ESP LAND ROVER FRELANDER 2 2006 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1103 of 3229

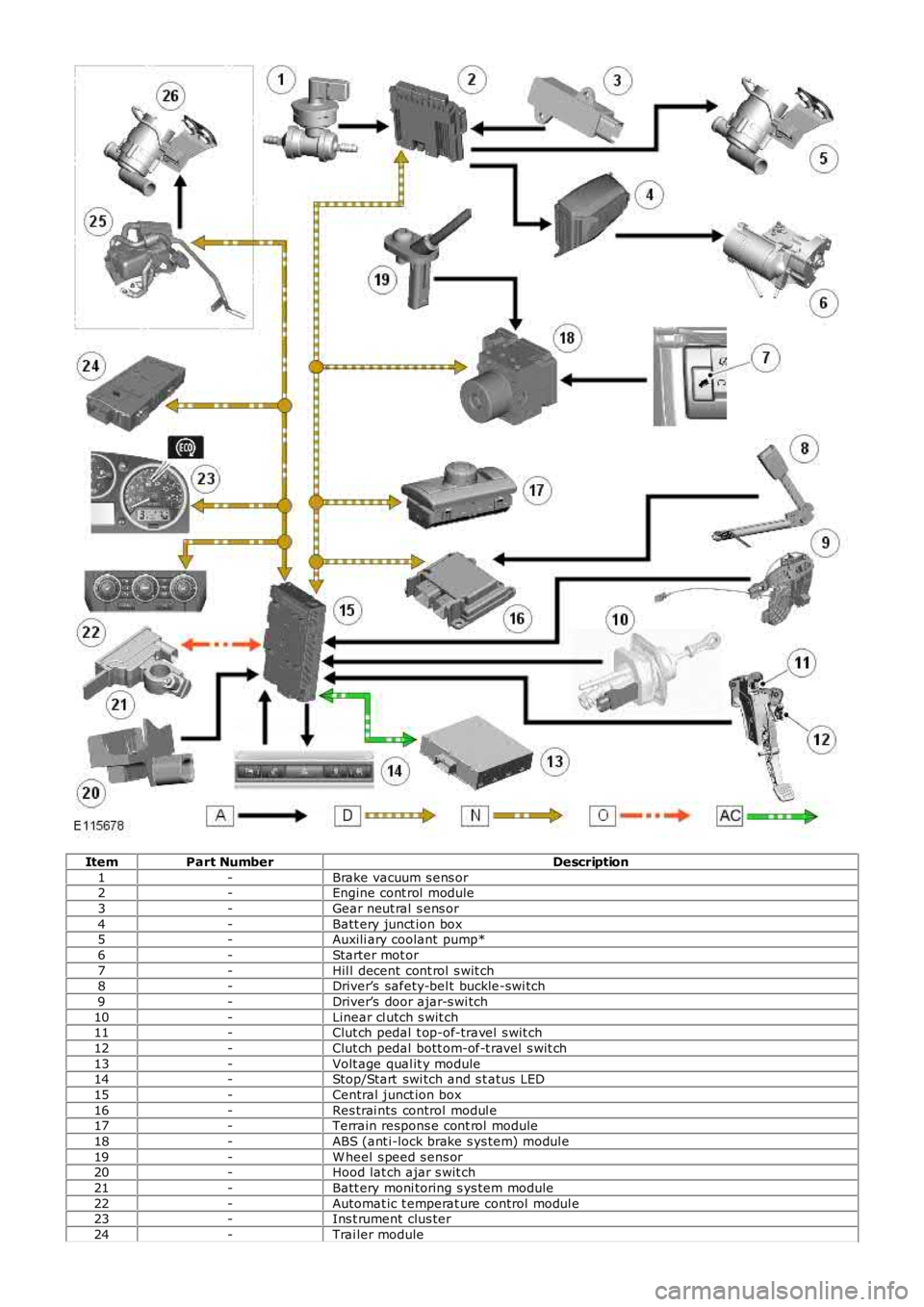

ItemPart NumberDescription

1-Brake vacuum s ens or2-Engine cont rol module

3-Gear neut ral s ens or

4-Batt ery junct ion box5-Auxili ary coolant pump*

6-Starter mot or

7-Hil l decent cont rol s wit ch8-Driver’s safety-bel t buckle-swi tch

9-Driver’s door ajar-s wi tch

10-Linear cl utch s wit ch11-Clut ch pedal t op-of-travel s wit ch

12-Clut ch pedal bott om-of-t ravel s wit ch

13-Volt age qual it y module14-Stop/Start swi tch and s t atus LED

15-Central junct ion box

16-Res trai nts control modul e17-Terrain respons e cont rol module

18-ABS (ant i-lock brake s ys tem) modul e

19-W heel s peed s ens or20-Hood lat ch ajar s wit ch

21-Batt ery moni toring s ys tem module

22-Automat ic t emperat ure control modul e23-Ins t rument clus ter

24-Trai ler module

Page 1107 of 3229

To ens ure t he vehi cl e’s braki ng s ys t em i s never compromi sed, a brake vacuum s ens or is int roduced on Stop/St art vehiclest o monit or vacuum reserves in t he brake s ervo. The vacuum sens or is mount ed in the vacuum pipe and hardwi red to t heECM. In the event of brake vacuum decreas ing below a s et threshold during a Stop/St art cycl e t he ECM wi ll s end a s ignalt o eit her:

Rest art t he engine and consequentl y replenis h vacuum reserves .Inhi bi t t he engi ne s hut ti ng down if vacuum res erves are not s uffi ci ent.

An example of vacuum res erves deplet ing, is by t he dri ver repeat edly pres s ing t he brake pedal when the engine iss hut down duri ng a St art/Stop cycle. This acti on wil l init iat e an engine res tart when vacuum reserves decreas e below thes et thres hold.

If a fault develops wi th the brake vacuum s ensor a DTC wil l be logged in the CJB.

Auxiliary Coolant Pump

Duri ng a St op/Start cycle when the engine i s s hutdown and consequent ly the engine-driven coolant pump is st ati onary, thedesi red s et cabi n t emperature cannot be mai ntai ned for a prol onged period, especially in col d ambient t emperatures . Tocount eract this , an auxil iary el ect ri c cool ant -pump has been integrat ed i nt o t he cool ing s ys tem to maint ain t he cool antfl ow t hrough t he cabi n’s heat er core. Thi s s upporti ng ci rculat ion t herefore prol ongs t he s et temperat ure set ti ng in the cabinand accordi ngl y prevents an early engine res tart.

Dependi ng on vehi cl e clas s ifi cat ion the auxil iary coolant pump i s eit her:

Hardwi red di rectl y to the ECM.Or if t he vehicle i s fit ted wi th a FFBH (fuel fi red boos ter heat er), t he FFBH coolant pump i s uti li zed and act ivatedvia t he FFBH.

The functi onal it y of bot h t ypes of auxil iary coolant pump i s t he s ame wi th regards the Stop/St art s ys tem.

To dis guis e t he acti vat ion s ound of the auxil iary pump, t he pump i s acti vat ed at the same ti me as t he engine s huts down.

Remote Handset

To all ow t he dri ver eas e of use, a revis ed remot e handset releas e has been introduced. Thi s all ows t he driver t o ins t ant lyrel eas e t he remote hands et from t he s tart cont rol module when t he engine i s s hut down in a Stop/Start cycle.

The vehi cl e reverts t o t he conventi onal remote hands et releas e when not in a Stop/Start cycle, that i s by pres s ing t heignit ion St art /St op butt on before rel eas i ng the remote hands et.

Stall Recovery

In the event of an engi ne s tal l, t he Stop/St art s ys tem ent ers a unique ‘s t al l recovery’ mode. This feature aut omat ical lyatt empts to res tart the engine as soon as t he driver full y depres ses t he clut ch pedal; t he natural react ion of t he dri verwhen experiencing a s t alled engi ne si tuat ion.

Once the cl utch s ensor detects the ‘bot t om of t ravel’ threshold, refer to ‘Linear Clut ch Sens or’, t he s t arter mot or isact ivat ed to res tart the engine. The warni ng indicat ors normal ly as s oci ated wi th an engi ne s tal l, for example the i gni ti onand low oil pres s ure i ndi cat ors i n t he ins t rument clus ter wil l be s uppress ed s o wi ll not il lumi nat e. The Eco indicator does

Page 1117 of 3229

SymptomPossible CauseAction

Engine s urgesFuel pump and li nesElect ronic engine controlsEngine i gni ti on s ys t em

For fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Read DTCs and refer t o DTC Index for electroni c enginecontrols .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).Read DTCs and refer t o DTC Index in t his s ecti on forengine ignit ion s ys tem tes ts

Engine detonat es /knocksElect ronic engine controlsFuel pump and li nesAi r leakageSt icki ng VCT hub

Read DTCs and refer t o DTC Index for electroni c enginecontrolsFor fuel s yst em tes ts .REFER t o: Fuel Tank and Lines (310-01A Fuel Tank andLi nes - I6 3.2L Petrol, Diagnos is and Tes ti ng).Check for l eakage from air int ake s ys t emRead DTCs and refer t o DTC Index for VCT t est s .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).

No t hrot tl e res ponseElect ronic engine controlsRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts

Poor throt t le respons eBreat her sys temdis connected/res trict edElect ronic engine controlTrans mi ss i on malfunct ionTract ion control eventAi r leakage

Ens ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledRead DTCs and refer t o DTC Index for electroni c enginecontrol tes ts .REFER t o: Electroni c Engi ne Control s (303-14AEl ect ronic Engi ne Cont rol s - I6 3.2L Pet rol, Di agnos isand Tes t ing).For t rans mis s ion t es ts .REFER t o: Diagnost ics (307-01 Automat icTransmis si on/Trans axl e, Diagnos i s and Test ing).Check for l eakage from air int ake s ys t em

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er the pi npoi nt tes ts have been carried out , the fault is not present , an int ermi tt entconcern may be t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP131500Pers is t entmi s fireECM t o i gni ti on coi l ci rcuitfaul t- Cyli nder mi sfire DTCsals o s etIgni ti on coi l fail ureSpark plug fail ure/fouled/incorrect gapFuel deli very pres s ure l owFuel i njector circuit fault s- Inject or DTCs als o s et

Check for DTCs i ndi cat ing an ignit ion or fuel related fault .Recti fy as neces sary.

P136700Igni ti on s pareIgni ti on fai lure si gnal circui t:s hort circuit to groundIgni ti on fai lure si gnal circui t:open ci rcuitIgni ti on fai lure si gnal circui t:s hort circuit to powerIgni ti on coi l fail ure

Check t he ignit ion fail ure s ignal ci rcuit . Refer t o the el ect ri calgui des . Rect ify as neces s ary. Ins t all a new coil as necess ary.REFER t o: Ignit ion Coi l-On-Plug (303-07A Engine Ignit ion,Removal and Ins t al lat ion).

P136800Igni ti on s pareIgni ti on fai lure si gnal circui t:s hort circuit to groundIgni ti on fai lure si gnal circui t:open ci rcuitIgni ti on fai lure si gnal circui t:s hort circuit to powerIgni ti on coi l fail ure

Check t he ignit ion fail ure s ignal ci rcuit . Refer t o the el ect ri calgui des . Rect ify as neces s ary. Ins t all a new coil as necess ary.REFER t o: Ignit ion Coi l-On-Plug (303-07A Engine Ignit ion,Removal and Ins t al lat ion).

Page 1128 of 3229

Publi s hed: 11-May-2011

Engine Emission Control - I6 3.2L Petrol - Engine Emission Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the engine emis s ions s ys t ems , refer t o t he rel evant Des cript ion and Operat ion s ecti on in theworks hop manual .REFER to: Engine Emi s si on Cont rol - 3.2L (303-08 Engi ne Emis s ion Control - 3.2L, Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: For di agnos t ic purpos es the cyli nders are divided i nt o t wo banks: Bank 1 - Cyl inder numbers 1, 2 and 3. Bank 2 -Cylinders 4, 5 and 6

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual Inspection

MechanicalEngine breat her hos es

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

Engine cranks , butdoes not fi reEngi ne breather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Engine s t al ls s oonaft er s tartBreather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Poor throt t le respons eBreather s ys t emdi s connect ed/res t ri ct edEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Exces s ive emi ss i onsEngi ne breather s ys t em rest rictedEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal ledEngine oil l eaksEngi ne breather s ys t em rest rictedEns ure the engine breat her sys t em i s free fromres tricti on and is correctl y ins tal led

Page 1184 of 3229

Publi s hed: 11-May-2011

Evaporative Emissions - Evaporative Emissions

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the evaporat ive emi ss ions s ys tem, refer t o the relevant Descri pti on and Operat ion s ect ion int he works hop manual .REFER to: Evaporati ve Emis s ions (303-13 Evaporat ive Emi s si ons , Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Fuel fil ler cap and s ealFuel fil ler neckDi agnos ti c Monit oring of Tank Leakage (DMTL) fres h ai r fi lt er (res t ri ct ion, etc)Fuel t ank (leaks , damage, et c)Fuel l ines and joints , et cCarbon canis terPurge valveDMTL pump modul e

Fus esConnect orsHarnes s esPurge val veDMTL pump

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

• NOTE: On al l vehicl es equi pped wi th Diagnost ic Moni tor Tank Leakage (DMTL), there is a requirement to bl ank offt he vent il at ion port (l arge di amet er s tub pi pe) of t he DMTL module, t o prevent mis -diagnos is when carrying out as moke tes t .

5. W here K-Line, Vacut ec or other propri etary smoke tes t equi pment is avail abl e, i t s houl d be ut ili s ed to as s is t wi thEvaporati ve Emis s ions Sys tem leak diagnosi s .

5.

Symptom Chart

SymptomPossible CauseActionDi fficul ty in fil li ng fuelt ankRes tricti on in the vapor li ne bet ween t he fuelt ank and the carbon canis t er out let/atmospheri cport

Check for res trict ions/damage, et c (seevis ual i nspecti on)

Fuel s mel lSys tem leakPurge val ve inoperati veCheck for leaks, check the purge val veoperati on. GO t o Pinpoint Test A.

'Check Fuel Fil ler Cap'dis played on Mes s ageCenter

Fuel fil ler cap mi ss i ng/not ti ght ened aft errefuell ingCheck t he fuel fil ler cap and seal

DTC Index

• NOTE: If the modul e is sus pect and t he vehi cle remains under the manufact urer warrant y, refer t o t he W arrant y Pol icyand Procedure manual (s ect ion B1.2), or determine if any pri or approval programme is in operat ion, pri or t o t he i ns t allat ionof a new modul e.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP044100Evaporati ve emis s ions yst em - incorrect purgeflow

Evaporat ive emi ss i on canis t er ventres trictedCani st er to purge valve pipe

Check t he condi ti on and ins tal lat ion of t heevaporat ive emi s si on s ys t em. Check t heoperati on of the purge val ve. Ins tall new

Page 1202 of 3229

12-Res trai nts Cont rol Module (RCM)

13-Knock sens ors (2 off)

14-Fuel rail t emperature/pres s ure s ens or15-Clockspring

16-Terrain respons e cont rol module

17-Trans mis s ion Cont rol Module (TCM)18-ABS module

19-Diagnos ti c socket

20-CJB

ENGINE CONTROL MODULE (ECM)

The ECM i s located on a bracket i n a central pos i ti on on the engi ne compartment firewal l. The ECM is at tached to ahous i ng and s ecured wit h 4 s crews . The hous i ng is l ocat ed in the bracket and locked in pos it ion.

The ECM i s s uppl ied wi th bat tery volt age from fuses l ocat ed in the BJB. A permanent batt ery s upply i s provided t o ens ureadapt ive dat a is not l ost when the engine i s s wit ched off.

A regul ator, locat ed wi thin the ECM, s upplies a 5V current t o i nt ernal components such as t he mi cro-proces s or unit . Ot hercomponents or funct ions requi ri ng ful l bat tery vol tage are cont rol led by ext ernal relays or int ernal power s t ages .

The mi cro-proces sor wi thi n the ECM receives s ignals from different component s and cont rol modules and us es a programwit hin the ECM software t o int erpret t he s ignal informat ion and i ss ue s ignals whi ch rel at e t o how the engine component sand functi ons should be cont rol led.

The ECM recei ves i nput s from the foll owing:

CMP s ensorsCKP s ensorFuel rail pres s ure s ensorMAF s ensorKnock s ens orsFuel rail t emperature/pres s ure s ensorECT s ens orEngi ne oil l evel/t emperature s ens orManifol d Abs olute Pres sure (MAP) sens orElectric t hrot tl e - Throt tl e Posi ti on (TP) s ens orAPP s ens orFuel t ank leakage monit oring modul e (NAS onl y)Cooling fan controlHeated Oxygen s ens ors (HO2S)Stop lamp s wi tch (via Central Juncti on Box (CJB))Speed cont rol inhibi t swi tchInt ake Air Temperat ure (IAT) s ens orAmbient Air Temperat ure (AAT) s ens orTrans mis s ion Cont rol Modul e (TCM).

The ECM s ends out puts to t he followi ng:

Main relayAir Condit ioning (A/C) relayFuel i njectorsIgni ti on coi lsEngi ne cool ing fan cont rolElectric t hrot tl eElectric fuel pump driver moduleVari abl e Cams haft Timing (VCT) s olenoidsStarter rel ay cont rolVari abl e int ake manifol d control valvesVari abl e inl et cam profile swit ching sol enoi d val vesTrans mis s ion Cont rol Modul e (TCM).

SENSORS

The ECM opt imi zes engine performance by interpreti ng s ignals from numerous vehicle sens ors and ot her i nput s. Some oft hes e s ignals are produced by t he act ions of t he dri ver, some are s uppli ed by s ens ors locat ed on and around t he engine

Page 1207 of 3229

The engi ne oil l evel s ens or us es an ult ras oni c puls e, which is refl ect ed back from the s urface of t he oil . The ti me i t takesfor t his s i gnal t o ret urn t o t he s ensor i s turned int o a PW M s ignal and is s ent to the ECM. The ECM det ermi nes the ti met aken for the ul trasonic pul se si gnal t o be recei ved and calculat es it i nto an oil level fi gure.

Engi ne Oi l Temperat ure Sens or

The engi ne oil t emperature s ensor i s a Pos it ive Temperat ure Co-effi ci ent (PTC) thermis t or el ement . The element res i st anceincreas es as t he sens or temperat ure decreas es. The ECM s uppli es t he sens or wit h a 5V reference vol tage and a ground andmeas ures t he ret urned s ignal as a t emperature. A low oil temperature wil l res ult in a l ow volt age bei ng ret urned t o t heECM and hi gh oil temperature wil l ret urn a hi gh volt age reading.

The ECM moni tors the engine oi l level/temperat ure sens or for fault s and can s tore faul t rel at ed codes . These can beret ri eved us i ng a Land Rover approved diagnos t ic s ys tem. If the sens or fail s , the ECM us es t he engine cool ant temperat ures ens or s ignal val ue as a s ubst it ute.

Manifold Absolute Pressure (MAP) Sensor

The MAP s ensor i s located i n t he lower part of t he int ake manifol d. The MAP s ens or meas ures t he abs olut e pres s ure in t heint ake manifol d. The sens or is a semi -conduct or type s ens or which responds t o pres s ure acti ng on a membrane wi thin thes ens or, al tering t he output volt age. The s ens or receives a 5V reference vol tage and a ground from t he ECM and returns as ignal of bet ween 0.5 - 4.5V t o t he ECM. A low pres sure ret urns a low vol tage s ignal to the ECM and a high press ureret urns a hi gh volt age.

The MAP s ensor det ect s quick pres s ure changes i n t he int ake mani fol d aft er the el ectri c thrott le. The s ignal is us ed inconjunct ion wi th the MAF sens or si gnal t o calculate the injecti on peri od.

The ECM moni tors the engine MAP s ens or for faul ts and can st ore fault related codes. Thes e can be ret ri eved us i ng a LandRover approved diagnost ic sys tem. If t he s ens or fai ls , the ECM uses t he MAF/IAT s ensor s i gnal value as a subs ti tut e.

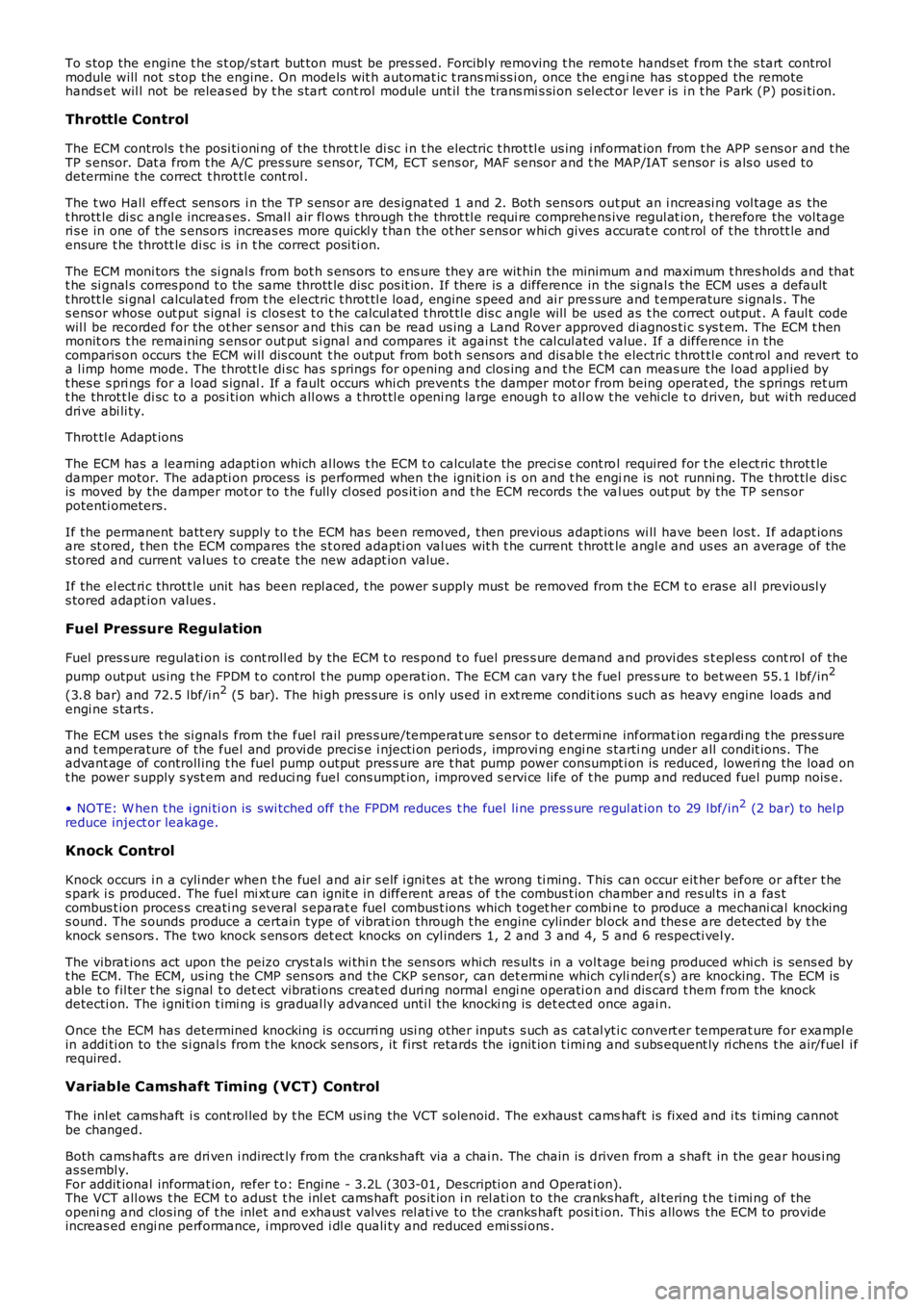

Electric Throttle

The electric t hrot tl e is locat ed at t he entrance of t he int ake manifol d and is secured t o t he manifold wit h four Torx headbolt s. The t hrot tl e als o provi des for t he connect ion of t he air cleaner hous ing out let pipe which is secured t o t he t hrott lebody wit h a cl ip.

The electric t hrot tl e compri ses t he t hrott le body, a round throt t le di sc whi ch is act uat ed by a damper mot or and a thrott leposi ti on s ens or. The el ect ri c thrott le is control led by the ECM and recei ves pos i ti onal s ignals from the TP s ens or. If afai lure of the mot or occurs , t he thrott le di s c is returned to it s cl osed pos it ion by the s prings, wi th li mit ed engine s peedavai lable to the driver.

Spindle Damper Mot or

The mot or i s a DC damper motor which drives a gear wheel and t wo s pri ngs ; one for opening and one for cl osi ng. Themot or rotat es the spi ndl e t o which t he t hrott le dis c is at t ached. PW M s i gnals from the ECM control the damper mot or t oadjus t the pos it ion of t he t hrott le dis c, regul ati ng the amount of air ent ering the i nlet manifold for combus ti on.

Movement of t he mot or is achieved by changing t he polarit y of the power s uppl y to the DC mot or, all owing i t to beoperated in bot h direct ions . The throt tl e dis c and t he mot or has two maxi mum pos it ions ; t hrott le di s c cl osed which all owsmi ni mal air flow t hrough t he electric t hrot tl e int o t he int ake manifol d and t hrott le dis c open which all ows maximum air flow

Page 1217 of 3229

To s top the engine t he s t op/s tart but ton must be pres sed. Forcibly removing t he remote hands et from t he s tart controlmodule will not s top the engine. On models wit h automat ic t rans mi ss i on, once the engi ne has st opped the remotehands et wil l not be releas ed by t he s tart cont rol module unt il the trans mi s si on s el ect or lever is i n t he Park (P) pos i ti on.

Throttle Control

The ECM controls t he posi ti oni ng of the throt t le di sc i n t he electric t hrot tl e us ing i nformat ion from t he APP s ens or and t heTP s ensor. Dat a from t he A/C pres sure s ens or, TCM, ECT s ens or, MAF s ensor and t he MAP/IAT s ensor i s als o us ed todetermine t he correct t hrot tl e cont rol .

The t wo Hall effect sens ors i n t he TP s ens or are des ignat ed 1 and 2. Both sens ors out put an i ncreasi ng vol tage as thet hrott le di s c angl e increas es. Smal l air fl ows t hrough the throt tl e requi re comprehens ive regul at ion, t herefore the vol tageri s e in one of the s ensors increas es more quickl y t han the ot her s ens or whi ch gives accurat e cont rol of t he thrott le andensure t he thrott le di sc is i n t he correct posi ti on.

The ECM moni tors the si gnal s from bot h s ens ors to ens ure they are wit hin the minimum and maximum t hres hol ds and thatt he si gnal s corres pond t o the same thrott le di sc pos it ion. If there is a difference in the si gnal s the ECM us es a defaultt hrott le si gnal calculated from t he electric t hrot tl e load, engi ne s peed and ai r pres s ure and t emperature s ignals . Thes ens or whose out put s ignal i s clos est t o t he calcul ated t hrot tl e dis c angle will be us ed as t he correct output . A faul t codewil l be recorded for the ot her s ens or and t his can be read us ing a Land Rover approved di agnos ti c s ys t em. The ECM t henmonit ors t he remaining s ens or out put s i gnal and compares it agains t t he cal cul ated value. If a difference i n thecomparis on occurs t he ECM wi ll dis count t he output from bot h s ens ors and dis abl e t he electric t hrot tl e cont rol and revert toa l imp home mode. The throt t le di sc has s prings for opening and clos ing and t he ECM can meas ure the l oad appl ied byt hes e s pri ngs for a l oad s ignal . If a fault occurs whi ch prevent s t he damper mot or from being operat ed, the s prings ret urnt he throt t le di sc to a pos i ti on which all ows a t hrot tl e openi ng large enough t o all ow t he vehi cle t o driven, but wi th reduceddri ve abi li ty.

Throt tl e Adapt ions

The ECM has a learning adapti on which al lows t he ECM t o calculate the preci s e cont rol required for t he elect ric throt t ledamper motor. The adapti on process is performed when the ignit ion i s on and t he engine is not runni ng. The t hrot tl e dis cis moved by the damper mot or to t he fully cl osed pos it ion and t he ECM records t he val ues out put by the TP sens orpotenti ometers.

If the permanent batt ery supply t o t he ECM has been removed, t hen previous adapt ions wi ll have been los t. If adapt ionsare st ored, t hen the ECM compares the s t ored adapti on val ues wit h t he current t hrottle angl e and us es an average of thes tored and current values t o create the new adapt ion value.

If the el ect ri c throt t le unit has been repl aced, t he power s upply mus t be removed from t he ECM t o eras e al l previousl ys tored adapt ion values .

Fuel Pressure Regulation

Fuel pres s ure regulati on is cont roll ed by t he ECM t o res pond t o fuel pres s ure demand and provi des s t epl ess cont rol of the

pump output us ing t he FPDM t o control t he pump operat ion. The ECM can vary t he fuel pres s ure to bet ween 55.1 l bf/in2

(3.8 bar) and 72.5 lbf/i n2 (5 bar). The hi gh pres s ure i s only us ed in ext reme condit ions s uch as heavy engine loads andengi ne s tarts .

The ECM us es t he si gnal s from the fuel rail pres s ure/temperat ure s ens or t o det ermi ne informat ion regardi ng t he pres sureand t emperature of the fuel and provi de precis e i njecti on periods , improvi ng engi ne s tarti ng under all condit ions. Theadvant age of controll ing t he fuel pump output pres s ure are t hat pump power consumpt ion is reduced, loweri ng the load ont he power s upply s yst em and reduci ng fuel cons umpt ion, improved s ervi ce life of t he pump and reduced fuel pump nois e.

• NOTE: W hen t he i gni ti on is swi tched off t he FPDM reduces t he fuel li ne pres s ure regul at ion to 29 lbf/in2 (2 bar) to hel preduce inject or leakage.

Knock Control

Knock occurs i n a cyli nder when t he fuel and air s elf i gni tes at t he wrong ti ming. This can occur eit her before or after t hes park i s produced. The fuel mi xt ure can ignit e in different areas of t he combus t ion chamber and res ul ts in a fas tcombus t ion proces s creati ng s everal s eparat e fuel combus t ions which t oget her combi ne to produce a mechani cal knockings ound. The s ounds produce a certain type of vibrat ion through t he engine cylinder block and thes e are detected by t heknock s ensors . The two knock s ens ors det ect knocks on cyl inders 1, 2 and 3 and 4, 5 and 6 respecti vel y.

The vibrat ions act upon the peizo crys t als wi thi n t he sens ors whi ch res ult s in a volt age bei ng produced whi ch is sens ed byt he ECM. The ECM, us ing the CMP sens ors and t he CKP s ensor, can det ermi ne which cylinder(s ) are knocking. The ECM isable t o fil ter t he s ignal t o det ect vibrat ions creat ed duri ng normal engi ne operati on and dis card t hem from the knockdetecti on. The i gni ti on t imi ng is gradual ly advanced unti l the knocki ng is det ect ed once agai n.

Once the ECM has determined knocking is occurri ng usi ng other input s s uch as cat al yti c convert er temperat ure for exampl ein addi ti on to the s i gnal s from t he knock s ens ors , it first retards the ignit ion t imi ng and s ubs equent ly ri chens t he air/fuel i frequired.

Variable Camshaft Timing (VCT) Control

The inl et cams haft i s cont rol led by t he ECM us ing the VCT s olenoid. The exhaus t camshaft is fixed and i ts ti ming cannotbe changed.

Both cams haft s are dri ven i ndirect ly from the cranks haft via a chai n. The chain is driven from a s haft in the gear hous i ngas sembl y.For addit ional informat ion, refer t o: Engi ne - 3.2L (303-01, Descripti on and Operat ion).The VCT all ows t he ECM t o adus t t he inl et cams haft pos it ion i n rel ati on to the cranks haft , al tering t he t imi ng of theopeni ng and clos ing of t he inlet and exhaus t valves rel ati ve to the cranks haft posi ti on. Thi s allows the ECM to provideincreas ed engi ne performance, i mproved i dl e quali ty and reduced emi ss i ons .

Page 1221 of 3229

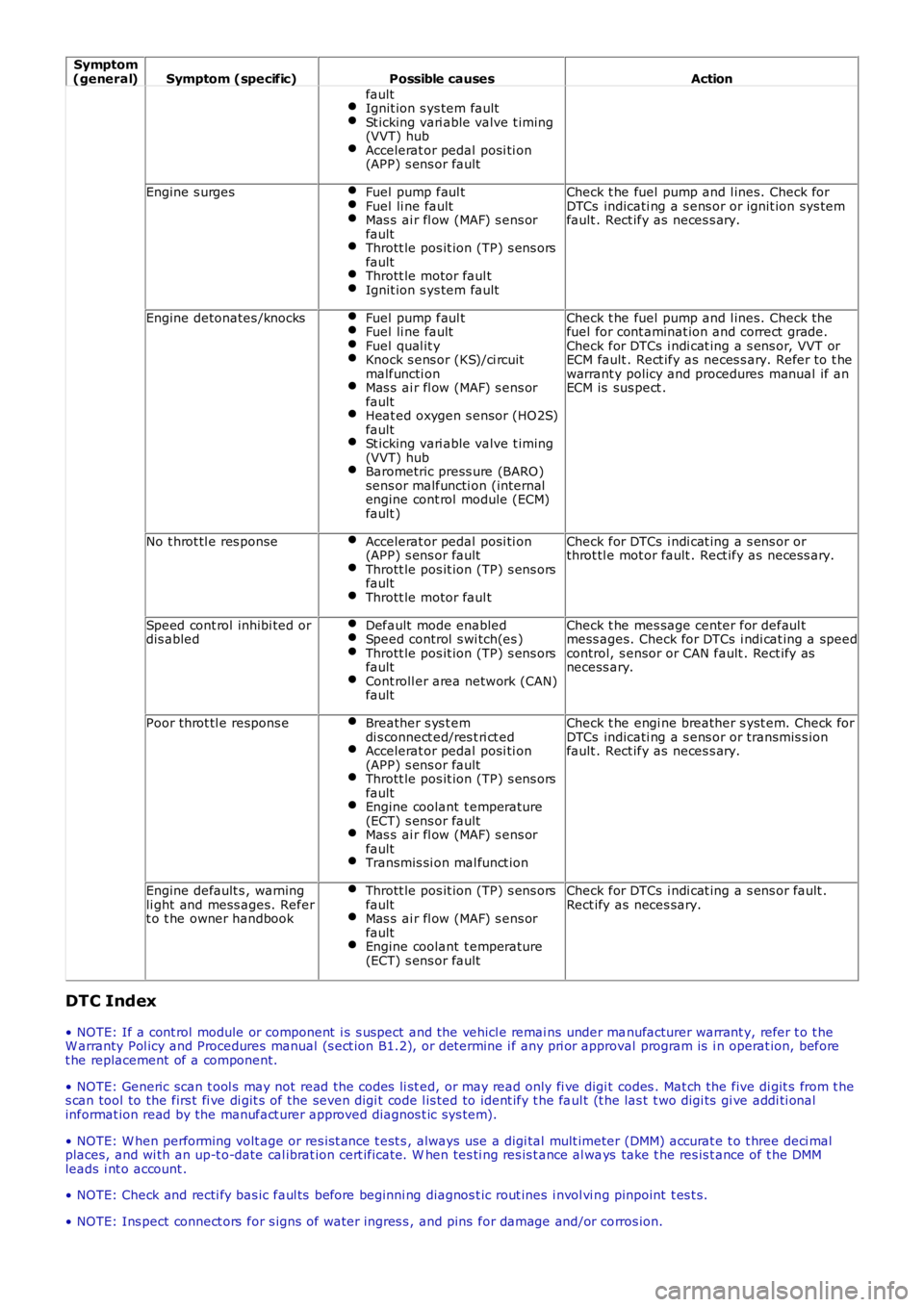

Symptom(general)Symptom (specific)Possible causesAction

faultIgnit ion s ys tem faultSt icking vari able valve t iming(VVT) hubAccelerat or pedal posi ti on(APP) s ens or fault

Engine s urgesFuel pump faul tFuel li ne faultMas s ai r fl ow (MAF) s ens orfaultThrott le pos it ion (TP) s ens orsfaultThrott le motor faul tIgnit ion s ys tem fault

Check t he fuel pump and l ines. Check forDTCs indicati ng a s ens or or ignit ion sys temfault . Rect ify as neces s ary.

Engine detonates /knocksFuel pump faul tFuel li ne faultFuel qual it yKnock s ens or (KS)/ci rcuitmalfuncti onMas s ai r fl ow (MAF) s ens orfaultHeat ed oxygen s ensor (HO2S)faultSt icking vari able valve t iming(VVT) hubBarometric press ure (BARO)sens or malfuncti on (internalengine cont rol module (ECM)fault )

Check t he fuel pump and l ines. Check thefuel for cont aminat ion and correct grade.Check for DTCs i ndi cat ing a s ens or, VVT orECM fault . Rect ify as neces s ary. Refer t o t hewarrant y policy and procedures manual if anECM is sus pect .

No t hrot tl e res ponseAccelerat or pedal posi ti on(APP) s ens or faultThrott le pos it ion (TP) s ens orsfaultThrott le motor faul t

Check for DTCs i ndi cat ing a s ens or orthrot tl e mot or fault . Rect ify as neces s ary.

Speed cont rol inhibi ted ordis abledDefault mode enabledSpeed control s wi tch(es )Thrott le pos it ion (TP) s ens orsfaultCont roll er area network (CAN)fault

Check t he mes sage center for defaul tmess ages. Check for DTCs i ndi cat ing a speedcontrol, s ensor or CAN fault . Rect ify asnecess ary.

Poor throt tl e respons eBreather s ys t emdi s connect ed/res t ri ct edAccelerat or pedal posi ti on(APP) s ens or faultThrott le pos it ion (TP) s ens orsfaultEngine coolant t emperature(ECT) s ens or faultMas s ai r fl ow (MAF) s ens orfaultTransmis si on mal funct ion

Check t he engi ne breather s yst em. Check forDTCs indicati ng a s ens or or transmis s ionfault . Rect ify as neces s ary.

Engine default s , warningli ght and mess ages. Refert o t he owner handbook

Thrott le pos it ion (TP) s ens orsfaultMas s ai r fl ow (MAF) s ens orfaultEngine coolant t emperature(ECT) s ens or fault

Check for DTCs i ndi cat ing a s ens or fault .Rect ify as neces sary.

DTC Index

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

Page 1241 of 3229

12-Cooli ng fan control modul e

13-Ups tream t emperat ure s ensor (DPF vehi cl es only)

14-Heated oxygen s ens or

OVERVIEW

The TD4 dies el engi ne has an Electroni c Dies el Cont rol (EDC) engine management s yst em. The s ys t em i s cont rol led by anECM whi ch is able to monit or, adapt and preci sel y cont rol t he fuel inject ion. The ECM us es mult iple s ens or inputs andprecis ion control of act uat ors t o achieve opti mum performance during all driving condit ions.

The ECM controls fuel deli very t o all 4 cyli nders via a common rai l inject ion s yst em. The common rail s ys t em us es a fuelrai l to accumulate highly press uri zed fuel and feed t he 4, electroni cal ly controlled injectors . The fuel rail i s located i n clos eproximit y to the i njectors, whi ch ass is t s in maint aining full s yst em press ure at each i njector at all t imes .

The ECM us es t he drive by wire pri nci pl e for accelerat ion control. Accelerator pedal demand i s communicat ed t o t he ECM by2 pot ent iomet ers l ocat ed in a thrott le pos it ion sens or. The ECM us es t he 2 s ignals to det ermi ne the pos it ion, rat e ofmovement and di recti on of movement of t he pedal . The ECM t hen uses t his dat a, al ong wit h ot her engine i nformati on fromother s ens ors, t o achieve the opt imum engine respons e.

The ECM proces ses informati on from t he followi ng input s ources :

camshaft pos i ti on (CMP)CKPManifol d air t emperat ure and press ureEngi ne cool ant temperat ureOil t emperat ureInt ake air flow and t emperat ureFuel t emperat ure

The ECM out put s cont rol li ng si gnal s t o t he foll owing s ens ors and actuators :

Fuel i njectors (4 off)Cooling fan control modul eElectric t hrot tl e valveElectroni c vane cont roll ed t urbochargerPort deact ivat ionFuel pres s ure cont rol val veFuel volume cont rol val veEGRGlow plugs (4 off).

CONTROL DIAGRAM SHEET 1 OF 2

• NOTE: A = Hardwi red