ESP LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 296 of 3229

programs.

Incorrect Program Usage

Selecti on of an inappropri at e program i s dis couraged in t he followi ng ways:

The act ive program icon is conti nual ly di spl ayed i n t he ins t rument clus ter mes s age centerThe Terrai n Res pons e control modul e 'l ocks ' out cert ain funct ions i n s ome programs, for exampl e:- cruis e control is only avai lable wi th the special programs off or gras s/gravel/s now program- t rans mis s ion 'Sport' mode i s deact ivated i n all s peci al programs .W hen t he i gni ti on has been in t he off mode, cont inuall y for more t han 6 hours , t he Terrai n Respons e s yst emdefault s t o t he special programs off.

Selecti on of an inappropri at e program for the t errain condit ions wil l not endanger the dri ver or cause damage to thevehi cl e. Cont inued us e of an inappropri ate program may reduce t he li fe of s ome component s . The driver may not icereduced vehi cl e res ponse, wi th the engine and t rans mi ss i on bei ng les s respons ive t han in s peci al programs off. Al so, i ns ome programs, HDC wil l remai n on, si gni fi ed by il lumi nat ion of t he HDC indicator in the i nst rument clus t er. The dri ver mayals o not ice t orque 'wi nd-up' i n t he act ive on-demand coupli ng caus ing a braking effect when the vehicl e is manoeuvred i ns ome s peci al programs .

Driver Information

The high-l ine i nst rument clus t er fit t ed to al l vehi cl es wit h Terrain Res pons e, cont ains a mess age center which di spl aysvehi cl e i nformat ion to t he driver. The mes s age cent er contai ns the Terrain Res ponse program icons which dis play t hecurrent ly s elected program. If no s ymbol i s dis played, no special program is sel ect ed and the sys tem is in 'Specialprograms off'.

Any required changes t o t he s ub-s ys t ems are al s o pass ed t o t he dri ver i n t he form of i ndi cat or ill uminat ion i n t heins t rument clus ter or appropriat e mes s ages i n t he mes s age center, 'HDC OFF' for example.

In certai n operati ng condi ti ons , t he Terrai n Res pons e s yst em al s o dis plays advi ce or warning mess ages to ens ure thedri ver i s us ing t he vehi cl e t o it s full potenti al, for example, s t eering angle is dis played i n t he mes sage center t o avoi ddri vi ng in deep rut s wit h s t eering l ock appli ed.

DIAGNOSTICS

The Terrai n Res pons e control modul e s tores informati on on detect ed Terrai n Respons e faul ts and CAN errors whi ch can beint errogat ed usi ng IDS. The Terrain Res ponse s ub-s ys t ems and t he ins trument cl ust er als o s tore informat ion relat ing t oCAN errors from t he Terrain Res pons e control modul e.

The cont rol module al s o s tores the mil es travel ed and ti me el aps ed for t he i ndi vi dual programs which can al so be ret ri evedus ing IDS. Thi s informat ion aids di agnos is of t he Terrain Res pons e s ys tem and als o provi des an indicati on of Terrai nRespons e s yst em abus e by t he dri ver whi ch can l ead to premat ure component failure.

This i nformat ion can al so be us ed to check cus t omer concerns , for exampl e, hi gh fuel cons umpt ion whi ch may be due t ocont inued us e of a cert ain program.

Terrain Response System Fault Diag nosis

Terrai n Res pons e relies on the correct funct ionali ty of t he 4 s ub-s ys tems . If one of the s ub-s ys tems develops a fault , theTerrai n Res pons e s ys tem wil l not funct ion, even though the fault i s NOT in t he Terrain Res pons e s ys tem.

T he T errain Response control module and rotary control should only be investigated if there are no apparent faultsin any of the sub-systems. If a fault in a sub-system is subsequently corrected, the T errain Response system willfunction normally after an ignition mode 1 and 2 (on and off) cycle.

Terrain Response Sub-System Faults

W hen a fault occurs i n a s ub-s yst em, t he dri ver i s alert ed by t he il lumi nat ion of a warning indicator and/or an appropri atemes s age for that s ub-s yst em in t he i ns t rument clus ter mes s age cent er. There wi ll be no warning of a Terrain Res ponses ys t em fault .

W hen a sub-sys t em faul t is present and t he dri ver at tempt s t o s el ect a different Terrain Res pons e program us i ng therot ary control or at t he next ignit ion mode 2 (on) cycl e, a mes sage 'SY STEM FAULT SPECIAL PROGRAMS NOT AVAILABLE'wil l appear in the mess age cent er. This impl ies t hat t he Terrain Res pons e s ys tem has a faul t, but only because asub-system fault is preventing its operation. Thi s mes sage will be di spl ayed for 5 s econds per ignit ion mode 2 cycl e, butis repeat ed i f a further s electi on is made by the driver usi ng t he Terrai n Respons e rot ary control or at t he next ignit ionmode 2 (on) cycle.

• NOTE: The mes s age 'SY STEM FAULT SPECIAL PRO GRAMS NOT AVAILABLE' can al so be generated by a fault i n t he Terrai nRespons e rot ary control or control modul e. Refer to the foll owing i nformat ion for det ail s of rot ary control or control modul efaul ts .

It is not possible for the T errain R esponse control module to cause any fault behavior (w arning indicator illuminationor message generation) in any of the 4 sub-systems. Illuminati on of a s ub-s ys t em warning i ndi cat or and/or as ub-s ys t em relat ed mes sage wi ll NEVER be ass ociated wit h a Terrain Res ponse cont rol module or Terrain Res pons es ys t em fault .

The s ub-s ys t em control modul es can det ect a fault wit h the CAN s ignal from t he Terrai n Res pons e control modul e. If afaul t in t he Terrain Res pons e s ys tem is det ect ed, the s ub-s ys tem cont rol modules wi ll operate in t he 'Special programs off's ett ing. The s ub-s ys t em control modul es wil l record a fault code for a fail ure of t he Terrai n Res pons e CAN si gnal . Thes efaul ts can be retrieved us ing IDS and wi ll provide us eful informat ion t o i ndi cat e i nves ti gat ion of t he Terrain Res pons econt rol module or t he CAN net work.

Terrain Response Rotary Control or Control Module Fault

Page 297 of 3229

If a fault occurs i n t he Terrai n Res pons e rot ary cont rol, al l rotary cont rol i con amber Light Emi tt ing Di odes (LED's ) wil l bet urned off and rotat ion of t he rot ary control i s ignored. The i ns t rument clus ter mess age cent er will di spl ay a mes s age'SY STEM FAULT SPECIAL PROGRAMS NOT AVAILABLE' when t he fault occurs , if t he fault i s pres ent and the driver att emptst o s el ect a s pecial program (if t he cont rol module is able to do thi s) or at t he next i gni ti on mode 2 (on) cycle.

The Terrai n Res pons e rotary cont rol and t he cont rol module are an i nt egral unit . If a fault occurs in eit her component , thewhole uni t wil l requi re replacement. ENSURE T HAT T HE FAULT IS WIT H T HE T ERRAIN RESPONSE CO NT ROL MO DULEAND NOT IN A SUB-SYST EM MODULE BEFO RE REPLACING T HE MODULE.

If a CAN faul t exi s ts and prevent s Terrai n Res pons e s yst em operat ion, all of t he Terrai n Res pons e rotary cont rol icon LED'swil l be il lumi nat ed and rot ati on of the rot ary cont rol i s ignored.

If the i nst rument clus ter does not receive a Terrain Res ponse s ys t em CAN mess age from the Terrain Res ponse cont rolmodule, t he mes sage 'SY STEM FAULT SPECIAL PROGRAMS NO T AVAILABLE' wi ll be dis played when t he faul t occurs and willbe repeat ed at every ignit ion mode 2 (on) cycl e.

User Error

The fol lowing incorrect us age of t he s yst em may be mi si nterpreted as a s ys t em fault :

Engi ne not running - Program changes and driver advi s ory mes s ages are only avail abl e wi th the engine runni ngSpeci al program change att empted wi th DSC or ABS acti ve (t his i ncl udes ABS cycling which is operat ional when HDCis bei ng used on s lippery or l oose surfaces)Speci al program change att empted wi th overheat condi ti on pres ent on the act ive on-demand coupling.

Page 298 of 3229

Publi s hed: 11-May-2011

Ride and Handling Optimization - Ride and Handling Optimization

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Terrain Respons e s ys t em, refer t o t he rel evant Descript ion and Operat ion secti on in theworks hop manual .REFER to: Ri de and Handl ing Opt imi zat ion (204-06 Ri de and Handl ing Opt imizati on, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

* Ti re condit ion, pres sures, et cDriveline, Engine, Transmis s ion, Sus pensi on,component s (correct ins tall ati on, damage, etc)

Fus esHarness es /Connect orsTerrai n res pons e modul eEngi ne Cont rol Module (ECM)Transmis s ion Control Modul e (TCM)Ant i-Lock Brake Sys t em control modul eAct ive On-demand cont rol moduleDynami c s us pensi on cont rol module * Controllerarea network (CAN) ci rcuit s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

DTC Index

• NOTE: If the control modul e/t rans mis s ion i s s uspect and the vehicle remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/transmis s ion.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Terrain Res pons e Cont rol Modul e (ATCM) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Page 320 of 3229

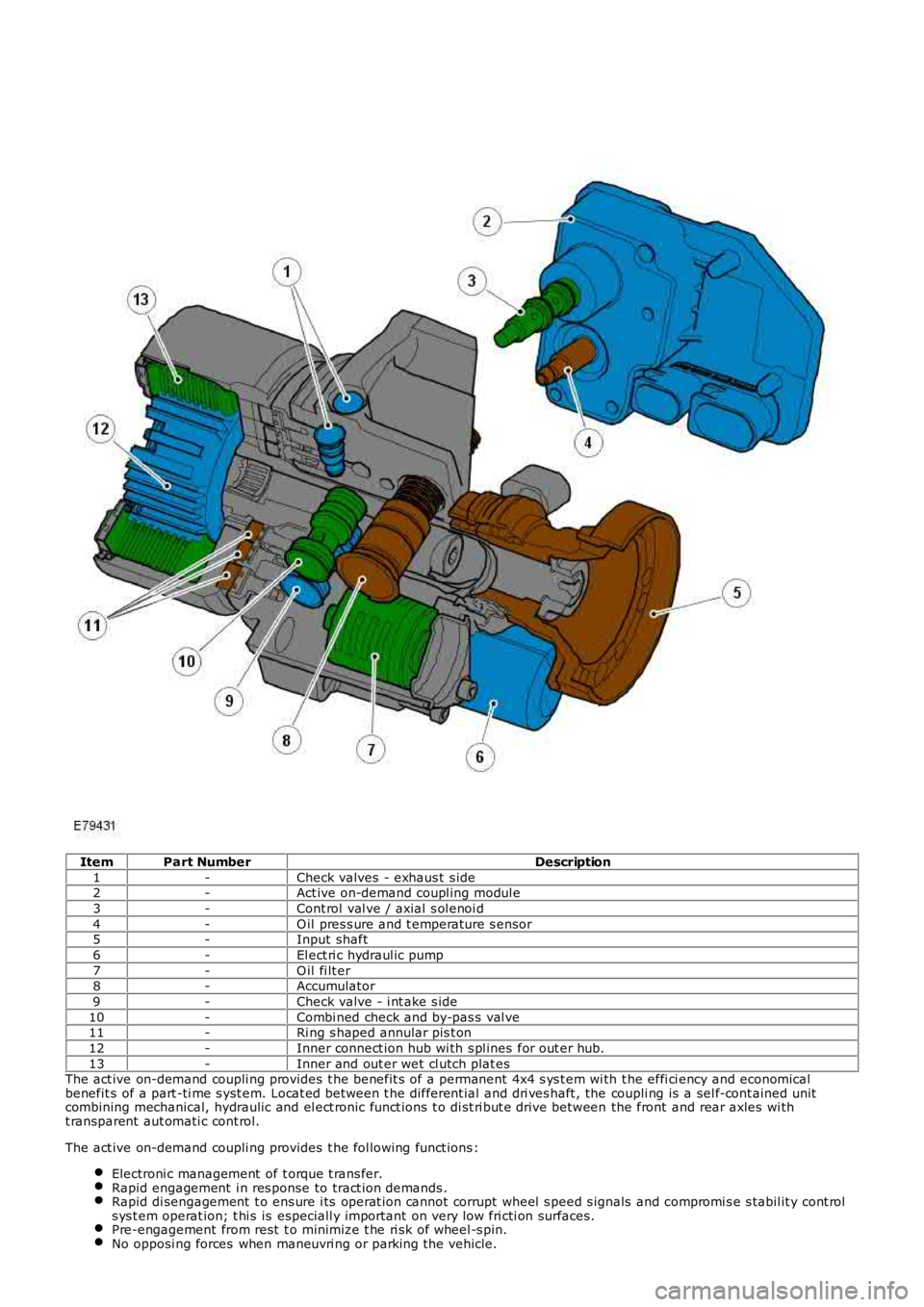

ItemPart NumberDescription

1-Check valves - exhaus t s ide2-Act ive on-demand coupl ing modul e

3-Cont rol val ve / axial s ol enoi d

4-O il pres s ure and t emperature s ensor5-Input shaft

6-El ect ri c hydraul ic pump

7-O il fi lt er8-Accumulator

9-Check valve - i nt ake s ide

10-Combi ned check and by-pas s val ve11-Ri ng s haped annular pis t on

12-Inner connect ion hub wi th s pl ines for out er hub.

13-Inner and out er wet cl utch plat esThe act ive on-demand coupli ng provides t he benefit s of a permanent 4x4 s ys t em wi th the effi ci ency and economicalbenefit s of a part -ti me s yst em. Locat ed between t he different ial and dri ves haft , the coupli ng is a sel f-cont ained unitcombining mechanical, hydraulic and el ect ronic funct ions t o di st ri but e drive between the front and rear axles wi tht ransparent aut omati c cont rol.

The act ive on-demand coupli ng provides t he fol lowing funct ions :

Electroni c management of t orque t rans fer.Rapid engagement i n res ponse to tract ion demands .Rapid di sengagement t o ens ure i ts operat ion cannot corrupt wheel s peed s ignals and compromi s e s tabil it y cont rols ys t em operat ion; t hi s is especiall y important on very low fri cti on surfaces.Pre-engagement from rest t o minimize t he ri sk of wheel -s pin.No opposi ng forces when maneuvri ng or parking t he vehicle.

Page 321 of 3229

Not s ens it ive to brake tes ti ng on a chas si s dynamomet er.

Generati on 4 Acti ve On-Demand Coupli ng - Vehicles from 2009MY

The generati on 4 coupl ing does not have the di fferenti al s peed dri ven pump used on the previ ous generat ion 3coupl ing, but i s fit ted wi th a bigger capacit y electrically operated axial pump and a hi gh pres s ure accumul ator.The proport ional throt t le valve and press ure s ens or on t he generat ion 3 coupli ng is replaced wit h a proport ionalpres s ure reducing val ve.The t orque li mit er pres sure reducing valve on the generat ion 3 coupli ng is replaced by an electroni c cont rol valveand cont rol ling software.

The generati on 4 acti ve on-demand coupli ng gives t he fol lowing improvements over t he previous generati on 3 coupl ing:

Reduced bas e t orque at high different ial s peedsTorque acti vat ion i s now i ndependent of different ial s peedAccurat e t orque l imi ter cont rolEnergy s tored in hi gh pres s ure accumul ator givi ng a low maximum current consumpt ion of t he electric pump andfas t er res pons e.

Control Module - G eneration 3 and 4 Couplings

The cont rol module, at tached to the cas ing of t he act ive on-demand coupling, forms a s ingle unit wit h t he cont rolvalve/axial s ol enoi d. By anal yzi ng informat ion from other vehi cl e modules and s ensors t he cont rol module regul ates t heaxial sol enoi d t o cont rol t he hydraul ic flui d pres s ure s uppl ied t o t he clut ch pl ates. Some of t he modul es and s ens ors thecont rol module communi cat es wit h are li s ted below:

Hardwi red:- Control valve / axi al s olenoid- Electric hydrauli c pump- Oi l press ure and temperat ure sens orHigh speed CAN (cont rol ler area net work):- Engine cont rol module- Anti -l ock brake s ys t em / t racti on cont rol module- Tracti on res ponse swit ch- Y aw rate sens or- Steering wheel rot at ion sens or

The axial sol enoi d cons t ant ly adjust s t he cont rol valve output us ing a Pul se W i dt h Modulat ion (PW M) s i gnal. The flui dpres s ure deli vered t o t he cl utch plat es determines t he amount of t orque t hat is delivered t o t he rear axl e.

The act ive on-demand coupli ng has int egrated oi l press ure and temperature s ens ors to enable the control modul e t oaccurat ely manage t he t orque t ransfer under all environment al and operat ing condit ions . Usi ng thes e s ignals the controlmodule will us e s t rategi es to protect the coupli ng from overheati ng; in extreme cas es to protect t he coupli ng from damaget he coupli ng wil l dis engage i f the t emperat ure of t he hydraul ic flui d exceeds 105°C. The coupl ing wi ll ret urn to normalfuncti onal it y when t he temperat ure fall s below 101°C.

The cont rol module has an int egrated di agnos ti cs sys tem, whi ch cons tant ly moni tors the act ive on-demand couplings ys t em as wel l as it s input and output s ignals . If t he control modul e detects a fault a Diagnost ic Troubl e Code (DTC) i ss tored. The DTC is acces s ed usi ng t he Land Rover approved di agnos t ic s yst em.

Electric Hydraulic Pump

W hen negoti ati ng very low frict ion s urfaces s uch as wet gras s , snow or i ce; i nit ial wheel -s pin can cut i nt o t he s urface andreduce gri p. W it h a re-act ive on-demand coupl ing, almos t 60 degrees of wheel rotat ion woul d occur before torque could bet ransmit ted t hrough t he coupl ing.

On Generat ion 3 coupli ngs , t o count eract thi s Land Rover devel oped a uni que high-pres s ure pre-charge faci li ty whi chenergizes t he hydraul ic circui t as s oon as the engi ne is s t art ed. Es s ent ial ly an el ect ri cal ly operat ed hydraul ic pump wasdesi gned to maintai n a pot ent ial of 500 Nm (369 l b ft ) of t orque pres s ure wi thi n the coupli ng. (This pre-charge t orquecapacit y has been increas ed to 1500Nm (1106 l b ft ) for t he Generat ion 4 coupli ng.)

Vehicles fit ted wi th Terrai n Res pons e als o add furt her benefi ts by varying t he level of pre-charge t o deli ver opti mumt racti on over a range of di fferent t errai n s urfaces . The level of pre-charge is varied dependi ng on t he part icul ar terrainres ponse mode, for exampl e:

Terrai n respons e in 'Speci al Programs Off' mode as common wit h vehi cl es wit hout terrain res pons e, the coupli ng isprogrammed t o transmit 500 Nm 369 lb ft of t orque on Generat ion 3 couplings and 1500 Nm (1106 l b ft) of t orqueon Generat ion 4 couplings t o t he rear axle when the vehicle moves from res t i n a s t raight l ine. Thi s s trategymi ni mi zes t ract ion l os s from a s t andi ng-s tart regardles s of t he terrain. W hen the vehicle accelerat es the pres surein the coupling is decreas ed to improve fuel economy.The abili ty to sens e t he s teeri ng angl e all ows t he coupli ng t o be programmed t o provide no torque trans fer t hrought he coupli ng. This prevent s t he coupli ng locking when t he vehicle i s maneuvring at low s peeds and acute s teeri ngangl es.In 'Grass / Gravel / Snow' mode t he coupl ing i s programmed to maint ai n i ts pre-charge s t at e unt il much highers peeds are obtained. The s ame applies even i f the vehicle is t raveli ng at low speeds and acut e s t eering angles , ast racti on takes precedence over coupli ng lock-up on l ow-fri ct ion s urfaces .

For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Mechanical Hydraulic Pump - Generation 3 Couplings - Vehicles up to 2009MY

The dri ves haft i s att ached t o t he coupl ing's front clut ch pl ate as s embly (i nput ), with the rear cl ut ch plat e as sembl yconnected t o t he different ial pini on (out put ). A s was h-pl ate wit h 6 hydrauli c rol lers is al so att ached t o t he different ialpinion. W hen there is no s peed difference bet ween the coupling's input and out put, the rol lers do not funct ion.

Page 451 of 3229

5-Brake shoe retai ni ng s pri ng

6-Brake shoe return s pri ng

7-Brake shoe mechanical adjust er8-Lower (l eadi ng) brake s hoe

9-Parki ng brake l ever cabl e

10-Parki ng brake cabl e equalizer11-Parki ng brake i nner cabl e

12-Equali zer fas t ener

13-Parki ng brake mi cros wit ch14-Parki ng brake l ever as sembl y

15-Parki ng brake outer cable

16-Brake dus t s hield

OVERVIEW

The parking brake is a manual ly actuat ed s ys t em t hat operat es brake s hoes located i n t he rear brake di scs . The ins idecent er of the rear brake dis c is manufact ured t o form the brake drum.

BRAKE SHOE ASSEMBLY

The brake s hoes are mount ed horizontal ly on an int egral brake dus t s hield and backplat e, and form an upper t rai li ng andlower l eading brake s hoe type s yst em. Retai ni ng pins pas s t hrough hol es in the dus t s hield and corres ponding hol es ineach brake s hoe bracket . Each pi n is secured t o t he brake s hoe wit h a ret ai ning cli p. The ret ai ning pins al low movement oft he brake s hoe toward the drum surface duri ng parking brake operat ion, but prevent si deways movement of the brake shoeaway from the dus t s hi eld.

An expander unit and manual adjust er are l ocat ed along t he hori zont al axis of t he dus t shi el d. The expander uni t isposi ti oned at the front of the dus t s hield and forms t he locati on for t he leading and t rai ling ends of t he brake s hoebracket s . The manual adjus t er i s mounted at t he rear of t he dust s hiel d and forms t he l ocati on and ful crum poi nt for theoppos it e ends of t he brake s hoe bracket s.

The manual adjus t er provides the means to adjust t he brake s hoe l ining t o drum clearance for maintenance purposes .Acces s t o t he manual adjus t er knurl ed wheel i s t hrough a formed hole in the front of the brake dis c. Adjust ment isrequired if t he brake s hoes or dis cs are renewed. A bedding-in procedure must al so be performed t o make s ure the drumbrakes operate sat is fact oril y.For addit ional informat ion, refer t o: Parking Brake Shoes Bedding-In (206-05 Parking Brake and Actuati on, GeneralProcedures).

The corres pondi ng ends of bot h t he upper and l ower brake shoe brackets are mai ntained i n contact wit h t he expander uni tand manual adjus t er by 2 ret urn springs . The return s pri ngs are l ocat ed bet ween t he ends of each upper and l ower brakes hoe and att ach to hol es formed in the brake shoe brackets . The ret urn springs pull t he brake s hoes away from t he drumwhen t he parking brake is released.

PARKING BRAKE LEVER

The parking brake lever is l ocat ed in t he floor cons ole bet ween the driver and pass enger s eats , and compri ses a toot hedquadrant , pawl and pres s-butt on rel eas e mechanis m. A si ngl e cabl e wi th a formed t hreaded rod-end connect s t he quadrantt o the equali zer unit , and is secured wit h eit her a locknut or a l ocking was her and nut.

The t hreaded rod all ows adjus tment s t o t he parking brake cable tens ion and parki ng brake lever travel t o be performed formaint enance purpos es.For addit ional informat ion, refer t o: Parking Brake Cabl e Adjus tment (206-05 Parki ng Brake and Actuat ion, GeneralProcedures).

The parking brake cable is routed from t he parking brake l ever equalizer, and al ong the chas si s t o t he rear parking brakeexpander uni t. The parki ng brake cabl e prot rudes t hrough t he brake dust s hiel d, and is formed wit h a nippl e that connectst o the expander unit . The oppos i te ends of each Left-Hand (LH) and Ri ght -Hand (RH) parking brake cabl e are formed wit h anipple that connect to the equali zer unit . The equal izer uni t makes sure t he LH and RH parki ng brake as s embl ies operat es imul taneous l y when the parking brake i s applied.

A micros wit ch is locat ed on t he base of the parki ng brake lever. The micros wit ch operates t he parking brake warni ngindicat or l amp l ocat ed in t he i ns t rument clus ter, when the parki ng brake i s appl ied.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

PRINCIPLES OF OPERATION

As t he parking brake lever i s applied, t he toot hed quadrant rotat es and pul ls on the t hreaded rod and cable equali zer. Theequal izer pul ls t he 2 parki ng brake cables and operat es the 2 expander uni ts s i mult aneous ly. Movement of t he expanderunit caus es t he upper and l ower brake s hoes t o pivot agains t the manual adjus ter fulcrum, and t he brake s hoes cont actt he brake drum agai nst t he t ens i on of the 2 ret urn s pri ngs .

As t he parking brake lever quadrant rot ates , t he teet h on t he pawl engage wit h corresponding t eeth on the quadrant . Int he appl ied pos it ion, the pawl t eet h are held under spring t ensi on agai nst the quadrant teet h t o prevent the l ever fromdis engagi ng.

W i th the parki ng brake appli ed and the i gnit ion i n power mode 6 (ignit ion), t he mi cros wit ch connect s a ground to theins t rument clus ter and il lumi nat es t he parking brake warning i ndi cat or lamp.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

W hen t he parking brake lever pres s-butt on is pres sed and t he l ever moved t o rel eas e t he parki ng brake, t he pawl teet hare rais ed clear from the quadrant t eet h. As the parki ng brake l ever i s lowered, t he parking brake cable cl oses t heexpander uni t and the brake s hoes are immediatel y moved away from the brake drum by the 2 ret urn s pri ngs .

Page 512 of 3229

The HDC s wi tch i s non-lat chi ng and is ins tall ed in the floor cons ole, forward of the gear s el ect or lever. Moment aril ypres s ing and releasi ng t he HDC s wit ch connects an ignit ion power feed t o t he ABS module. W it h t he fi rs t pres s and rel easeof the HDC s wit ch, t he ABS module enables operat ion of t he HDC funct ion. W hen t he HDC swi tch i s pres s ed and rel eas edagai n, the ABS modul e dis ables operat ion of t he HDC funct ion.

To prevent mis -use of, or in the event of a broken HDC s wi tch, if t he s wit ch is press ed for more t han 10 s econds nochange of s tat e occurs. A DTC i s s tored in t he ABS module memory if t he input from the HDC swi tch i s held hi gh for moret han 1 mi nut e.

HDC Activating Stoplamps

Operat ion of t he vehi cl e s toplamps during HDC is controll ed by the CJB. The ABS module monit ors t he brake s yst emhydraulic press ure and request s t he CJB, vi a t he high s peed CAN bus, t o energi ze the s t opl amps duri ng act ive braki ng.

A press ure thres hold and ti me fil ter prevents t he s topl amps from fli ckeri ng whil e HDC i s braking.

Stop/St art Vehicl es - From 2010 MY

Acti vat ion of Hi ll Descent Cont rol wi ll deact ivate the St op/St art s yst em. However, if Hi ll Des cent Control i s acti vat ed whent he engi ne is s hutdown in a St op/St art cycl e t he engi ne wil l aut omati cal ly rest art . If during t his event the St op/St arts ys t em cannot det ect t he dri ver's occupancy, for exampl e eit her t he driver’s safety belt or door is unl at ched, t he engi newil l not res tart. The St op/Start sys tem wi ll request the driver to depres s t he clut ch to res tart the engine. The dri ver wi ll beinformed of t his by ‘RESTART REQUIRED PRESS CLUTCH’ being di spl ayed i n t he mes sage center.

The dri ver mus t respond t o t hi s reques t wit hin a li mit ed t ime period, or otherwi s e a convent ional engine res tart us i ng theignit ion swi tch will be requi red.For addit ional informat ion, refer t o: Starti ng Sys t em (303-06C Starti ng Syst em - TD4 2.2L Di es el, Vehicles Bui lt From:01-03-2009, Descripti on and Operat ion).

WHEEL SPEED SENSORS

Page 524 of 3229

s peed control '+' and '-' but t ons (dependant on vehi cl e s peci fi cat ion). The HDC Target speed wi ll als o vary depending ont he Terrai n Respons e™ mode sel ect ed.

Duri ng changes of target s peed, the ABS modul e li mit s vehicle decelerat ion and accelerat ion t o -0.5 met ers per s econd

s quared (m/s2) (-1.64 feet per s econd squared (ft/s2)); and +0.5 m/s2 (+1.64 ft/s2) res pect ively.

To provide a s afe t rans it ion from acti ve braking t o brakes off, the ABS module i nvokes a fade out st rat egy that graduall yrel eas es t he braking effort during act ive braking. The fade out s t rat egy occurs i f any of t he fol lowi ng condit ions i s detectedduri ng act ive braki ng:

HDC i s s elected off us i ng the HDC s wit ch.Failure of a component us ed by HDC, but not crit ical t o fade out funct ion.Accelerator pedal pres s ed when t rans mis s ion i s i n neut ral .Brakes overheat .

If fade out is i nvoked becaus e of HDC de-s el ect ion or component failure, the HDC functi on is cancel led by t he ABS module.If fade out is i nvoked becaus e t he accelerator pedal i s pres s ed wit h t he t ransmis s ion i n neut ral , or because of brakeoverheat , t he HDC funct ion remains in s tandby and res umes operati on when t he accelerat or pedal is releas ed or the brakeshave cooled.

The fade out s t rategy i ncreas es t he t arget speed at a cons tant accelerati on rat e of 0.5 m/s2 (1.64 ft/s2), unti l themaximum t arget speed i s reached, or unti l no act ive braki ng is required for 0.5 second. If t he accelerat or pedal is

posi ti oned wit hin t he range t hat infl uences t arget s peed, the accelerat ion rate is increas ed t o 1.0 m/s2 (3.3 ft /s2).

W hen fade out is i nvoked becaus e of component fai lure, a warning chime is sounded and the HDC informat ion i ndi cat orlamp is ext inguis hed. The HDC warning i ndicat or lamp is t hen il lumi nat ed (on low-li ne ins trument cl ust er), or a mes s ageadvi s ing of t he fault i s dis played in the mess age cent er (on hi gh-l ine i ns t rument clus ter).

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

W hen fade out is i nvoked becaus e of brake overheat, on vehicles wi th the hi gh-li ne ins t rument clus ter, a mes sage advis ingt hat HDC is t emporarily unavail abl e is di s pl ayed. On vehicles wit h t he low-line ins trument cl us t er, t he HDC warningindicat or l amp flas hes . At t he end of fade out, t he HDC informati on indicat or flas hes. The flas hing warni ng and informat ionindicat or l amps, and/or di spl ayed mes s age cont inue whi le HDC remai ns sel ect ed, unt il t he brakes have cooled.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

To monit or for brake overheat, t he ABS modul e monit ors t he amount of braking acti vi ty and, from thi s, es ti mat es thet emperature of each brake. If the es t imat ed temperature of any brake exceeds a pres et li mit , t he ABS module i nvokes t hefade out s t rategy. Aft er the fade out cycle, t he HDC funct ion i s re-enabl ed when the ABS modul e es ti mates that all of thebrake t emperatures are at l ess than 64% of the preset t emperat ure l imi t.

Roll Stability Control

The RSC funct ion us es the brakes and the engine t o at tempt t o rest ore vehicle s tabilit y, i f the vehicle is forced i nt o ahars h maneuver t hat ri sks i t ti pping over.

The ABS module monit ors dri ver i nput s and vehicle behavior usi ng various powert rai n s ignals and t he i nput s from thewheel s peed s ens ors, t he s teering angle s ens or, the roll rate sens or, yaw rate and lateral accel erat ion s ensors. Thes einputs are compared wit h modeled behavi or and, if t he vehicle behavior reaches a given ris k level, t he ABS module cut st he engi ne power, or brakes one or more wheels suffi ci ent ly to al low the vehicle to regain s t abi li ty and hel p the driverremai n i n cont rol .

W hi le t he i gni ti on is energi zed, RSC i s permanentl y enabl ed even if t he DSC functi on is sel ect ed off.

Terrain Response™ System Integration

The Terrai n Res pons e™ funct ion integrat es t he ABS and other vehicle s ys tem cont rol modules t o as si s t the vehicle whendri vi ng off-road or during di fficult s urface condit ions . Terrai n Respons e is act ivated when the rotary cont rol s wit ch is s et t oa Terrain Res ponse special program.

W hen a Terrai n Respons e s peci al program i s acti vat ed, t he ABS module along wi th ot her vehicle s ys t em control modul eswil l operate in accordance wi th programmed software maps . The s oftware maps al low t he ABS s ys tem to functi on wit h at hreshol d that wi ll as si s t the s elected Terrai n Respons e s pecial program.For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Page 630 of 3229

5-Bolt (2 of)6-Variable tract valveThe intake manifold att aches t o t he cylinder head wit h 6 bolt s and t he oil pan with 2 bolt s .

The manifold is capable of varying both int ake tract length and plenum volume by means of 2 separat e valves .

At low engine s peeds , long int ake tract s are ut iliz ed to provide opt imum engine t orque. Short er t racts are us ed at medium s peeds ,again, t o optimiz e engine t orque for t he exist ing engine s peed range.

At higher engine s peeds the benefit s of opt imizing t he t ract lengt hs are outweighed by the necess it y of maintaining anappropriate supply of air to meet t he engines requirement s . Therefore, t he plenum valve is opened t o create a s ingle, largeplenum volume to provide t he maximum quant ity of air t o charge the engines cylinders.For addit ional information, refer t o: Int ake Air Dis tribut ion and Filtering (303-12A Int ake Air Dis t ribution and Filt ering - I6 3.2LPet rol, Des cript ion and O perat ion).

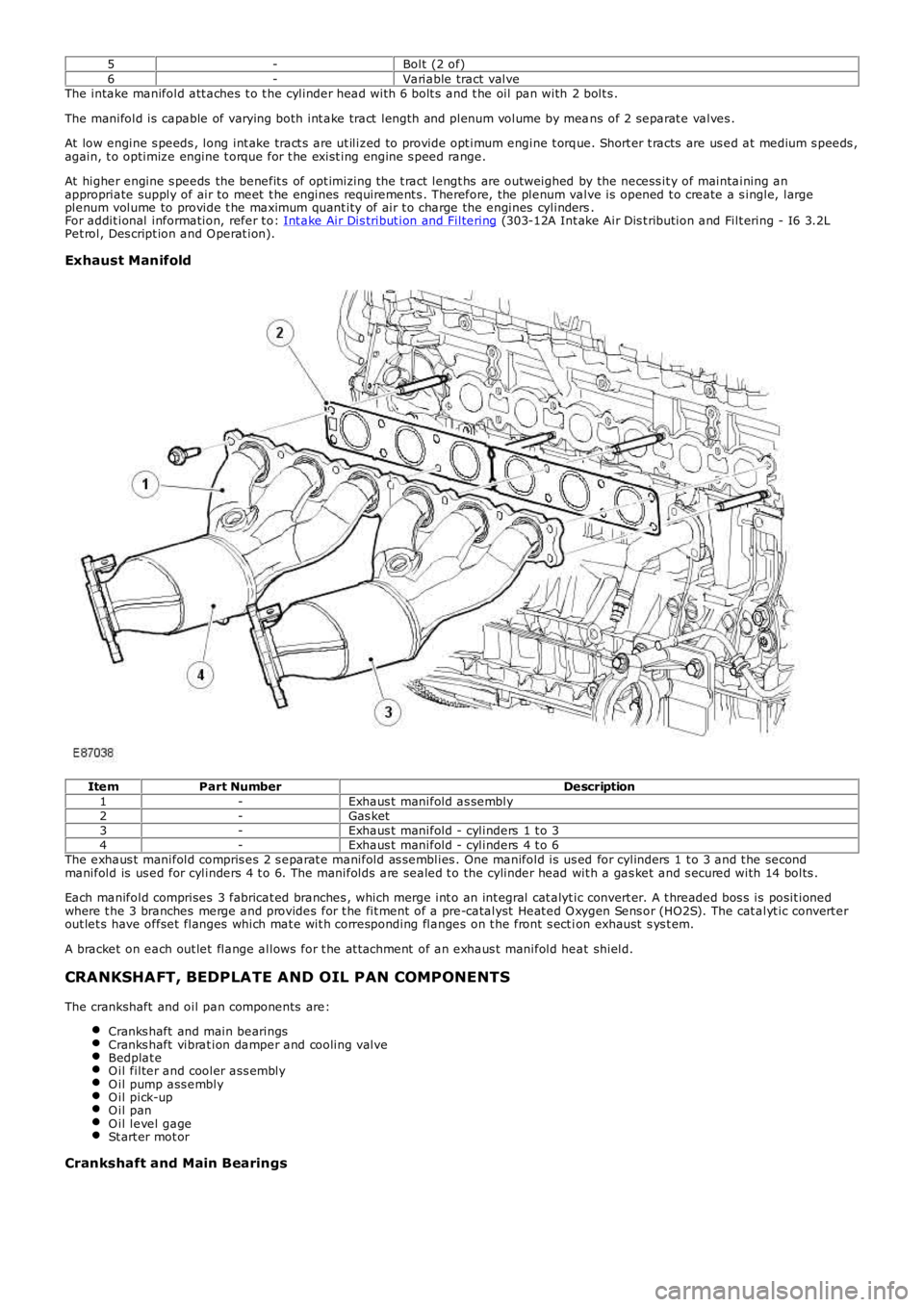

Exhaust Manifold

ItemPart NumberDescription1-Exhaus t manifold as sembly2-Gas ket3-Exhaus t manifold - cylinders 1 t o 34-Exhaus t manifold - cylinders 4 t o 6The exhaus t manifold compris es 2 s eparat e manifold as semblies . One manifold is us ed for cylinders 1 t o 3 and t he secondmanifold is us ed for cylinders 4 t o 6. The manifolds are sealed t o the cylinder head wit h a gas ket and s ecured with 14 bolts .

Each manifold comprises 3 fabricat ed branches , which merge int o an int egral cat alyt ic convert er. A t hreaded bos s is posit ionedwhere t he 3 branches merge and provides for t he fit ment of a pre-catalyst Heat ed O xygen Sens or (HO2S). The cat alyt ic convert erout let s have offset flanges which mat e wit h corresponding flanges on t he front s ect ion exhaust s ys t em.

A bracket on each out let flange allows for t he at t achment of an exhaus t manifold heat shield.

CRANKSHAFT, BEDPLATE AND OIL PAN COMPONENTS

The crankshaft and oil pan components are:

Cranks haft and main bearingsCranks haft vibrat ion damper and cooling valveBedplat eO il filter and cooler ass emblyO il pump ass emblyO il pick-upO il panO il level gageSt art er mot or

Crankshaft and Main Bearings

Page 640 of 3229

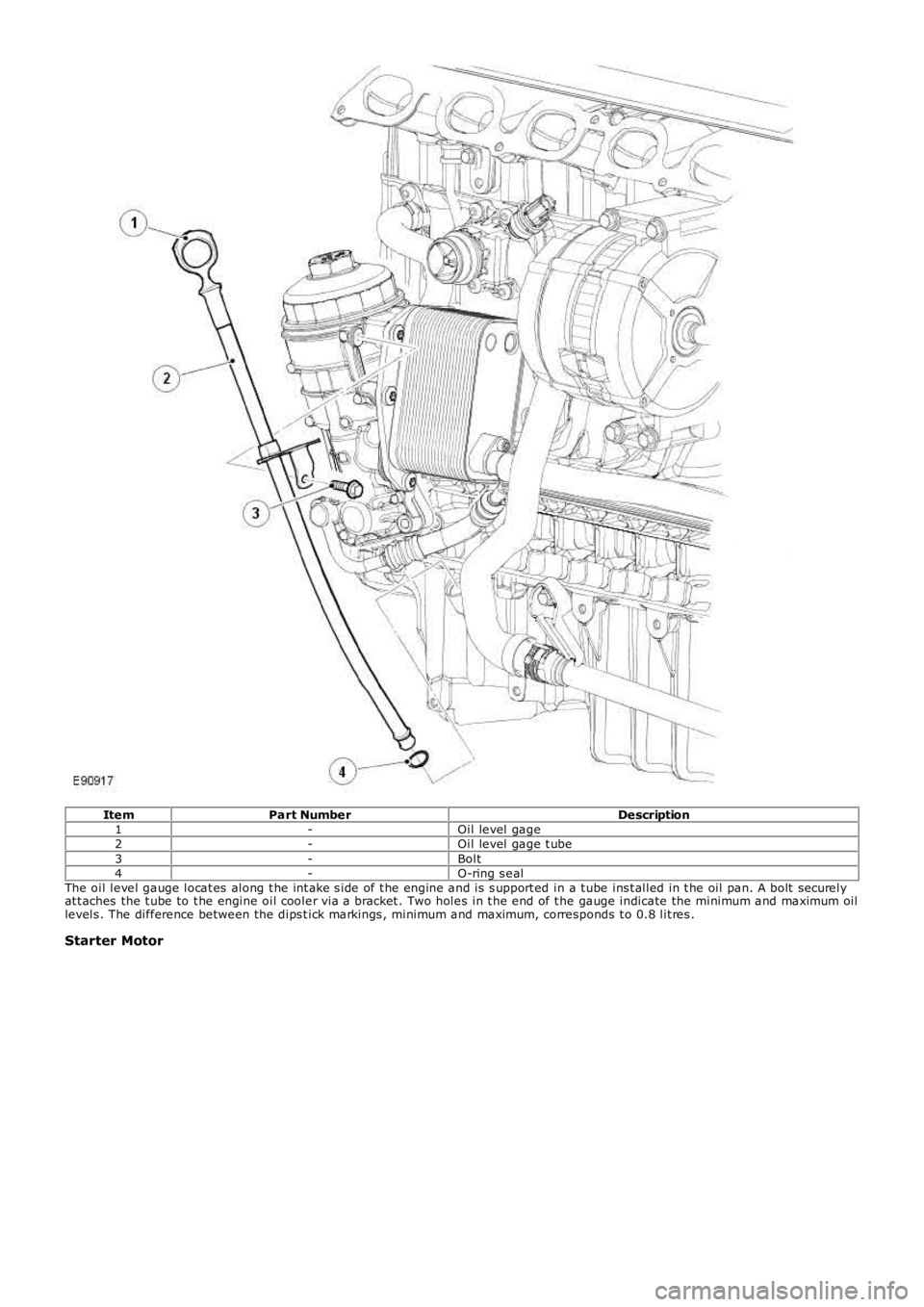

ItemPart NumberDescription1-Oil level gage2-Oil level gage t ube3-Bolt4-O-ring s ealThe oil level gauge locat es along t he int ake s ide of t he engine and is s upport ed in a t ube ins t alled in t he oil pan. A bolt s ecurelyat t aches the t ube to t he engine oil cooler via a bracket . Two holes in t he end of t he gauge indicate the minimum and maximum oillevels . The difference between the dips t ick markings , minimum and maximum, corresponds t o 0.8 lit res .

Starter Motor