warning LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 492 of 3229

Installation

All vehicles

1. CAUTION: Make s ure that the mati ng faces are cl ean and

free of foreign mat eri al.

Inst all t he brake mas ter cyli nder.

T orque: 26 Nm 1.

2. CAUTION: Make s ure that the mati ng faces are cl ean and

free of foreign mat eri al.

Inst all t he brake boost er.

T orque: 22 Nm 2.

3. CAUTION: Make s ure that the mati ng faces are cl ean and

free of foreign mat eri al.

Inst all t he brake fluid tubes.

T orque: 15 Nm 3.

Vehicles with manual transmission 4. CAUTION: Make s ure that the mati ng faces are cl ean and

free of foreign mat eri al.

Connect t he clutch flui d li ne.

4.

All vehicles Connect t he brake boost er vacuum l ine.

5.

Connect t he low brake fl uid warning i ndi cat or swit ch el ect ri cal

connector.

6.

Left-hand drive vehicles Inst all t he ECM bracket.

T orque: 10 Nm 7.

Inst all t he ECM.

8.

All vehicles Inst all t he dri ver l ower ai r bag modul e.

Refer t o: Dri ver Lower Air Bag Module (501-20B Supplemental

Res traint Sys t em, Removal and Inst all at ion).

9.

Inst all t he winds hield wiper motor and l inkage.

Refer t o: W i nds hield W i per Mot or (501-16 W ipers and W as hers ,

Removal and Ins tall ati on).

10.

Connect t he batt ery ground cable.

11.

Page 500 of 3229

1

2

Publi s hed: 11-May-2011

Anti-Lock Control - Anti-Lock Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Ant i-lock Braking Sys t em (ABS), refer to the relevant Des cri pt ion and Operati on s ect ion i nt he works hop manual . REFER t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Pri or to any t es ti ng or ins pect ion, the vehicle should be check for any relevant warning l amps bei ng il lumi nat ed. Ifa warning l amp is ill uminat ed, check for DTCs and refer to t he relevant DTC Index, if no warni ng lamp is i ll uminated,cont inue wi th diagnos t ic procedures below.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.

Visual InspectionMechanicalElectrical

Brake flui d levelVacuum s ys t emW heel s peed sens or ins tall ati onW heel s peed sens or ai r gapSt eering wheel rot ati on sens orAccel erometer/s ens or clus t er i nst all ati onIncorrect wheel or t ire s ize

W arning light operat ionFus esW heel s peed s ens orsConnect ors /Pi nsHarnes s esSt eering wheel rot ati on s ens orAccel eromet er/sens or cl ust erHydraul ic Control Uni t (HCU)

2.

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check t he ant i-lock braking sys tem and s teering rot ati on s ens or modules forDi agnos ti c Trouble Codes (DTCs) and refer t o t he rel evant DTC Index.4.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Ant i-Lock Braki ng Sys t em (ABS) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : BRAKE VACUU M ASSIST FU NCTION

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

A1: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE OFF

Set i gnit ion s wit ch t o OFF.

Pump t he brake pedal s ix ti mes and hold firm press ure on t he pedal .

Did t he pedal t ravel decreas e and t he pedal go hard as i t was pumped?YesGO t o A2.NoCHECK the vacuum circui t to the brake boos t er. Start the engine and idle for three mi nut es, s wi tchignit ion OFF t hen repeat t he tes t. If t he pedal t ravel does not decreas e, s uspect the brake boos t er.

A2: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE RUNNING

Page 514 of 3229

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

As t he wheel s peed s ens ors are acti ve devi ces , a return s ignal is availabl e when t he road wheels are not rot ati ng. Thisenabl es the ABS modul e t o check t he condi ti on of the s peed s ens ors whil e the vehicl e is st ati onary.

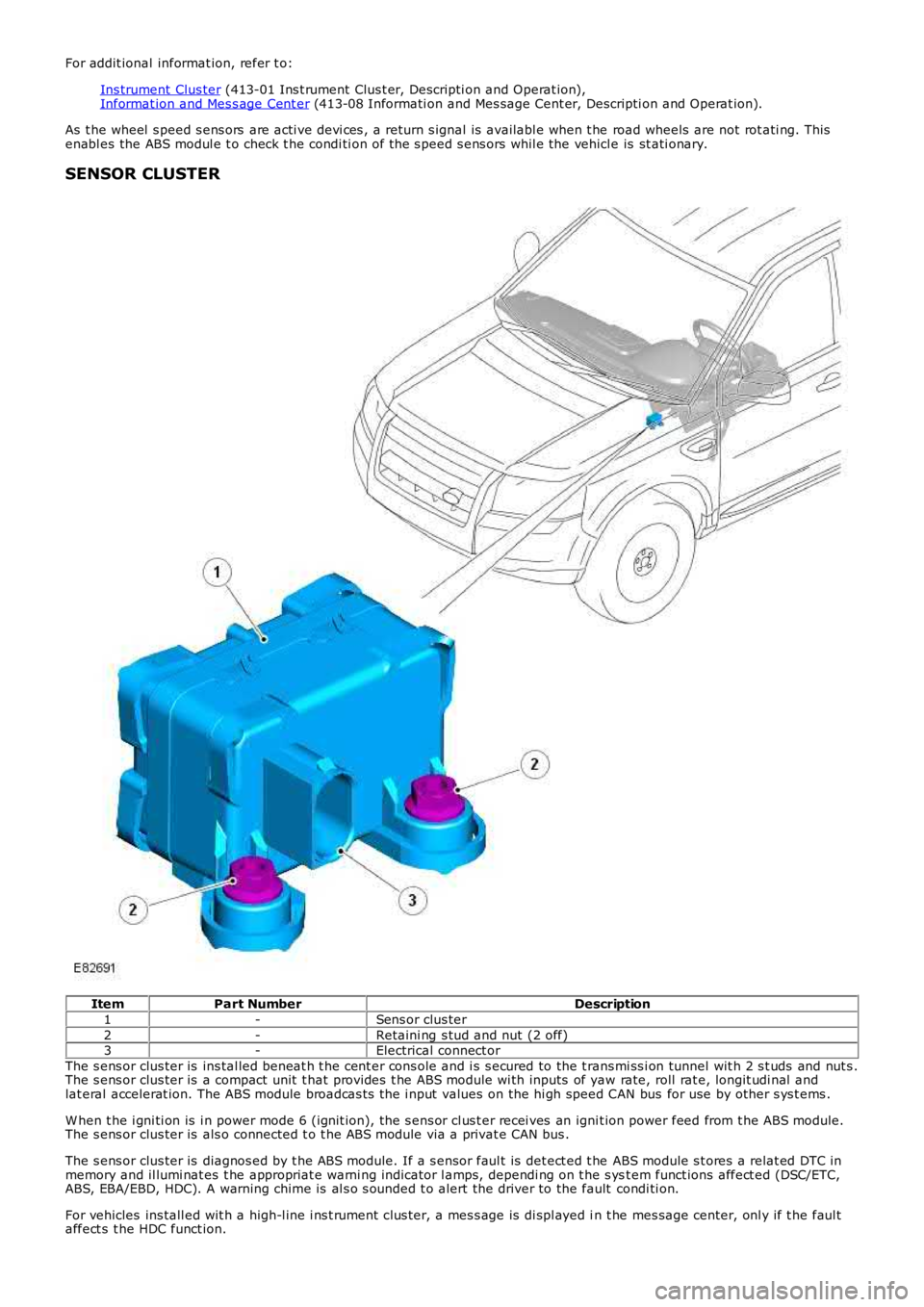

SENSOR CLUSTER

ItemPart NumberDescription

1-Sens or clus ter

2-Retaini ng s tud and nut (2 off)3-Electrical connect or

The s ens or clus ter is ins tal led beneat h t he cent er cons ole and i s s ecured to the t rans mi ss i on tunnel wit h 2 s t uds and nut s .The s ens or clus ter is a compact unit t hat provides t he ABS module wi th inputs of yaw rate, roll rat e, longit udi nal andlat eral accelerat ion. The ABS module broadcas ts the i nput values on the hi gh speed CAN bus for use by other s ys t ems .

W hen t he i gni ti on is i n power mode 6 (ignit ion), the s ens or cl us t er recei ves an ignit ion power feed from t he ABS module.The s ens or clus ter is als o connected t o t he ABS module via a privat e CAN bus .

The s ens or clus ter is diagnos ed by t he ABS module. If a s ensor faul t is det ect ed t he ABS module s t ores a relat ed DTC inmemory and il lumi nat es t he appropriat e warni ng indicator l amps, dependi ng on t he s yst em funct ions affect ed (DSC/ETC,ABS, EBA/EBD, HDC). A warning chime is al s o s ounded t o alert the driver to the fault condi ti on.

For vehicles ins tall ed wit h a high-l ine i ns t rument clus ter, a mes s age is di spl ayed in t he mes sage center, onl y if t he faul taffect s t he HDC funct ion.

Page 516 of 3229

wheel i s read by the opt ical-di git al s ens ors t o produce s teeri ng wheel rotat ional speed s ignals . The s teering angle s ens oris abl e t o meas ure a rot at ion range of +/- 720 degrees , alt hough t he s teering mechani s m wi ll only al low the s t eeringwheel t o rotat e a maxi mum of +/-540 degrees .

Signals from t he st eeri ng angl e s ens or are trans mi tt ed on t he vehicle hi gh s peed CAN bus , and received and proces sed byother s yst ems s uch as DSC. The trans mi tt ed i nformat ion i ncl udes det ails of st eering wheel angle and s t eering wheelrot ati onal s peed, along wit h s ignal i ntegri ty informati on.

If a fault occurs wi thi n t he st eeri ng angl e s ens or, a DTC wi ll be s et and s tored in t he s teering angle s ens or memory. Thes teeri ng angle s ensor faul t is al s o s tored in the ABS modul e memory that i lluminates t he appropri at e warning i ndi cat orlamps , depending on the sys tem functi ons affect ed (DSC/ETC, ABS, EBA/EBD, HDC). A warni ng chi me i s als o s ounded t oalert the driver to the fault condi ti on.

For vehicles ins tall ed wit h a high-l ine i ns t rument clus ter, a mes s age is di spl ayed in t he mes sage center, onl y if t he faul taffect s t he HDC funct ion.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

The s teeri ng angle s ensor and ABS modul e are abl e t o be i nt errogat ed us ing t he Land Rover approved diagnos t icequi pment.

Clockspring

The clocks pri ng is a rot ary coupling that provides t he electrical connect ion bet ween the fixed s t eering wheel module, andt he st eeri ng wheel mount ed cont rols and Supplement al Res t raint Sys tem (SRS) dri ver's ai rbag.

A colored indicator i s provided wi thi n the cl ocks pring and is vis i bl e t hrough a t rans parent pers pex cover when the s t eeringwheel i s removed, and t he st eeri ng angl e s ens or is aligned t o t he cent ral posi ti on. The indicator makes s ure t he s teeringangl e s ensor and s t eering s ys tem are correct ly al igned fol lowi ng repairs t o the st eeri ng mechanis m.

Service Information

Before s eparat ing the s t eering component s from the connect ing s t eering column, t he clocks pri ng mus t be ali gned to thecent er pos i ti on (i ndi cat or vi s ible) and t he wheels point ing s t raight ahead. The clockspring i s ret ained i n the cent ralposi ti on wit h a locki ng s crew.

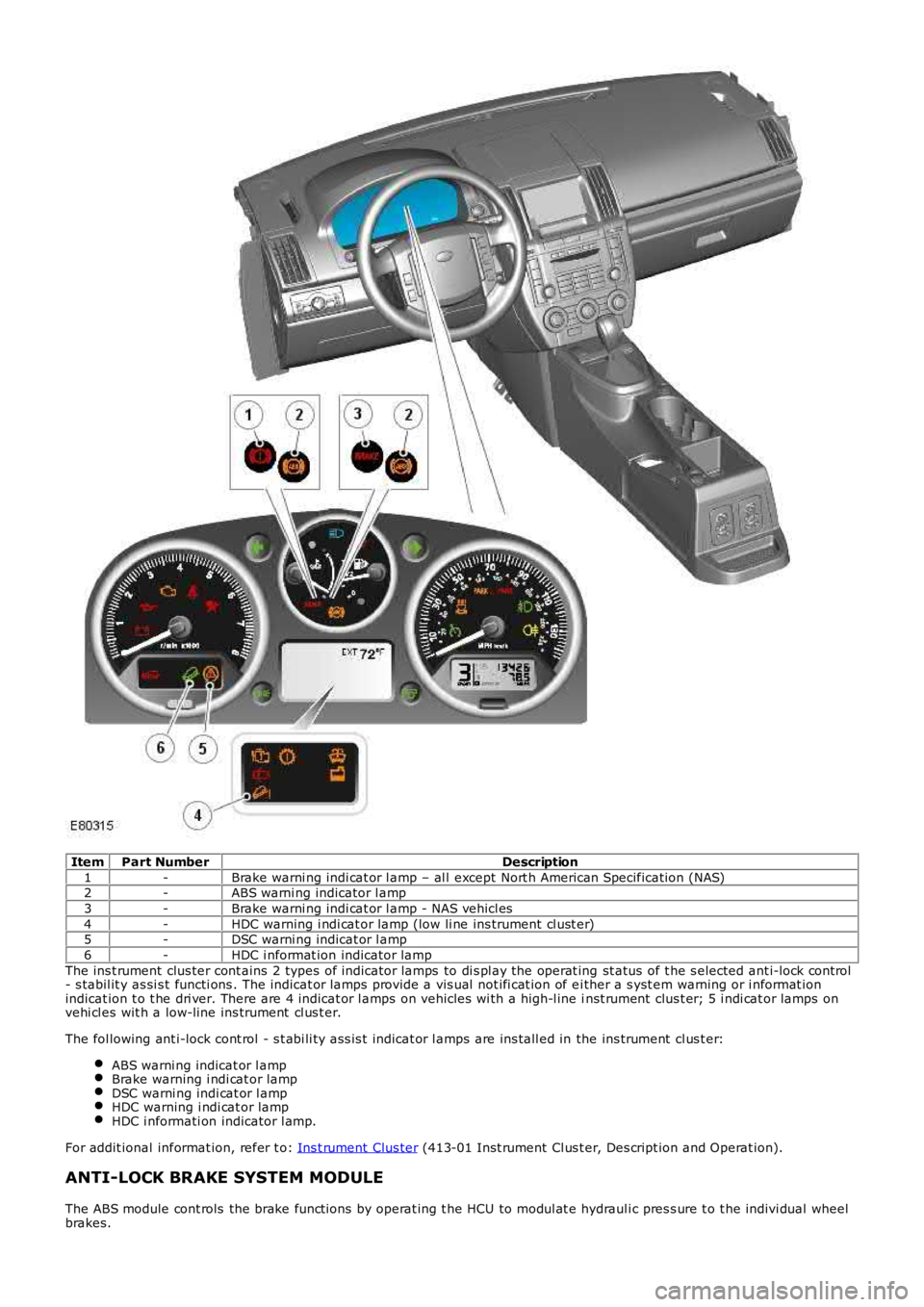

INSTRUMENT CLUSTER INDICATOR LAMPS

Page 517 of 3229

ItemPart NumberDescription

1-Brake warni ng indi cat or l amp – al l except Nort h American Specificati on (NAS)2-ABS warni ng indicator l amp

3-Brake warni ng indi cat or l amp - NAS vehicl es

4-HDC warning i ndi cat or lamp (low li ne ins trument cl ust er)5-DSC warni ng indicat or l amp

6-HDC i nformat ion indicator lamp

The ins t rument clus ter cont ains 2 types of indicator lamps to di s pl ay the operat ing st atus of t he s elected ant i-lock cont rol- s tabil it y as si s t functi ons . The indicat or l amps provide a vis ual not ifi cat ion of ei ther a s yst em warning or i nformat ionindicat ion t o t he dri ver. There are 4 indicat or l amps on vehicles wi th a high-l ine inst rument clus t er; 5 i ndi cat or lamps onvehi cl es wit h a low-line ins trument cl us t er.

The fol lowing ant i-lock cont rol - s t abi li ty as s is t indicat or l amps are ins tall ed in the ins trument cl us t er:

ABS warni ng indicat or l ampBrake warning i ndi cat or lampDSC warni ng indi cat or l ampHDC warning i ndi cat or lampHDC i nformati on indicator l amp.

For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

ANTI-LOCK BRAKE SYSTEM MODULE

The ABS module cont rols the brake funct ions by operat ing t he HCU to modul at e hydrauli c pres s ure t o t he indivi dual wheelbrakes.

Page 524 of 3229

s peed control '+' and '-' but t ons (dependant on vehi cl e s peci fi cat ion). The HDC Target speed wi ll als o vary depending ont he Terrai n Respons e™ mode sel ect ed.

Duri ng changes of target s peed, the ABS modul e li mit s vehicle decelerat ion and accelerat ion t o -0.5 met ers per s econd

s quared (m/s2) (-1.64 feet per s econd squared (ft/s2)); and +0.5 m/s2 (+1.64 ft/s2) res pect ively.

To provide a s afe t rans it ion from acti ve braking t o brakes off, the ABS module i nvokes a fade out st rat egy that graduall yrel eas es t he braking effort during act ive braking. The fade out s t rat egy occurs i f any of t he fol lowi ng condit ions i s detectedduri ng act ive braki ng:

HDC i s s elected off us i ng the HDC s wit ch.Failure of a component us ed by HDC, but not crit ical t o fade out funct ion.Accelerator pedal pres s ed when t rans mis s ion i s i n neut ral .Brakes overheat .

If fade out is i nvoked becaus e of HDC de-s el ect ion or component failure, the HDC functi on is cancel led by t he ABS module.If fade out is i nvoked becaus e t he accelerator pedal i s pres s ed wit h t he t ransmis s ion i n neut ral , or because of brakeoverheat , t he HDC funct ion remains in s tandby and res umes operati on when t he accelerat or pedal is releas ed or the brakeshave cooled.

The fade out s t rategy i ncreas es t he t arget speed at a cons tant accelerati on rat e of 0.5 m/s2 (1.64 ft/s2), unti l themaximum t arget speed i s reached, or unti l no act ive braki ng is required for 0.5 second. If t he accelerat or pedal is

posi ti oned wit hin t he range t hat infl uences t arget s peed, the accelerat ion rate is increas ed t o 1.0 m/s2 (3.3 ft /s2).

W hen fade out is i nvoked becaus e of component fai lure, a warning chime is sounded and the HDC informat ion i ndi cat orlamp is ext inguis hed. The HDC warning i ndicat or lamp is t hen il lumi nat ed (on low-li ne ins trument cl ust er), or a mes s ageadvi s ing of t he fault i s dis played in the mess age cent er (on hi gh-l ine i ns t rument clus ter).

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

W hen fade out is i nvoked becaus e of brake overheat, on vehicles wi th the hi gh-li ne ins t rument clus ter, a mes sage advis ingt hat HDC is t emporarily unavail abl e is di s pl ayed. On vehicles wit h t he low-line ins trument cl us t er, t he HDC warningindicat or l amp flas hes . At t he end of fade out, t he HDC informati on indicat or flas hes. The flas hing warni ng and informat ionindicat or l amps, and/or di spl ayed mes s age cont inue whi le HDC remai ns sel ect ed, unt il t he brakes have cooled.

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

To monit or for brake overheat, t he ABS modul e monit ors t he amount of braking acti vi ty and, from thi s, es ti mat es thet emperature of each brake. If the es t imat ed temperature of any brake exceeds a pres et li mit , t he ABS module i nvokes t hefade out s t rategy. Aft er the fade out cycle, t he HDC funct ion i s re-enabl ed when the ABS modul e es ti mates that all of thebrake t emperatures are at l ess than 64% of the preset t emperat ure l imi t.

Roll Stability Control

The RSC funct ion us es the brakes and the engine t o at tempt t o rest ore vehicle s tabilit y, i f the vehicle is forced i nt o ahars h maneuver t hat ri sks i t ti pping over.

The ABS module monit ors dri ver i nput s and vehicle behavior usi ng various powert rai n s ignals and t he i nput s from thewheel s peed s ens ors, t he s teering angle s ens or, the roll rate sens or, yaw rate and lateral accel erat ion s ensors. Thes einputs are compared wit h modeled behavi or and, if t he vehicle behavior reaches a given ris k level, t he ABS module cut st he engi ne power, or brakes one or more wheels suffi ci ent ly to al low the vehicle to regain s t abi li ty and hel p the driverremai n i n cont rol .

W hi le t he i gni ti on is energi zed, RSC i s permanentl y enabl ed even if t he DSC functi on is sel ect ed off.

Terrain Response™ System Integration

The Terrai n Res pons e™ funct ion integrat es t he ABS and other vehicle s ys tem cont rol modules t o as si s t the vehicle whendri vi ng off-road or during di fficult s urface condit ions . Terrai n Respons e is act ivated when the rotary cont rol s wit ch is s et t oa Terrain Res ponse special program.

W hen a Terrai n Respons e s peci al program i s acti vat ed, t he ABS module along wi th ot her vehicle s ys t em control modul eswil l operate in accordance wi th programmed software maps . The s oftware maps al low t he ABS s ys tem to functi on wit h at hreshol d that wi ll as si s t the s elected Terrai n Respons e s pecial program.For addit ional informat ion, refer t o: Ride and Handli ng Opti mizat ion (204-06 Ride and Handli ng Opt imi zat ion, Descripti onand Operat ion).

Page 666 of 3229

Publ ished: 11-May-2011

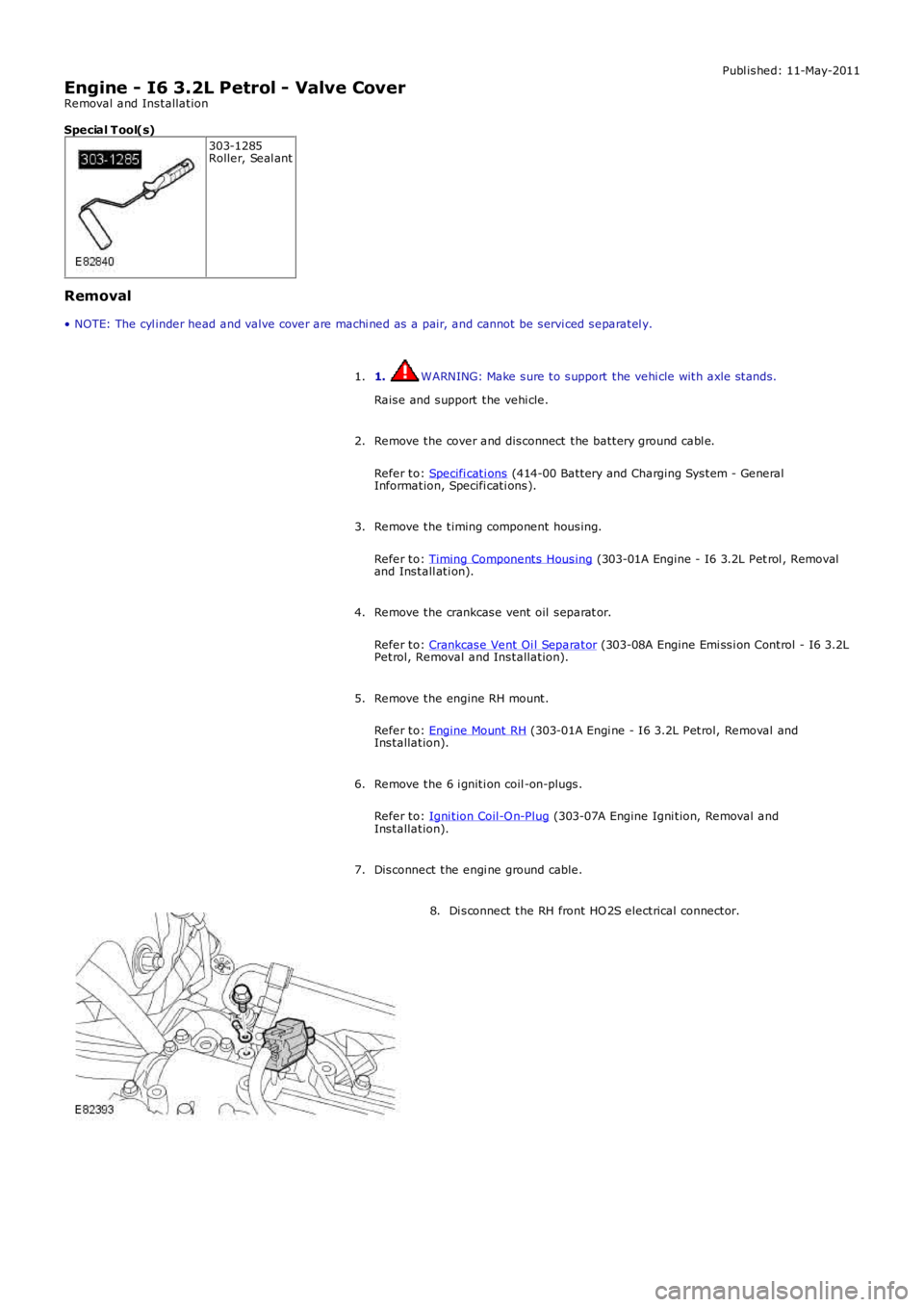

Engine - I6 3.2L Petrol - Valve Cover

Removal and Installation

Special T ool(s) 303-1285

Roller, Seal ant

Removal

• NOTE: The cyl inder head and valve cover are machi ned as a pair, and cannot be serv i ced separatel y.

1. WARNING: Make sure to support the vehi cle with axle stands.

Raise and support the vehi cle.

1.

Remove the cover and disconnect the battery ground cabl e.

Refer to: Specifi cati ons (414-00 Battery and Charging System - General

Information, Specifi cati ons).

2.

Remove the timing component housing.

Refer to: Timing Components Housing (303-01A Engine - I6 3.2L Pet rol , Removal

and Install ati on).

3.

Remove the crankcase vent oil separat or.

Refer to: Crankcase Vent Oi l Separator (303-08A Engine Emi ssi on Control - I6 3.2L

Petrol, Removal and Installation).

4.

Remove the engine RH mount.

Refer to: Engine Mount RH (303-01A Engi ne - I6 3.2L Petrol, Removal and

Installation).

5.

Remove the 6 i gniti on coil -on-plugs.

Refer to: Igni tion Coil-On-Plug (303-07A Engine Igni tion, Removal and

Installation).

6.

Disconnect the engi ne ground cable.

7. Di sconnect the RH front HO2S electrical connector.

8.

Page 912 of 3229

maximum t ime of run-on i s 360 s econdsThe EFCM can, by modul at ing the PW M control s i gnal, i nform t he ECM about the fan's st at us and any faul ts .

PW M cont rol of the fan mot or provides variabl e cont rol of fan speed t o ensure mi nimum fan noi se and reduced energycons umpt ion when fan operati on is required. The cont rol module is mount ed above the wade wat er ent ry li nesFor addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14A Electroni c Engine Controls - I6 3.2L Pet rol ,Des cript ion and Operat ion).

The cool ant expansi on tank provi des an expans ion volume and permit s eas y in-s ervice bleeding of t he cool ing s ys tem.Coolant level s ens ing i s precis e t o provide early warning i n t he event of low cool ant l evel . To prevent i ntrusi on int o t heexpans ion t ank's cas i ng, whi ch could be a potent ial leak path, a magnet ic float wi thin the t ank act ivat es a s wit ch locatedouts ide the t ank.

Page 943 of 3229

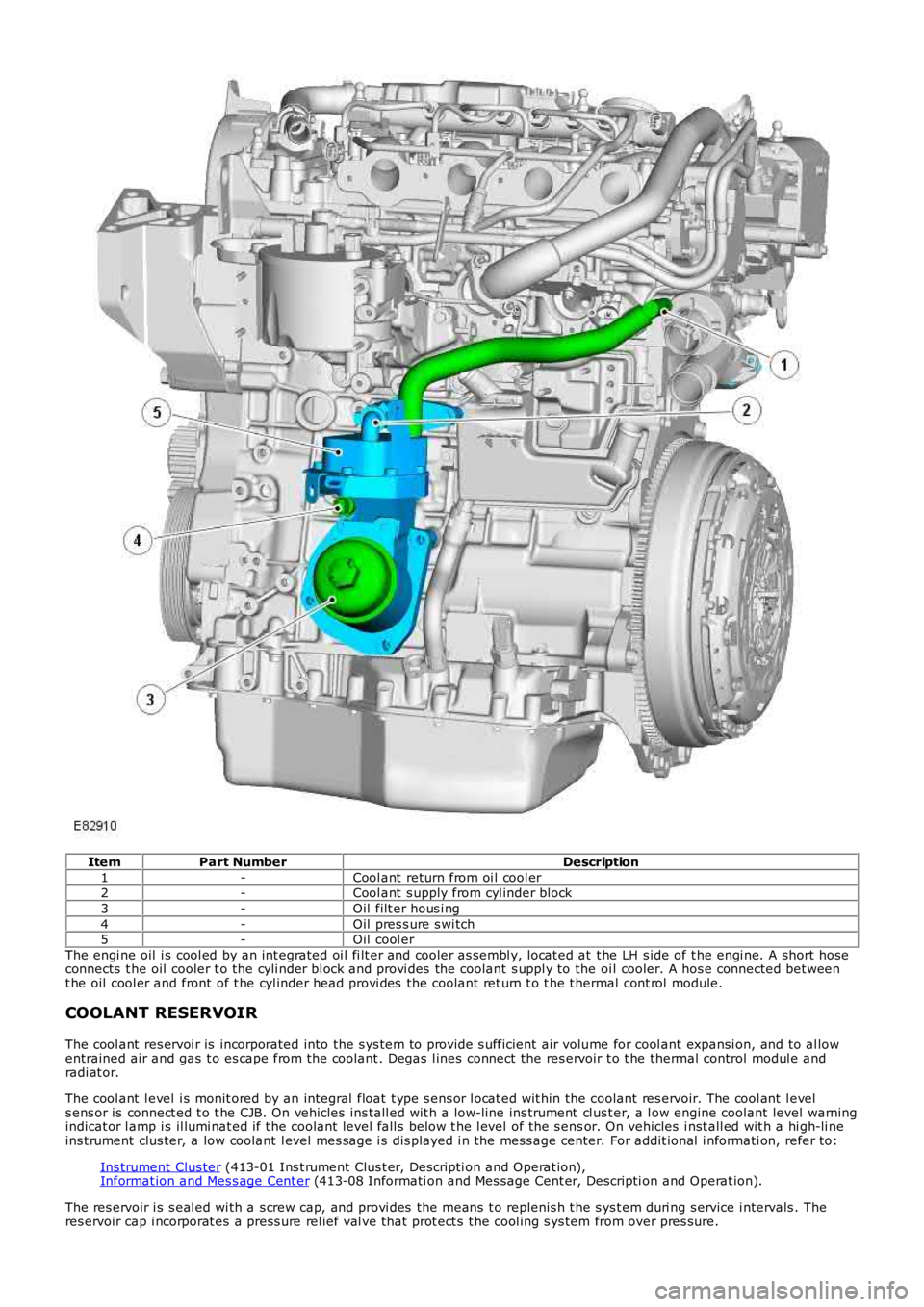

ItemPart NumberDescription

1-Cool ant return from oi l cool er2-Cool ant s upply from cyl inder block

3-Oil filt er hous i ng

4-Oil pres s ure s wi tch5-Oil cool er

The engi ne oil i s cool ed by an int egrated oi l fi lt er and cooler as sembl y, locat ed at t he LH s ide of t he engi ne. A s hort hoseconnects t he oil cooler t o the cyli nder bl ock and provi des the coolant s uppl y to the oi l cooler. A hos e connected bet weent he oil cool er and front of t he cyl inder head provi des the coolant ret urn t o t he t hermal cont rol module.

COOLANT RESERVOIR

The cool ant res ervoi r is incorporated into the s ys tem to provide s ufficient air volume for cool ant expansi on, and to al lowentrained air and gas t o es cape from the coolant . Degas l ines connect the res ervoir t o t he thermal control modul e andradi at or.

The cool ant l evel i s monit ored by an integral float t ype s ens or l ocat ed wit hin the coolant res ervoir. The cool ant l evels ens or is connect ed t o t he CJB. On vehicles ins tall ed wit h a low-line ins trument cl us t er, a l ow engine coolant level warningindicat or l amp i s il lumi nat ed if t he coolant level fall s below t he l evel of the s ensor. On vehicles i nst all ed wit h a hi gh-li neins t rument clus ter, a low coolant l evel mes sage i s dis played i n the mess age center. For addit ional i nformati on, refer to:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

The res ervoir i s s eal ed wi th a s crew cap, and provi des the means t o replenis h t he s ys t em duri ng s ervice i ntervals . Theres ervoir cap i ncorporat es a press ure rel ief val ve that prot ect s t he cool ing s ys tem from over pres sure.

Page 1100 of 3229

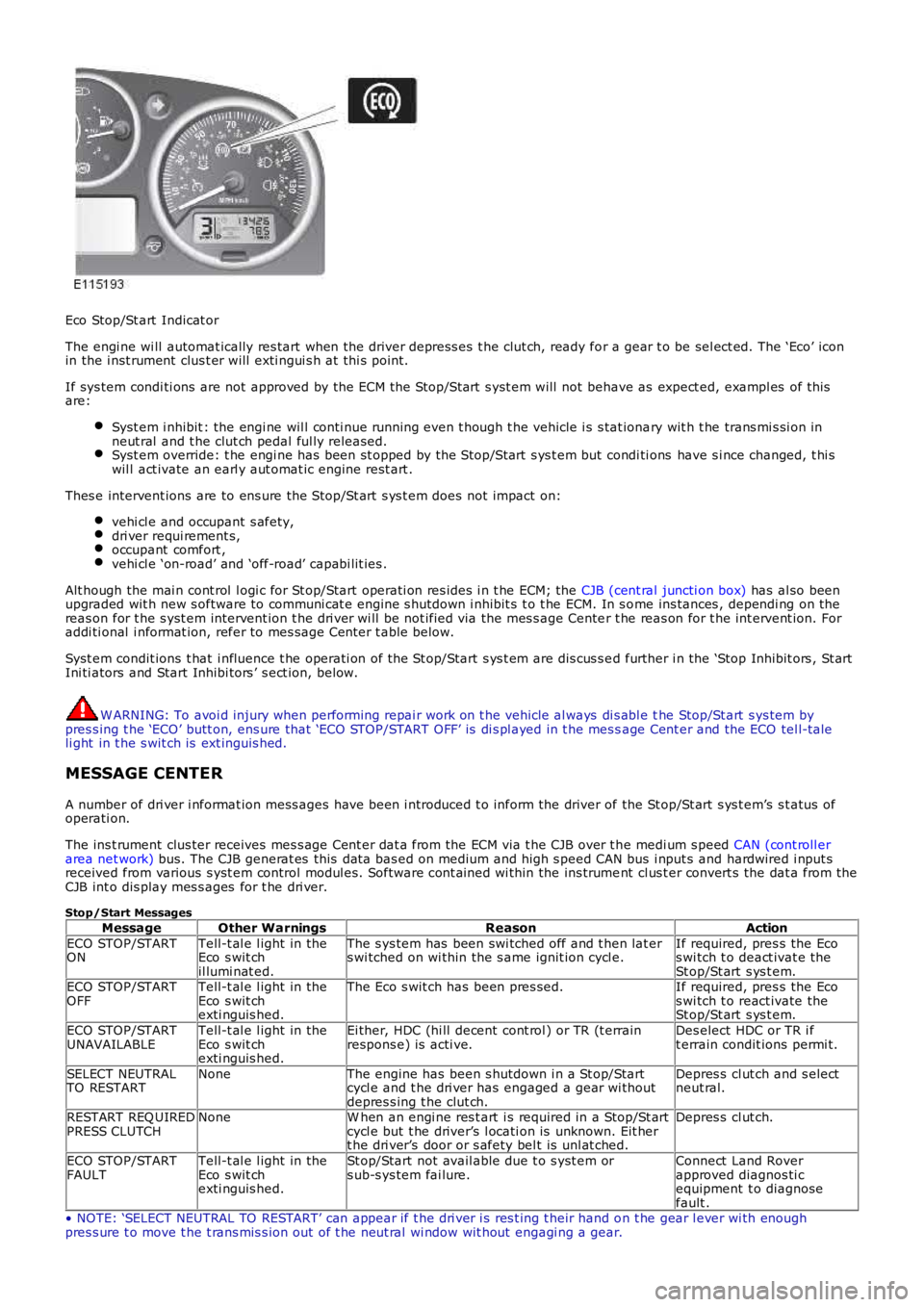

Eco Stop/St art Indicat or

The engi ne wi ll automat ically res tart when the driver depress es t he clut ch, ready for a gear t o be sel ect ed. The ‘Eco’ iconin the i nst rument clus t er will exti ngui s h at thi s point.

If sys tem condi ti ons are not approved by the ECM the St op/St art s yst em will not behave as expect ed, exampl es of thisare:

Syst em i nhibit : the engi ne wil l conti nue running even t hough t he vehicle i s s tat ionary wit h t he trans mi s si on inneut ral and t he clut ch pedal ful ly released.Syst em override: t he engi ne has been st opped by the St op/St art s ys t em but condi ti ons have s i nce changed, t hi swil l act ivate an earl y aut omat ic engine rest art .

Thes e intervent ions are to ens ure the St op/St art s ys t em does not impact on:

vehi cl e and occupant s afety,dri ver requi rement s,occupant comfort ,vehi cl e ‘on-road’ and ‘off-road’ capabi lit ies .

Alt hough the mai n cont rol l ogi c for St op/Start operati on res ides i n t he ECM; the CJB (cent ral juncti on box) has al so beenupgraded wit h new s oftware to communi cat e engine s hutdown i nhibit s t o t he ECM. In s ome ins tances , dependi ng on thereas on for t he s yst em intervent ion t he dri ver wi ll be not ified via the mes s age Center t he reas on for t he int ervent ion. Foraddi ti onal i nformat ion, refer to mes sage Center t able below.

Syst em condit ions t hat i nfluence t he operati on of the St op/Start s ys t em are dis cus s ed further i n the ‘Stop Inhibit ors , St artIni ti ators and Start Inhibi tors ’ s ect ion, below.

W ARNING: To avoi d injury when performing repai r work on t he vehicle al ways di s abl e the Stop/St art s ys tem bypres s ing t he ‘ECO’ butt on, ens ure that ‘ECO STOP/START OFF’ is di s pl ayed in t he mes sage Cent er and the ECO tel l-taleli ght in t he s wit ch is ext inguis hed.

MESSAGE CENTER

A number of dri ver i nformat ion mess ages have been i ntroduced t o inform the driver of the St op/St art s ys t em’s s t atus ofoperati on.

The ins t rument clus ter receives mes s age Cent er dat a from the ECM via t he CJB over t he medi um s peed CAN (cont roll erarea net work) bus. The CJB generat es this dat a bas ed on medium and high s peed CAN bus i nput s and hardwired i nput sreceived from various s yst em control modul es. Software cont ained wi thin the ins trument cl us t er convert s the dat a from theCJB int o dis play mes s ages for t he dri ver.

Stop/Start Messages

MessageOther WarningsReasonAction

ECO STOP/STARTONTell-t al e l ight in theEco s wit chil lumi nat ed.

The s ys tem has been swi tched off and t hen lat ers wi tched on wi thin the s ame ignit ion cycl e.If required, pres s the Ecos wi tch t o deact ivat e theSt op/St art s ys t em.ECO STOP/STARTOFFTell-t al e l ight in theEco s wit chexti nguis hed.

The Eco s wit ch has been pres sed.If required, pres s the Ecos wi tch t o react ivate theSt op/St art s ys t em.

ECO STOP/STARTUNAVAILABLETell-t al e l ight in theEco s wit chexti nguis hed.

Ei ther, HDC (hi ll decent cont rol ) or TR (t errainrespons e) is acti ve.Des elect HDC or TR i ft errain condit ions permi t.

SELECT NEUTRALTO RESTARTNoneThe engine has been s hutdown i n a St op/Startcycl e and t he dri ver has engaged a gear wi thoutdepres s ing t he clut ch.

Depres s cl ut ch and s electneut ral.

RESTART REQ UIREDPRESS CLUTCHNoneW hen an engi ne res t art i s required in a Stop/St artcycl e but t he driver’s l ocati on is unknown. Eit hert he dri ver’s door or s afety bel t is unl at ched.

Depres s cl ut ch.

ECO STOP/STARTFAULTTell-t al e l ight in theEco s wit chexti nguis hed.

St op/Start not avail able due t o s yst em ors ub-s ys tem fai lure.Connect Land Roverapproved diagnos ti cequipment t o diagnosefault .• NOTE: ‘SELECT NEUTRAL TO RESTART’ can appear if t he dri ver i s res t ing t heir hand on t he gear l ever wi th enoughpres s ure t o move t he t rans mis s ion out of t he neut ral wi ndow wit hout engagi ng a gear.