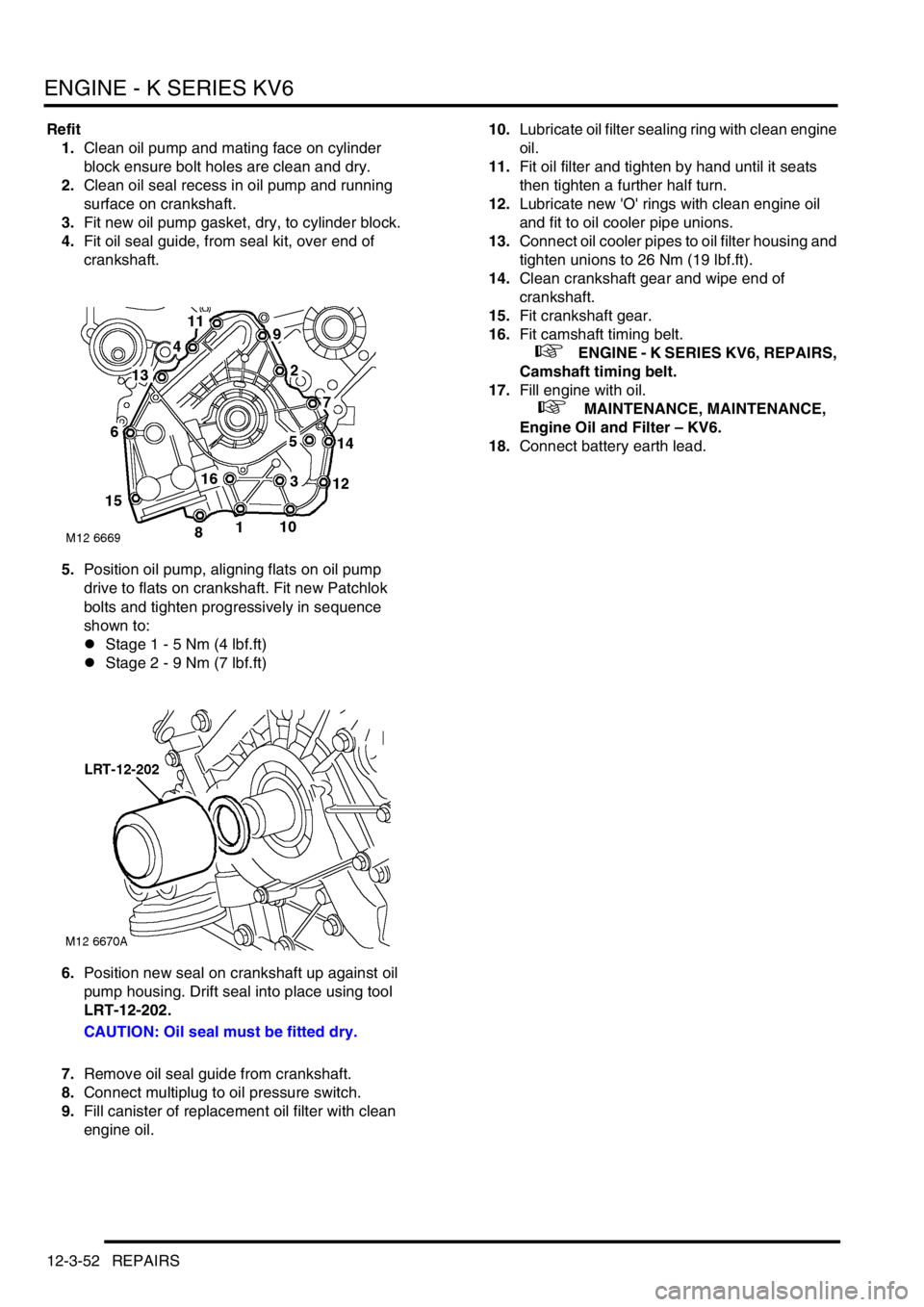

filter.8.Using sequence shown, remove and discard 16

bolts securing oil pump to cylinder block.

9.Remove oil pump.

10.Remove and discard oil pump gasket.

11.Remove and discard crankshaft front oil seal

from oil pump housing.

Page 229 of 1007

ENGINE - K SERIES KV6

12-3-52 REPAIRS

Refit

1.Clean oil pump and mating face on cylinder

block ensure bolt holes are clean and dry.

2.Clean oil seal recess in oil pump and running

surface on crankshaft.

3.Fit new oil pump gasket, dry, to cylinder block.

4.Fit oil seal guide, from seal kit, over end of

crankshaft.

5.Position oil pump, aligning flats on oil pump

drive to flats on crankshaft. Fit new Patchlok

bolts and tighten progressively in sequence

shown to:

lStage 1 - 5 Nm (4 lbf.ft)

lStage 2 - 9 Nm (7 lbf.ft)

6.Position new seal on crankshaft up against oil

pump housing. Drift seal into place using tool

LRT-12-202.

CAUTION: Oil seal must be fitted dry.

7.Remove oil seal guide from crankshaft.

8.Connect multiplug to oil pressure switch.

9.Fill canister of replacement oil filter with clean

engine oil.10.Lubricate oil filter sealing ring with clean engine

oil.

11.Fit oil filter and tighten by hand until it seats

then tighten a further half turn.

12.Lubricate new 'O' rings with clean engine oil

and fit to oil cooler pipe unions.

13.Connect oil cooler pipes to oil filter housing and

tighten unions to 26 Nm (19 lbf.ft).

14.Clean crankshaft gear and wipe end of

crankshaft.

15.Fit crankshaft gear.

16.Fit camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

17.Fill engine with oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

18.Connect battery earth lead.

Page 230 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-53

Sump - reseal

$% 12.60.38

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Drain engine oil.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

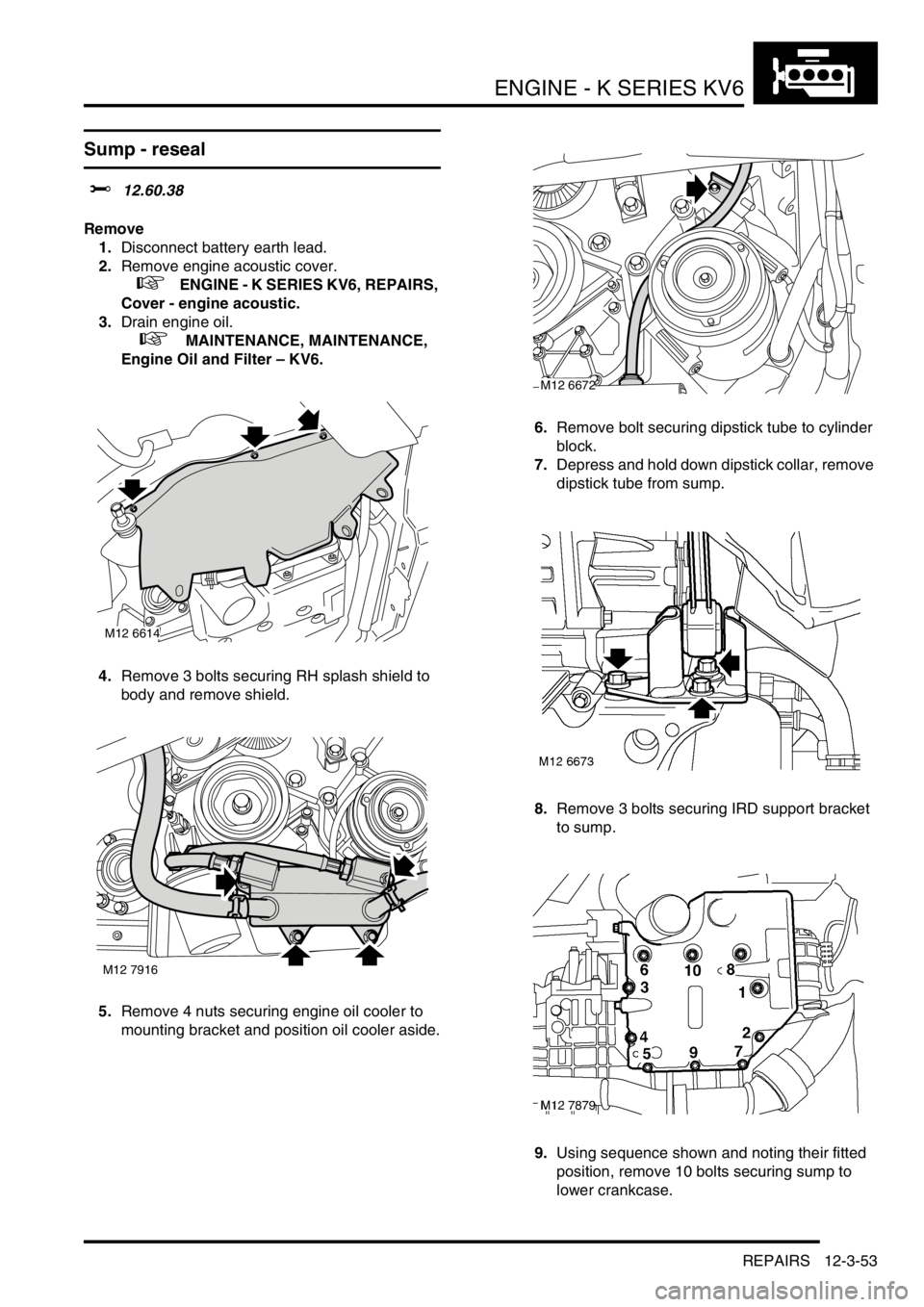

4.Remove 3 bolts securing RH splash shield to

body and remove shield.

5.Remove 4 nuts securing engine oil cooler to

mounting bracket and position oil cooler aside.6.Remove bolt securing dipstick tube to cylinder

block.

7.Depress and hold down dipstick collar, remove

dipstick tube from sump.

8.Remove 3 bolts securing IRD support bracket

to sump.

9.Using sequence shown and noting their fitted

position, remove 10 bolts securing sump to

lower crankcase.

M12 6614

M12 7916

M12 6672