LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: weight, TPMS, AC Compressor control valve, Ecm, spark plugs replace, alarm, timing belt

Page 4201 of 4500

2.INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET

a. This is a method in which trouble is located by using a manifold gauge set. Read the manifold

gauge pressure when these conditions are established.

Test conditions:

Temperature at the air inlet with the switch set at RECIRC is 30 to 35°C (86 to 95°F)

Engine is running at 2,000 rpm

Blower speed control switch is at "HI"

Temperature control dial is at "COOL"

HINT:

It should be noted that the gauge indications may vary slightly due to ambient temperature

conditions.

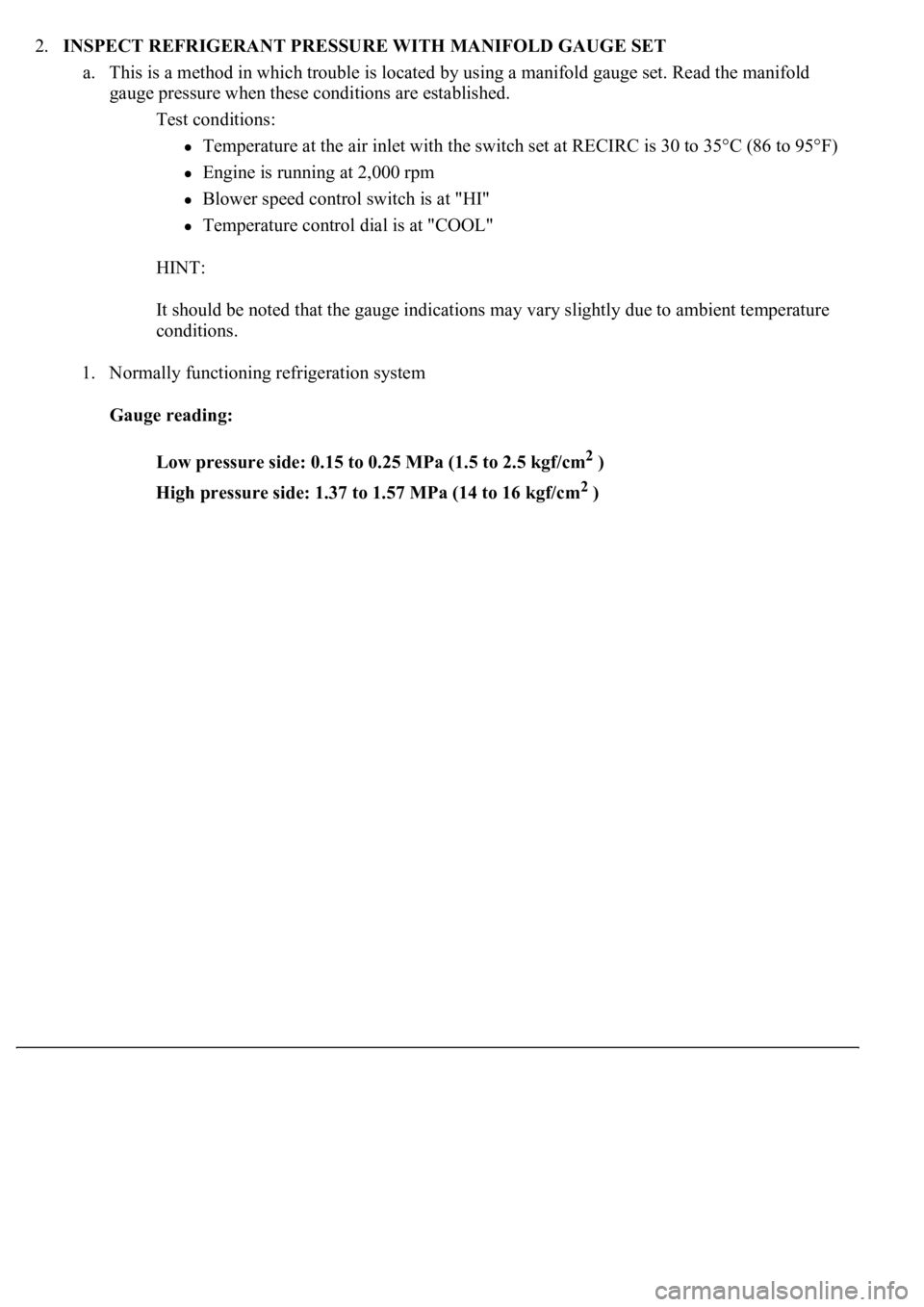

1. Normally functioning refrigeration system

Gauge reading:

Low pressure side: 0.15 to 0.25 MPa (1.5 to 2.5 kgf/cm

2 )

High pressure side: 1.37 to 1.57 MPa (14 to 16 kgf/cm

2 )

Page 4202 of 4500

Fig. 8: Identifying Normally Functioning Refrigeration System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

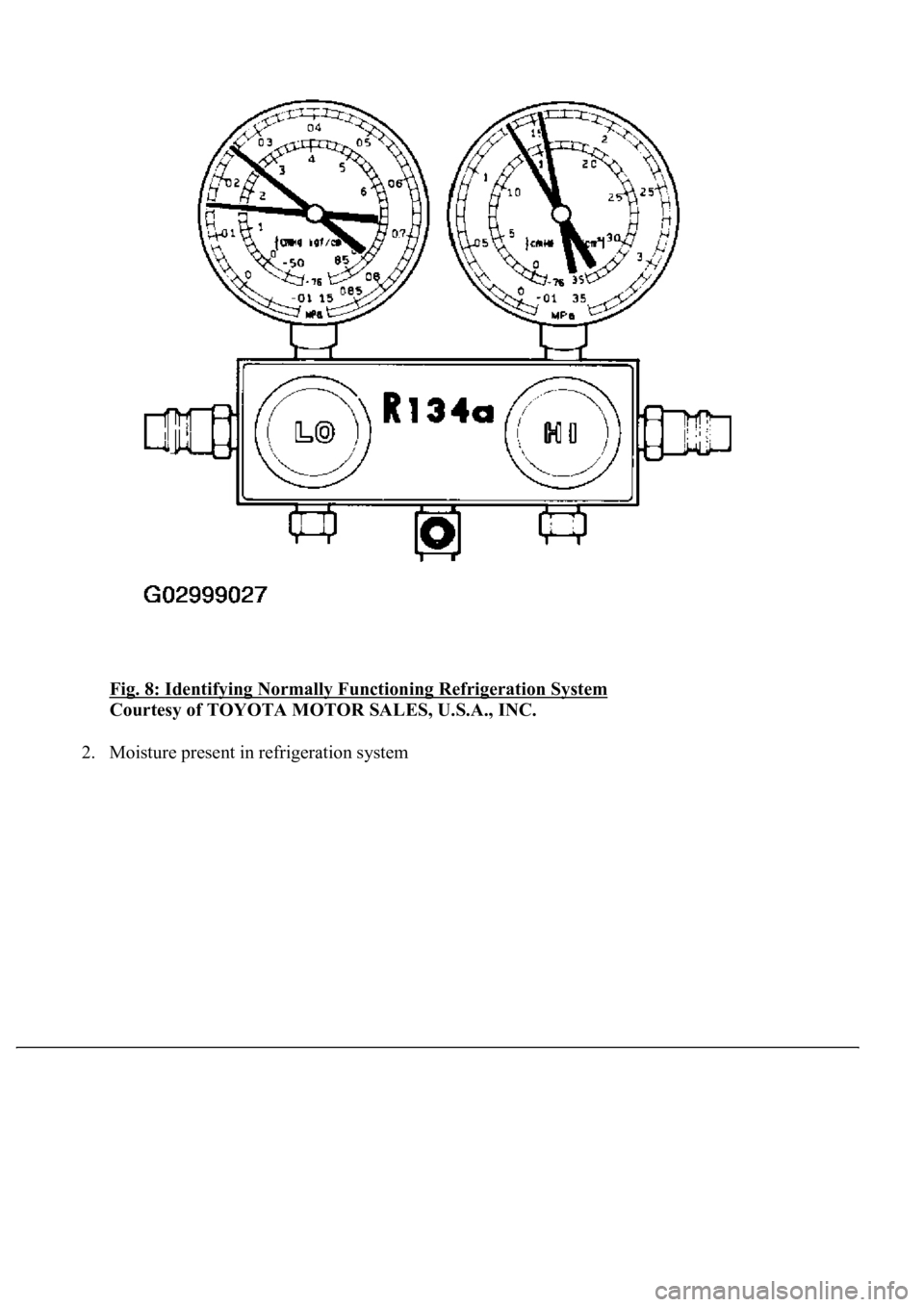

2. Moisture present in refri

geration system

Page 4203 of 4500

Fig. 9: Identifying Moisture Present In Refrigeration System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 10: Refrigerant Pressure With Manifold Gauge Set Chart (Moisture Present)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

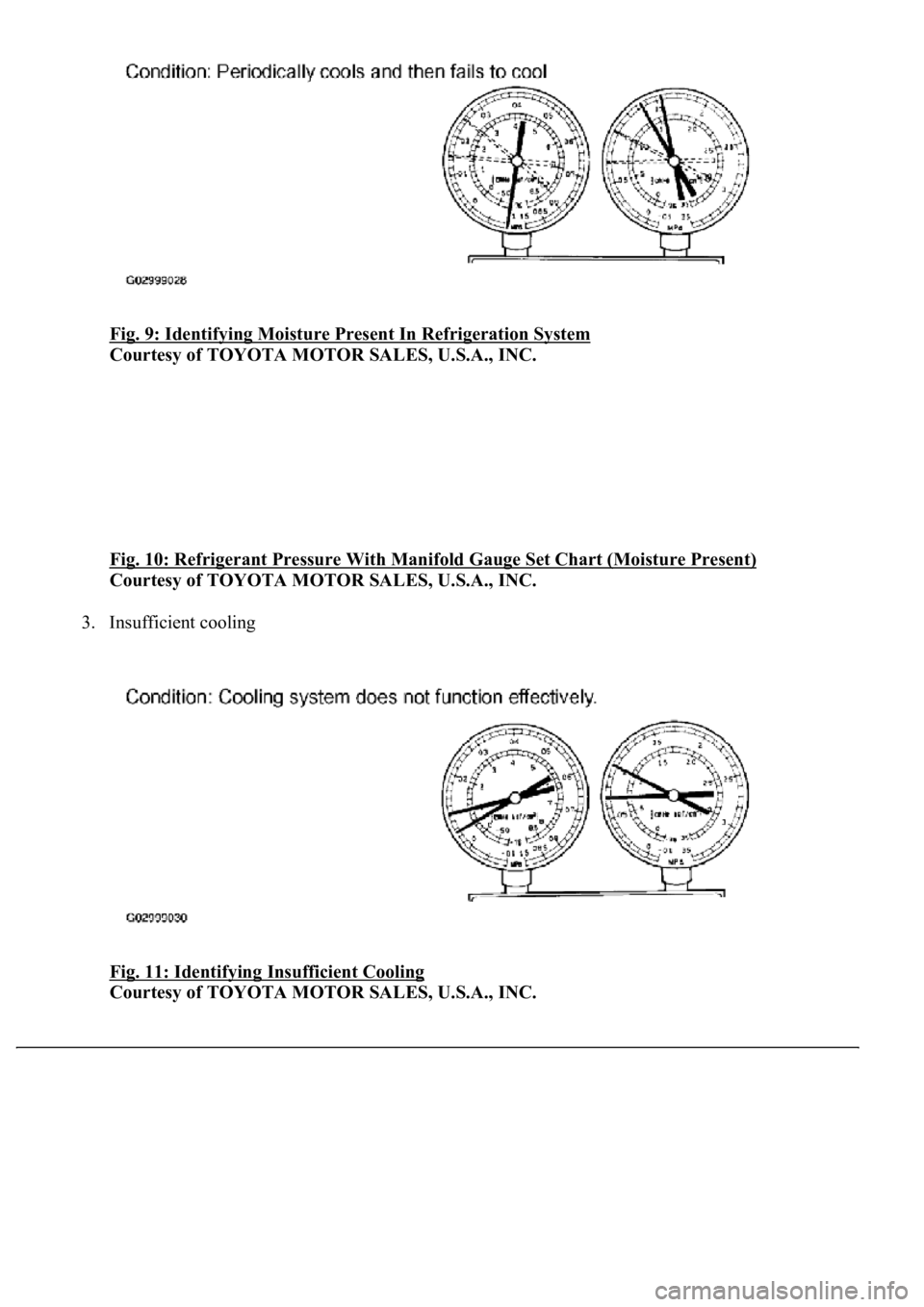

3. Insufficient cooling

Fig. 11: Identifying Insufficient Cooling

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 4204 of 4500

Fig. 12: Refrigerant Pressure With Manifold Gauge Set Chart (Insufficient Cooling)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

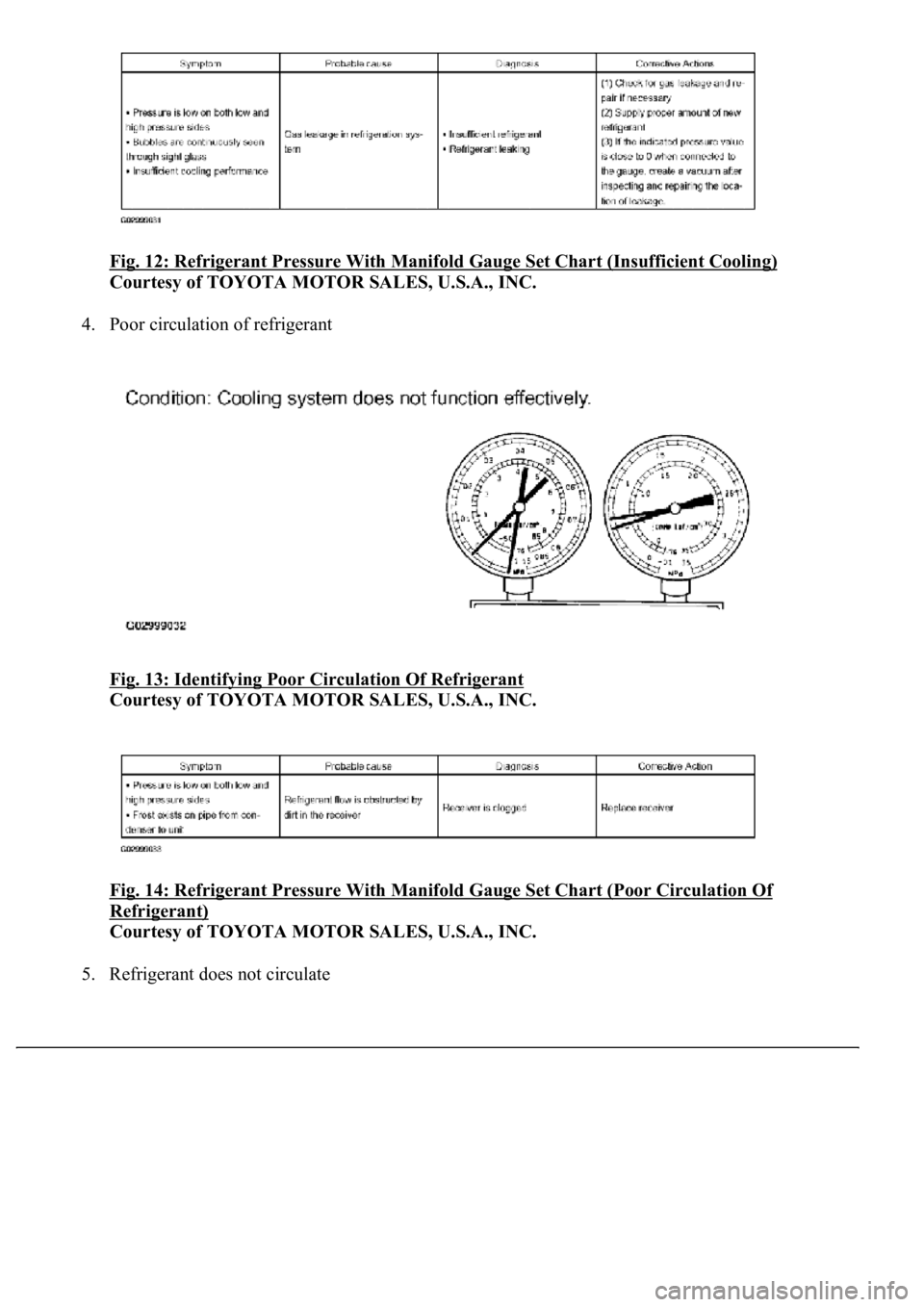

4. Poor circulation of refrigerant

Fig. 13: Identifying Poor Circulation Of Refrigerant

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 14: Refrigerant Pressure With Manifold Gauge Set Chart (Poor Circulation Of

Refrigerant)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

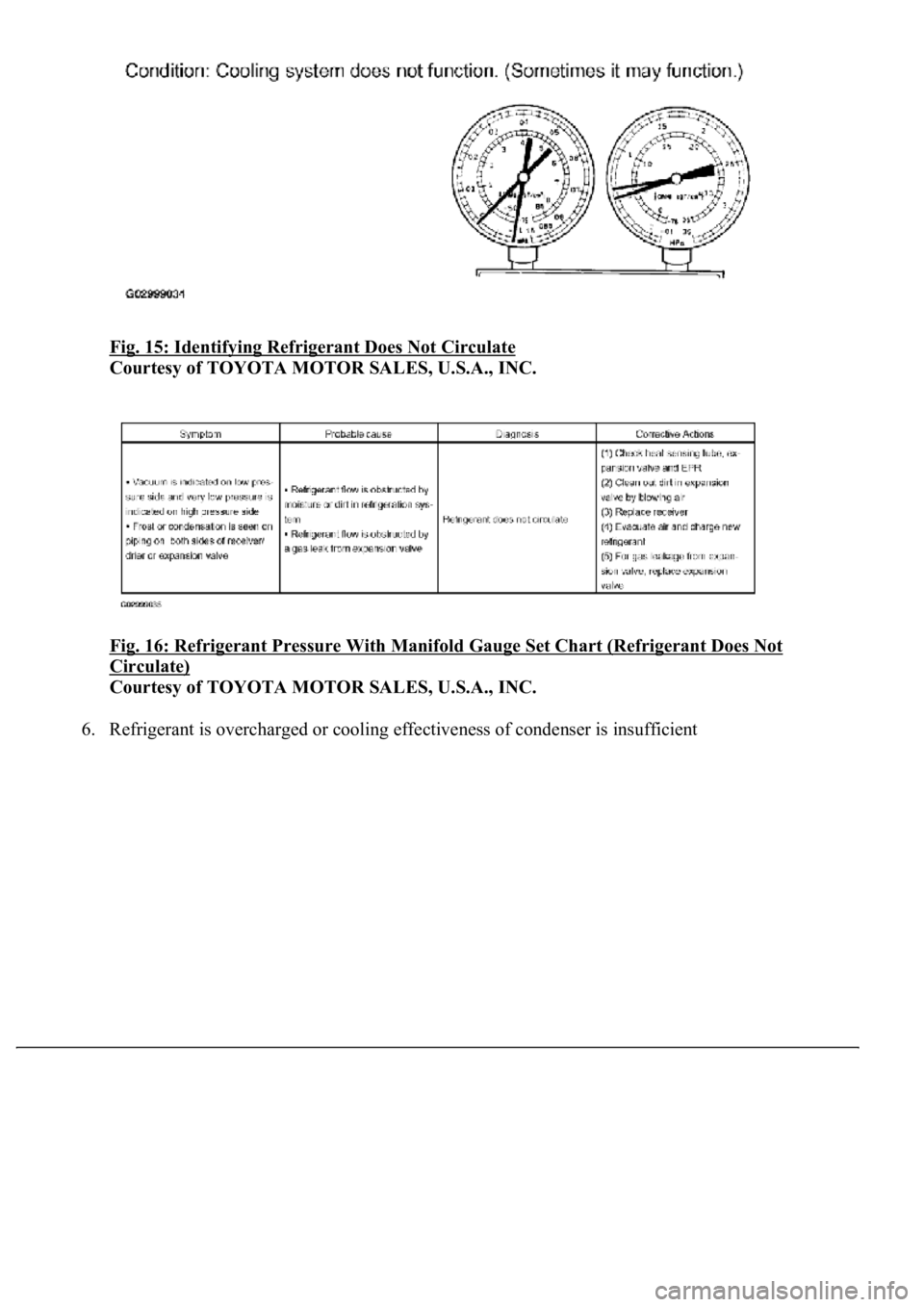

5. Refri

gerant does not circulate

Page 4205 of 4500

Fig. 15: Identifying Refrigerant Does Not Circulate

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 16: Refrigerant Pressure With Manifold Gauge Set Chart (Refrigerant Does Not

Circulate)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

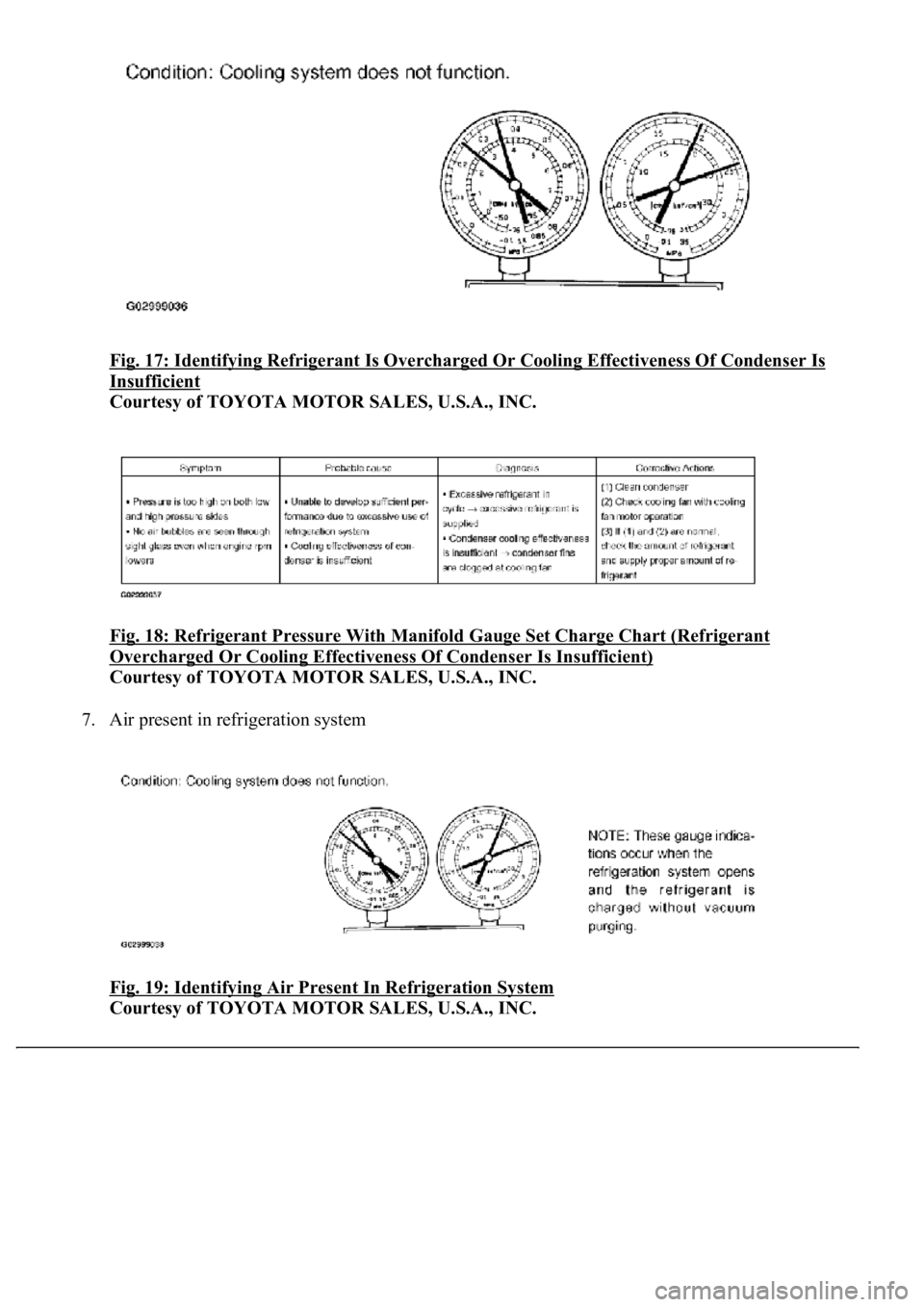

6. Refri

gerant is overcharged or cooling effectiveness of condenser is insufficient

Page 4206 of 4500

Fig. 17: Identifying Refrigerant Is Overcharged Or Cooling Effectiveness Of Condenser Is

Insufficient

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 18: Refrigerant Pressure With Manifold Gauge Set Charge Chart (Refrigerant

Overcharged Or Cooling Effectiveness Of Condenser Is Insufficient)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7. Air present in refrigeration system

Fig. 19: Identifying Air Present In Refrigeration System

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

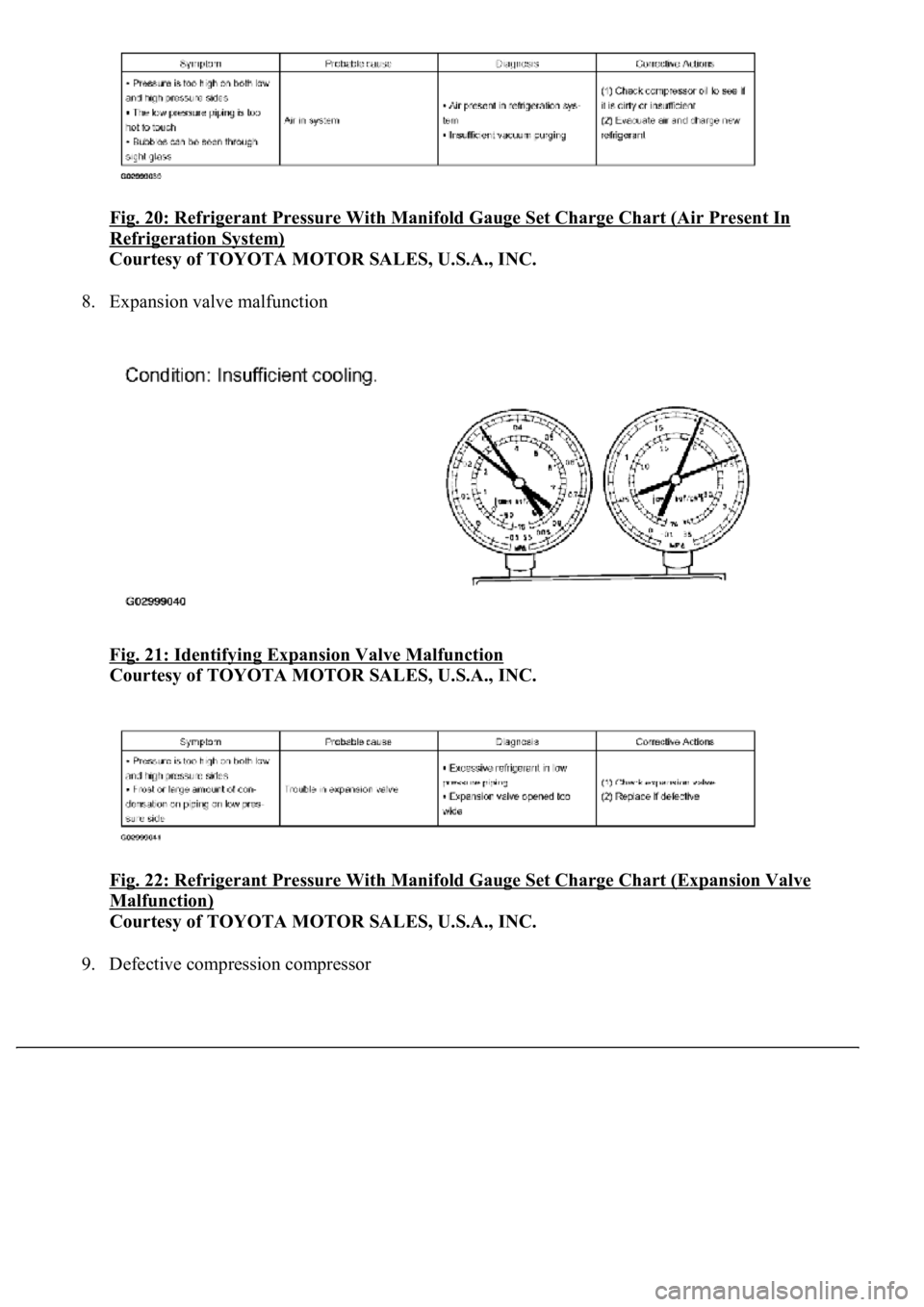

Page 4207 of 4500

Fig. 20: Refrigerant Pressure With Manifold Gauge Set Charge Chart (Air Present In

Refrigeration System)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8. Expansion valve malfunction

Fig. 21: Identifying Expansion Valve Malfunction

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 22: Refrigerant Pressure With Manifold Gauge Set Charge Chart (Expansion Valve

Malfunction)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

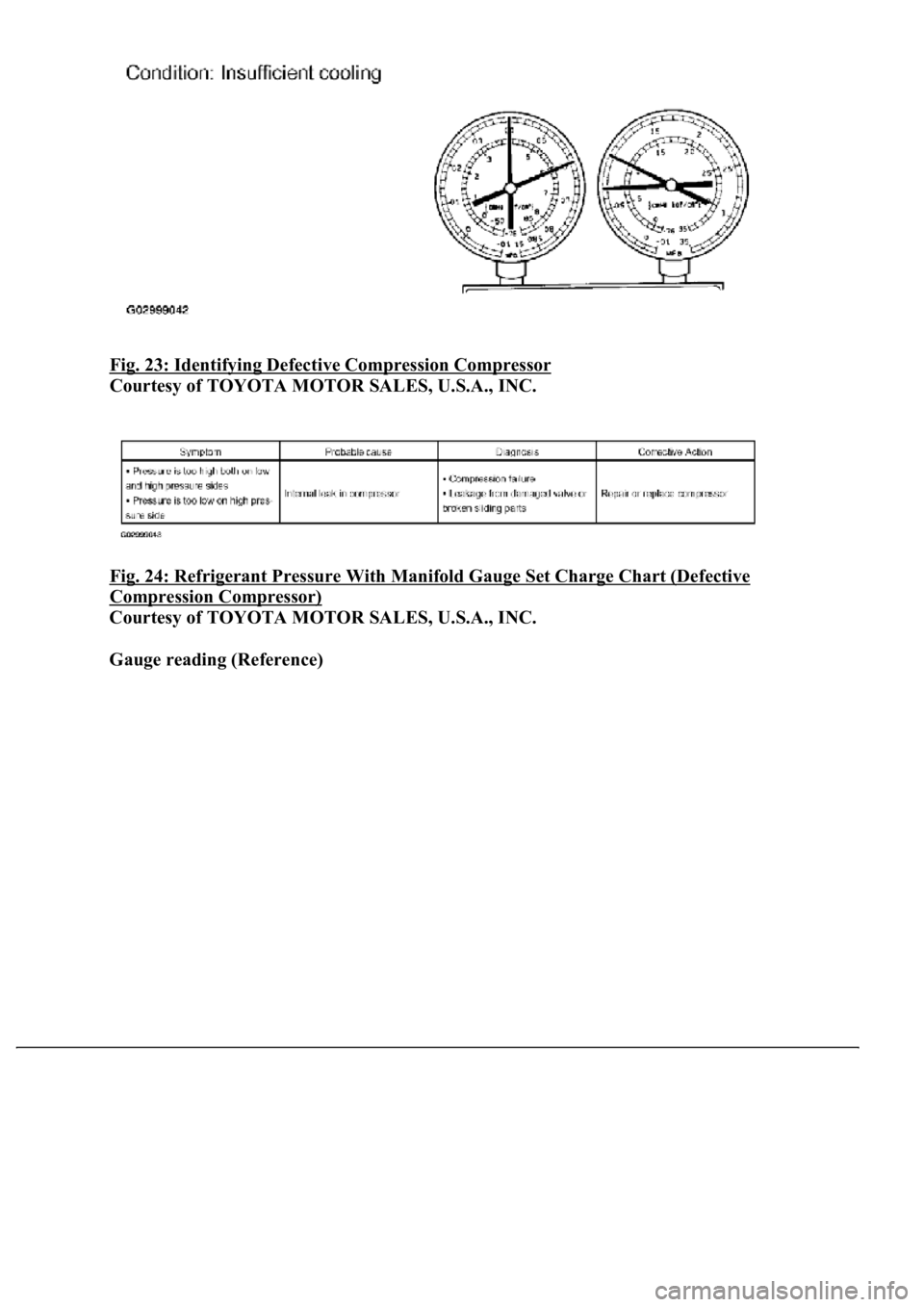

9. Defective compression compressor

Page 4208 of 4500

Fig. 23: Identifying Defective Compression Compressor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

<0029004c004a0011000300150017001d00030035004800490055004c004a004800550044005100570003003300550048005600560058005500480003003a004c0057004b0003003000440051004c00490052004f00470003002a00440058004a0048000300

360048005700030026004b00440055004a004800030026004b[art (Defective

Compression Compressor)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

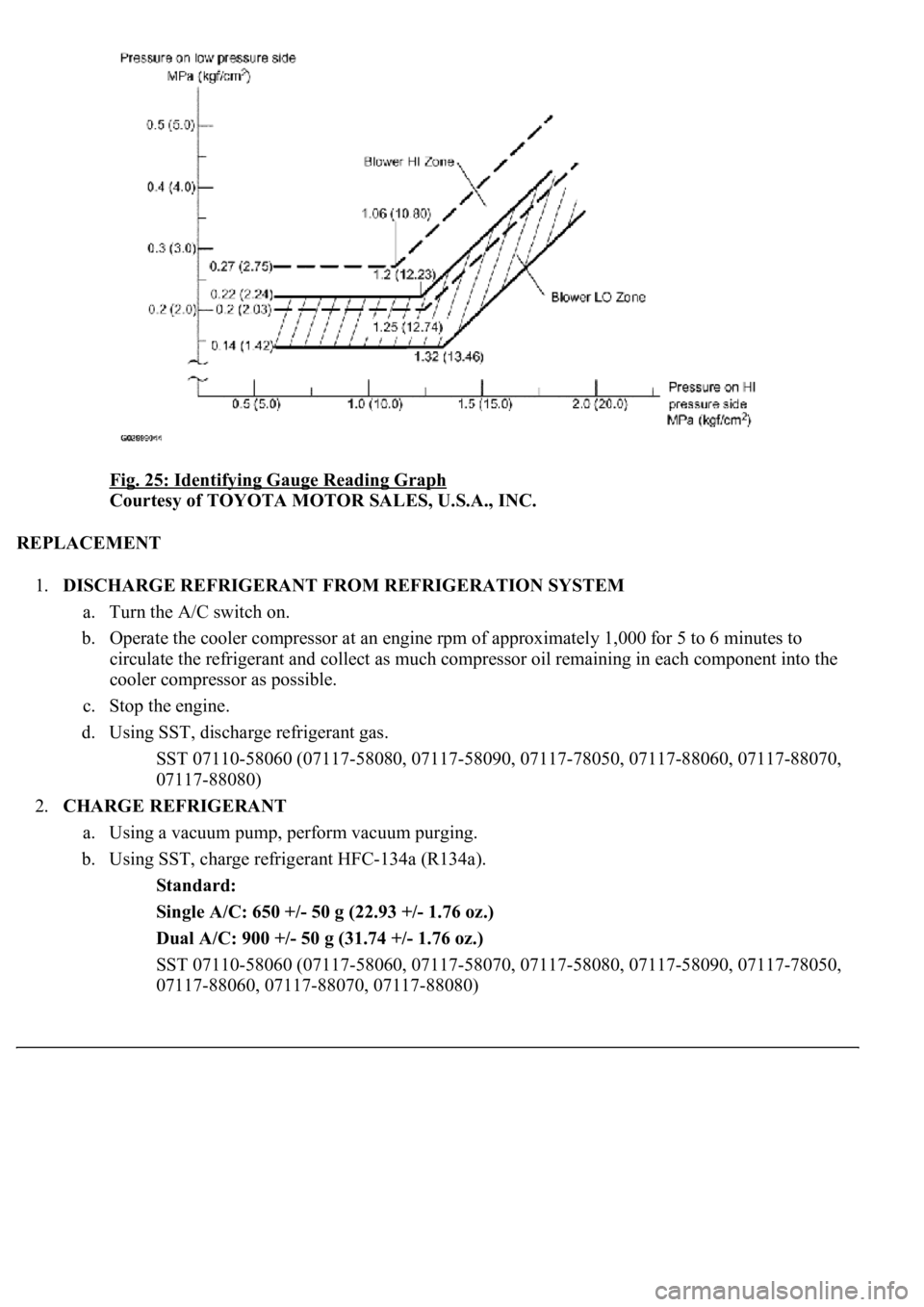

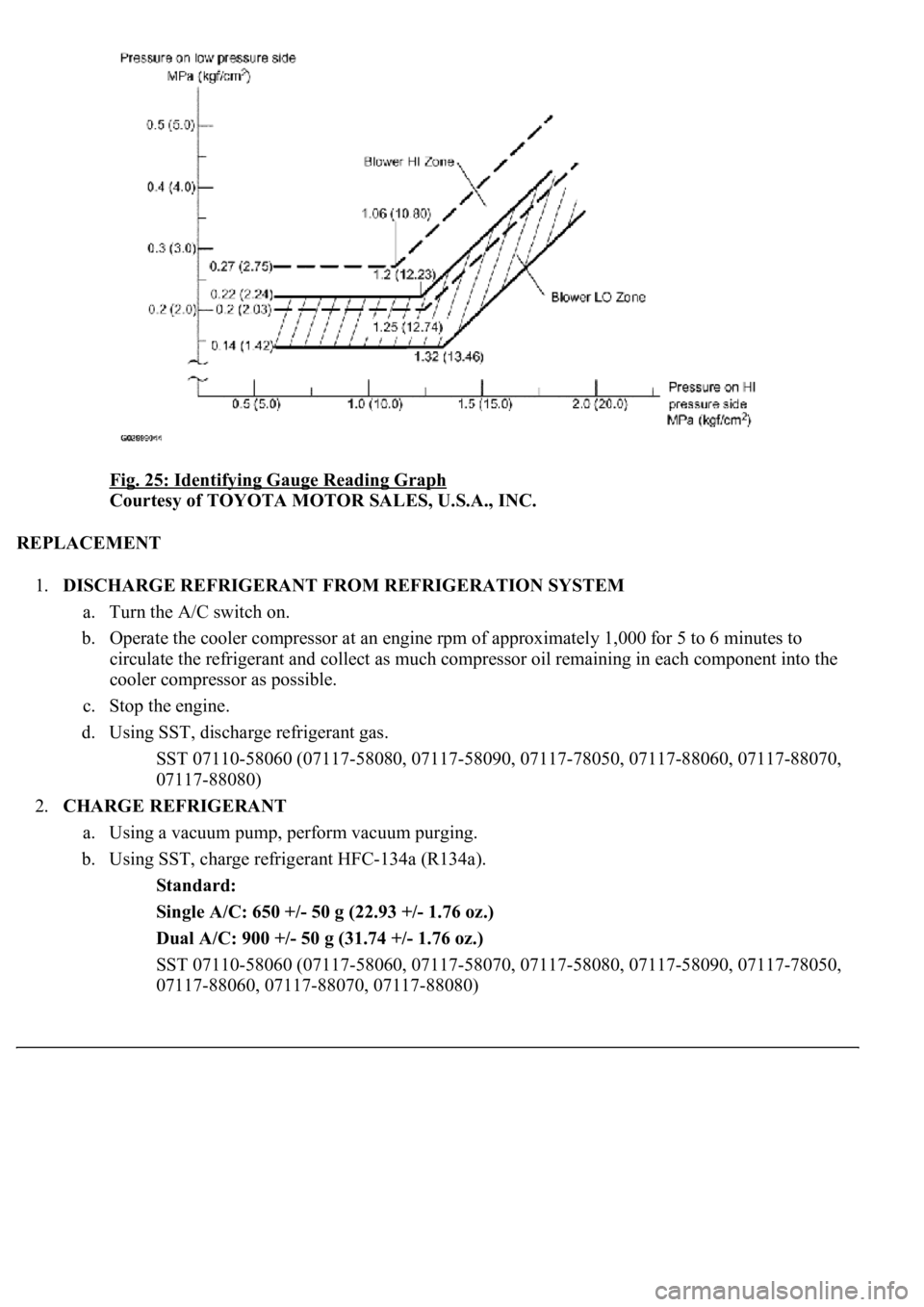

Gauge reading (Reference)

Page 4209 of 4500

Fig. 25: Identifying Gauge Reading Graph

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REPLACEMENT

1.DISCHARGE REFRIGERANT FROM REFRIGERATION SYSTEM

a. Turn the A/C switch on.

b. Operate the cooler compressor at an engine rpm of approximately 1,000 for 5 to 6 minutes to

circulate the refrigerant and collect as much compressor oil remaining in each component into the

cooler compressor as possible.

c. Stop the engine.

d. Using SST, discharge refrigerant gas.

<00360036003700030013001a00140014001300100018001b0013001900130003000b0013001a00140014001a00100018001b0013001b0013000f00030013001a00140014001a00100018001b0013001c0013000f00030013001a00140014001a0010001a00

1b001300180013000f00030013001a00140014001a0010001b[8060, 07117-88070,

07117-88080)

2.CHARGE REFRIGERANT

a. Using a vacuum pump, perform vacuum purging.

b. Using SST, charge refrigerant HFC-134a (R134a).

Standard:

Single A/C: 650 +/- 50 g (22.93 +/- 1.76 oz.)

Dual A/C: 900 +/- 50 g (31.74 +/- 1.76 oz.)

<00360036003700030013001a00140014001300100018001b0013001900130003000b0013001a00140014001a00100018001b001300190013000f00030013001a00140014001a00100018001b0013001a0013000f00030013001a00140014001a0010001800

1b0013001b0013000f00030013001a00140014001a00100018[8090, 07117-78050,

07117-88060, 07117-88070, 07117-88080)

Page 4210 of 4500

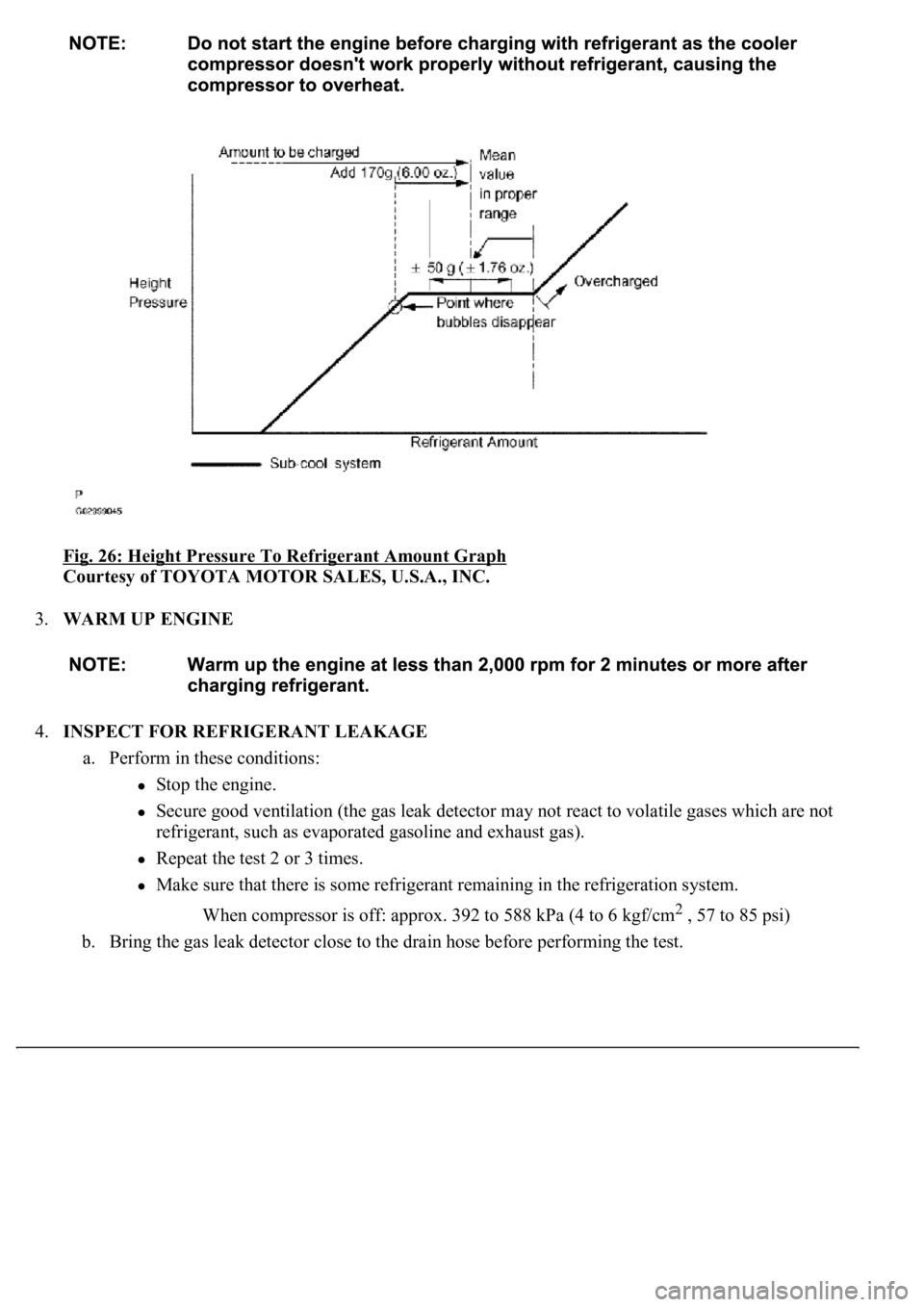

Fig. 26: Height Pressure To Refrigerant Amount Graph

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3.WARM UP ENGINE

4.INSPECT FOR REFRIGERANT LEAKAGE

a. Perform in these conditions:

Stop the engine.

Secure good ventilation (the gas leak detector may not react to volatile gases which are not

refrigerant, such as evaporated gasoline and exhaust gas).

Repeat the test 2 or 3 times.

Make sure that there is some refrigerant remaining in the refrigeration system.

When compressor is off: approx. 392 to 588 kPa (4 to 6 kgf/cm

2 , 57 to 85 psi)

b. Bring the gas leak detector close to the drain hose before performing the test.

Trending: charging, height, water pump, Spd, air conditioning, battery replacement, oil pressure