ESP LAND ROVER FRELANDER 2 2006 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 762 of 3229

11-VGT oil return port

12-VGT oil s uppl y port

The cyl inder block is manufact ured from cas t -i ron and feat ures double layer wal ls t hat provide high st rengt h and ri gidit y.An air cus hion i s formed between t he l ayers and als o acts t o reduce t he NVH l evel s produced by the engine. The blockfeat ures 5 bol ted mai n beari ng journals that als o provi de high s t rength and rigi dit y to the l ower end of t he engine.

The cyl inders are direct ly bored int o t he cyl inder bl ock and do not require cyl inder liners. Two gui de s leeves are l ocated int he cyl inder bl ock, and provided t o correct ly al ign t he cyl inder head and gas ket to the cyli nder block.

A hole formed in the LH rear of the cyli nder bl ock below the st art er motor, provides the locat ion for an engine t imi ngs pecial t ool . W hen i nserted, the special tool locates i n a corres ponding hol e in the flywheel to temporaril y hol d t hecrankshaft wit h No. 1 pis t on at the Top Dead Cent er (TDC) posi ti on.

The oil filt er and cool er hous ing, and main oi l gal lery are locat ed on t he LH s ide of t he cylinder block. The mai n oil gall eryis a longit udinal dril li ng that runs t he l engt h of the cyli nder bl ock, and s uppl ies pres s urized oi l to al l the engine movi ngcomponents . Pres s uri zed oi l is di verted from t he main oi l gal lery to s upply the main and bi g-end bearings via diagonal oildri ll ings in the cyli nder block, and in t he crankshaft journals . The mai n oil gall ery i s s eal ed at each end wit h a s crewedplug.

A cros s dril ling above No. 2 mai n beari ng direct s pres surized oil from the main oi l gal lery to a port at t he Right-Hand (RH)s ide of t he cyl inder bl ock. The port s upplies press urized oil via a banjo t ype connect ion to t he VGT beari ngs. Ret urn oi lfrom the VGT is direct ed via a pipe and a connect ion at the RH si de of the bl ock, i nt o t he oil pan. A vert ical dril li ng at theLH front of the cyli nder bl ock s upplies press uri zed oil from the mai n oil gall ery, up t o a corresponding oi l gal lery in t hecyl inder head.

Engi ne cool ing i s achi eved wit h int er-cyl inder coolant chambers and expans ion chamber dril li ngs , formed i n t he cyl inderblock cool ant jacket . The coolant chambers direct coolant t hrough openings i n t he block upper s urface to the cyli nder head.Core pl ugs seal t he ext eri or openings formed i n t he cyl inder block coolant jacket.

Oil Spray Jets

Page 770 of 3229

12-Dual mas s flywheel (manual t rans mi ss i on vehi cl es )

13-Bol t (8 off)

14-Torque convert er flex-pl ate (automat ic trans mi ss i on vehi cl es)15-Mai n beari ng lower half s hel l (4 off)

16-Lower t hrus t washer (2 off)

17-Mai n beari ng hal f cap (5 off)18-Oil pump

19-Oil level gage tube (lower)

20-Bol t21-Locati ng dowel

22-Oil pan hous i ng

23-Oil pan hous i ng bol t (20 off)24-Oil pan capt ive bolt (21 off)

25-Oil drai n plug s eal

26-Oil drai n plug27-Oil pan

28-Oil t emperature s ens or

29-Screw (2 off)30-Oil level gage tube (upper)

31-Oil level gage

32-Oil pump drive chai n33-Cranks haft pull ey bolt

34-Pl ain was her

35-Cranks haft pull ey and t ors ional vi brati on damper36-CKP sens or target ring

37-W oodruff key (2 off)

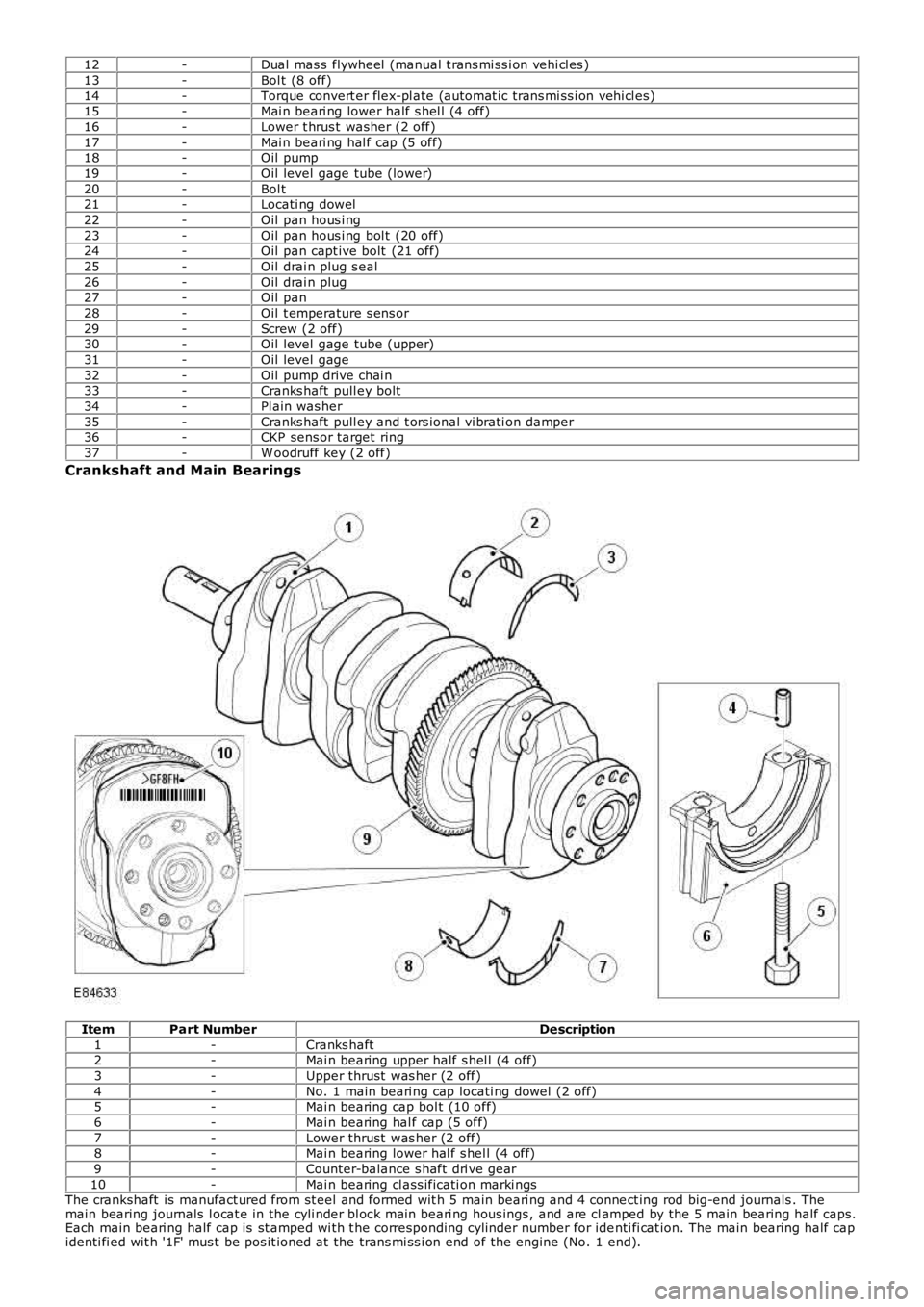

Crankshaft and Main Bearings

ItemPart NumberDescription

1-Cranks haft2-Mai n bearing upper half s hel l (4 off)

3-Upper thrust was her (2 off)

4-No. 1 main beari ng cap locati ng dowel (2 off)5-Mai n bearing cap bol t (10 off)

6-Mai n bearing hal f cap (5 off)

7-Lower thrust was her (2 off)8-Mai n bearing lower hal f s hel l (4 off)

9-Counter-balance s haft dri ve gear

10-Mai n bearing cl ass ificati on marki ngsThe crankshaft is manufact ured from st eel and formed wit h 5 main beari ng and 4 connect ing rod big-end journals . Themain bearing journals l ocat e in the cyli nder bl ock mai n beari ng hous ings , and are clamped by the 5 main bearing half caps.Each main beari ng half cap is st amped wi th t he corresponding cylinder number for identi fi cat ion. The main bearing half capidenti fi ed wit h '1F' mus t be pos it ioned at the trans mi ss i on end of the engine (No. 1 end).

Page 791 of 3229

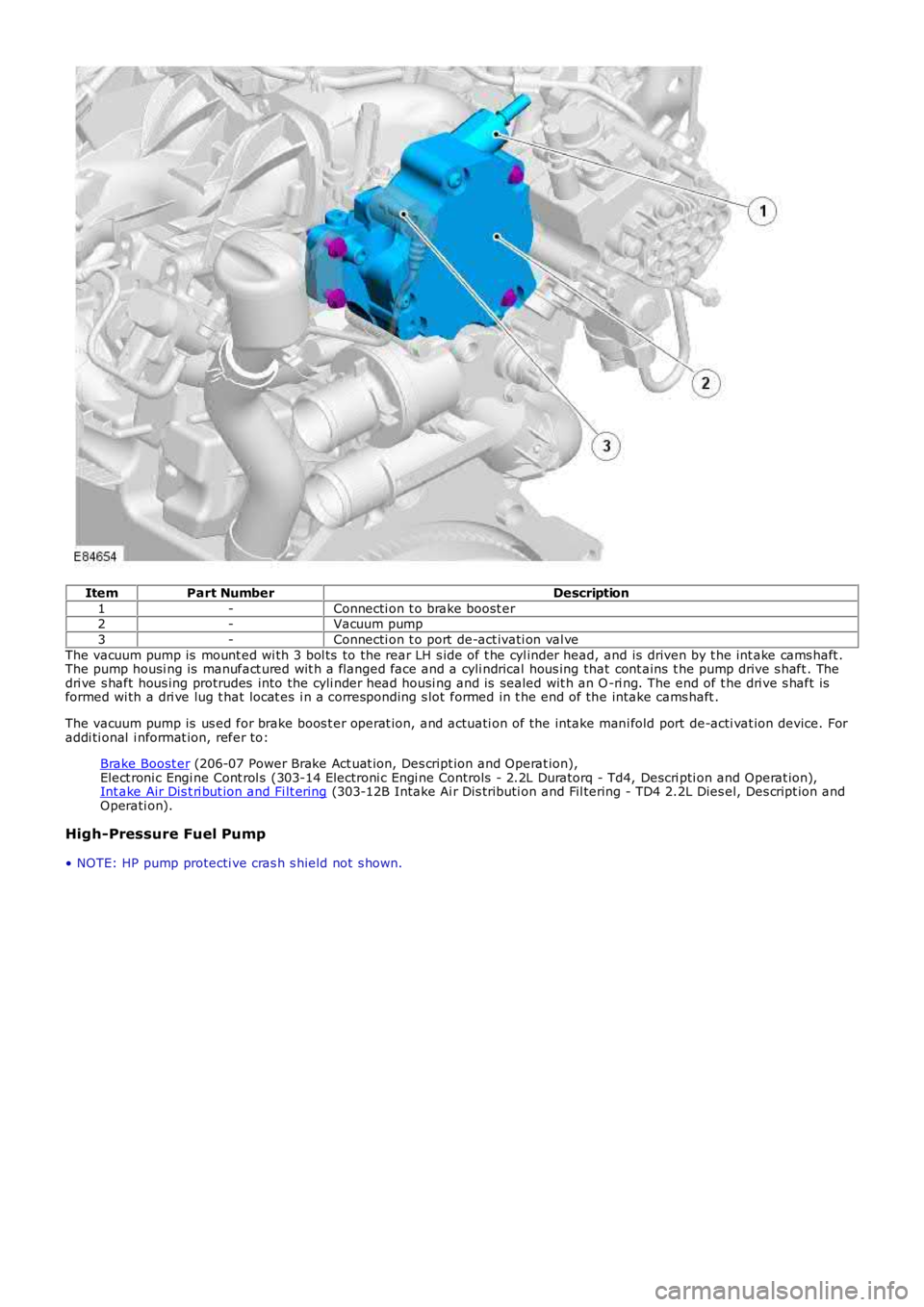

ItemPart NumberDescription

1-Connecti on t o brake boost er2-Vacuum pump

3-Connecti on t o port de-act ivati on val ve

The vacuum pump is mount ed wi th 3 bol ts to the rear LH s ide of t he cyl inder head, and is driven by t he int ake cams haft .The pump housi ng is manufact ured wit h a flanged face and a cyli ndrical hous ing that cont ains t he pump drive s haft . Thedri ve s haft hous ing protrudes into the cyli nder head housi ng and is sealed wit h an O-ri ng. The end of t he dri ve s haft isformed wi th a dri ve lug t hat locat es i n a corresponding s lot formed in t he end of the intake cams haft .

The vacuum pump is us ed for brake boos t er operat ion, and actuati on of the intake mani fold port de-acti vat ion device. Foraddi ti onal i nformat ion, refer to:

Brake Boost er (206-07 Power Brake Act uat ion, Des cript ion and Operat ion),Elect roni c Engi ne Cont rol s (303-14 Electroni c Engi ne Controls - 2.2L Duratorq - Td4, Descri pti on and Operat ion),Int ake Air Dis t ri but ion and Fi lt ering (303-12B Intake Ai r Dis tributi on and Fil tering - TD4 2.2L Dies el, Des cript ion andOperati on).

High-Pressure Fuel Pump

• NOTE: HP pump protecti ve cras h s hield not s hown.

Page 981 of 3229

SymptomPossible CauseAction

Poor throt t le respons eBreat her s ys temdis connected/res trictedElectronic engine controlTrans mi ss ion malfunct ionTract ion cont rol eventAir l eakage

Ens ure the engine breat her sys tem isfree from rest ri ct ion and is correct lyi nst all edRead DTCs and refer t o DTC Index forel ect ronic engine cont rol tes t s.REFER t o: Elect roni c Engi ne Cont rol s(303-14A Elect ronic Engine Cont rols - I63.2L Petrol , Diagnosi s and Test ing).For t rans mis s ion s ys tem tes ts .REFER t o: Diagnos t ics (307-01 Automat icTrans mi s si on/Trans axl e, Diagnos i s andTes ti ng).Check for ai r leakage i n i nt ake airs ys tem

DTC Index

• NOTE: If the control modul e/component i s s us pect and the vehicle remains under manufacturer warranty, refer to theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces and wit h a current cal ibrat ion cert ificate. W hen tes ti ng res i st ance, always take the res is tance of the DMM l eads i ntoaccount.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines t hat invol ve pinpoint t es t s .

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionP008700Fuel rail /s yst em pres sure -t oo lowLeakage at the fuel linesFuel pres s ure s ensor faul tFuel pump faul tFuel pump control modul e fault

Check t he fuel s yst em for leaks.REFER to: Fuel Tank and Lines (310-01A FuelTank and Li nes - I6 3.2L Petrol, Diagnos isand Tes t ing).Rect ify as neces s ary. Check for DTCsindicati ng a fuel press ure, fuel pres s ures ens or, pump or pump modul e faul t.

P008800Fuel rail /s yst em pres sure -t oo highRes t ri ct ed fuel l inesFuel pres s ure s ensor faul tFuel pump faul tFuel pump control modul e fault

Check t he fuel s yst em fordamage/res trict ions.REFER to: Fuel Tank and Lines (310-01A FuelTank and Li nes - I6 3.2L Petrol, Diagnos isand Tes t ing).Rect ify as neces s ary. Check for DTCsindicati ng a fuel press ure, fuel pres s ures ens or, pump or pump modul e faul t.P008968Fuel press ure regulat orperformance - algorit hmbas ed fail ures

Low fuel pres s ureCheck for DTCs indicati ng a fuel pres s ure,fuel pres s ure s ensor, pump or pump modulefault .

P017068Fuel t rim, bank 1HO2S cont rol outs ide limit sNo acti on is necess ary. The code wil l cl earwhen the condit ions no l onger apply.

P017100Syst em too l ean (bank 1)Int ake ai r leak- Bet ween MAF s ensor andcyli nder headFuel s ys t em rest ricti onMAF s ens or fault- Low int ake flowExhaust leak, before catal yt icconvert er

Check for intake ai r leaks . Check for low fuelpres sure and MAF s ens or DTCs . Rect ify asneces sary. Check for exhaus t l eaks beforethe cat al yti c convert er

P017200Syst em too rich (bank 1)Res t ri ct ed air fil terOil cont aminat ed wit h fuel- Too many col d s tarts wit hvehicle s ubs equent ly notget ti ng hot enough for longenoughLeaking fuel i njectorsMAF s ens or fault- High i nt ake fl owLeaking evaporati ve emis s ionsys tem purge valve

Check t he condi ti on of the ai r cl eanerelement:REFER to: Air Cl eaner (303-12B Int ake AirDis t ribut ion and Fil tering - TD4 2.2L Dies el,Removal and Inst all at ion).Check engine t he oil condi ti on. Check forleaking i nject ors . Check for MAF s ensor,inject or and evaporati ve emis s ion sys temDTCs.

P017368Fuel t rim (bank 2)HO2S cont rol outs ide limit sNo acti on is necess ary. The code wil l cl earwhen the condit ions no l onger apply.

P017400Syst em too l ean (bank 2)Int ake ai r leak- Bet ween MAF s ensor andcyli nder headFuel s ys t em rest ricti on

Check for intake ai r leaks . Check for low fuelpres sure and MAF s ens or DTCs . Rect ify asneces sary. Check for exhaus t l eaks beforethe cat al yti c convert er

Page 994 of 3229

chambers. Thi s provides opti mum performance, all owing t he engi ne t o be extremely respons ive t o dri ver demands for al ldri vi ng condi ti ons . The fuel s yst em features a Bos ch Generat ion 3 common rai l injection s yst em that is moni tored andcont rol led by an engine control modul e (ECM), t o precis ely cont rol the fueli ng st rategy.

Fuel charging is achieved wit h a l ow and hi gh-pres sure fuel s yst em. The l ow-pres s ure fuel s ys tem compris es ;

a s addle t ype fuel tankt ank mount ed fuel deli very module wi th int egral trans fer pumpfuel s uppl y and ret urn linesfi lt er and water s eparator as sembl ya connect ing hos e between t he fuel filt er ass embly and the fuel lift pump.

• NOTE: The fuel l ift pump is i ntegral wi th the hi gh-pres s ure pump.

A return li ne and fuel leak off hos es from the hi gh-pres s ure pump, i nject ors and common fuel rai l form t he remai nder oft he low-pres sure fuel ret urn ci rcuit .For addit ional informat ion, refer t o: Fuel Tank and Lines - 2.2L Duratorq-TDCi (DW ) Dies el (310-01 Fuel Tank and Li nes ,Des cript ion and Operat ion).

The high-press ure fuel s ys t em compri s es ;

a hi gh-pres sure fuel pumpcommon fuel rail4 pi ezo-injectors wit h hi gh-pres s ure connecti on pipesa fuel press ure sens or.

The fuel charging and control s ys tem provides i nject ion press ures of up to 1800 bar (26,106 psi ). Fi ner at omizati on of theinject ed fuel is achieved wi th the 7 hol e piezo i njectors that are capable of near ins tant aneous res ponse to the ECMcommands , all owing up to 5 individual inject ions per st roke.

The high-press ure fuel pump i s mounted at t he rear of t he cyl inder head and i s dri ven by the exhaust cams haft . A fuel l iftpump i s int egral wit h t he high-pres s ure pump and is therefore al so driven when t he exhaus t cams haft rot ates . The li ftpump creat es suct ion i n the supply line to t he fuel t ank and draws t he fuel from the t ank. The fuel pas s es through the fuelfi lt er and is t hen delivered at lift pump pres s ure to the hi gh-pres sure pump i nlet port .

The advanced high-press ure fueli ng s ys t em enables pil ot inject ions to be delivered ahead of t he main charge of fuel. Thisproduces a s teady fl ame front and creates a progres s ive pres s ure ris e in t he cyl inder s imi lar to that achi eved wit h petrolengi nes. This reduct ion i n combust ion lag between t he i nject ion of fuel and combus tion occurring al lows fuel t o be i njectedwhil e combus t ion i s t aki ng place, creat ing i ncreas ed power and reducing creat ed combus t ion nois e, vibrat ion andhars hnes s (NVH) and emis s ions .

For model s fi tt ed wi th an exhaus t sys t em dies el parti cul ate fil ter, the hi gh-pres s ure fueling sys tem als o provi des pos tcombus t ion i njecti on of fuel into the combus ti on chambers. W hen regenerati on of the di esel part iculat e fi lt er is reques t ed,t he ECM all ows the fueli ng s ys t em t o deli ver fuel after t he combus t ion s troke and int o t he commencement of the exhausts troke. This pos t combus t ion i njecti on proces s caus es fuel to be burnt in the exhaust s ys tem and creates t he high exhaus tgas temperatures that are required to regenerate t he dies el part icul ate fi lt er.

Page 998 of 3229

C-HP pipe connecti on – fuel rail t o inject or (4 off)

1-Fuel rail

2-PCV3-Fuel rail press ure sens or

The fuel rai l is manufact ured from forged st eel and secured t o t he cyl inder head with 2 fixings . The fuel rai l st orespres s urized fuel from t he HP pump, and prevent s pres s ure fluct uat ions i n the HP s ys tem. A fuel rail pres s ure s ens or and aPW M PCV are ins tall ed int o t he bore at each end of the fuel rail . The pres s ure s ensor i s ins tal led at t he acces sory dri veend of the fuel rail ; the PCV ins tal led at t he transmis s ion end of t he fuel rai l.

High-pres sure fuel pipes connect t he fuel rai l t o t he HP pump and fuel inject ors . A l eak-off pipe connect s the fuel rail t ot he fuel fi lt er return circui t.

The common fuel rail, fuel press ure s ens or and PCV form an int egral as s embly, and mus t not be separat ed. If a faultoccurs that requires component renewal, t hen t he compl ete fuel rail as s embl y mus t be renewed.

Fuel Rail Pressure Sensor

The fuel rai l pres sure s ens or is mount ed i n t he end of the fuel rail (access ory drive end) and connected to t he ECM vi a t heengi ne harnes s. The press ure sens or is provi ded wit h a 5V power s upply, ground and signal connect ions . The fuel railpres s ure s ensor i s a pi ezo-res is ti ve type s ens or contai ni ng an actuati ng diaphragm. Deflect ion of t he diaphragm provides aproport ional si gnal (output) volt age t o t he ECM, dependant on t he fuel pres s ure wit hin t he fuel rai l.

Pressure Sensor ParametersPressure Sensor Output VoltageFuel Rail Pressure

0.5V230 bar (3,336 ps i)

4.5V1,600 bar (23,206 ps i)The ECM compares t he s ens or s ignal vol tage t o s tored memory val ues, i n order t o cal cul ate the actual fuel pres s urepres ent in t he fuel rail. The ECM then us es t he fuel rai l press ure informat ion t o cont rol t he operati ng posi ti on of the VCVand PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

Pressure Control Valve (PCV)

The PCV i s mounted i n t he end of the fuel rail (trans mi s si on end) and connect ed t o the ECM via t he engine harnes s . ThePCV i s a s olenoid-operat ed valve cont rol led by a 12V PW M si gnal . The ECM operat es the PCV to adjus t t he fuel pres s urewit hin the fuel rail . Rel ieved fuel is direct ed through t he fuel rail leak-off pipe t o t he fuel fi lt er ret urn circui t. The l eak-offfuel als o provi des cooli ng and lubricat ion for t he PCV.For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

The PCV i s normall y open when t he s ol enoi d is not energi zed by the ECM. The resi s tance val ue of the PCV sol enoi d coi l is3.6 ohms at 20°C (68°F).

The PCV i s als o us ed by t he ECM t o provide di rect cont rol of the fuel sys tem, in t he fol lowi ng si tuat ions :

Duri ng s udden t rans ient phas es i n engine s peed (s uddenl y li ft ing off the accel erat or pedal, for example) where VCVact ion is not s ufficient to affect t he s uppl y of fuel to the fuel rail .To cont rol fuel press ure in t he event that the VCV fai ls .Duri ng the fuel heat ing period, when supply fuel temperat ure is l ess than 40°C (104°F). The VCV i s ful ly opened byt he ECM and t he HP pump compres s es a maximum quanti ty of fuel t o rais e t he fuel t emperature. The PCV is t henmodulat ed by the ECM to provide l eak-off fuel from the fuel rail t o t he fuel fi lt er ret urn circui t. The fuel i s t henrecircul ated t hrough t he fuel fi lt er and back t o t he HP pump.W hen t he fuel s uppl y t emperature is greater t han 70°C (158°F). The PCV is modul ated by t he ECM t o releas e fuelrai l pres sure, s ubs equentl y decreasi ng the fuel temperat ure to protect the fuel sys tem component s. Leak-off fuelfrom the fuel rail is direct ed to the fuel fil ter return ci rcuit and back t o the fuel tank.Duri ng engi ne s hut down t o progres s ively coll aps e fuel rail pres s ure.

FUEL INJECTORS

Page 999 of 3229

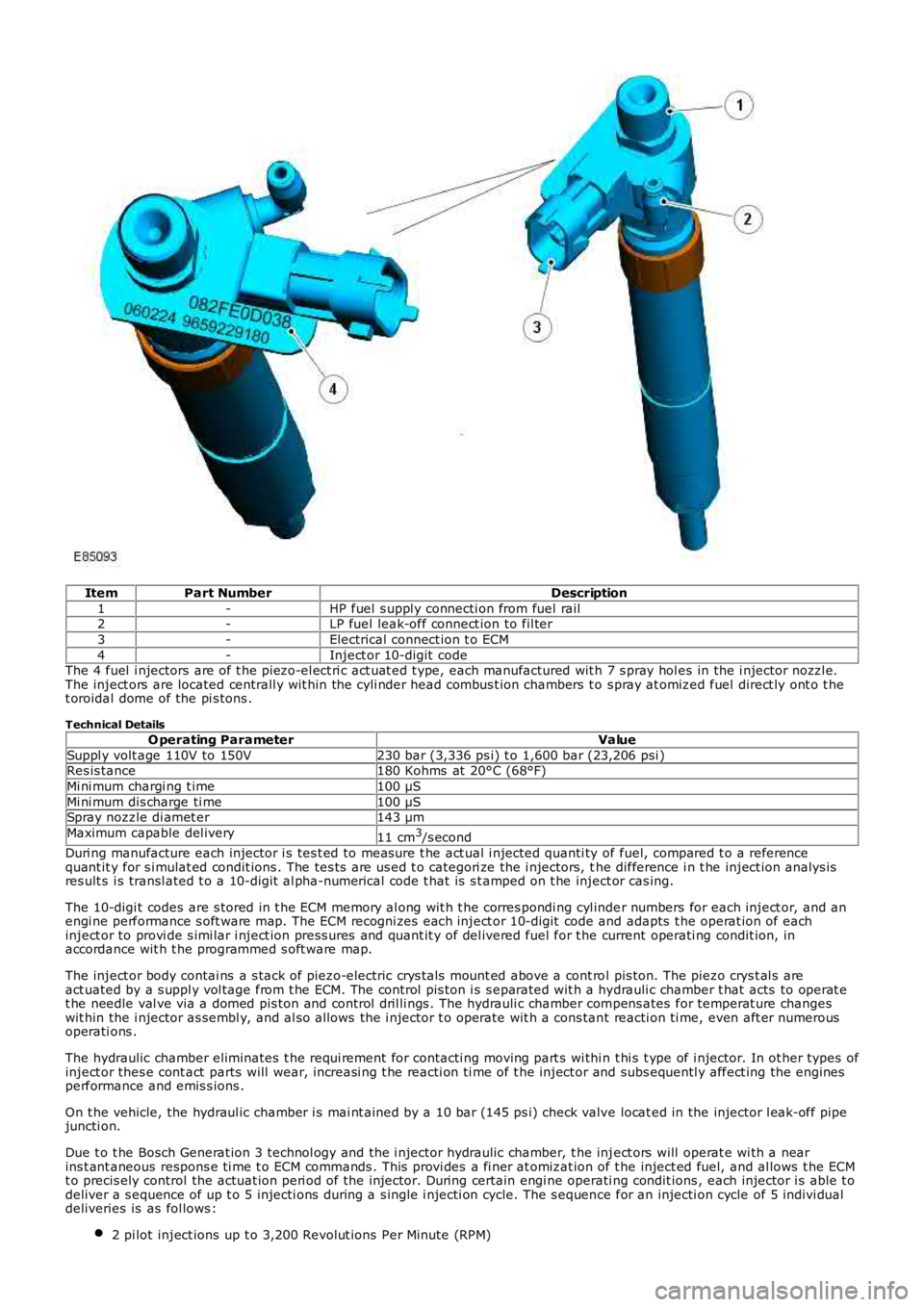

ItemPart NumberDescription

1-HP fuel s uppl y connecti on from fuel rail2-LP fuel leak-off connect ion to fil ter

3-Electrical connect ion t o ECM

4-Inject or 10-digit codeThe 4 fuel i njectors are of t he piezo-el ect ri c act uat ed t ype, each manufactured wit h 7 s pray hol es in the i njector nozzl e.The inject ors are located centrall y wit hin the cyli nder head combus t ion chambers t o s pray at omized fuel direct ly ont o t het oroidal dome of the pi s tons .

Technical Details

O perating ParameterValue

Suppl y volt age 110V to 150V230 bar (3,336 ps i) t o 1,600 bar (23,206 psi )Res is tance180 Kohms at 20°C (68°F)

Mi ni mum chargi ng t ime100 µS

Mi ni mum dis charge ti me100 µSSpray nozzle di amet er143 µm

Maximum capable del ivery11 cm3/s econd

Duri ng manufacture each injector i s tes t ed to measure t he act ual i njected quanti ty of fuel, compared t o a referencequant it y for s i mulat ed condit ions . The tes ts are us ed t o categori ze the i njectors, the difference i n t he inject ion analys isres ult s i s transl ated t o a 10-digit al pha-numerical code t hat is s t amped on t he inject or cas ing.

The 10-digi t codes are s tored in t he ECM memory al ong wit h t he corres pondi ng cyl inder numbers for each inject or, and anengi ne performance s oft ware map. The ECM recogni zes each inject or 10-digit code and adapts t he operat ion of eachinject or to provi de s imi lar i nject ion press ures and quant it y of del ivered fuel for the current operati ng condit ion, inaccordance wit h t he programmed s oft ware map.

The inject or body contai ns a s tack of piezo-electric crys t als mount ed above a cont rol pis ton. The piezo crys t al s areact uated by a s uppl y vol tage from t he ECM. The control pis ton i s s eparated wit h a hydrauli c chamber t hat acts to operat et he needle val ve via a domed pis ton and control dril li ngs . The hydrauli c chamber compens ates for temperat ure changeswit hin the i njector as sembl y, and al so allows the i njector t o operate wit h a cons tant reacti on ti me, even aft er numerousoperati ons .

The hydraulic chamber eliminates t he requi rement for contacti ng moving part s wi thi n t hi s t ype of i njector. In ot her types ofinject or thes e cont act parts will wear, increasi ng t he reacti on ti me of t he inject or and subs equentl y affect ing the enginesperformance and emis s ions .

On t he vehicle, the hydraul ic chamber i s mai nt ained by a 10 bar (145 ps i) check valve locat ed in the injector l eak-off pipejuncti on.

Due t o t he Bosch Generat ion 3 technol ogy and the i njector hydraulic chamber, t he inject ors will operat e wi th a nearins t ant aneous respons e ti me t o ECM commands . This provi des a fi ner at omizat ion of t he inject ed fuel, and al lows t he ECMt o precis ely control the actuat ion peri od of the injector. During certain engi ne operati ng condit ions , each injector i s able t odeliver a s equence of up t o 5 injecti ons during a s ingle i njecti on cycle. The s equence for an injecti on cycle of 5 indivi dualdeliveries is as fol lows :

2 pi lot inject ions up t o 3,200 Revolut ions Per Minute (RPM)

Page 1040 of 3229

Publi s hed: 11-May-2011

Accessory Drive - I6 3.2L Petrol - Accessory Drive

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Rear End Acces s ory Drive (READ), refer to the relevant Des cri pti on and Operati on s ect ionof the workshop manual.REFER to: Acces s ory Drive (303-05A Acces s ory Drive - I6 3.2L Pet rol , Descri pti on and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for s ys tem int egrit y and obvi ous s igns of damage.2.

Visual Inspection

Mechanical

READ beltREAD belt t ensi onREAD belt t ensi onerREAD belt pul leysREAD belt pul ley s eal s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

Symptom Chart

SymptomPossible CauseAction

READ belt noi se ors quealREAD belt pull ey(s )Lubricant or ot hercont aminat ionREAD belt

Check for pul ley ali gnment , freedom of rot ati on and damage. Repairor ins tall new parts as required.REFER to: Acces s ory Drive Component Bracket Ali gnment (303-05AAcces sory Dri ve - I6 3.2L Pet rol, General Procedures ) /Acces sory Dri ve Belt Idler Pulley (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion) /Acces sory Dri ve Pulley (303-05A Acces s ory Drive - I6 3.2L Petrol ,Removal and Inst all at ion).Check READ bel t for cont aminat ion. If contami nat ed, ins tall a newbel t.REFER to: Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion).Check READ bel t for correct applicati onREAD belt does nothold tens ionREAD belt cracking ordamagedTens i oner worn ordamaged

Ins pect READ bel t for cracki ng or damage. Inst all a new bel t asrequired.REFER to: Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2LPet rol , Removal and Inst all at ion).Check READ bel t tens ioner for damage and correct operati on. Ins tall anew READ belt t ensi oner as requi red.REFER to: Acces s ory Drive Belt Tens ioner (303-05A Acces s ory Drive -I6 3.2L Petrol, Removal and Ins tall ati on).

Component Tests

READ belt tensioner

Stat ic

The only checks requi red for the READ bel t tens ioner are for st ick, grab or bind.

1. Remove the drive belt i n t he area of t he t ens ioner.1.

2. Us ing t he correct t ool , rot at e t he t ens ioner from it s rel axed pos it ion t hrough it s full s troke and back t o t herelaxed posi ti on to make s ure t here i s no s t ick, grab or bind, and to make s ure t hat there is t ensi on on t het ensi oner s pri ng.

2.

3. If t he t ens i oner meet s the above cri teria, proceed to the dynamic t es t. If the tens ioner does not meet t he abovecrit eria ins tall a new t ens ioner.REFER t o: Access ory Dri ve Belt Tensi oner (303-05A Acces s ory Drive - I6 3.2L Pet rol , Removal and Ins t al lat ion).

3.

Dynamic

The READ belt t ensi oner can be checked dynamically as foll ows :

W i th the engine running, obs erve drive belt t ensi oner movement , the READ bel t tens ioner should move (respond) when theair condi ti oni ng clut ch cycles (if equipped), t he READ belt t ens ioner s houl d move (res pond) when t he engine s peed isincreas ed rapi dl y. If t he dri ve bel t tens ioner movement i s errati c wit hout ai r condit ioni ng cl utch cycl ing or engineaccelerati on, a pul ley or s haft may be bent , or di st ort ed. Excess i ve drive bel t ri deout (uneven dept h of grooves in the drivebelt ) can al s o caus e exces s ive drive belt t ensi oner movement. Check condi ti on by instal ling a known good bel t.REFER to: Acces s ory Drive Bel t (303-05A Acces s ory Drive - I6 3.2L Petrol, Removal and Inst all ati on).

Page 1079 of 3229

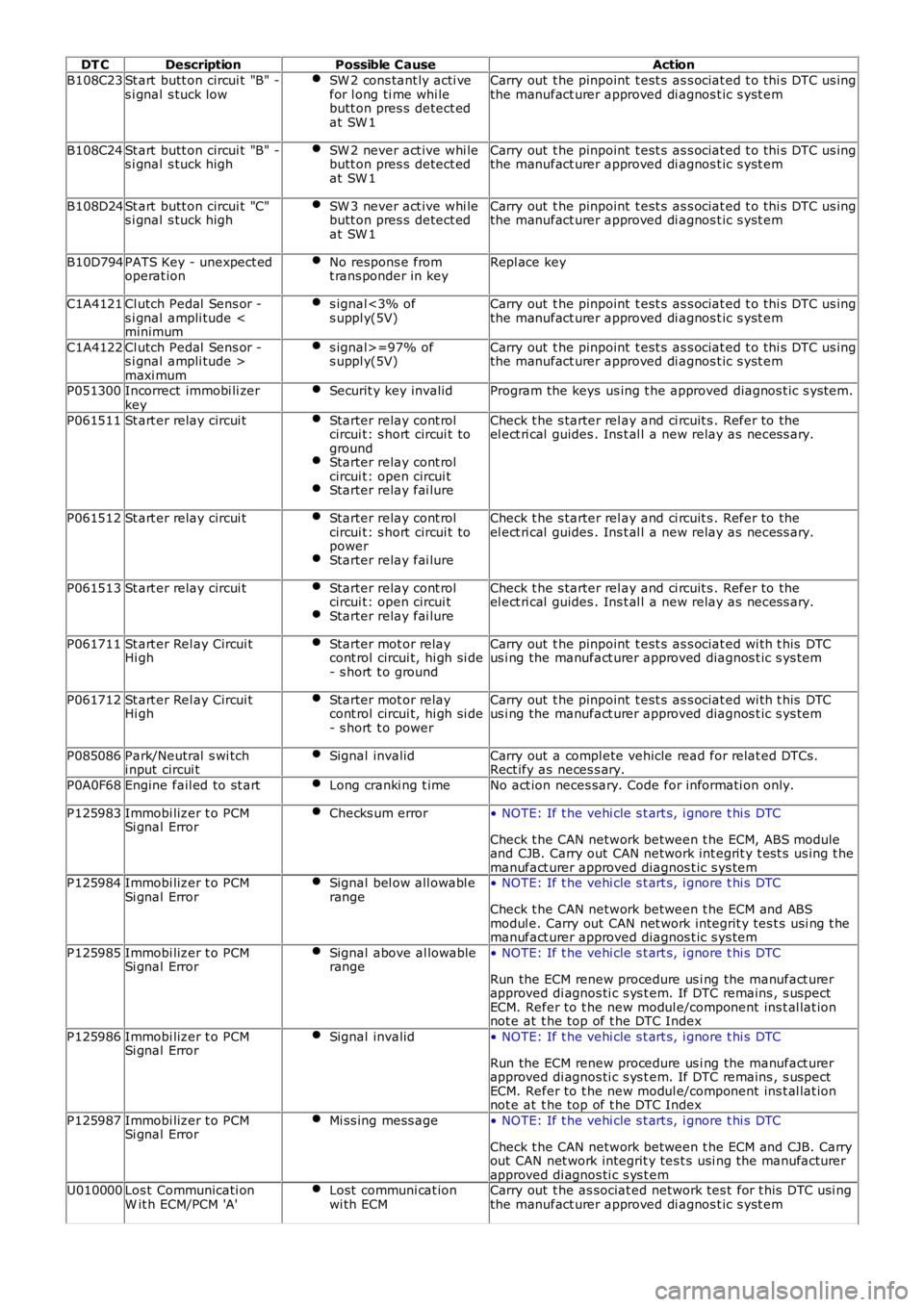

DT CDescriptionPossible CauseAction

B108C23St art butt on circui t "B" -s i gnal s tuck lowSW 2 cons tant ly acti vefor l ong ti me whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108C24St art butt on circui t "B" -s i gnal s tuck highSW 2 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108D24St art butt on circui t "C"s i gnal s tuck highSW 3 never act ive whi lebutt on pres s detect edat SW 1

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B10D794PATS Key - unexpect edoperat ionNo respons e fromt rans ponder in keyRepl ace key

C1A4121Cl utch Pedal Sens or -s i gnal ampli tude

C1A4122Cl utch Pedal Sens or -s i gnal ampli tude >maxi mum

s ignal>=97% ofs uppl y(5V)Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

P051300Incorrect immobi li zerkeySecurit y key invalidProgram the keys us ing t he approved diagnos t ic s yst em.

P061511St art er relay circui tStarter relay cont rolcircui t: s hort circui t togroundStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061512St art er relay circui tStarter relay cont rolcircui t: s hort circui t topowerStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061513St art er relay circui tStarter relay cont rolcircui t: open circui tStarter relay fai lure

Check t he s tarter rel ay and ci rcuit s . Refer to theel ect ri cal guides . Ins t al l a new relay as neces s ary.

P061711St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o ground

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P061712St art er Rel ay Circui tHi ghStarter mot or relaycont rol circui t, hi gh si de- s hort t o power

Carry out t he pinpoint t est s as s ociat ed wi th t his DTCus i ng the manufact urer approved diagnos t ic s ys tem

P085086Park/Neutral s wi tchi nput circui tSignal invalidCarry out a compl ete vehicle read for relat ed DTCs.Rect ify as neces s ary.

P0A0F68Engine fail ed to st artLong cranki ng t imeNo act ion neces sary. Code for informati on only.

P125983Immobi lizer t o PCMSi gnal ErrorChecks um error• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM, ABS moduleand CJB. Carry out CAN network int egrit y t est s us ing t hemanufact urer approved diagnos t ic s ys temP125984Immobi lizer t o PCMSi gnal ErrorSignal bel ow all owabl erange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and ABSmodul e. Carry out CAN net work integrit y tes t s usi ng t hemanufact urer approved diagnos t ic s ys tem

P125985Immobi lizer t o PCMSi gnal ErrorSignal above al lowablerange• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125986Immobi lizer t o PCMSi gnal ErrorSignal invalid• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Run the ECM renew procedure us i ng the manufact urerapproved di agnos ti c s ys t em. If DTC remains , s uspectECM. Refer to t he new modul e/component ins t al lat ionnot e at t he top of t he DTC Index

P125987Immobi lizer t o PCMSi gnal ErrorMi ss ing mess age• NOTE: If t he vehi cle s t art s, i gnore t hi s DTC

Check t he CAN network between t he ECM and CJB. Carryout CAN net work integrit y tes t s usi ng t he manufacturerapproved di agnos ti c s ys t emU010000Los t Communicati onW it h ECM/PCM 'A'Lost communi cat ionwi th ECMCarry out t he as sociat ed network tes t for t his DTC usi ngthe manufact urer approved di agnos t ic s yst em

Page 1100 of 3229

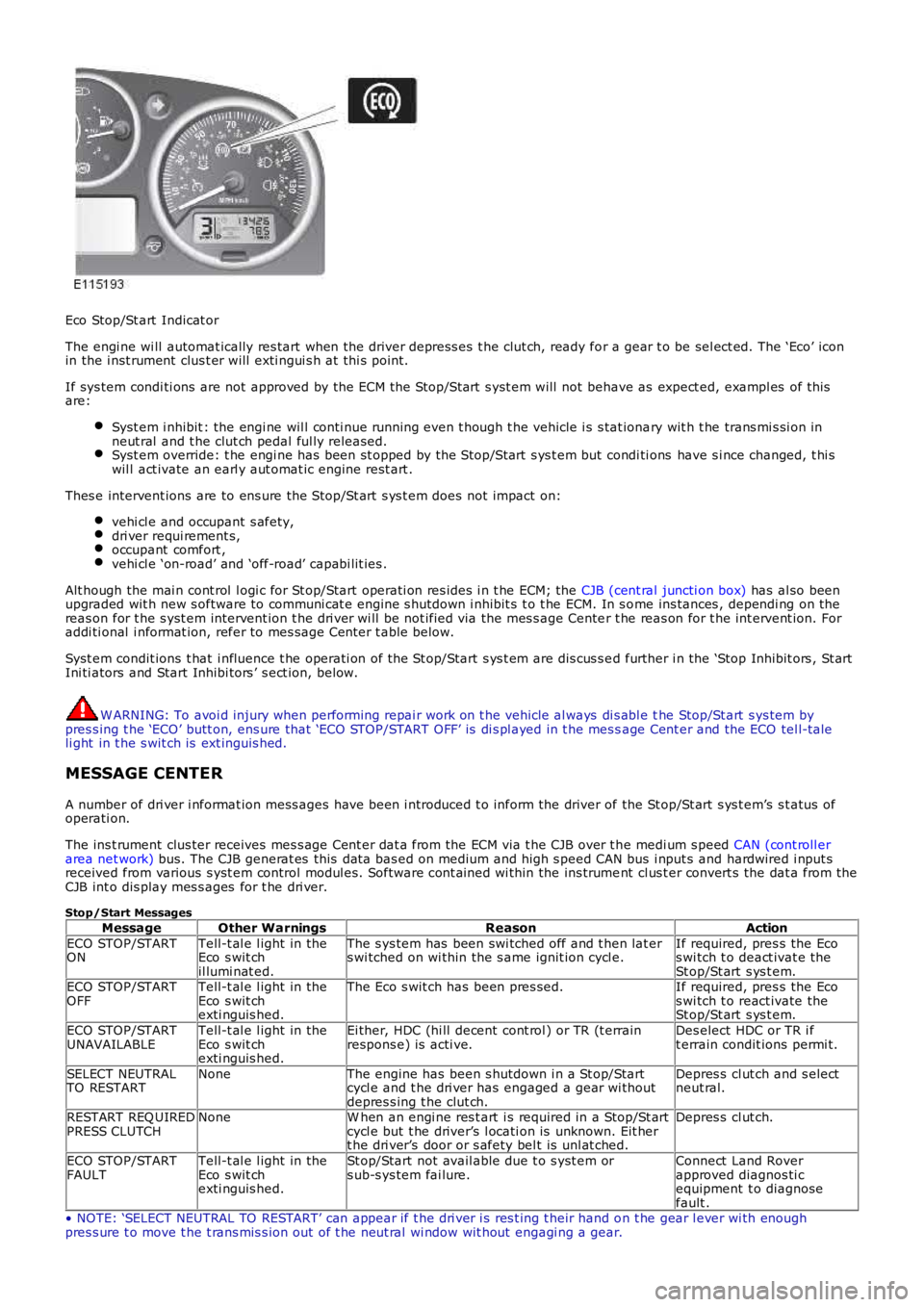

Eco Stop/St art Indicat or

The engi ne wi ll automat ically res tart when the driver depress es t he clut ch, ready for a gear t o be sel ect ed. The ‘Eco’ iconin the i nst rument clus t er will exti ngui s h at thi s point.

If sys tem condi ti ons are not approved by the ECM the St op/St art s yst em will not behave as expect ed, exampl es of thisare:

Syst em i nhibit : the engi ne wil l conti nue running even t hough t he vehicle i s s tat ionary wit h t he trans mi s si on inneut ral and t he clut ch pedal ful ly released.Syst em override: t he engi ne has been st opped by the St op/St art s ys t em but condi ti ons have s i nce changed, t hi swil l act ivate an earl y aut omat ic engine rest art .

Thes e intervent ions are to ens ure the St op/St art s ys t em does not impact on:

vehi cl e and occupant s afety,dri ver requi rement s,occupant comfort ,vehi cl e ‘on-road’ and ‘off-road’ capabi lit ies .

Alt hough the mai n cont rol l ogi c for St op/Start operati on res ides i n t he ECM; the CJB (cent ral juncti on box) has al so beenupgraded wit h new s oftware to communi cat e engine s hutdown i nhibit s t o t he ECM. In s ome ins tances , dependi ng on thereas on for t he s yst em intervent ion t he dri ver wi ll be not ified via the mes s age Center t he reas on for t he int ervent ion. Foraddi ti onal i nformat ion, refer to mes sage Center t able below.

Syst em condit ions t hat i nfluence t he operati on of the St op/Start s ys t em are dis cus s ed further i n the ‘Stop Inhibit ors , St artIni ti ators and Start Inhibi tors ’ s ect ion, below.

W ARNING: To avoi d injury when performing repai r work on t he vehicle al ways di s abl e the Stop/St art s ys tem bypres s ing t he ‘ECO’ butt on, ens ure that ‘ECO STOP/START OFF’ is di s pl ayed in t he mes sage Cent er and the ECO tel l-taleli ght in t he s wit ch is ext inguis hed.

MESSAGE CENTER

A number of dri ver i nformat ion mess ages have been i ntroduced t o inform the driver of the St op/St art s ys t em’s s t atus ofoperati on.

The ins t rument clus ter receives mes s age Cent er dat a from the ECM via t he CJB over t he medi um s peed CAN (cont roll erarea net work) bus. The CJB generat es this dat a bas ed on medium and high s peed CAN bus i nput s and hardwired i nput sreceived from various s yst em control modul es. Software cont ained wi thin the ins trument cl us t er convert s the dat a from theCJB int o dis play mes s ages for t he dri ver.

Stop/Start Messages

MessageOther WarningsReasonAction

ECO STOP/STARTONTell-t al e l ight in theEco s wit chil lumi nat ed.

The s ys tem has been swi tched off and t hen lat ers wi tched on wi thin the s ame ignit ion cycl e.If required, pres s the Ecos wi tch t o deact ivat e theSt op/St art s ys t em.ECO STOP/STARTOFFTell-t al e l ight in theEco s wit chexti nguis hed.

The Eco s wit ch has been pres sed.If required, pres s the Ecos wi tch t o react ivate theSt op/St art s ys t em.

ECO STOP/STARTUNAVAILABLETell-t al e l ight in theEco s wit chexti nguis hed.

Ei ther, HDC (hi ll decent cont rol ) or TR (t errainrespons e) is acti ve.Des elect HDC or TR i ft errain condit ions permi t.

SELECT NEUTRALTO RESTARTNoneThe engine has been s hutdown i n a St op/Startcycl e and t he dri ver has engaged a gear wi thoutdepres s ing t he clut ch.

Depres s cl ut ch and s electneut ral.

RESTART REQ UIREDPRESS CLUTCHNoneW hen an engi ne res t art i s required in a Stop/St artcycl e but t he driver’s l ocati on is unknown. Eit hert he dri ver’s door or s afety bel t is unl at ched.

Depres s cl ut ch.

ECO STOP/STARTFAULTTell-t al e l ight in theEco s wit chexti nguis hed.

St op/Start not avail able due t o s yst em ors ub-s ys tem fai lure.Connect Land Roverapproved diagnos ti cequipment t o diagnosefault .• NOTE: ‘SELECT NEUTRAL TO RESTART’ can appear if t he dri ver i s res t ing t heir hand on t he gear l ever wi th enoughpres s ure t o move t he t rans mis s ion out of t he neut ral wi ndow wit hout engagi ng a gear.