LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1181 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions - Evaporative Emissions

Des cript ion and Operat ion

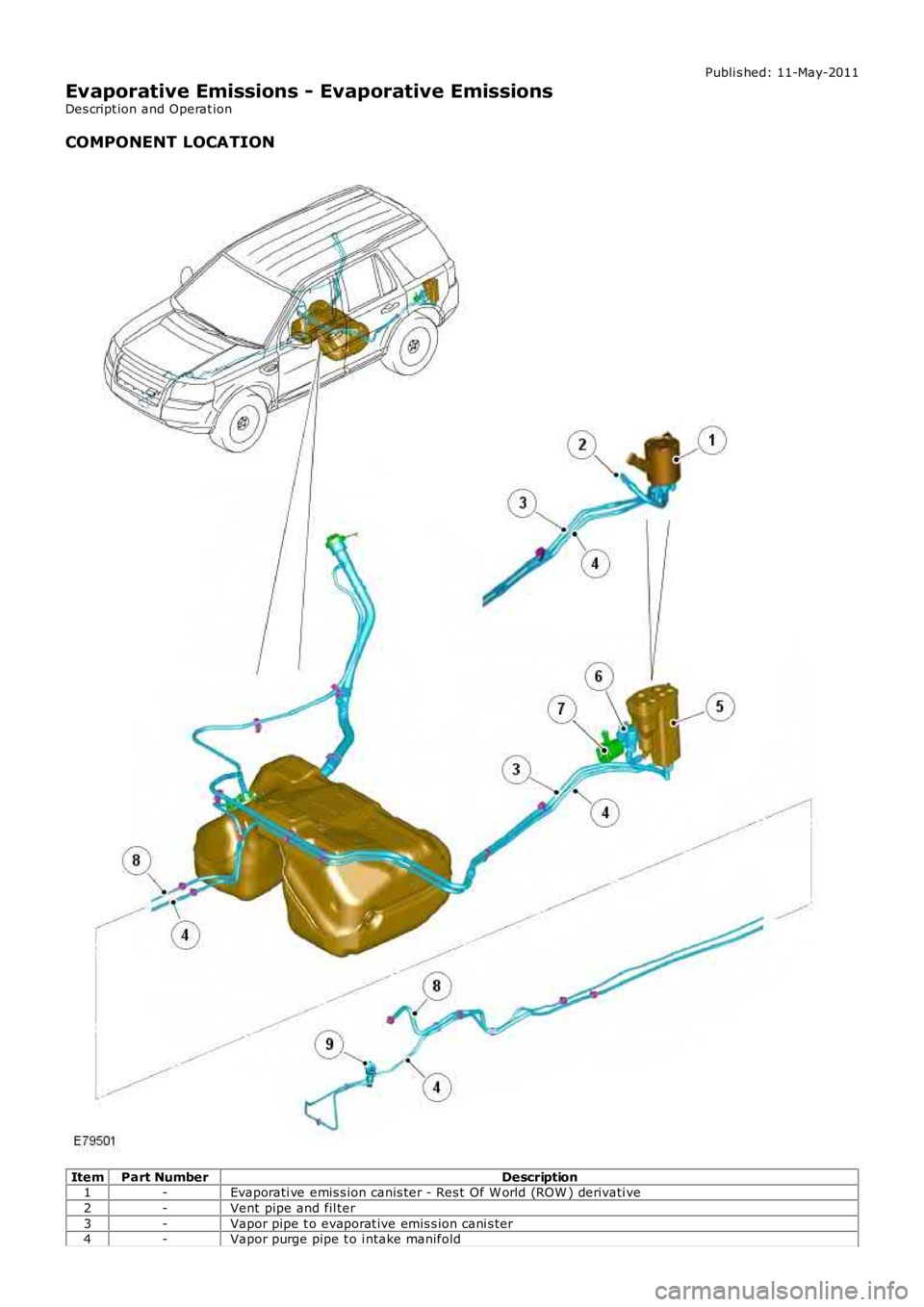

COMPONENT LOCATION

ItemPart NumberDescription1-Evaporati ve emis s ion canis ter - Res t Of W orld (ROW ) derivati ve

2-Vent pipe and fil ter

3-Vapor pipe t o evaporat ive emis s ion cani s ter4-Vapor purge pipe t o i ntake manifold

Page 1182 of 3229

5-Evaporati ve emis s ion canis ter - North Ameri can Specifi cat ion (NAS) deri vat ive

6-Fuel tank l eakage monit ori ng pump

7-Fuel tank l eakage monit ori ng pump filt er8-Fuel del ivery pi pe to engi ne

9-Evaporati ve emis s ion canis ter purge val ve

OVERVIEW

The evaporat ive emis si on (EVAP) control s ys tem reduces the l evel of hydrocarbons releas ed int o the at mos phere by fuelvapor venti ng from t he fuel t ank. The s yst em compris es a charcoal canis ter, purge valve and i nt erconnect ing vent pipesand hoses .

Fuel vapor is generated by the fuel in t he t ank and the amount of vapor produced increas es as the fuel heat s up. Fuelvapor can flow freely to the charcoal canis t er vi a the tank venti ng sys t em. The venting s yst em cons is ts of roll over val vesand a l iquid vapor s eparat or mounted i nternal ly i n t he tank and t hen ext ernall y via a breather l ine. The breather li neall ows the fuel vapor to fl ow t o t he charcoal cani st er.

On NAS vehicl es the vapor generat ed in the fuel tank duri ng refuel ing flows wit hout res t ri ct ion to t he charcoal canis ter.

On al l vehicles except NAS, t he vapor i s res t ri ct ed in it s path to t he charcoal canis ter but can fl ow freely during t herefuel ing operat ion t o at mos phere, vi a t he fi ller opening.

The vapor pas ses i nto the charcoal canis t er where it i s abs orbed and s tored by the charcoal. Becaus e t here i s a l imi t t o theamount of vapor the canis t er can contain, t he fuel vapor i s purged from the canis t er when t he engine i s running andburned i n the engi ne.

PRINCIPLES OF OPERATION

Charcoal Canister

The charcoal cani s ter cont ains a bed of acti vat ed charcoal or carbon. The charcoal is produced us ing s peci al manufact uri ngt echniques to treat the charcoal wit h oxygen. The oxygen t reatment opens up mi ll ions of pores between t he carbon at omsres ult ing i n a hi ghl y porous charcoal wi th a very l arge effecti ve surface area which is capable of abs orbing l arge quanti ti esof fuel vapor. Once treat ed t he charcoal is known as 'act ivated' carbon or charcoal. The charcoal canis t er on NAS vehi cl esus es a higher grade charcoal t o meet t he requirement s of t he emis s ion regul ati ons .

On-board Refueling Vapor Recovery

To meet On-board Refueli ng Vapor Recovery (O RVR) requi rement s, t he fuel t ank and associated component s are desi gnedt o mi ni mize fuel vapor los s duri ng refuel ing. This i s achi eved by prevent ing fuel vapor from t he fuel t ank venti ng direct ly tot he atmos phere. Ins t ead fuel vapor is di rected into the Evaporati ve Emis s ion (EVAP) canis t er where i t is s t ored beforebeing purged at i ntervals int o the engi ne’s int ake mani fol d.

Duri ng vehi cl e refueling the narrow fuel-fi ller-t ube below t he fuel -di spens er nozzle regi on, provi des a l iquid s eal agai ns tt he escape of vapor. A check valve al so locat ed i n the fi ller-t ube opens t o i ncomi ng fuel t o prevent spl as h back.

As t he fuel t ank fil ls , fuel vapor i s rout ed to the EVAP canis t er's charcoal fi lt er, where i t is abs orbed by t he charcoal 'sact ivat ed granules . The hydrocarbons from the fuel vapor are retai ned wit hin t he cani s ter, al lowing onl y puri fied ai r to berel eas ed t o at mosphere through the canis ter's vent pipe. The hydrocarbons s t ored in the canis t er are purged at i nt ervalsint o t he engi ne for combust ion.

The EVAP cani st er purge valve i s located i n t he engi ne compart ment . The Engine Control Modul e (ECM) operat es the val vet o purge fuel vapor from t he EVAP cani st er int o t he engi ne for combust ion. Purge rates (the ext ent that the purge valveopens ) are det ermined by t he engi ne operati ng condi ti ons . The purge rates are adjus ted t o mai ntai n vehi cl e dri vingcharact eri st ics and exhaus t emi ss i ons at opt imum levels . Engi ne operati ng condi ti ons that affect t he purge rate are:

s peed and load,engi ne cool ant temperat ure,t ime from engine s t art-up,clos ed loop fuel ing

Owi ng to the l imi ted st orage-volume of the EVAP canis ter:

NAS deri vat ive - 2.5 l it erROW derivat ive - 0.7 li ter

t he charcoal fi lt er is conti nuall y regenerat ed.

Regenerat ion is achieved when the engine is runni ng, by drawing ai r through t he EVAP cani s ter, vi a t he vent pipe, i nt o t heengi ne for combus ti on.

Fuel Tank Leakage Monitoring

Fuel t ank leakage monit oring i s a l egis lat ive requirement for NAS vehicles . The monit ori ng sys t em peri odi cal ly checks t heEVAP s ys t em and fuel t ank for l eaks when t he i gni ti on is off.

The monit ori ng s ys t em compri ses the previ ous ly des cri bed components of t he EVAP s ystem wit h the foll owing addit ionalcomponents :

air pump, anddust fil ter

The pump i s connected t o t he vent pi pe of the EVAP canis t er and i ncorporates :

a Pos it ive Temperat ure Coefficient (PTC) heat ing element ,

Page 1183 of 3229

change over val ve, anda reference ori fi ce

The pump i s only operat ed when the ignit ion i s 'off' and as cont rol led by t he ECM. The ECM al so monit ors t he pumpoperati on and t he change over valve for fault s . The dus t fil ter prot ect s t he pump from the i ngres s of mois t ure and foreignpart icles .

The fuel t ank leakage moni toring t est i s performed if t he foll owing fact ors are present:

t he engi ne has been operat ing for at leas t 10 mi nut es and is now at res t,t he fuel in the t ank is bet ween 15 and 85 percent vol ume,t he ambient temperat ure is above 0°C (32°F) and les s t han 40°C (104°F),t he engi ne has not been s t art ed for at leas t 3 hours prior t o it s l as t operat ion

The pump i s operated t o press uri ze the fuel tank and t he electrical current used to operat e t he pump i s meas ured wi th thechange-over val ve in di fferent s tat es. A comparis on of the current draw in each s tate indi cat es the degree of any fuelvapor l eak; i f appropriat e the ECM records t he appropri ate Di agnos t ic Trouble Code (DTC).

Page 1184 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions - Evaporative Emissions

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the evaporat ive emi ss ions s ys tem, refer t o the relevant Descri pti on and Operat ion s ect ion int he works hop manual .REFER to: Evaporati ve Emis s ions (303-13 Evaporat ive Emi s si ons , Des cript ion and Operat ion).

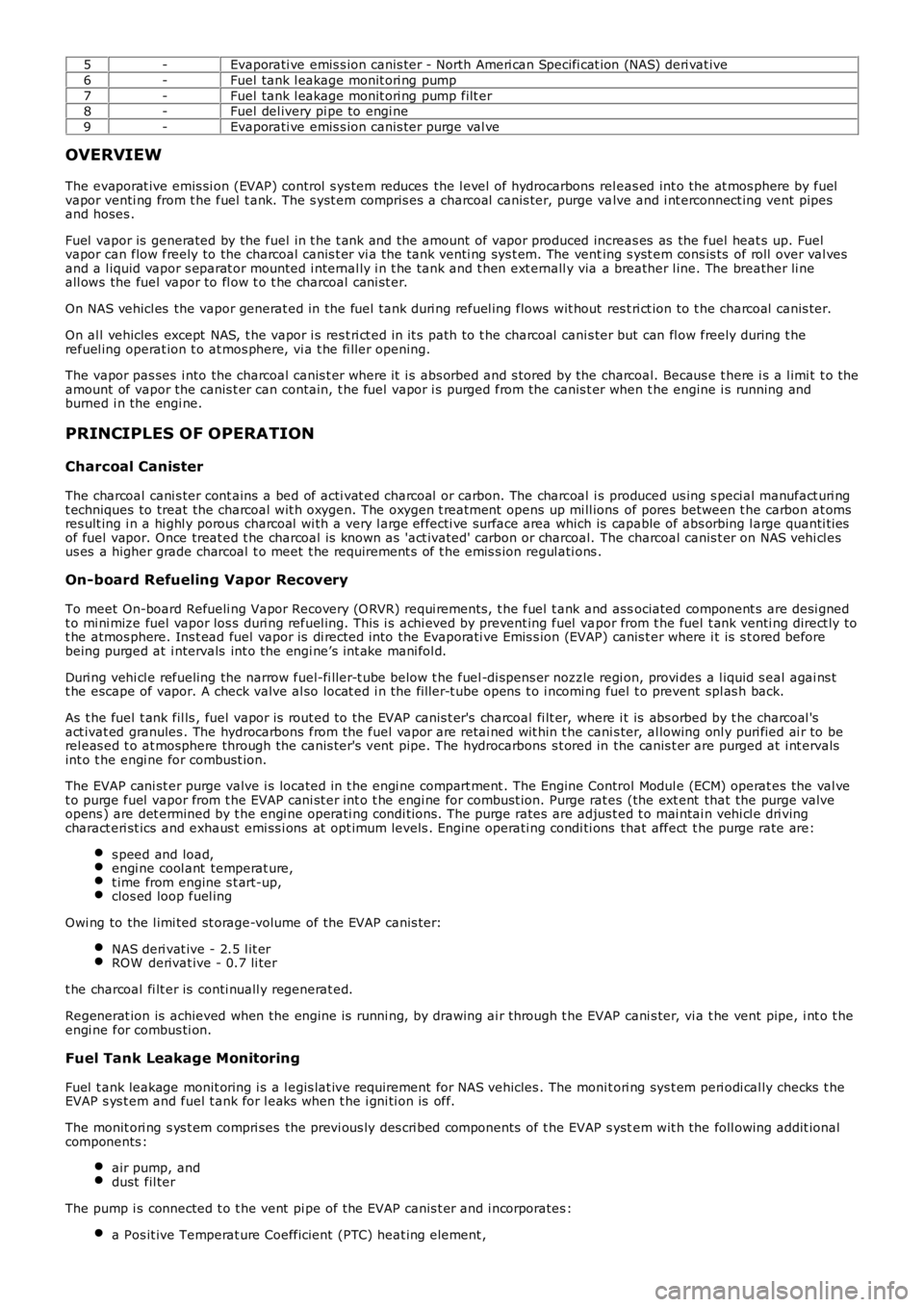

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Fuel fil ler cap and s ealFuel fil ler neckDi agnos ti c Monit oring of Tank Leakage (DMTL) fres h ai r fi lt er (res t ri ct ion, etc)Fuel t ank (leaks , damage, et c)Fuel l ines and joints , et cCarbon canis terPurge valveDMTL pump modul e

Fus esConnect orsHarnes s esPurge val veDMTL pump

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

• NOTE: On al l vehicl es equi pped wi th Diagnost ic Moni tor Tank Leakage (DMTL), there is a requirement to bl ank offt he vent il at ion port (l arge di amet er s tub pi pe) of t he DMTL module, t o prevent mis -diagnos is when carrying out as moke tes t .

5. W here K-Line, Vacut ec or other propri etary smoke tes t equi pment is avail abl e, i t s houl d be ut ili s ed to as s is t wi thEvaporati ve Emis s ions Sys tem leak diagnosi s .

5.

Symptom Chart

SymptomPossible CauseActionDi fficul ty in fil li ng fuelt ankRes tricti on in the vapor li ne bet ween t he fuelt ank and the carbon canis t er out let/atmospheri cport

Check for res trict ions/damage, et c (seevis ual i nspecti on)

Fuel s mel lSys tem leakPurge val ve inoperati veCheck for leaks, check the purge val veoperati on. GO t o Pinpoint Test A.

'Check Fuel Fil ler Cap'dis played on Mes s ageCenter

Fuel fil ler cap mi ss i ng/not ti ght ened aft errefuell ingCheck t he fuel fil ler cap and seal

DTC Index

• NOTE: If the modul e is sus pect and t he vehi cle remains under the manufact urer warrant y, refer t o t he W arrant y Pol icyand Procedure manual (s ect ion B1.2), or determine if any pri or approval programme is in operat ion, pri or t o t he i ns t allat ionof a new modul e.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP044100Evaporati ve emis s ions yst em - incorrect purgeflow

Evaporat ive emi ss i on canis t er ventres trictedCani st er to purge valve pipe

Check t he condi ti on and ins tal lat ion of t heevaporat ive emi s si on s ys t em. Check t heoperati on of the purge val ve. Ins tall new

Page 1185 of 3229

DT CDescriptionPossible CauseAction

damaged/res trictedThe purge valve is st uck in theopen or clos ed pos it ion

components as neces sary

P044200Evaporati ve emis s ions yst em leak detected(s mall leak)

The dynami c monit oring of t ankleakage (DMTL) s ys t em hasdet ect ed a s mal l leak in theevaporat ive emi ss i on sys t em

Carry out a check of t he fuel s ys t emint egrit y us ing l ocal equi pment(Vacutec/K-Line, etc). Recti fy as neces sary

P044400Evaporati ve emis s ions yst em purge cont rol valvecircui t open

Purge valve circui t: open circui tPurge valve fai lureCheck t he purge valve and ci rcuit s. Referto the el ect ri cal guides . Ins tal l a newval ve as neces s aryP044700Evaporati ve emis s ions yst em vent cont rol circui topen

Evaporat ive emi ss i on sys t emchange-over valve (COV) circui t(s ):open ci rcuitEvaporat ive emi ss i on sys t emchange-over valve (COV) circui t(s ):short ci rcuit t o groundEvaporat ive emi ss i on sys t emchange-over valve (COV) fai lure

Check t he COV and ci rcuit s. Refer t o t heelectrical gui des . Ins t all a new val ve asneces s ary (the COV is incorporated intothe fuel tank l eakage monit ori ng pump)

P044800Evaporati ve emis s ions yst em vent cont rol circui ts hort ed

Evaporat ive emi ss i on sys t emchange-over valve (COV) circui t(s ):short ci rcuit t o powerEvaporat ive emi ss i on sys t emchange-over valve (COV) fai lure

Check t he COV and ci rcuit s. Refer t o t heelectrical gui des . Ins t all a new val ve asneces s ary (the COV is incorporated intothe fuel tank l eakage monit ori ng pump)

P045500Evaporati ve emis s ions yst em leak detected(gros s leak/no flow)

Fuel fi ll er cap not fit tedFuel fi ll er cap s eal mis s ingEvaporat ive emi ss i on sys t em l eak,canis t er, pipework, et cEvaporat ive emi ss i on sys t emchange-over valve (COV) fai lure

Check t he fuel fil ler cap and seal condi ti onand fi tment . Carry out a check of t he fuels ys t em i ntegri ty us i ng local equipment(Vacutec/K-Line, etc). Recti fy as neces sary

P045800Evaporati ve emis s ions yst em purge cont rol valvecircui t low

Purge valve circui t: s hort circui t togroundPurge valve circui t: open circui tPurge valve fai lure

Check t he purge valve and ci rcuit s. Referto the el ect ri cal guides . Ins tal l a newval ve as neces s ary

P045900Evaporati ve emis s ions yst em purge cont rol valvecircui t high

Purge valve circui t: s hort circui t topowerPurge valve fai lure

Check t he purge valve and ci rcuit s. Referto the el ect ri cal guides . Ins tal l a newval ve as neces s ary

P240100Evaporati ve emis s ions yst em leak detecti onpump control ci rcuit l ow

Fuel t ank l eakage moni toring pumpcont rol ci rcuit : s hort circuit togroundFuel t ank l eakage moni toring pumpcont rol ci rcuit : open ci rcuitFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

P240200Evaporati ve emis s ions yst em leak detecti onpump control ci rcuit high

Fuel t ank l eakage moni toring pumpcont rol ci rcuit : s hort circuit topowerFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

P240500Evaporati ve emis s ions yst em leak detecti onpump s ens e circuit low

Fuel t ank l eakage moni toring pumpsens e circui t: s hort circui t togroundFuel t ank l eakage moni toring pumpsens e circui t: open circui tFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

P240600Evaporati ve emis s ions yst em leak detecti onpump s ens e circuit hi gh

Fuel t ank l eakage moni toring pumpsens e circui t: s hort circui t to powerFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

P240800Fuel cap s ens or/s wi tchcircui tCAN circuit : open circuitCAN circuit : s hort circui t to groundCAN module fault

Carry out a complete read for relat edDTCs. Recti fy as neces sary. Refer t o t hewarrant y poli cy and procedures manual i f amodule i s s uspectP240B00Evaporati ve emis s ions yst em leak detecti onpump heat er circui t low

Fuel t ank l eakage pump heat ercont rol ci rcuit : s hort circuit togroundFuel t ank l eakage pump heat ercont rol ci rcuit : open ci rcuitFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

Page 1186 of 3229

1

2

3

1

2

3

DT CDescriptionPossible CauseAction

P240C00Evaporati ve emis s ions yst em leak detecti onpump heat er circui t high

Fuel t ank l eakage pump heat ercont rol ci rcuit : s hort circuit topowerFuel t ank l eakage moni toring pumpfail ure

Check t he fuel t ank leakage moni toringpump and circui ts . Refer t o t he elect ricalguides. Ins tall a new pump as neces s ary

P245000Evaporati ve emis s ioncontrol s ys tem s wit chi ngvalve performance/s t uckopen

Evaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : s hort ci rcuit t o groundEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : open ci rcuitEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : s hort ci rcuit t o powerEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV) fault

Check t he COV and ci rcuit s. Refer t o t heelectrical gui des . Rect ify as neces s ary.Ins t al l a new COV as neces s ary (the COVis integral wi th the fuel tank leakagemonit ori ng pump)

P245100Evaporati ve emis s ioncontrol s ys tem s wit chi ngvalve s t uck clos ed

Evaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : s hort ci rcuit t o groundEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : open ci rcuitEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV)ci rcuit : s hort ci rcuit t o powerEvaporat ive emi ss i on cont rolsys tem s wit chi ng valve (COV) fault

Check t he COV and ci rcuit s. Refer t o t heelectrical gui des . Rect ify as neces s ary.Ins t al l a new COV as neces s ary (the COVis integral wi th the fuel tank leakagemonit ori ng pump)

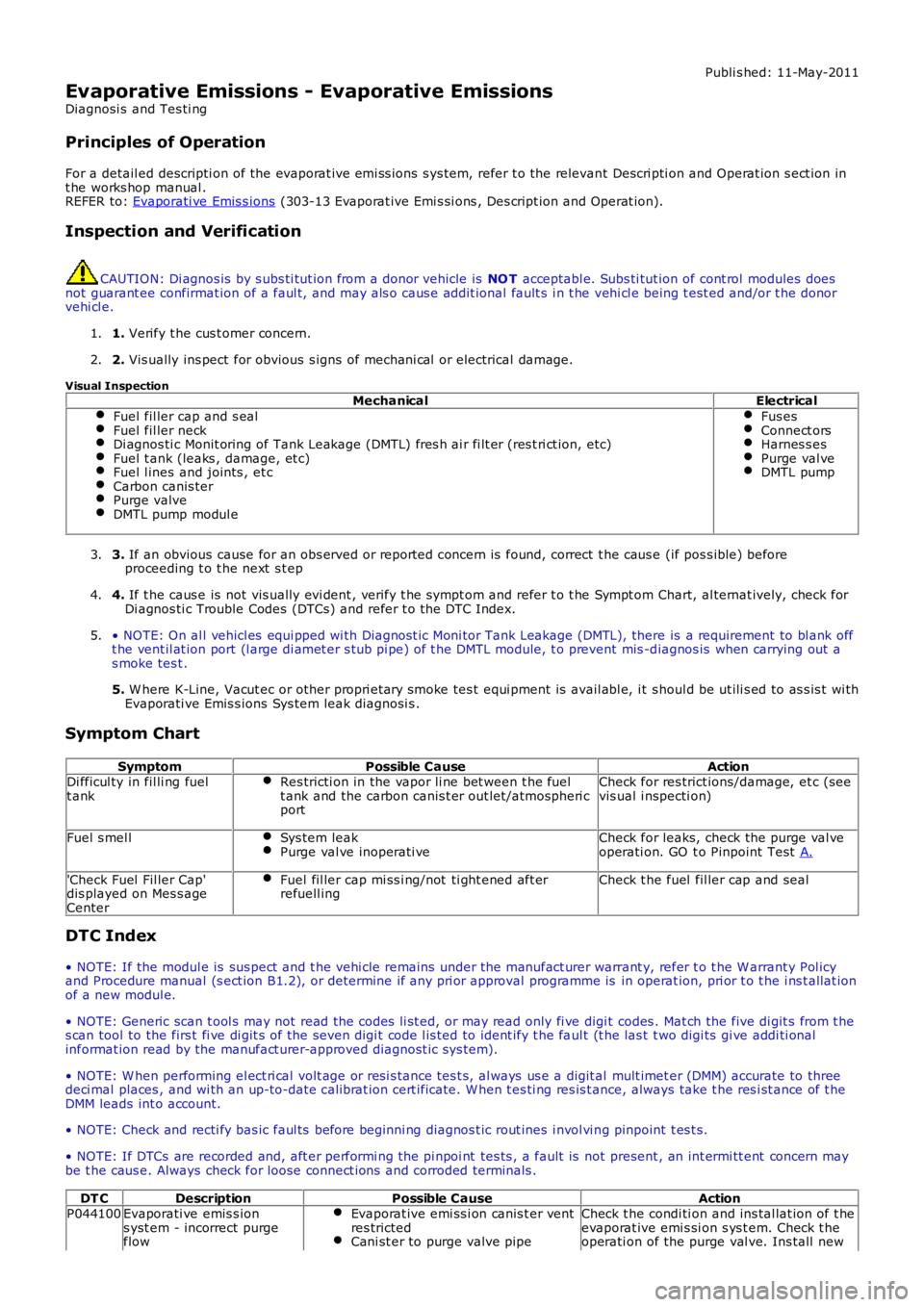

Pinpoint Tests

PINPOINT TEST A : EVAPORATIVE SYSTEM INCORRECT PURGE FLOW

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

A1: CHECK FUEL FILLER CAP INST ALLAT IO N AND CONDIT IO N OF CANIST ER, PIPES AND CONNECT ORSMake s ure t hat the fuel fil ler cap is correctl y ins tal led and t ight ened.

Check t he condi ti on of the carbon canis t er.

Check t he condi ti on of all acces si ble pi pes and connect ors i n t he vapor l ine.

Are the canis ter and al l pi pes and connect ors i n good condi ti on?YesGO to A2.NoREPAIR as necess ary. CLEAR t he DTC, tes t the sys tem for normal operat ion.

A2: CHECK T HAT T HE PURGE VALVE IS OPERAT INGDis connect the vapor pipe from the inlet port of t he evaporat ive purge val ve.

RUN the engine for 2 mi nutes , making s ure that the engi ne reaches normal operat ing temperat ure.

Check t hat the evaporat ive purge valve i s operat ing, by touch or by s ound (us ing a st ethos cope, itwil l be poss i bl e t o hear the valve operat ing).

Is the valve operat ing?YesCHECK for relat ed DTCs . Refer t o t he DTC Index above.NoCHECK for purge val ve rel at ed DTCs and refer to DTC Index.

Page 1187 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions - Evaporative Emission Canister

Removal and Inst all ati on

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

2. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

2.

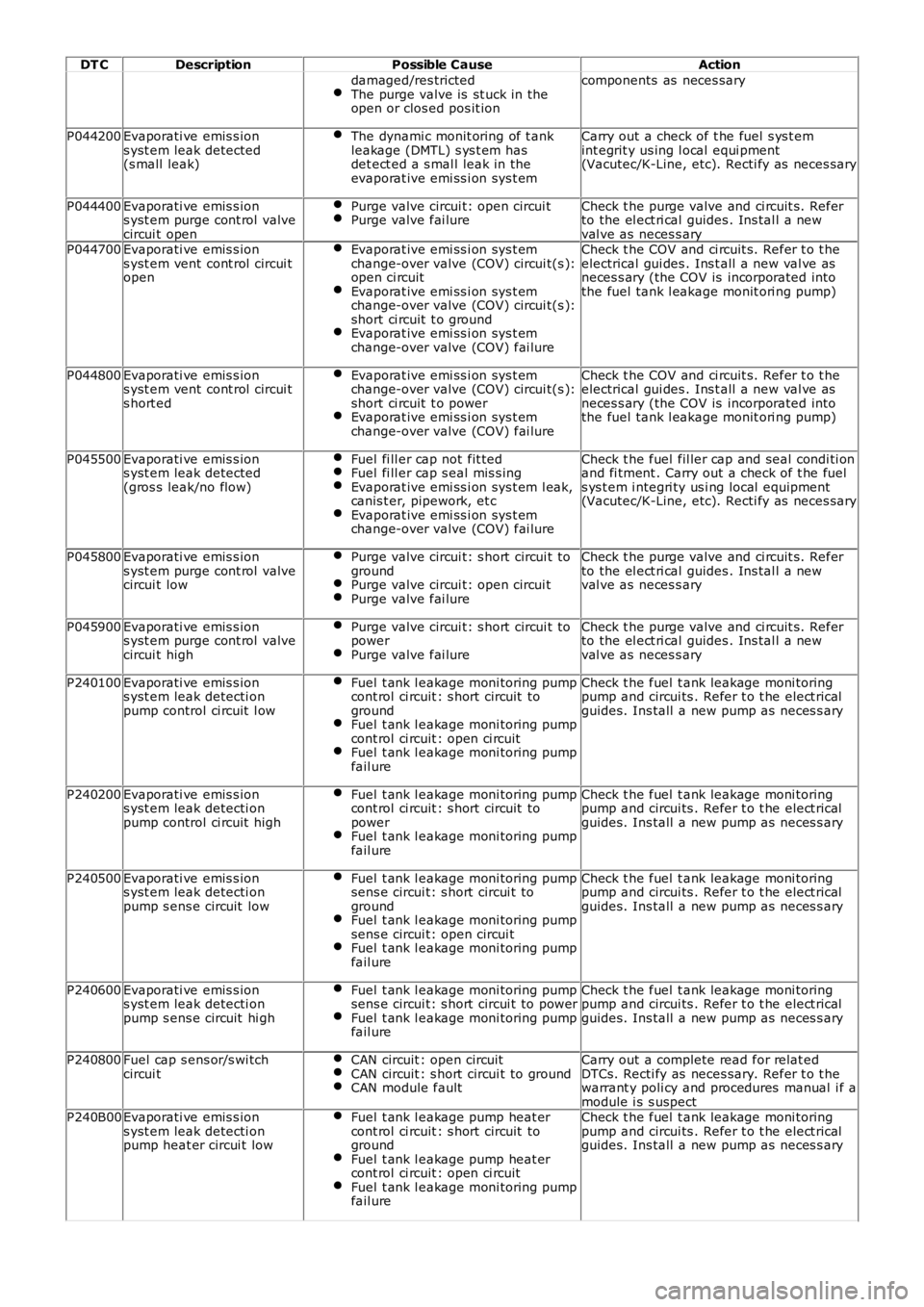

Remove t he rear wheel.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

3.

4.

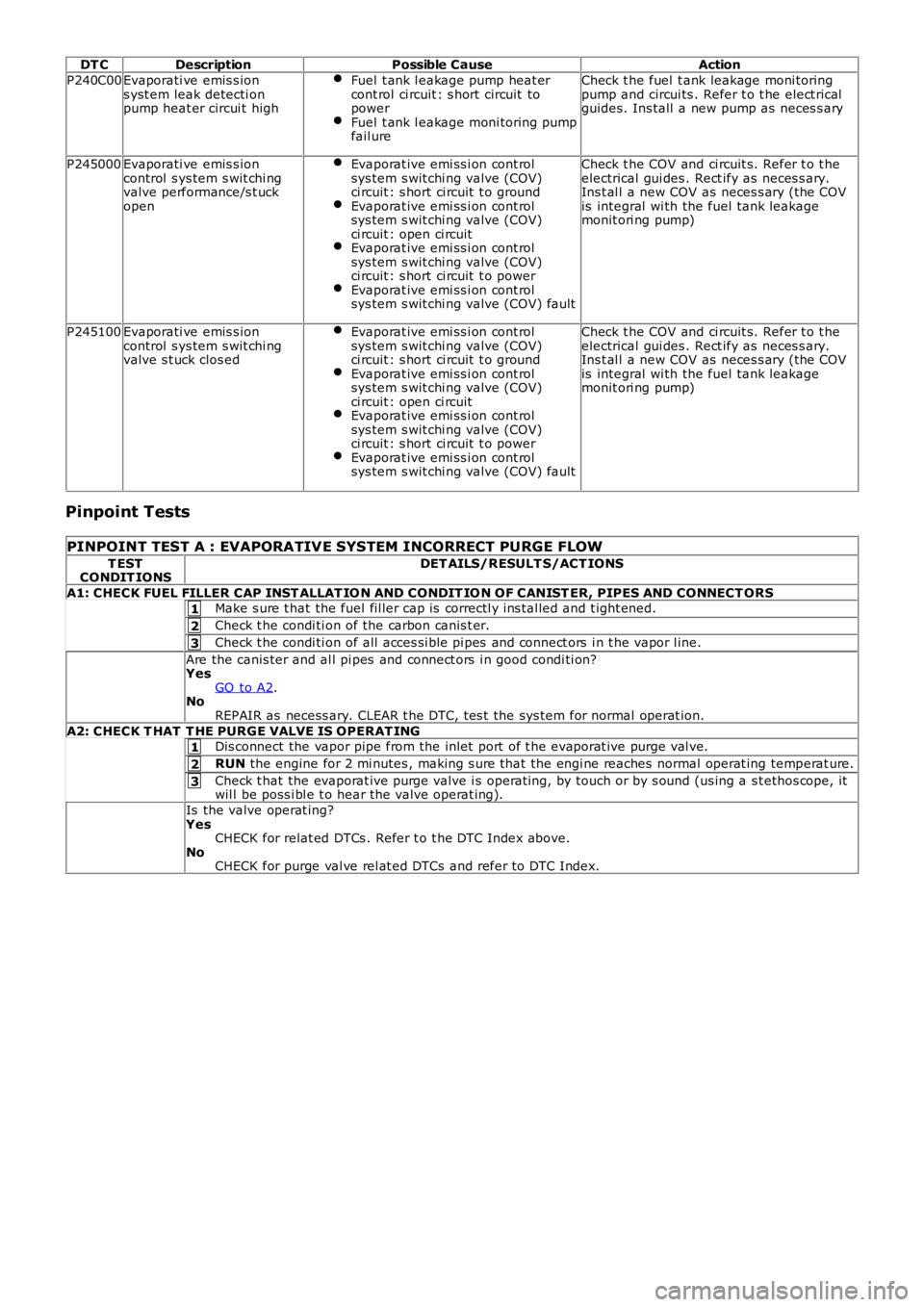

Page 1188 of 3229

T orque:

10 Nm 5.

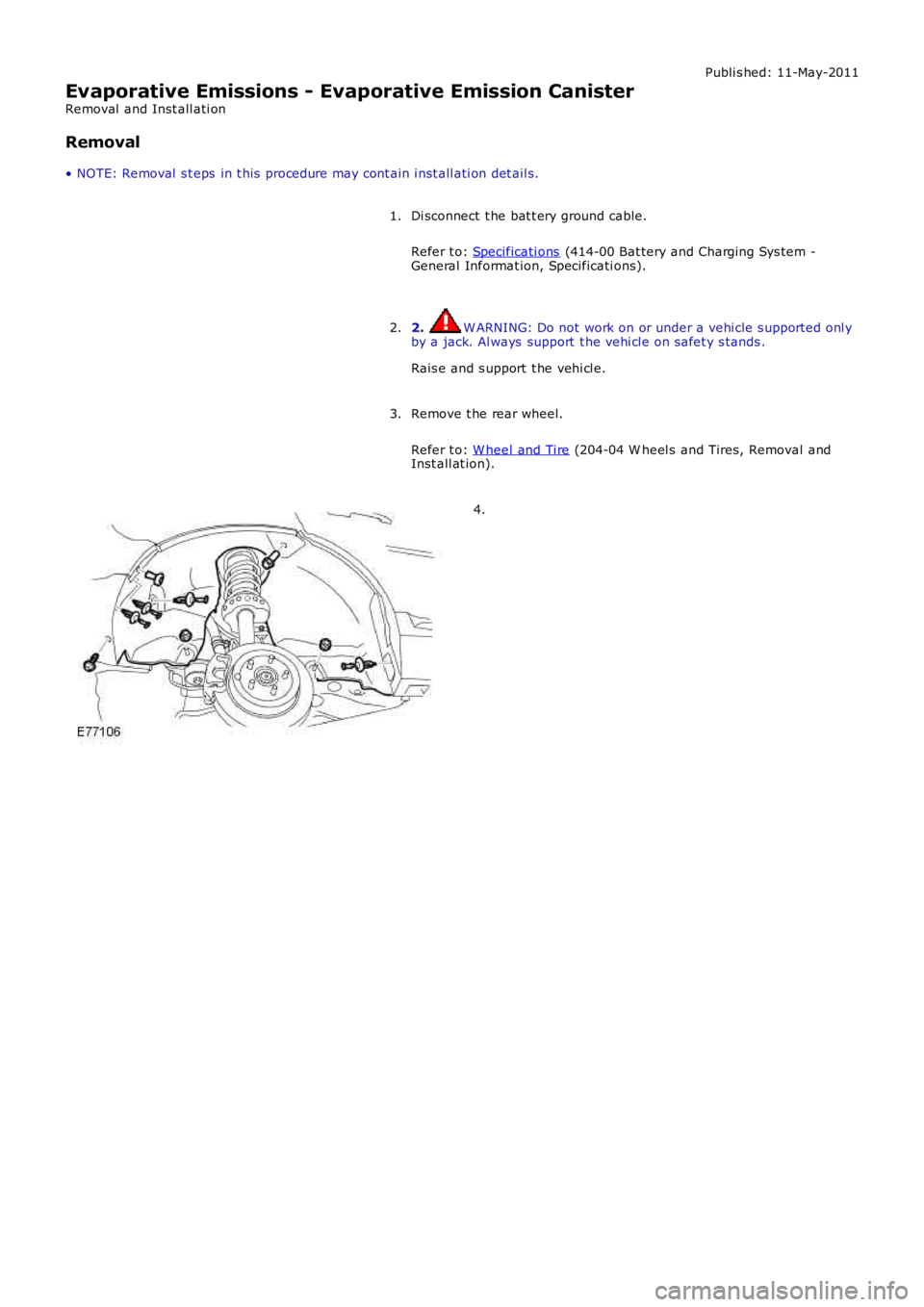

T orque:

10 Nm 6.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1189 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions - Evaporative Emission Canister Purge Valve

Removal and Inst all ati on

Removal

• NOTE: Take care not to dis connect the purge line from t he rear of t he int ake mani fol d, when removing t he purge valve.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

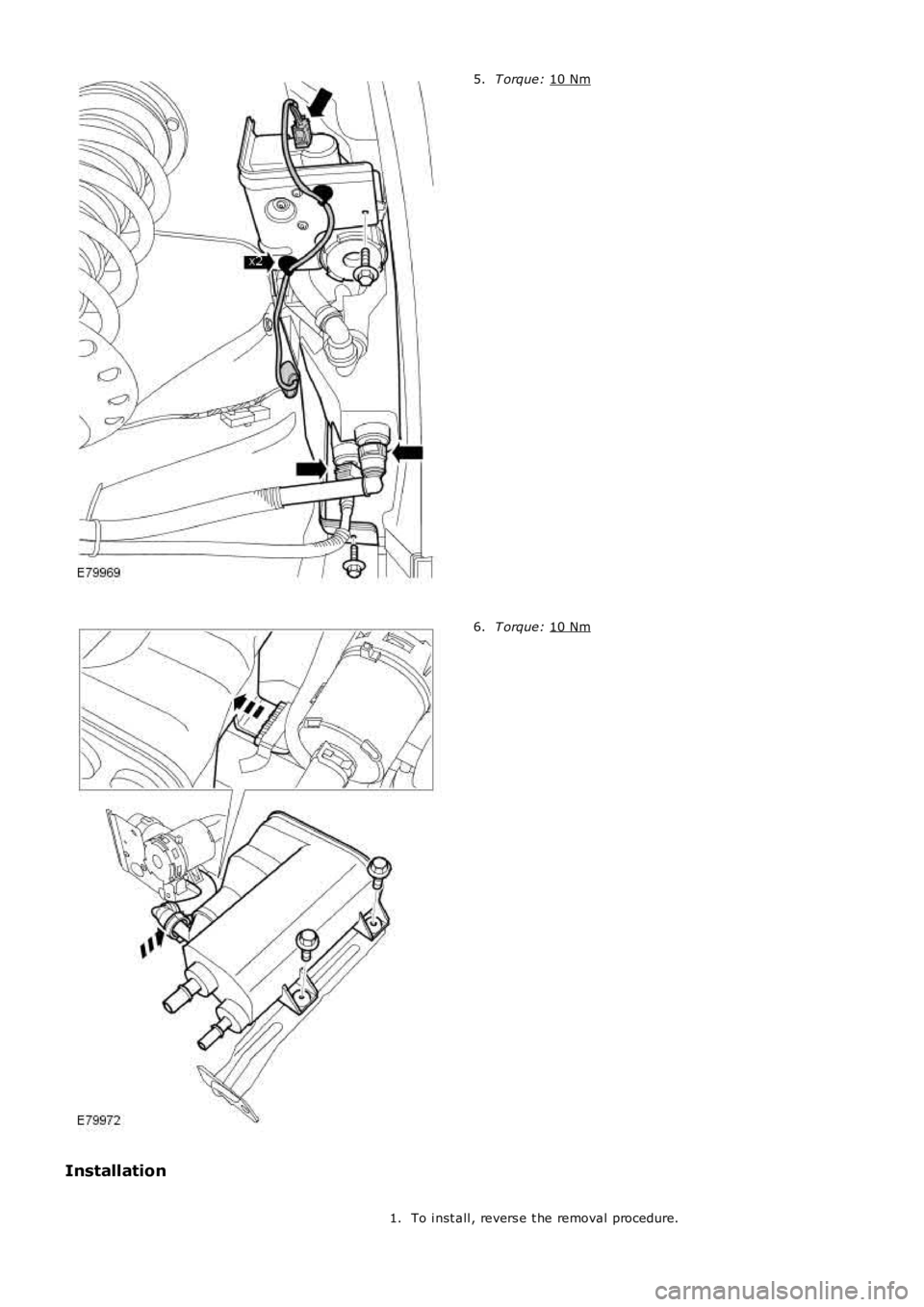

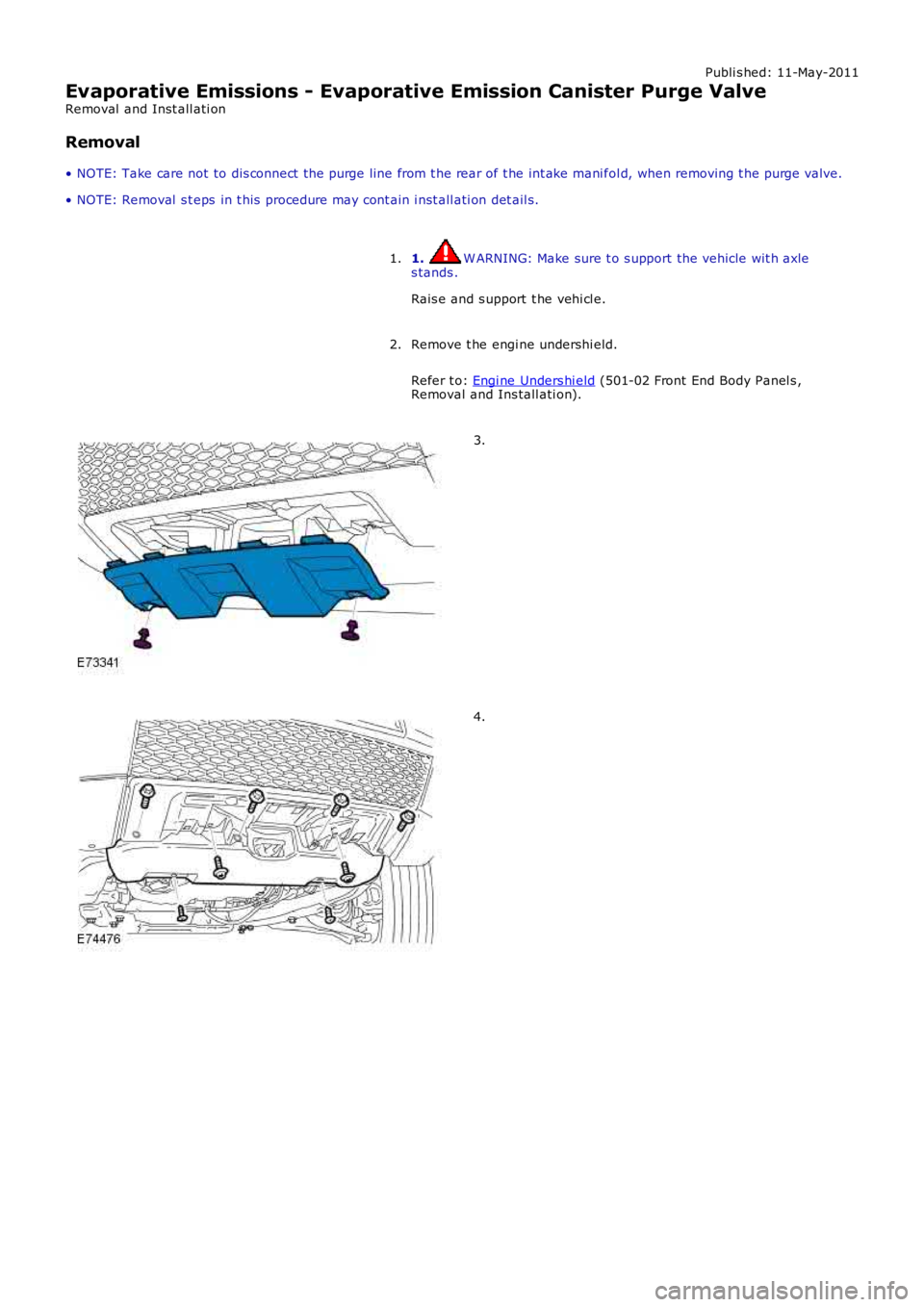

1. W ARNING: Make sure t o s upport the vehicle wit h axles tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he engi ne undershi eld.

Refer t o: Engi ne Unders hi eld (501-02 Front End Body Panel s ,Removal and Ins tall ati on).

2.

3.

4.

Page 1190 of 3229

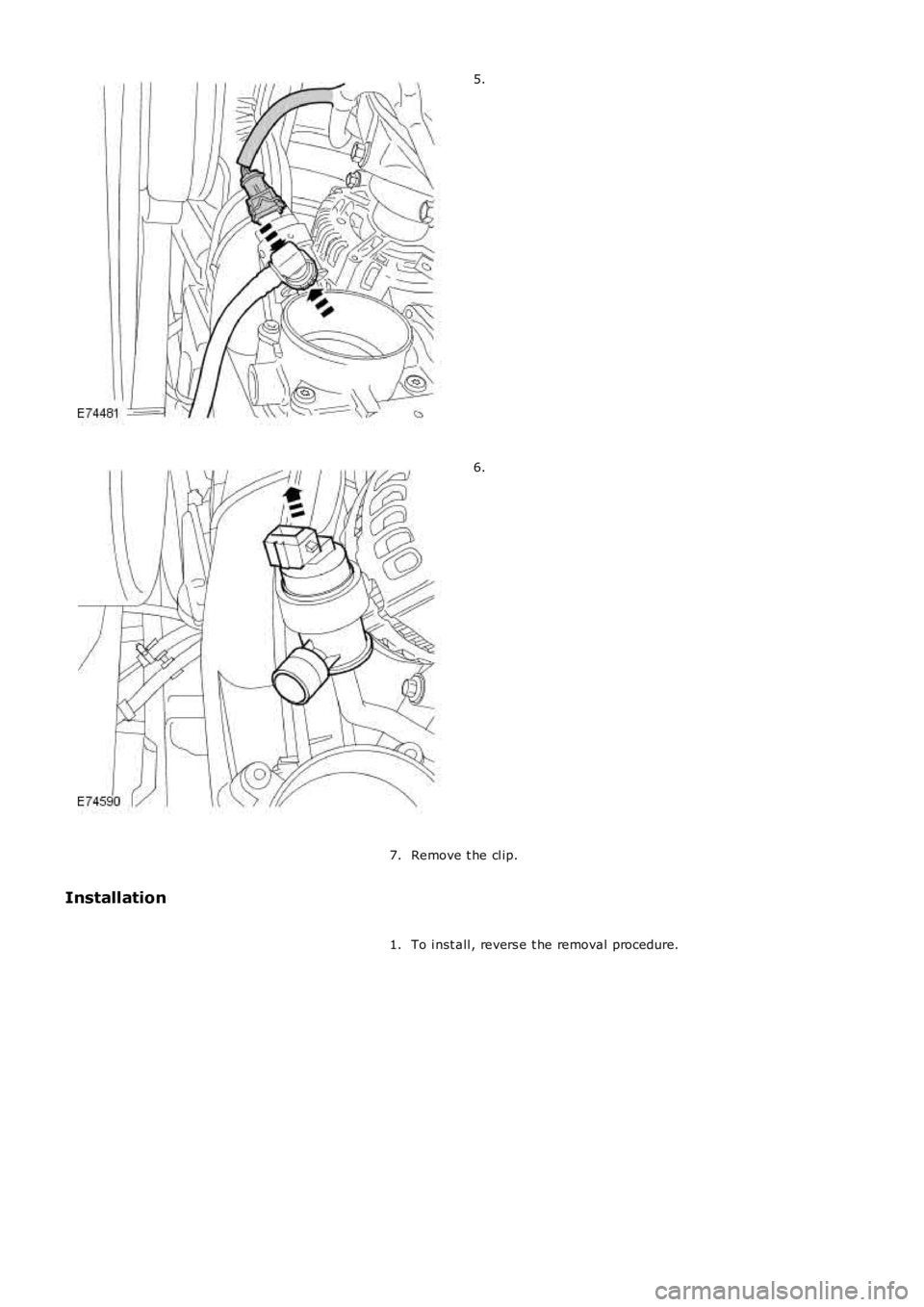

5.

6.

Remove t he cl ip.7.

Installation

To i nst all , revers e t he removal procedure.1.