LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1171 of 3229

ItemPart NumberDescription

1-Sol enoid-operated valve

2-Intake mani fold hel ical swirl port3-Vacuum-operat ed act uator

4-Intake mani fold fi ll ing port

5-But terfl y val ve (4 off)Port de-act ivati on is operat ed by 4-but terfl y val ves connect ed on a common shaft within t he i nt ake manifold. Eachbutt erfly valve i s housed wit hi n a corres ponding i ntake mani fold upper fi ll ing port . The common s haft i s connected t o avacuum-operated actuat or, and is operat ed by a sol enoi d val ve under t he cont rol of the ECM. The vacuum requi red for portde-acti vat ion i s s uppl ied from t he engi ne mounted vacuum pump.

For addit ional informat ion, refer t o:

Engi ne (303-01B Engine - TD4 2.2L Di esel , Des cri pti on and Operati on),Elect roni c Engi ne Cont rol s - 2.2L Dies el (303-14 Electronic Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).

Port de-act ivati on (opening of t he fi ll ing port s ) onl y occurs when the coolant t emperature is greater t han 10°C, and undert he foll owing condit ions:

Engi ne s peed is great er than 1,800 rpm.Engi ne load i s great er than 15%.

Page 1172 of 3229

Publi s hed: 11-May-2011

Intake Air Distribution and Filtering - TD4 2.2L Diesel - Intake Air

Distribution and Filtering

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the intake ai r di s tributi on and fi lt eri ng sys t em, refer t o t he rel evant Des cript ion and Operat ions ect ion i n t he works hop manual .REFER to: Intake Air Di s tributi on and Fil teri ng (303-12B Int ake Air Dis t ri but ion and Fi lt ering - TD4 2.2L Di esel , Des cri pti onand Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

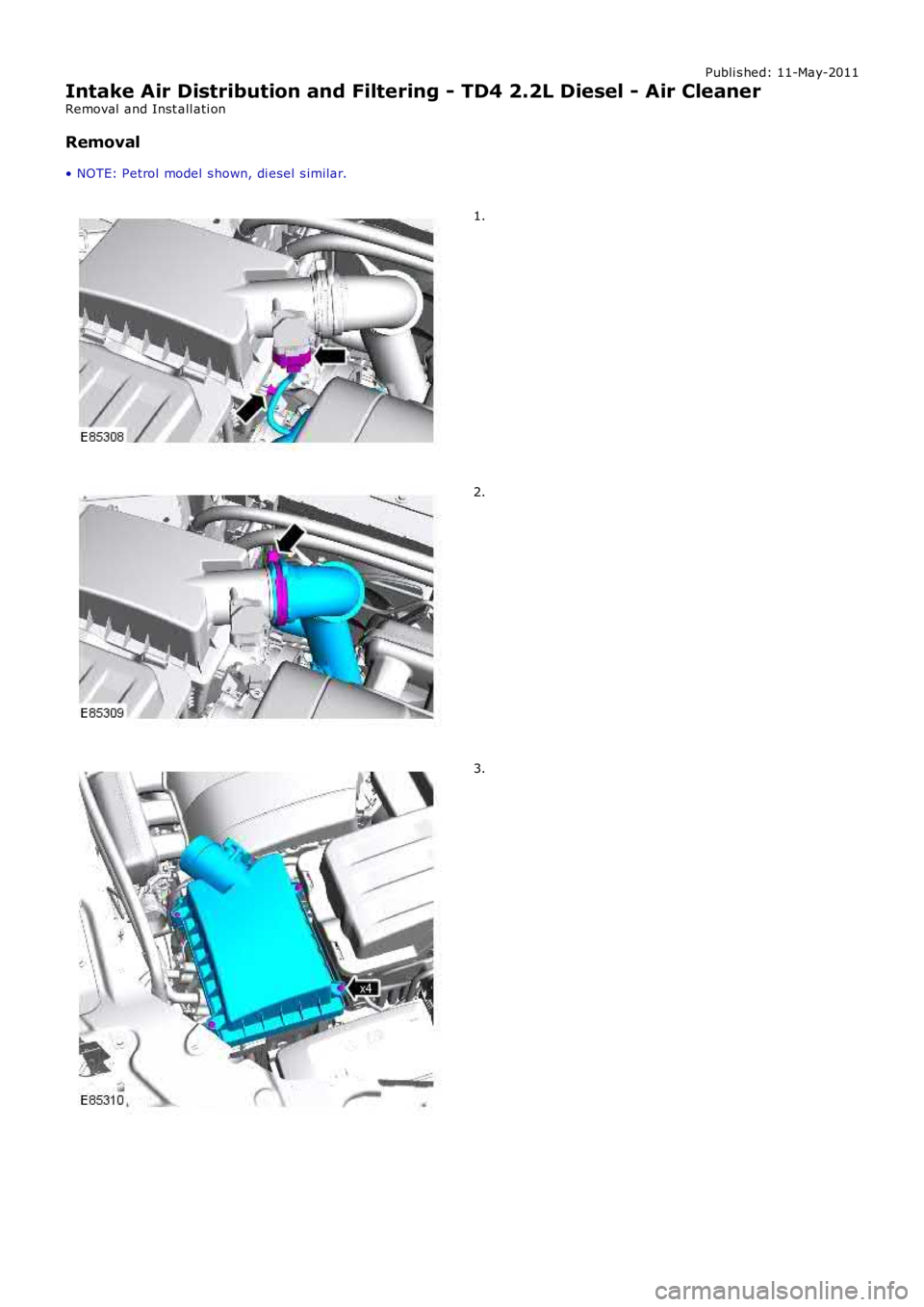

Visual InspectionMechanicalElectrical

Hos es and duct s (damage/connect ions )Air cl eaner element(cont aminated/bl ocked)Res tricted ai r int akeSeals and gas ket s

Mas s Ai r Fl ow (MAF) sens orSecondary Air Injecti on (AIR) Manifol d Abs ol ute Pres sure (MAP)s ens orThrot t le bodyHarnes s (s ecurit y/damage)Connect ions (s ecuri ty/damage)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseAction

Vehicle does not s tart/hards tarti ng/poor performanceRes t rict ed/blocked ai r int akeRes t rict ed/blocked ai r cleanerel ement

Ens ure the ai r int ake sys tem is freefrom bl ockage and is correctl y ins tal ledIns t al l a new ai r cl eaner element asneces sary.REFER to: Air Cl eaner Element (303-12,Removal and Inst all at ion).

Exces s ive i nt ake nois eIntake pi pe dis connect ed/damagedafter t he air cleanerAi r cl eaner as s embl y i ncorrect lyas s embled/damaged

Check for correct ins tal lati on andint egrit y of air i nt ake s ys t emCheck for correct ins tal lati on andint egrit y of the ai r cleaner as s embly.REFER to: Air Cl eaner Element (303-12,Removal and Inst all at ion).

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CausesAction

P006900MAP - Barometric Press ureCorrelat ionBoos t pres s ure s ensor circui t - s hort toground, power, open circui tBarometric pres s ure sens or fail ure

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost ic

Page 1173 of 3229

DT CDescriptionPossible CausesAction

sys t em

P007200Ambi ent Ai r TemperatureSensor Ci rcuit LowAmbi ent ai r temperature s ens or ci rcuit -s hort t o ground, open circuitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P007300Ambi ent Ai r TemperatureSensor Ci rcuit HighAmbi ent ai r temperature s ens or ci rcuit -s hort t o powerCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P009700Intake Air Temperat ureSensor 2 Ci rcuit LowIntake ai r temperat ure sens or vol tagebel ow lower l imi tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP009800Intake Air Temperat ureSensor 2 Ci rcuit Hi ghIntake ai r temperat ure sens or vol tageabove upper l imi tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP010000Mas s or Volume Ai r Flow ACircui tMAF Sens or s ignal circui t - s hort t oground, power, open circui tCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010221Mas s or Volume Ai r Flow ACircui t LowAi r fl ow PW M raw s ignal above upperl imitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010226Mas s or Volume Ai r Flow ACircui t LowAi r fl ow PW M correct ed si gnal aboveupper li mitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010322Mas s or Volume Ai r Flow ACircui t HighAi r fl ow PW M raw s ignal above upperl imitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P010327Mas s or Volume Ai r Flow ACircui t HighAi r fl ow PW M correct ed si gnal aboveupper li mitCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP011200Intake Air Temperat ureSensor 1 Ci rcuit LowIntake ai r temperat ure sens or 1 circuit -s hort t o groundCarry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t emP110222Mas s Air Fl ow Sens or inRange But Lower ThanExpect ed

Ai r Mass (meas ured) is too l ow (notpl aus i bl e) wit h calculated reference ai rmass during overrun: rati o ofcalculat ed/act ual too hi gh

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P110321Mas s Air Fl ow Sens or inRange But Higher ThanExpect ed

Ai r Mass (meas ured) is too hi gh (notpl aus i bl e) wit h calculated reference ai rmass during overrun: rati o ofcalculat ed/act ual too l ow

Carry out t he pinpoint t est sass ociated wit h t hi s DTC us ing t hemanufact urer approved diagnost icsys t em

P222700Baromet ri c Pres s ure Ci rcuitRange/PerformanceAt mos pheric Press ure Sens or defect iveIns tal l a new module, refer to thenew module/component ins tall ati onnot e at t he t op of the DTC Index.REFER t o: Powert rain Cont rol Module(PCM) (303-14, Removal andIns tal lat ion).

Page 1174 of 3229

Publi s hed: 11-May-2011

Intake Air Distribution and Filtering - TD4 2.2L Diesel - Air Cleaner

Removal and Inst all ati on

Removal

• NOTE: Petrol model s hown, di esel s imilar. 1.

2.

3.

Page 1175 of 3229

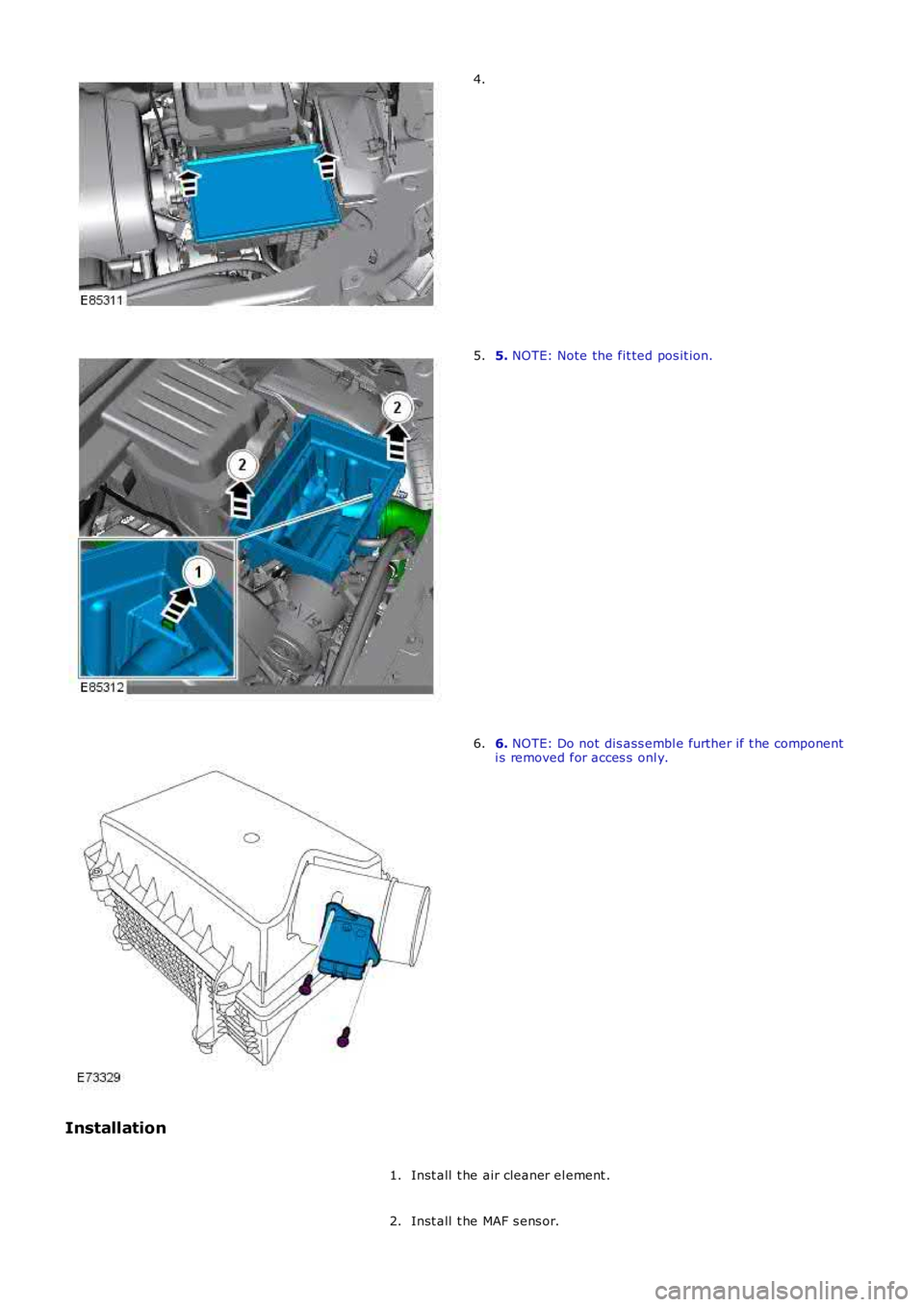

4.

5.

NOTE: Note the fit ted pos it ion.

5. 6.

NOTE: Do not dis ass embl e further if t he component

i s removed for acces s onl y.

6.

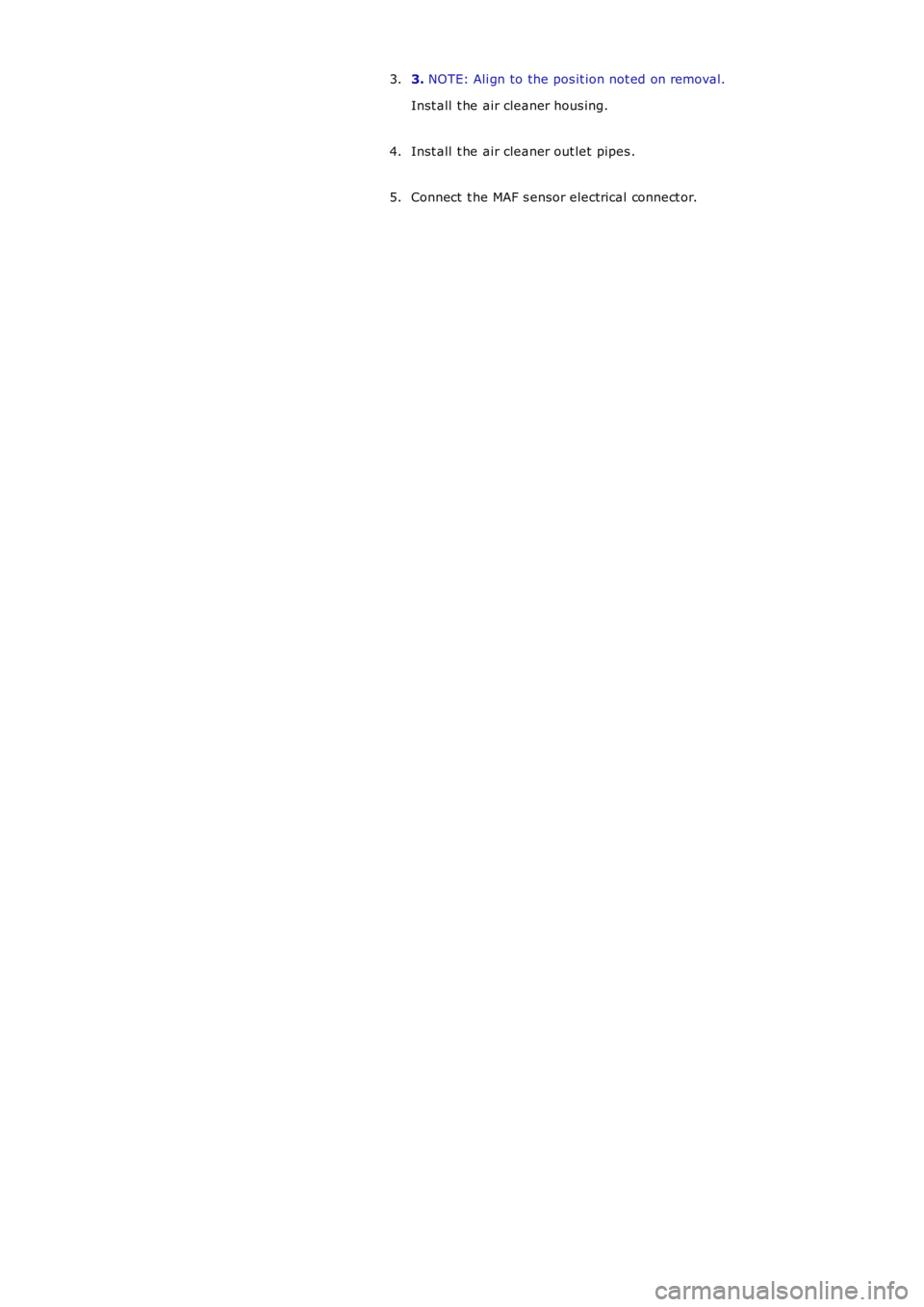

Installation Inst all t he air cleaner el ement .

1.

Inst all t he MAF s ens or.

2.

Page 1176 of 3229

3.

NOTE: Ali gn to the pos it ion not ed on removal.

Inst all t he air cleaner hous ing.

3.

Inst all t he air cleaner out let pipes .

4.

Connect t he MAF s ensor electrical connect or.

5.

Page 1177 of 3229

Publi s hed: 11-May-2011

Intake Air Distribution and Filtering - TD4 2.2L Diesel - Charge Air Cooler

Removal and Inst all ati on

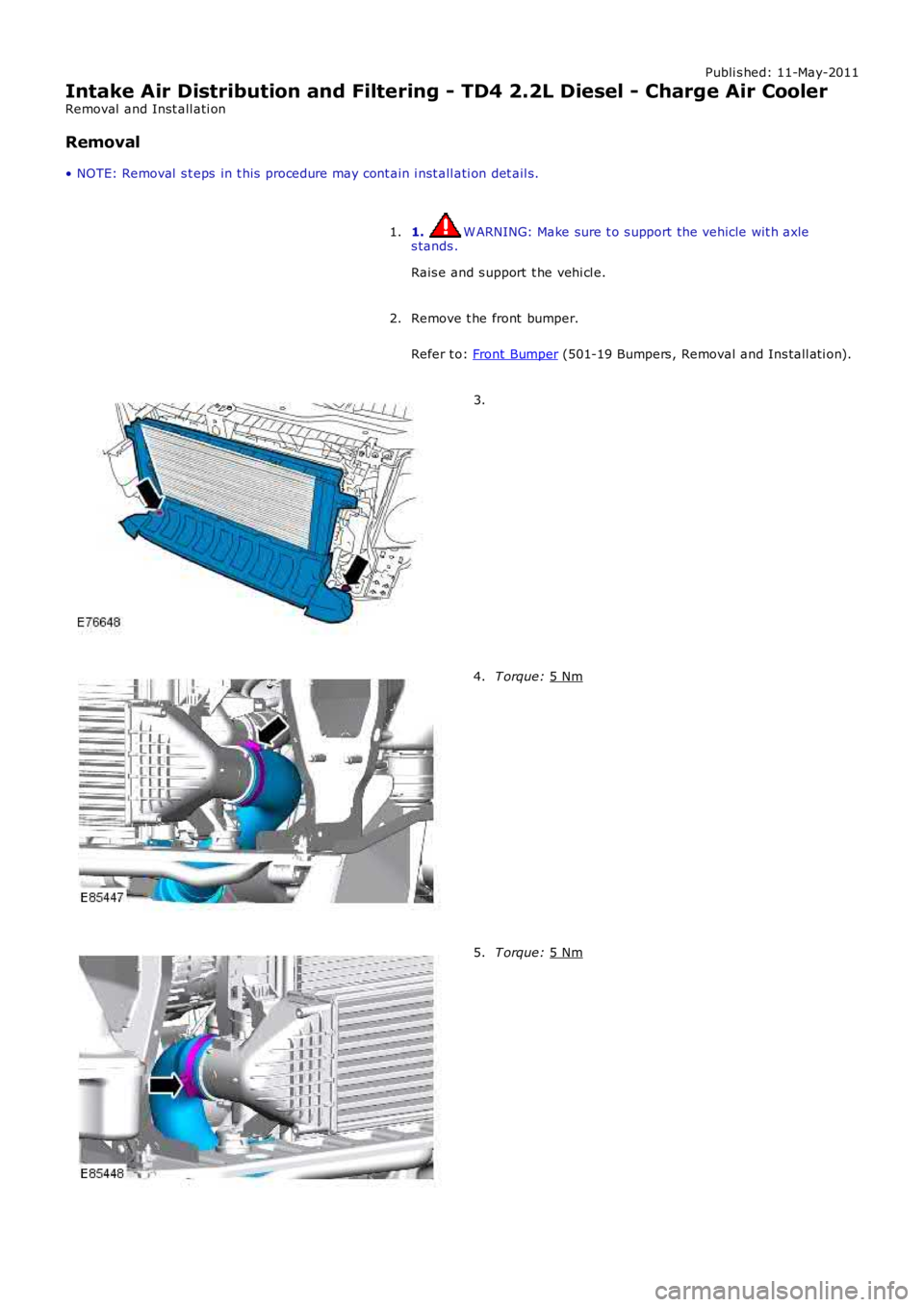

Removal

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

1. W ARNING: Make sure t o s upport the vehicle wit h axle

s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he front bumper.

Refer t o: Front Bumper (501-19 Bumpers , Removal and Ins tall ati on).

2. 3.

T orque:

5 Nm 4.

T orque:

5 Nm 5.

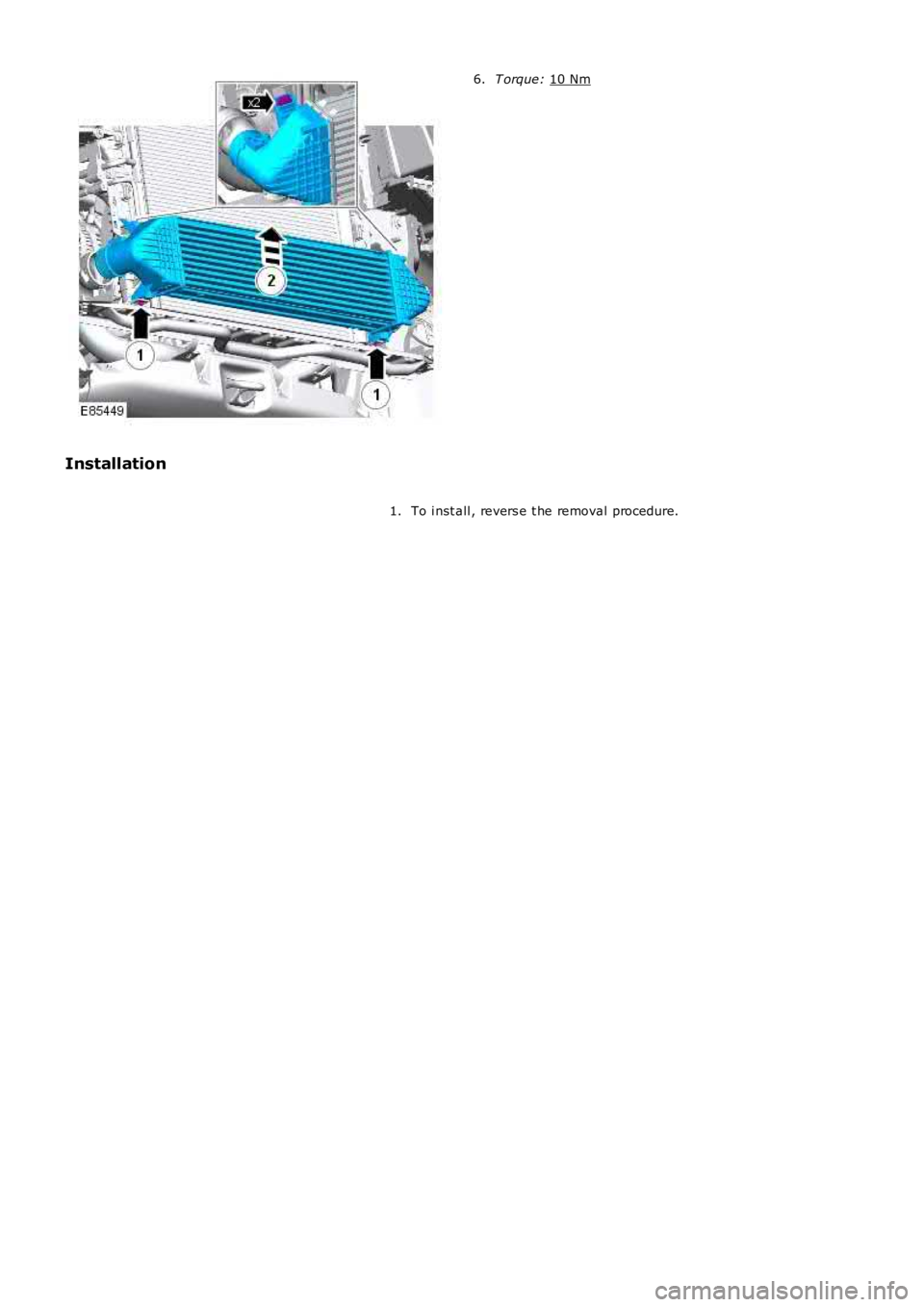

Page 1178 of 3229

T orque:

10 Nm 6.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1179 of 3229

Publi s hed: 11-May-2011

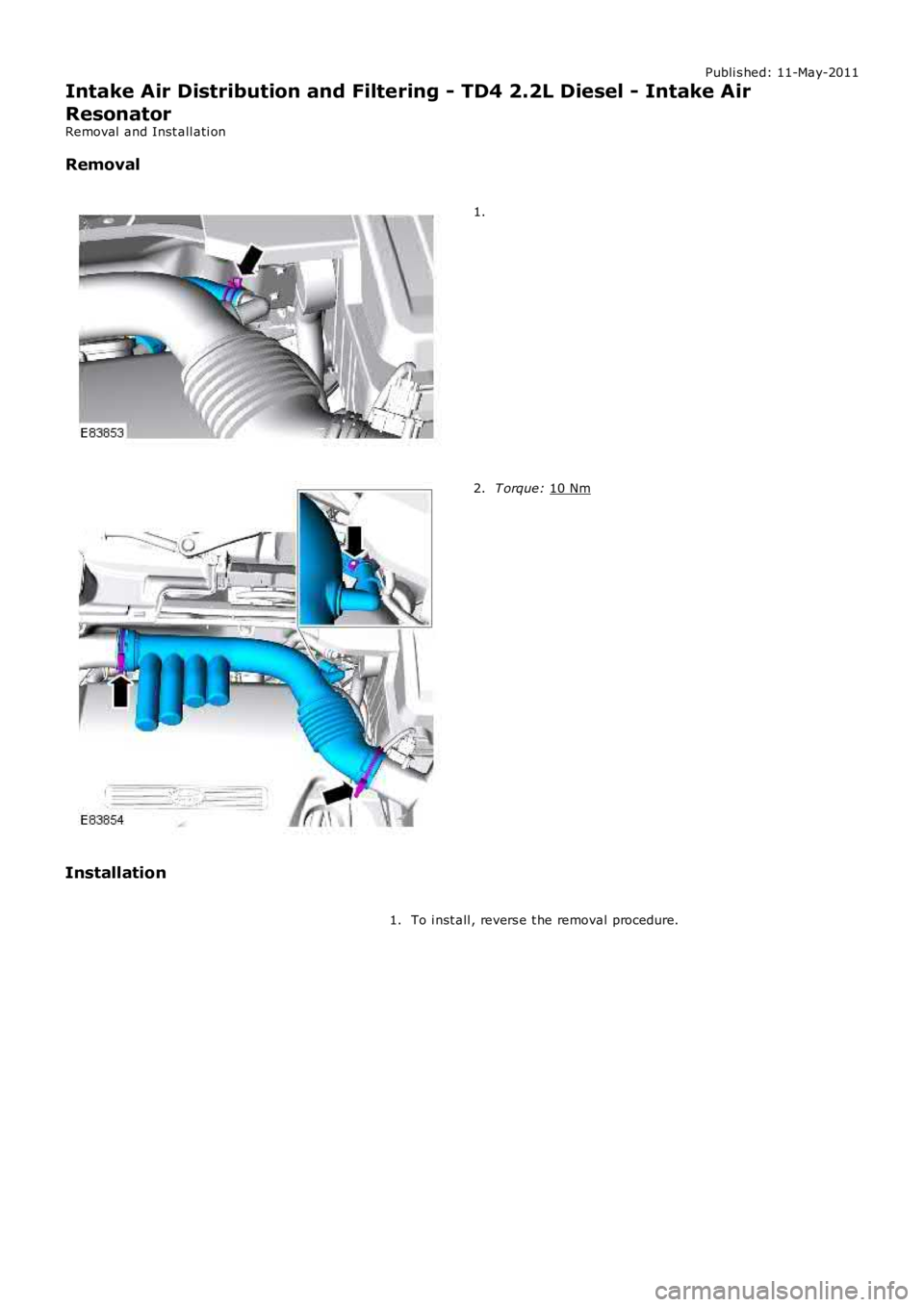

Intake Air Distribution and Filtering - TD4 2.2L Diesel - Intake Air

Resonator

Removal and Inst all ati on

Removal 1.

T orque:

10 Nm 2.

Installation To i nst all , revers e t he removal procedure.

1.

Page 1180 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions -

Torque SpecificationsDescriptionNmlb-ft

Evaporati ve emis s ions cani st er bolt s107

Evaporati ve emis s ions cani st er pipe nut s107Fuel t ank leakage monit oring pump fi lt er107

Fuel t ank leakage monit oring pump107