ESP LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 139 of 3229

DT CDescriptionPossible CauseAction

U3000-62Control Module Algori thmBas ed Fai lures Si gnalcompare failure

Steering wheel rot at ions ens or mi s-ali gnedModule i nternal fai lure

Check for correct i nst all at ion of s ens or. Ins t al l anew st eeri ng wheel rotat ion s ensor as requi red,refer t o new module/component ins tal lati on note att he t op of the DTC Index.U3000-64Control Module Algori thmBas ed Fai lures Si gnalplaus ibil it y fai lure

Steering wheel rot at ions ens or mi s-ali gnedModule i nternal fai lure

Check for correct i nst all at ion of s ens or. Ins t al l anew st eeri ng wheel rotat ion s ensor as requi red,refer t o new module/component ins tal lati on note att he t op of the DTC Index.U3000-81Control Module Bus Signal/ Mes s age Fai lures Inval ids eri al dat a received

Loss of power t o moduleCAN Bus faul tModule i nternal fai lure

Carry out CAN net work and power feed t es ts us ingmanufact urer approved di agnos t ic s yst em. Ins t all anew st eeri ng wheel rotat ion s ensor as requi red,refer t o new module/component ins tal lati on note att he t op of the DTC Index.

U3000-87Control Module Bus Signal/ Mes s age Fai luresMi ss ing mess age

Loss of power t o moduleCAN Bus faul tMis s ing modul e

Carry out CAN net work and power feed t es ts us ingmanufact urer approved di agnos t ic s yst em. Check formis s ing modules on CAN network

U3000-92Control ModuleComponent Fail uresPerformance or incorrectoperati on

Steering wheel rot at ions ens or mi s-ali gnedModule i nternal fai lure

Check for correct i nst all at ion of s ens or. Ins t al l anew st eeri ng wheel rotat ion s ensor as requi red,refer t o new module/component ins tal lati on note att he t op of the DTC Index.U3003-62Batt ery Vol tage Al gorit hmBas ed Fai lures Si gnalcompare failure

Mis -match i n batt eryvolt age, of 2 volt s ormore, bet ween CJB ands teeri ng wheel rotat ions ens or module

Carry out t he pinpoint t es t s as sociat ed to thi s DTCus ing the manufact urer approved di agnos ti c s yst em

Page 176 of 3229

of each road wheel t o i ts res pect ive hub.Loos en road wheel nut s. Rais e vehicle to a wheel free condit ion.For addit ional informat ion, refer t o: Lifti ng (100-02 Jacki ng and Lifti ng, Des cript ion and O perati on).Remove the road wheels .Vis uall y check t ires for condi ti on, l umps or bul ges . Check tread dept h acros s t he widt h of the ti re and around thecircumference; ens ure t hat remai ni ng t read depth does not cont ravene local legis lat ive requi rement s.

• NOTE: Do not i ns t all wheel s at t hi s s tage.

Braking System

CAUTION: For vehi cl es operati ng under arduous condi ti ons s ee relevant s ecti on.

1. Ins pect front brake pads for wear.For addit ional informat ion, refer t o: Specificati ons (206-03 Front Dis c Brake, Specificati ons ).

2. Ins pect rear brake pads for wear.For addit ional informat ion, refer t o: Specificati ons (206-04 Rear Di sc Brake, Specifi cat ions ).

3. Check brake cal ipers for si gns of fl ui d l eaks .

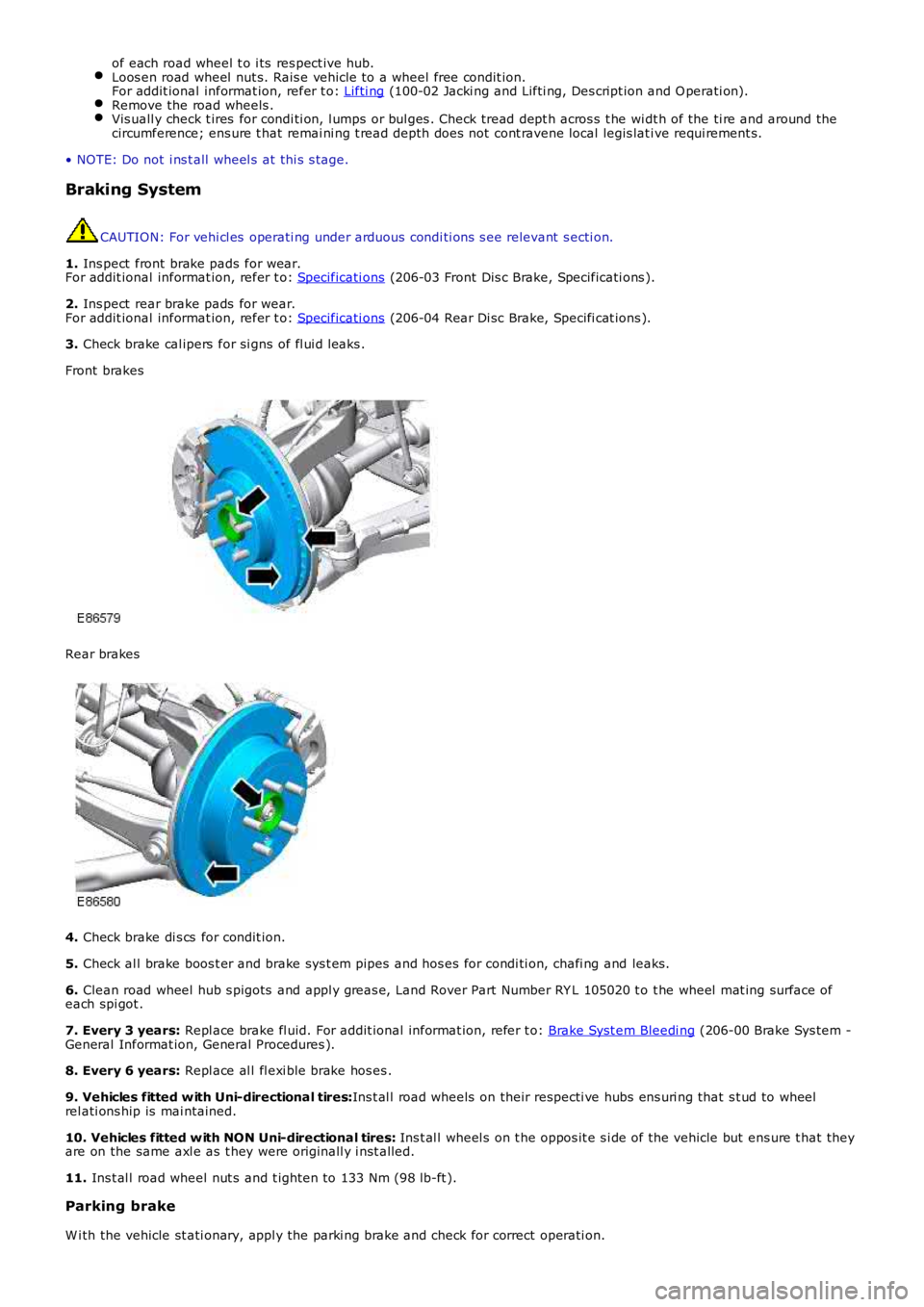

Front brakes

Rear brakes

4. Check brake di s cs for condit ion.

5. Check al l brake boos t er and brake sys t em pipes and hos es for condi ti on, chafi ng and leaks.

6. Clean road wheel hub s pigots and appl y greas e, Land Rover Part Number RY L 105020 t o t he wheel mat ing surface ofeach spi got .

7. Every 3 years: Repl ace brake fl uid. For addit ional informat ion, refer t o: Brake Syst em Bleedi ng (206-00 Brake Sys tem -General Informat ion, General Procedures ).

8. Every 6 years: Repl ace al l fl exi ble brake hos es .

9. Vehicles fitted w ith Uni-directional tires:Ins t al l road wheels on their respecti ve hubs ens uri ng that s t ud to wheelrel ati ons hip is mai ntained.

10. Vehicles fitted w ith NON Uni-directional tires: Ins t al l wheel s on t he oppos it e s i de of the vehicle but ens ure t hat theyare on the same axl e as t hey were originall y i ns t alled.

11. Ins t al l road wheel nut s and t ighten to 133 Nm (98 lb-ft ).

Parking brake

W i th the vehicle st ati onary, appl y the parki ng brake and check for correct operati on.

Page 187 of 3229

of each road wheel t o i ts res pect ive hub.

Loos en road wheel nut s. Rais e vehicle to a wheel free condit ion.

For addit ional informat ion, refer t o: Lifti ng (100-02 Jacki ng and Lifti ng, Des cript ion and O perati on).

Remove the road wheels .

Vis uall y check t ires for condi ti on, l umps or bul ges . Check tread dept h acros s t he wi

dt h of the ti re and around the

circumference; ens ure t hat remai ni ng t read depth does not cont ravene local legis lat i ve requi rement s.• NOTE: Do not i ns t all wheel s at t hi s s tage.

Braking System CAUTION: For vehi cl es operati ng under arduous condi ti ons s ee relevant s ecti on.

1. Ins pect front brake pads for wear.

For addit ional informat ion, refer t o: Specificati ons (206-03 Front Dis c Brake, Specificati ons ).

2. Ins pect rear brake pads for wear.

For addit ional informat ion, refer t o: Specificati ons (206-04 Rear Di sc Brake, Specifi cat ions ).

3. Check brake cal ipers for si gns of fl ui d l eaks .

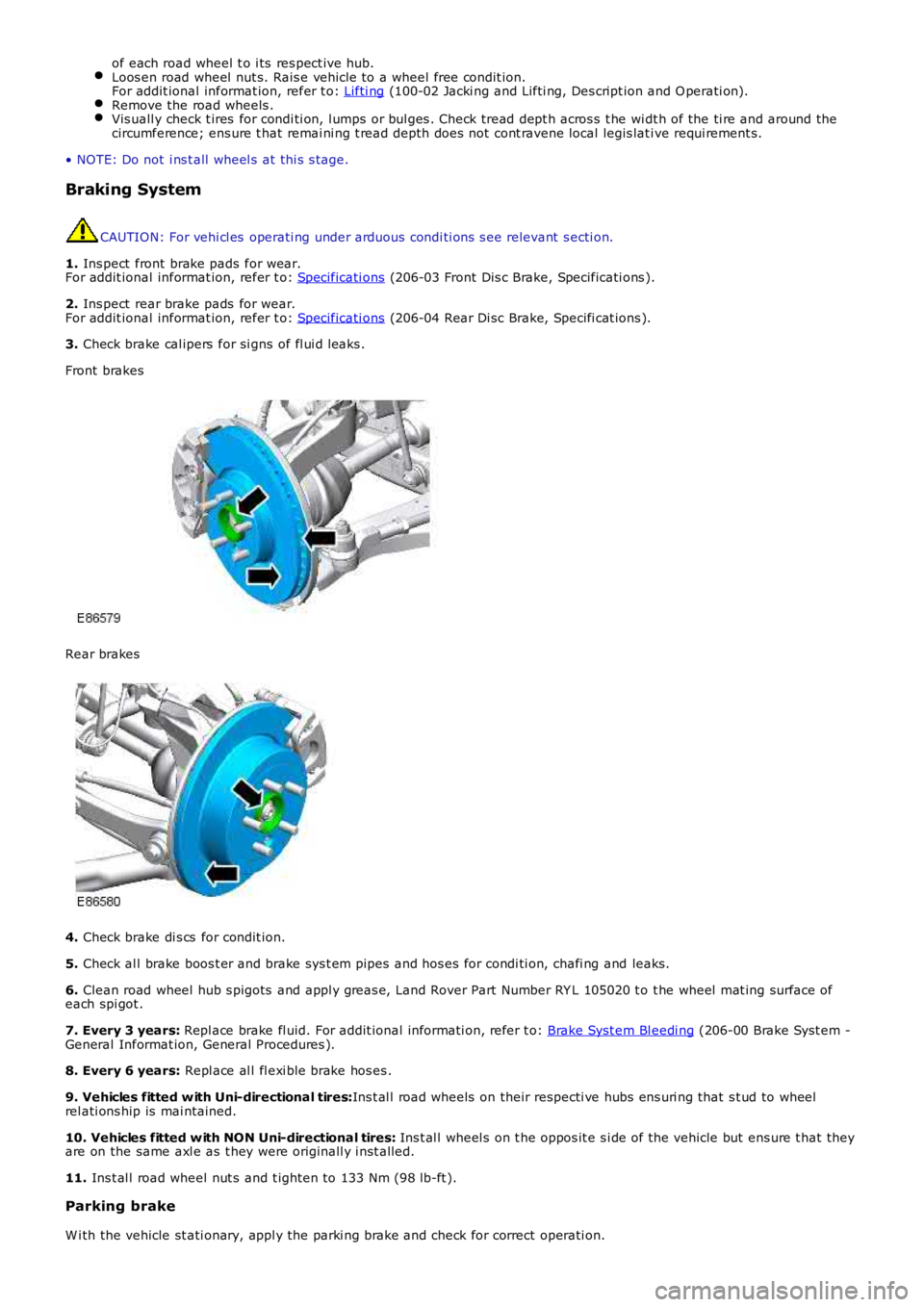

Front brakes Rear brakes

4.

Check brake di s cs for condit ion.

5. Check al l brake boos t er and brake sys t em pipes and hos es for condi ti on, chafi ng and leaks.

6. Clean road wheel hub s pigots and appl y greas e, Land Rover Part Number RY L 105020 t o t he wheel mat ing surface of

each spi got .

7. Every 3 years: Repl ace brake fl uid. For addit ional informati on, refer t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em -

General Informat ion, General Procedures ).

8. Every 6 years: Repl ace al l fl exi ble brake hos es .

9. Vehicles fitted w ith Uni-directional tires: Ins t al l road wheels on their respecti ve hubs ens uri ng that s t ud to wheel

rel ati ons hip is mai ntained.

10. Vehicles fitted w ith NON Uni-directional tires: Ins t al l wheel s on t he oppos it e s i de of the vehicle but ens ure t hat they

are on the same axl e as t hey were originall y i ns t alled.

11. Ins t al l road wheel nut s and t ighten to 133 Nm (98 lb-ft ).

Parking brake

W i th the vehicle st ati onary, appl y the parki ng brake and check for correct operati on .

Page 223 of 3229

Publi s hed: 11-May-2011

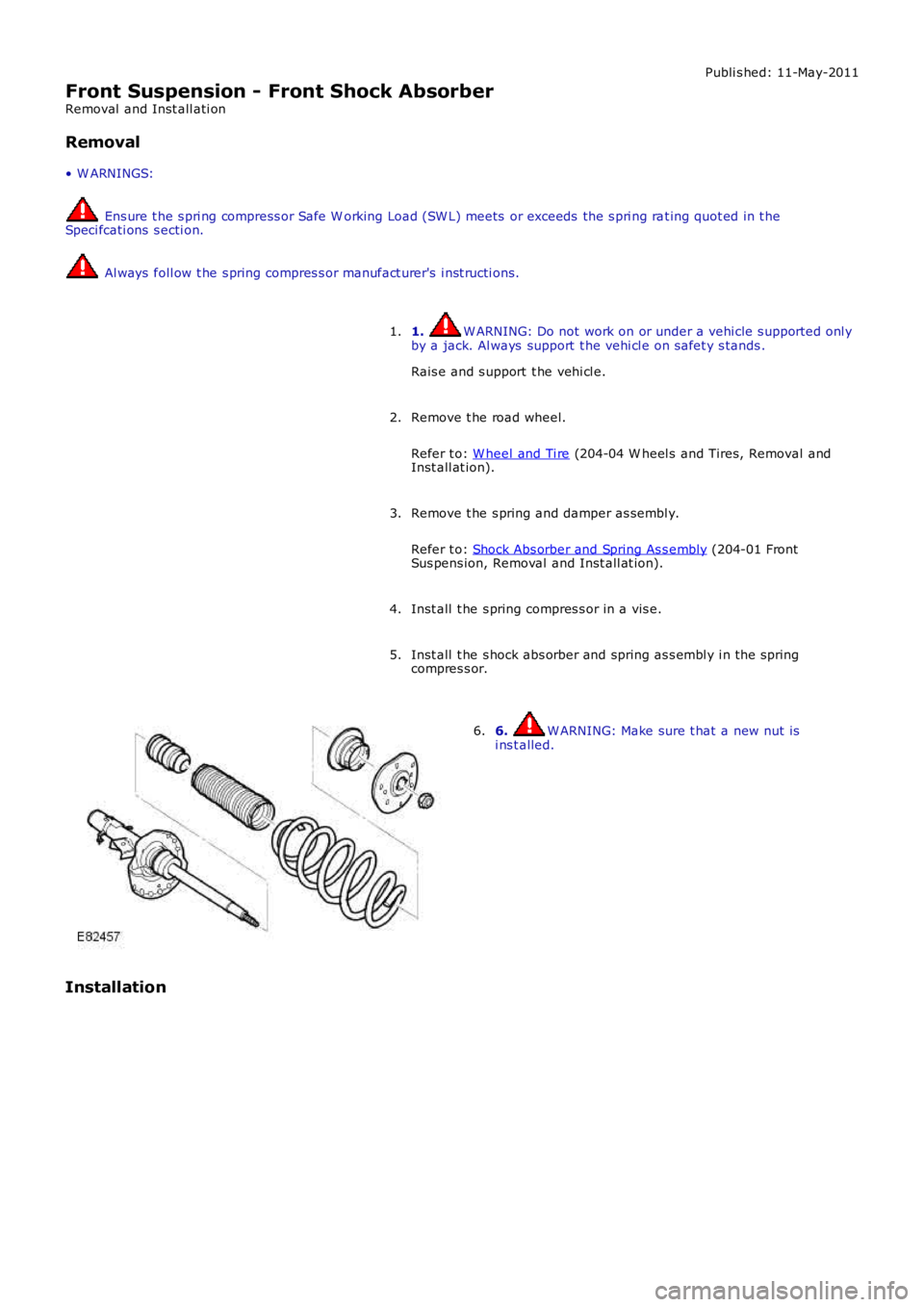

Front Suspension - Front Shock Absorber

Removal and Inst all ati on

Removal

• W ARNINGS:

Ens ure t he s pri ng compress or Safe W orking Load (SW L) meets or exceeds the s pri ng rat ing quot ed in t heSpeci fcati ons s ecti on.

Al ways foll ow t he s pring compres s or manufact urer's i nst ructi ons.

1. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he road wheel.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

2.

Remove t he s pring and damper as sembl y.

Refer t o: Shock Abs orber and Spring As s embly (204-01 FrontSus pens ion, Removal and Inst all at ion).

3.

Inst all t he s pring compres s or in a vis e.4.

Inst all t he s hock abs orber and spring as s embl y i n the springcompres s or.5.

6. W ARNING: Make sure t hat a new nut isi ns t alled.6.

Installation

Page 228 of 3229

Publi s hed: 11-May-2011

Front Suspension - Spring

Removal and Inst all ati on

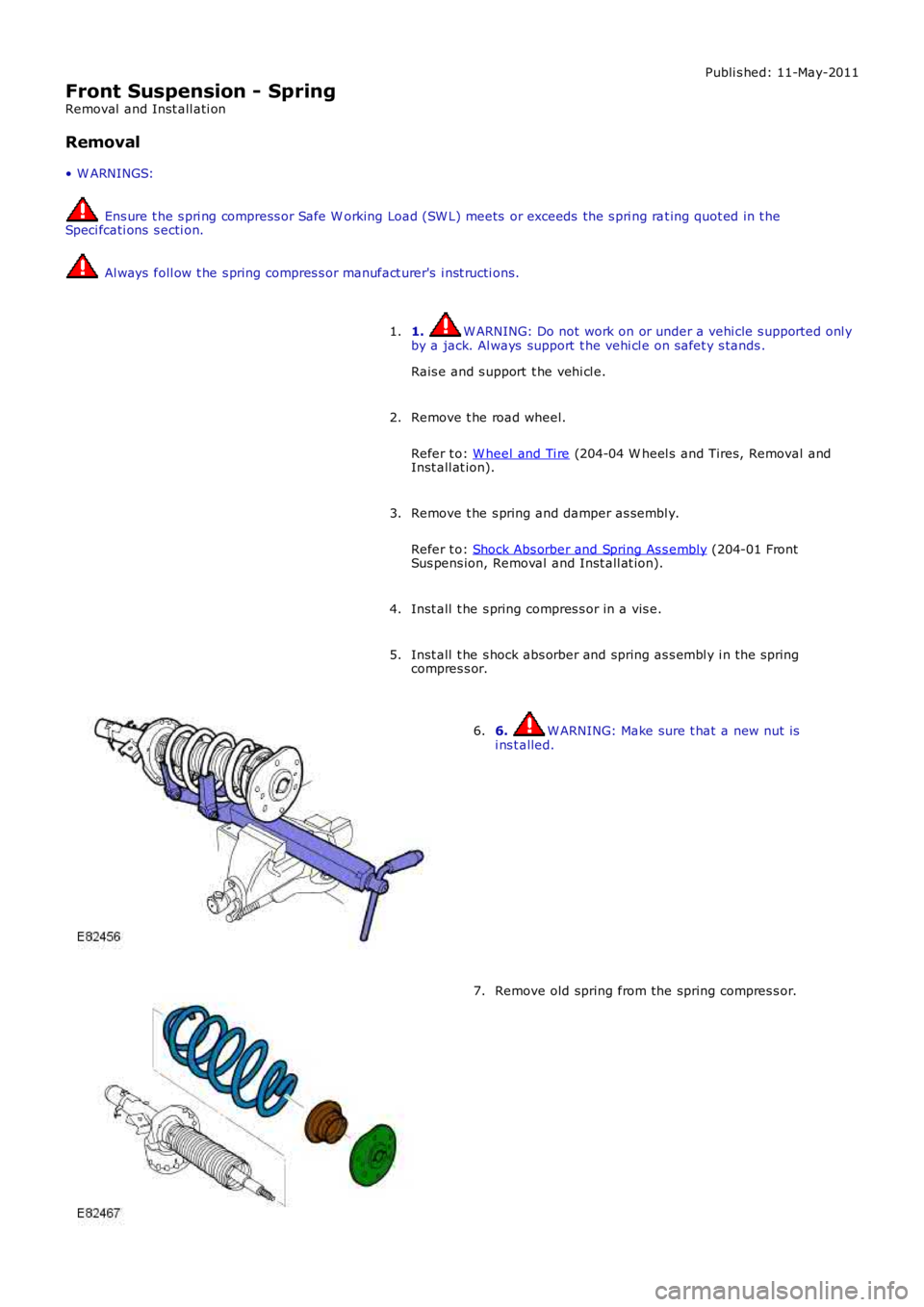

Removal

• W ARNINGS:

Ens ure t he s pri ng compress or Safe W orking Load (SW L) meets or exceeds the s pri ng rat ing quot ed in t heSpeci fcati ons s ecti on.

Al ways foll ow t he s pring compres s or manufact urer's i nst ructi ons.

1. W ARNING: Do not work on or under a vehi cle s upported onl yby a jack. Al ways support t he vehi cl e on s afet y s tands .

Rais e and s upport t he vehi cl e.

1.

Remove t he road wheel.

Refer t o: W heel and Ti re (204-04 W heel s and Tires, Removal andInst all at ion).

2.

Remove t he s pring and damper as sembl y.

Refer t o: Shock Abs orber and Spring As s embly (204-01 FrontSus pens ion, Removal and Inst all at ion).

3.

Inst all t he s pring compres s or in a vis e.4.

Inst all t he s hock abs orber and spring as s embl y i n the springcompres s or.5.

6. W ARNING: Make sure t hat a new nut isi ns t alled.6.

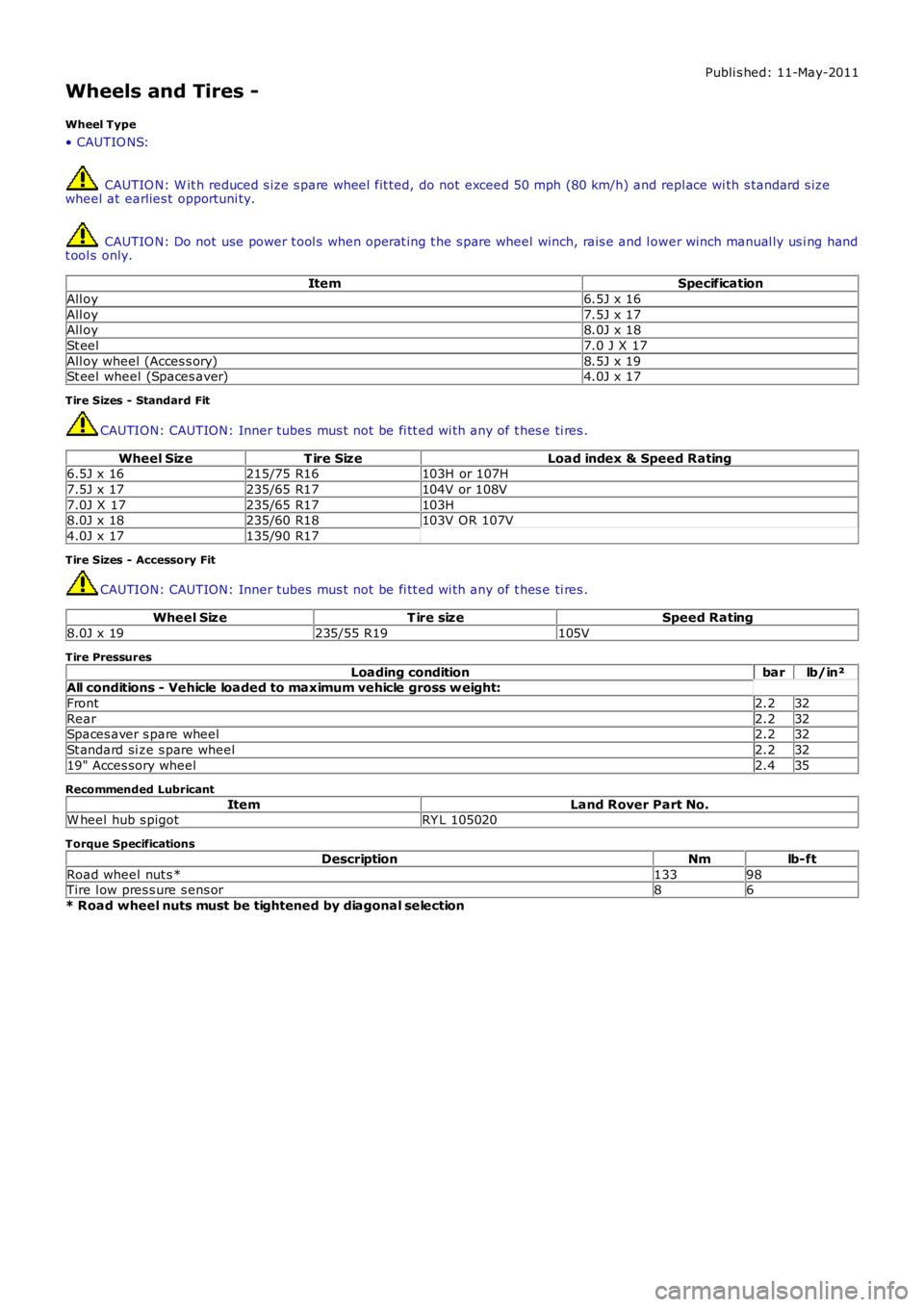

Remove old spring from the spring compres s or.7.

Page 272 of 3229

Publi s hed: 11-May-2011

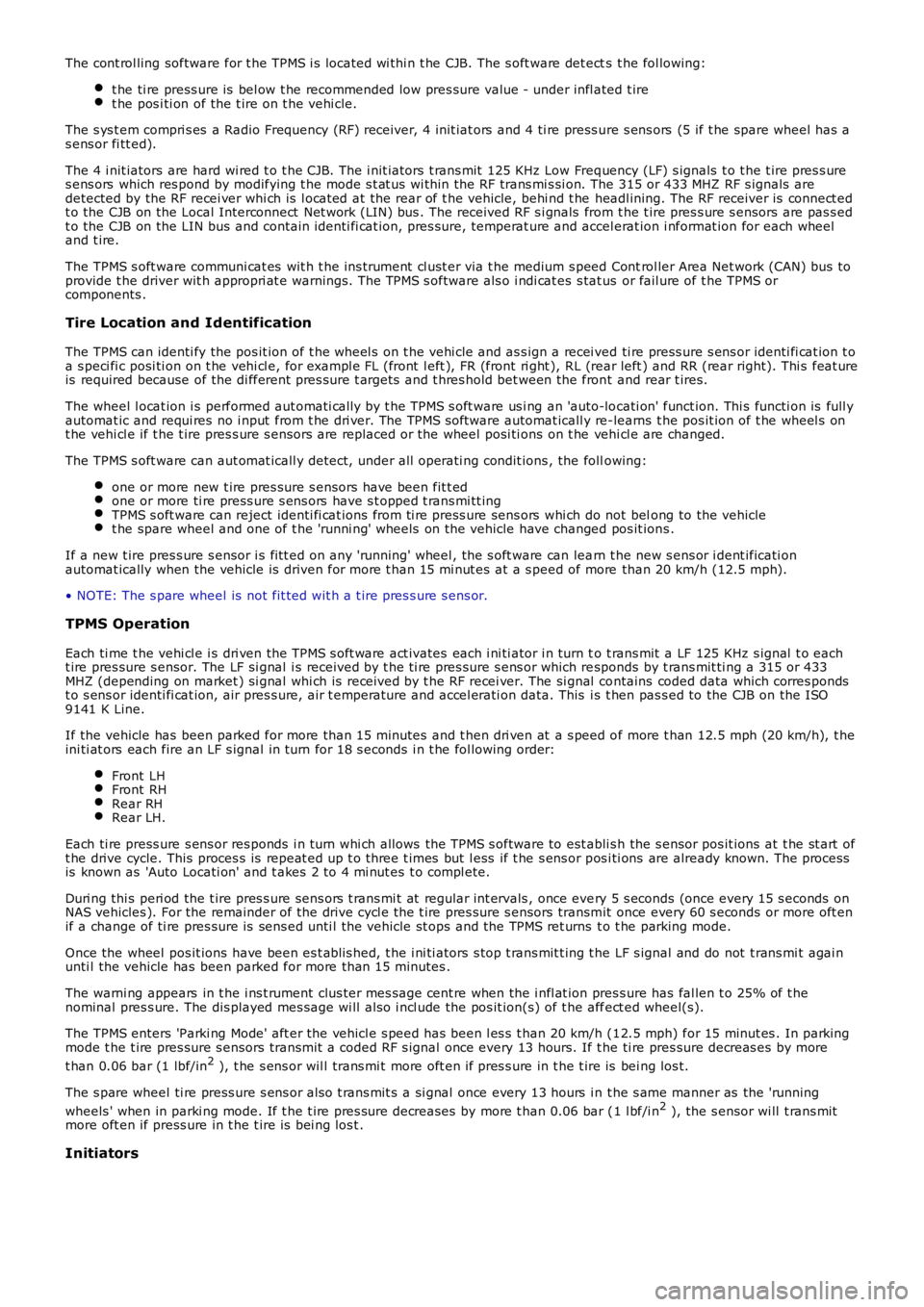

Wheels and Tires -

Wheel Type

• CAUTIO NS:

CAUTIO N: W it h reduced s ize s pare wheel fit ted, do not exceed 50 mph (80 km/h) and repl ace wi th s tandard s izewheel at earlies t opportuni ty.

CAUTIO N: Do not use power t ool s when operat ing t he s pare wheel winch, rais e and l ower winch manual ly us i ng handt ool s only.

ItemSpecification

All oy6.5J x 16

All oy7.5J x 17All oy8.0J x 18

St eel7.0 J X 17

All oy wheel (Acces s ory)8.5J x 19St eel wheel (Spaces aver)4.0J x 17

Tire Sizes - Standard Fit

CAUTION: CAUTION: Inner tubes mus t not be fi tt ed wi th any of t hes e ti res .

Wheel SizeT ire SizeLoad index & Speed Rating6.5J x 16215/75 R16103H or 107H

7.5J x 17235/65 R17104V or 108V

7.0J X 17235/65 R17103H8.0J x 18235/60 R18103V OR 107V

4.0J x 17135/90 R17

Tire Sizes - Accessory Fit

CAUTION: CAUTION: Inner tubes mus t not be fi tt ed wi th any of t hes e ti res .

Wheel SizeT ire sizeSpeed Rating

8.0J x 19235/55 R19105V

Tire Pressures

Loading conditionbarlb/in²All conditions - Vehicle loaded to maximum vehicle gross w eight:

Front2.232

Rear2.232Spaces aver s pare wheel2.232

St andard si ze s pare wheel2.232

19" Acces sory wheel2.435

Recommended Lubricant

ItemLand Rover Part No.W heel hub s pigotRY L 105020

Torque Specifications

DescriptionNmlb-ft

Road wheel nut s *13398Tire l ow pres s ure s ens or86

* Road wheel nuts must be tightened by diagonal selection

Page 276 of 3229

The cont rol ling software for t he TPMS i s located wi thi n t he CJB. The s oft ware det ects t he fol lowing:

t he ti re press ure is bel ow t he recommended low pres sure value - under infl ated t iret he pos i ti on of the t ire on t he vehi cle.

The s ys t em compri s es a Radio Frequency (RF) receiver, 4 init iat ors and 4 ti re press ure s ens ors (5 if t he spare wheel has as ens or fi tt ed).

The 4 i nit iators are hard wi red t o t he CJB. The i nit iators t rans mit 125 KHz Low Frequency (LF) s ignals t o t he t ire pres s ures ens ors which res pond by modifying t he mode s t at us wi thin the RF trans mi s si on. The 315 or 433 MHZ RF s ignals aredetected by the RF recei ver whi ch is l ocat ed at the rear of t he vehicle, behi nd t he headl ining. The RF receiver is connect edt o the CJB on the Local Interconnect Net work (LIN) bus . The received RF s i gnals from t he t ire pres s ure s ensors are pas s edt o the CJB on the LIN bus and contain identi fi cat ion, pres sure, temperat ure and accel erat ion i nformat ion for each wheeland t ire.

The TPMS s oft ware communi cat es wit h t he ins trument cl ust er via t he medium s peed Control ler Area Net work (CAN) bus toprovide t he driver wit h appropri at e warnings. The TPMS s oftware als o i ndi cat es s tat us or fail ure of t he TPMS orcomponents .

Tire Location and Identification

The TPMS can identi fy the pos it ion of t he wheel s on t he vehi cle and as s ign a recei ved ti re press ure s ens or identi fi cat ion t oa s peci fi c posi ti on on t he vehi cl e, for exampl e FL (front l eft ), FR (front ri ght ), RL (rear left ) and RR (rear right). Thi s feat ureis required because of the di fferent pres sure t argets and t hres hold bet ween the front and rear t ires.

The wheel l ocat ion i s performed aut omati cal ly by t he TPMS s oft ware us i ng an 'auto-locati on' funct ion. Thi s functi on is full yautomat ic and requi res no i nput from t he dri ver. The TPMS software automat icall y re-learns t he pos it ion of t he wheel s ont he vehi cl e if t he t ire pres s ure s ensors are replaced or the wheel posi ti ons on t he vehi cl e are changed.

The TPMS s oft ware can aut omat icall y detect, under all operati ng condit ions , the following:

one or more new t ire pres sure s ensors have been fit t edone or more ti re press ure s ens ors have s t opped t rans mi tt ingTPMS s oft ware can reject identi fi cat ions from ti re press ure sens ors whi ch do not belong to the vehiclet he spare wheel and one of t he 'runni ng' wheels on the vehicle have changed pos it ions .

If a new t ire pres s ure s ensor i s fi tt ed on any 'running' wheel , the s oft ware can learn t he new s ens or i dent ificati onautomat ically when the vehicle is driven for more t han 15 mi nut es at a s peed of more than 20 km/h (12.5 mph).

• NOTE: The s pare wheel is not fit ted wit h a t ire pres s ure s ens or.

TPMS Operation

Each ti me t he vehi cl e i s dri ven the TPMS s oft ware act ivates each i ni ti ator i n turn to t rans mit a LF 125 KHz s ignal t o eacht ire pres sure s ensor. The LF si gnal i s received by t he ti re pres sure s ens or which responds by t rans mit ti ng a 315 or 433MHZ (depending on market ) si gnal whi ch is received by t he RF recei ver. The si gnal contains coded data which corres pondst o s ens or identi fi cat ion, air pres s ure, air t emperature and accel erati on data. This i s t hen pas s ed to the CJB on the ISO9141 K Line.

If the vehicle has been parked for more than 15 minutes and t hen dri ven at a s peed of more t han 12.5 mph (20 km/h), t heini ti at ors each fire an LF s ignal in turn for 18 s econds i n t he fol lowing order:

Front LHFront RHRear RHRear LH.

Each ti re press ure s ens or res ponds i n t urn whi ch allows the TPMS s oftware to est ablis h the s ensor pos it ions at t he st art oft he drive cycle. This proces s is repeat ed up t o t hree t imes but l ess if t he s ens or pos i ti ons are already known. The processis known as 'Auto Locati on' and t akes 2 to 4 mi nut es t o compl ete.

Duri ng thi s peri od the t ire pres s ure sens ors t rans mi t at regular int ervals , once every 5 s econds (once every 15 s econds onNAS vehicles ). For the remainder of the drive cycl e t he t ire pres sure s ensors transmit once every 60 s econds or more oft enif a change of ti re pres sure is sens ed unti l the vehicle st ops and the TPMS ret urns t o t he parking mode.

Once the wheel pos it ions have been es t abl is hed, t he i ni ti ators s top t rans mit t ing t he LF s ignal and do not t rans mi t agai nunti l the vehicle has been parked for more than 15 minutes .

The warni ng appears in t he i ns t rument clus ter mes s age cent re when the i nfl at ion press ure has fal len t o 25% of t henominal pres s ure. The dis played mes sage wi ll als o i ncl ude the pos it ion(s) of t he affect ed wheel(s).

The TPMS enters 'Parki ng Mode' aft er the vehicl e s peed has been l es s t han 20 km/h (12.5 mph) for 15 minut es . In parkingmode t he t ire pres sure s ensors transmit a coded RF s ignal once every 13 hours. If t he ti re pres sure decreas es by more

t han 0.06 bar (1 lbf/in2 ), t he s ens or wil l trans mi t more oft en if pres s ure in t he t ire is bei ng los t.

The s pare wheel ti re press ure s ens or als o t rans mit s a si gnal once every 13 hours i n t he s ame manner as the 'running

wheels ' when in parki ng mode. If t he t ire pres sure decreases by more t han 0.06 bar (1 l bf/i n2 ), the s ensor wi ll t rans mitmore oft en if press ure in t he t ire is bei ng los t .

Initiators

Page 293 of 3229

Publi s hed: 11-May-2011

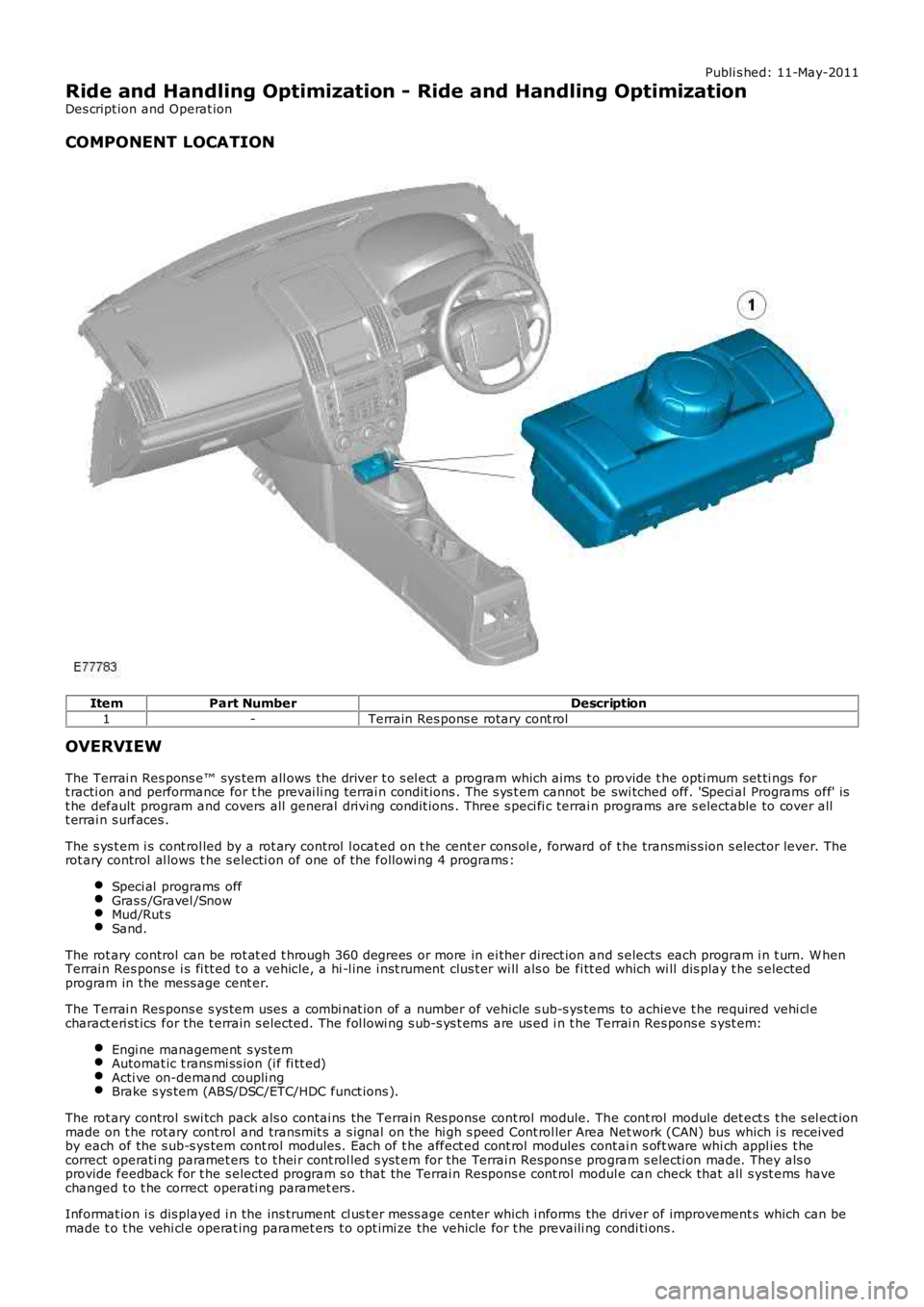

Ride and Handling Optimization - Ride and Handling Optimization

Des cript ion and Operat ion

COMPONENT LOCATION

ItemPart NumberDescription

1-Terrain Res pons e rotary cont rol

OVERVIEW

The Terrai n Res pons e™ sys tem all ows the driver t o s el ect a program which aims t o provide t he opti mum set ti ngs fort racti on and performance for t he prevai li ng terrai n condit ions . The s ys t em cannot be swi tched off. 'Speci al Programs off' ist he default program and covers all general drivi ng condit ions . Three s peci fi c terrain programs are s electable to cover allt errai n s urfaces .

The s ys t em i s cont rol led by a rot ary control l ocat ed on t he cent er cons ol e, forward of t he transmis s ion s elector lever. Therot ary control al lows t he s electi on of one of the followi ng 4 programs :

Speci al programs offGras s /Gravel /SnowMud/Rut sSand.

The rot ary control can be rot at ed t hrough 360 degrees or more in ei ther direct ion and s elects each program i n t urn. W henTerrai n Res pons e i s fi tt ed t o a vehicle, a hi -l ine i nst rument clus t er wi ll als o be fi tt ed which wi ll dis play t he s electedprogram in the mess age cent er.

The Terrai n Res pons e s ys tem uses a combi nat ion of a number of vehicle s ub-s ys tems to achieve t he required vehi cl echaract eri st ics for the t errain s elected. The fol lowi ng s ub-s ys t ems are us ed i n t he Terrai n Res pons e s yst em:

Engi ne management s ys temAutomat ic t rans mi ss ion (i f fi tt ed)Acti ve on-demand coupli ngBrake s ys tem (ABS/DSC/ETC/HDC funct ions ).

The rot ary control swi tch pack als o contai ns the Terrain Res ponse cont rol module. The cont rol module det ect s t he s el ect ionmade on t he rot ary cont rol and transmit s a s ignal on the hi gh s peed Cont rol ler Area Net work (CAN) bus which i s receivedby each of the s ub-s ys tem cont rol modules . Each of t he affect ed cont rol modules contai n s oft ware whi ch appl ies t hecorrect operati ng paramet ers t o t hei r cont rol led s yst em for the Terrai n Respons e program s electi on made. They als oprovide feedback for t he s elected program s o that the Terrai n Respons e cont rol module can check that all s yst ems havechanged t o t he correct operati ng paramet ers .

Informat ion i s dis played i n the ins trument cl us t er mess age center which i nforms the driver of improvement s which can bemade t o t he vehi cl e operat ing paramet ers t o opt imi ze the vehicle for t he prevaili ng condi ti ons .

Page 294 of 3229

Inexperi enced off-road dri vers may benefi t from t he automat ic as s is tance of t he Terrai n Respons e s yst em and t he driverinformat ion. Experienced off-road drivers can s elect the specific programs for ext reme condit ions t o acces s cont rol over t hevehi cl e s yst ems (for example; accel erator pedal maps , t rans mis s ion s hift maps , traction s ett ings ) which are not access i bl eon vehicles wi thout Terrai n Res pons e.

Stop/St art Vehicl es - From 2010 MY

Acti vat ion of t he Terrai n Res pons e s peci al programs wi ll deact ivate the St op/St art syst em.

However, if Terrain Res pons e is acti vat ed when t he engi ne is shut down in a Stop/St art cycl e t he engi ne wil l aut omat ical lyres t art . If duri ng thi s event t he Stop/Start sys tem cannot detect the driver's occupancy, for example ei ther t he dri ver’ss afety bel t or door i s unlatched, the engine wi ll not res t art . The St op/St art s yst em will reques t t he driver t o depres s theclutch t o rest art t he engine. The dri ver wi ll be i nformed of t his by ‘RESTART REQUIRED PRESS CLUTCH’ being di spl ayed i nt he mes sage center.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

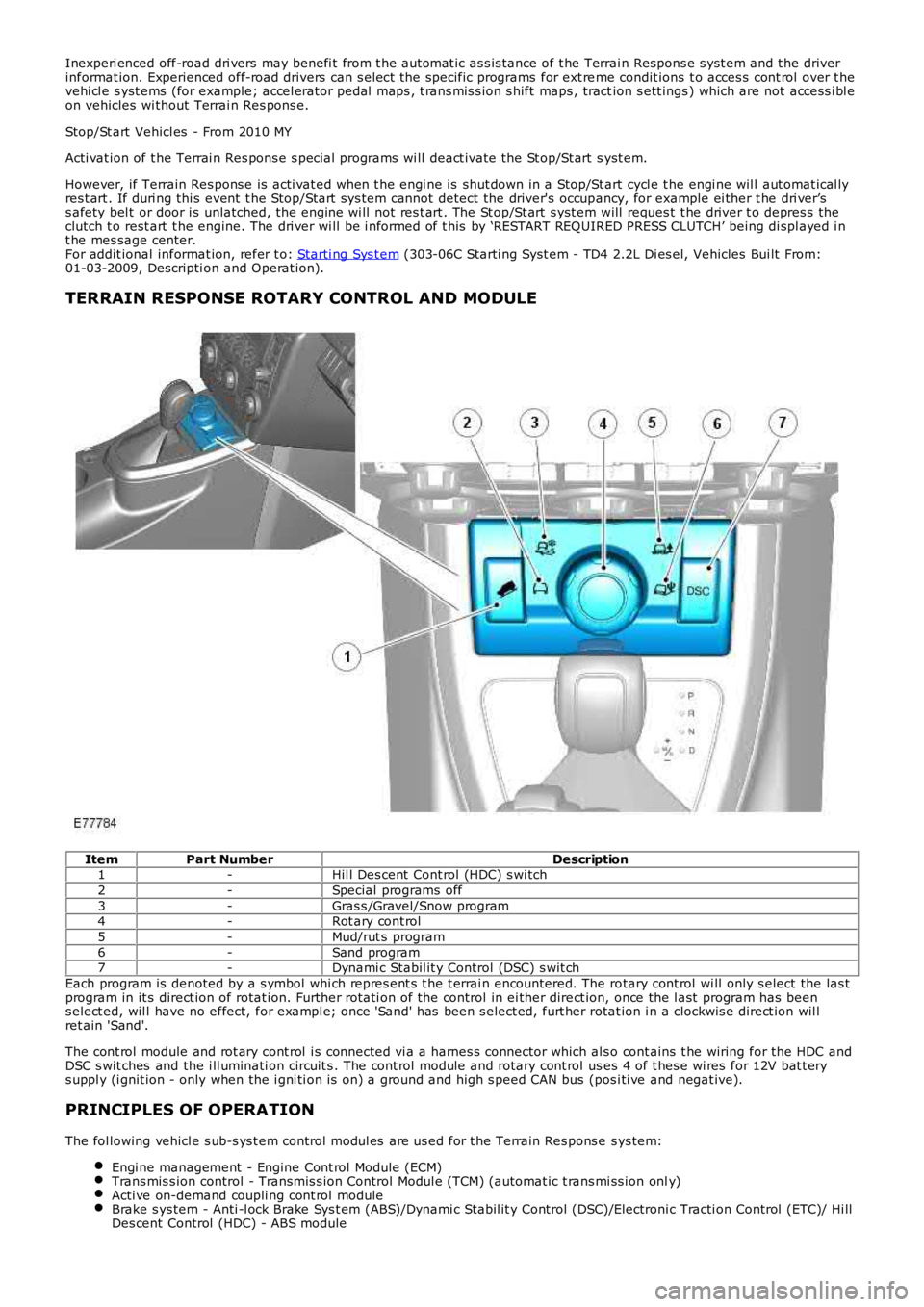

TERRAIN RESPONSE ROTARY CONTROL AND MODULE

ItemPart NumberDescription1-Hil l Des cent Cont rol (HDC) s wi tch

2-Special programs off

3-Gras s /Gravel/Snow program4-Rot ary cont rol

5-Mud/rut s program

6-Sand program7-Dynami c Stabil it y Control (DSC) s wit ch

Each program is denoted by a s ymbol whi ch repres ent s t he t errai n encountered. The rotary cont rol wi ll only s elect the las tprogram in it s direct ion of rotat ion. Further rot ati on of the control in ei ther direct ion, once the l ast program has beens elect ed, wil l have no effect, for exampl e; once 'Sand' has been s elect ed, furt her rotat ion i n a clockwis e direct ion wil lret ain 'Sand'.

The cont rol module and rot ary cont rol i s connected vi a a harnes s connector which al so cont ains t he wiring for the HDC andDSC s wit ches and the i ll uminati on circuit s . The cont rol module and rotary cont rol uses 4 of t hes e wi res for 12V bat t erys uppl y (i gnit ion - only when the i gni ti on is on) a ground and high s peed CAN bus (pos i ti ve and negat ive).

PRINCIPLES OF OPERATION

The fol lowing vehicl e s ub-s ys t em control modul es are us ed for t he Terrain Res pons e sys tem:

Engi ne management - Engine Cont rol Module (ECM)Trans mis s ion control - Transmis s ion Control Modul e (TCM) (automat ic t rans mi ss ion only)Acti ve on-demand coupli ng cont rol moduleBrake s ys tem - Anti -l ock Brake Sys t em (ABS)/Dynami c Stabil it y Control (DSC)/Electroni c Tracti on Control (ETC)/ Hi llDes cent Control (HDC) - ABS module

Page 295 of 3229

Each sub-sys tem operates in di fferent ways in relati on t o t he sel ect ed Terrai n Res pons e program t o achieve t he opt imumt racti on, s t abi lit y and eas e of cont rol for t he t errai n encount ered.

Engine Management System (EMS)

The EMS can change t he accel erator pedal maps to change the amount of t orque per percent age of pedal travel .

Each terrain program uses a combi nat ion of operat ing paramet ers for each sub-sys tem. Changing bet ween terrain programsini ti at es a di fferent s et of operat ing characteris ti cs which wil l be noti ceable to the driver, for example; i f the accel erat orpedal i s held i n a const ant pos i ti on and the terrain program is changed from Gras s /Gravel /Snow t o Sand, the driver wil lnoti ce the t orque and engine s peed increas e. If t he t errai n program is changed from Sand t o Grass /Gravel/Snow, t he dri verwil l not ice a reduct ion in t orque and engine s peed.

• NOTE: The change i n t orque and engine s peed can take approximat ely 30 s econds and care mus t be taken not to confus et he Terrai n Respons e s yst em operat ion wit h an EMS faul t.

Transmission Control (Automatic transmission only)

The t ransmis s ion control modul e changes t he shi ft maps for the Terrain Respons e program s elect ed. Thi s changes t he s hi ftpoints providing early or l at e ups hift s and downs hi ft s .

For example, i n t he Gras s /Gravel /Snow program, the trans mi ss i on wil l perform early ups hi ft s and very late downs hifts toensure t he transmis si on is in t he highes t gear pos si ble. The hil l det ect ion funct ion of t he Trans mis s ion Cont rol module(TCM) will l ock t he t orque converter and hold whi chever gear i s s el ect ed t o t he engine s peed (RPM) li mit i f neces s ary whendescending a s t eep incli ne. This provi des maximum engi ne braking before t he dri ver needs t o appl y t he brakes.

Sport mode i s only avail abl e when t he general program i s s elected. Sport mode i s disabled i n all Terrain Res pons e s peci alprograms. 'CommandShift ™' is avail abl e in any program.

Active On-Demand Coup ling Control

The act ive on-demand coupli ng cont rol module has 2 operati ng s trat egies ; pre-empt ive and react ive.

The pre-empti ve st rat egy anti ci pat es and predict s the locki ng torque val ue required t o mi ni mi ze sl ip and maxi mizes tabil it y. Each Terrain Res pons e program has a different t hres hol d and i nput cri teria for the pre-empt ive s t rategy. Forexampl e, a higher locki ng t orque would be appl ied on s li ppery s urfaces .

The reacti ve s trategy vari es the amount of locking t orque in res pons e t o t he actual s lip level and t he dynamic behavi or oft he vehi cl e. Each Terrain Res pons e program has a different t hres hol d and input for the react ive s trategy. The reacti ves trategy i mproves vehi cl e t racti on and compos ure by eliminati ng any wheel s pin which has occurred aft er the pre-empt ives trategy was appli ed. The l ocking res pons e appli ed is appli cable to the t errain program sel ect ed. For exampl e, verys ens i ti ve on s lippery surfaces to provide maximum t racti on and mi nimi ze surface damage.

The locking t orque calculati ons use various s ignals from other s ub-s yst ems , for example, engi ne torque, accel erator pedalposi ti on, s elect ed gear, st eeri ng angl e, vehicle s peed, lat eral accelerat ion, yaw behavi or.

The DSC funct ion of t he ABS s ys t em can override t he act ive on-demand coupli ng cont rol and reduce any appl ied l ocki ngt orque during DSC act ion.

ABS System Control

The ABS module cont rols several functi ons and adjust s t he operati ng paramet ers of t hes e funct ions t o opti mize thes elect ed Terrain Res pons e program.

Tracti on Control

Tracti on cont rol us es different s li p/accel erati on thresholds to i mprove t ract ion and vehicle compos ure. For example, t hes ys t em s ens it ivit y is increased on s lippery surfaces s uch as wet grass or s now t o reduce wheel s pi n. If wheel s pi n wasall owed in t hese ci rcums tances, l oss of t ract ion may res ul t from surface damage (wet grass ) or t he car being unable tomove (snow) due t o wheel spi n.

Dynamic St abi li ty Cont rol

If DSC is s wi tched off (wit h t he DSC s wi tch adjacent to t he Terrain Res pons e rotary cont rol ) when usi ng a TerrainRespons e s peci al program, if t he s peci al program i s s ubs equent ly changed for a di fferent program, DSC is aut omat icall ys wit ched back on.

The DSC us es different t hres hol d values for t he s elected program t o aut omati call y reduce DSC i ntervent ion, removing t herequirement for t he dri ver t o dis able t he DSC s ys tem in order to reduce engine intervent ion whi ch is s omet imes i nduced i nextreme off-road condi ti ons . In ext reme s and condit ions , there may be an addit ional benefit of dis abling the DSC funct ionus ing t he DSC s wit ch in addi ti on to sel ect ing t he s and program.

In the Mud/Ruts program the DSC sys tem is cal ibrat ed t o tol erate a higher 'yaw' thres hold. This al lows a greaterdifferent ial between t he actual and des i red wheel turni ng behavi or before DSC i ntervenes . Thi s all ows the DSC s ys t em t oignore the effect of rut s 'jarring' t he car or adjust ing t he front wheel s t eering angle.

The Terrai n Res pons e s ys tem can al ter t he balance bet ween engine and brake i ntervention. For example, when t he s andprogram is sel ect ed, t he DSC s ys tem reduces it s rel iance on engi ne int erventi on and increas es the us e of brakeint erventi on to maint ai n t he vehi cl es momentum and prevent it from becomi ng bogged down i f wheel s li p i s detected.

Hil l Descent Cont rol

HDC i s automat icall y s wit ched on or off and target s peeds are adjus t ed in res pons e to t he Terrai n Res pons e programs elect ed. The res pons iveness of the HDC functi on is al so increas ed where requi red.

Automat ic operat ion of HDC ai ms t o as s is t the driver by s wit chi ng t he sys t em on or off when it is of most benefi t. HDC isonly aut omat icall y s wit ched on when the mud/rut s program i s s elect ed. HDC i s not automati cal ly s elected in ot her