brake sensor MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 712 of 909

M–82

TROUBLESHOOTING

FOREWORDA6E638027100202

End Of Sie

SYMPTOM TROUBLESHOOTINGA6E638027100203•Verify the symptoms, and perform troubleshooting according to the appropriate number.

End Of Sie

NO.1 FREQUENT FRONT WHEEL SLIPA6E638027100204

Warning

•During simulation driving, vehicle stability may decrease extremely and cause an accident. Be

sure to perform the simulation test driving in a safe area.

Malfunction vehicle delivered

Questionnaire

Verify malfunction symptoms

Symptom troubleshooting

Verify that malfunctions have been repaired

Troubleshooting completedConfirm all customer problems using a questionnaire.

Confirm malfunction on actual vehicle.

DTC inspection

Inspect for DTCs using WDS or equivalent.

Perform applicable troubleshooting inspection according to

diagnostic index.

A6E63802001

No. Symptom Description

1 Frequent front wheel slip Front wheels slip frequently during acceleration on low-friction road.

2

Tight corner braking effectBrakes seem to be applied during tight cornering while driving very

slowly on paved road.

3 Abnormal noise and/or vibration from

coupling unitThere is abnormal noise and/or vibration from coupling unit during

driving.

1 Frequent front wheel slip

[TROUBLESHOOTING HINTS]

•Tire traction performance is extremely poor for given road friction. (4WD system is normal.)

•Improper wheel alignment (4WD system is normal.)

•Rear differential oil temperature is extremely high (Fail-safe condition)

•Differential oil temperature sensor malfunction (Fail-safe condition)

•Compare slip frequency with another vehicle of the same model (under the same road conditions and tire traction

performance).

•Replace tires with others of the same model and perform test under the same road conditions to determine if the

malfunction was caused by tire traction performance.

•Coupling component malfunction

•4WD solenoid malfunction

Page 713 of 909

TROUBLESHOOTING

M–83

M

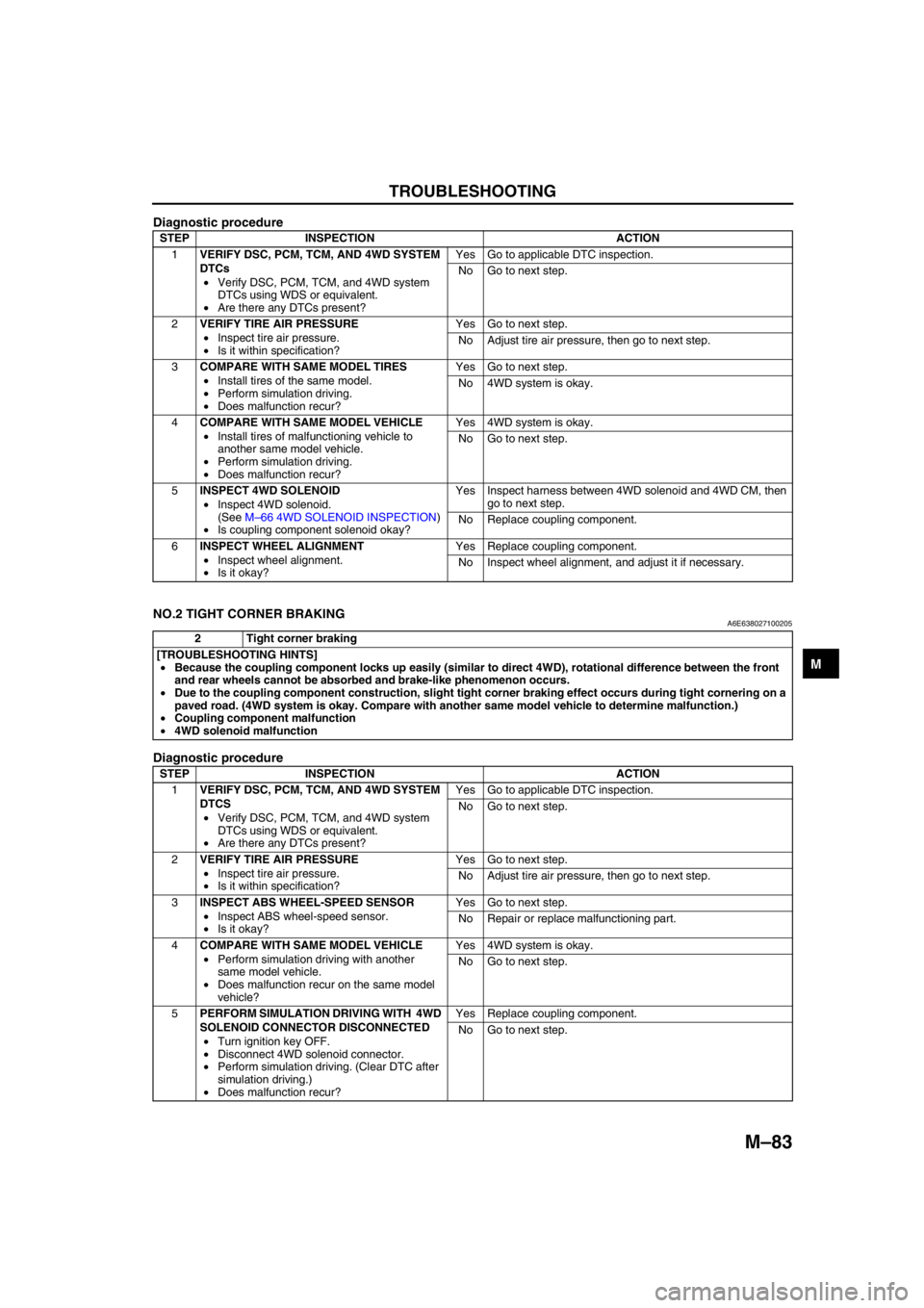

Diagnostic procedure

End Of Sie

NO.2 TIGHT CORNER BRAKINGA6E638027100205

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCs

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3COMPARE WITH SAME MODEL TIRES

•Install tires of the same model.

•Perform simulation driving.

•Does malfunction recur?Yes Go to next step.

No 4WD system is okay.

4COMPARE WITH SAME MODEL VEHICLE

•Install tires of malfunctioning vehicle to

another same model vehicle.

•Perform simulation driving.

•Does malfunction recur?Yes 4WD system is okay.

No Go to next step.

5INSPECT 4WD SOLENOID

•Inspect 4WD solenoid.

(See M–66 4WD SOLENOID INSPECTION)

•Is coupling component solenoid okay?Yes Inspect harness between 4WD solenoid and 4WD CM, then

go to next step.

No Replace coupling component.

6INSPECT WHEEL ALIGNMENT

•Inspect wheel alignment.

•Is it okay?Yes Replace coupling component.

No Inspect wheel alignment, and adjust it if necessary.

2 Tight corner braking

[TROUBLESHOOTING HINTS]

•Because the coupling component locks up easily (similar to direct 4WD), rotational difference between the front

and rear wheels cannot be absorbed and brake-like phenomenon occurs.

•Due to the coupling component construction, slight tight corner braking effect occurs during tight cornering on a

paved road. (4WD system is okay. Compare with another same model vehicle to determine malfunction.)

•Coupling component malfunction

•4WD solenoid malfunction

STEP INSPECTION ACTION

1VERIFY DSC, PCM, TCM, AND 4WD SYSTEM

DTCS

•Verify DSC, PCM, TCM, and 4WD system

DTCs using WDS or equivalent.

•Are there any DTCs present?Yes Go to applicable DTC inspection.

No Go to next step.

2VERIFY TIRE AIR PRESSURE

•Inspect tire air pressure.

•Is it within specification?Yes Go to next step.

No Adjust tire air pressure, then go to next step.

3INSPECT ABS WHEEL-SPEED SENSOR

•Inspect ABS wheel-speed sensor.

•Is it okay?Yes Go to next step.

No Repair or replace malfunctioning part.

4COMPARE WITH SAME MODEL VEHICLE

•Perform simulation driving with another

same model vehicle.

•Does malfunction recur on the same model

vehicle?Yes 4WD system is okay.

No Go to next step.

5PERFORM SIMULATION DRIVING WITH 4WD

SOLENOID CONNECTOR DISCONNECTED

•Turn ignition key OFF.

•Disconnect 4WD solenoid connector.

•Perform simulation driving. (Clear DTC after

simulation driving.)

•Does malfunction recur?Yes Replace coupling component.

No Go to next step.

Page 734 of 909

P–1

P

PBRAKING SYSTEM

OUTLINE................................................................ P-2

OUTLINE OF CONSTRUCTION.......................... P-2

FEATURES .......................................................... P-2

SPECIFICATIONS ............................................... P-2

STRUCTURAL VIEW ........................................... P-3

ABS/TCS................................................................ P-4

OUTLINE.............................................................. P-4

DYNAMIC STABILITY CONTROL......................... P-6

OUTLINE.............................................................. P-6

COMBINE SENSOR

(FORWARD-G SENSOR) ................................. P-8

CONTROLLER AREA NETWORK (CAN) ........... P-8

ON-BOARD DIAGNOSTIC..................................... P-9

OUTLINE.............................................................. P-9

OUTLINE.............................................................. P-10

SUPPLEMENTAL SERVICE INFORMATION ... P-10

GENERAL PROCEDURES.................................. P-10

PRECAUTION (BRAKES).................................. P-10

CONVENTIONAL BRAKE SYSTEM.................... P-11

POWER BRAKE UNIT

REMOVAL/INSTALLATION ............................ P-11

VACUUM SWITCH INSPECTION

(MZR-CD (RF TURBO)) .................................. P-11

VACUUM SWITCH

REMOVAL/INSTALLATION

(MZR-CD (RF TURBO)) .................................. P-12

VACUUM PUMP INSPECTION

(MZR-CD (RF TURBO)) .................................. P-12

VACUUM PUMP REMOVAL/INSTALLATION

(MZR-CD (RF TURBO)) .................................. P-13

FRONT BRAKE (DISC) INSPECTION............... P-13

FRONT BRAKE (DISC)

REMOVAL/INSTALLATION ............................ P-14

DISC PAD (FRONT) REPLACEMENT .............. P-16

PARKING BRAKE SYSTEM................................ P-17

PARKING BRAKE (LEVER TYPE)

ADJUSTMENT ................................................ P-17

DYNAMIC STABILITY CONTROL....................... P-17

DSC HU/CM INSPECTION ................................ P-17

COMBINE SENSOR

(FORWARD-G SENSOR) INSPECTION ........ P-20

ON-BOARD DIAGNOSTIC................................... P-21

DSC ON-BOARD DIAGNOSIS .......................... P-21

DTC C1119 ........................................................ P-26

DTC C1949, C1950............................................ P-27

DTC U2511 ........................................................ P-29 FEATURES

SERVICE

Page 735 of 909

P–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E690201020201•The construction and operation of the braking system is the same as that of the current Mazda6 (GG) L8, LF,

L3 engine 2WD model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E690201020202Modifications to match vehicle characteristics

•Due to the addition of the MZR-CD (RF Turbo) engine, the vacuum pump and vacuum switch have been

added.

•Due to the addition of the 4WD model, DSC HU/CM uses the forward-G signal from combine sensor to control

DSC.

End Of Sie

SPECIFICATIONSA6E690201020203

Bold frames: New specifications

End Of Sie

OUTLINE

ItemSpecification

New Mazda6 (GG, GW) Current Mazda6 (GG)

Brake pedalType Suspended

Pedal lever ratio 2.7

Max. stroke (mm {in}) 128.5 {5.06}

Master

cylinderType Tandem (with level sensor)

Cylinder diameter (mm {in}) 20.64 {0.813}

Front disc

brakeType Ventilated disc

Cylinder bore (mm {in}) 57.15 {2.250}

Pad dimensions (area × thickness) L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

4,010 {6.42} × 12.0 {0.47}L8, LF (GCC specs.):

4,220 {6.75} × 10.0 {0.39}

LF (European (L.H.D. U.K.) specs.),

L3: 4,010 {6.42} × 12.0 {0.47} (mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.)

specs.), L3, MZR-CD (RF Turbo):

283 {11.1} × 25.0 {0.984}L8, LF (GCC specs.):

274 {10.8} × 24.0 {0.945}

LF (European (L.H.D. U.K.) specs.),

L3: 283 {11.1} × 25.0 {0.984} (mm {in} × mm {in})

Rear brake

(disc)Type Solid disc

Cylinder bore (mm {in}) 34.93 {1.375}

Pad dimensions (area × thickness)

2,810 {4.51} × 8.0 {0.31}

(mm

2 {in2} × mm {in})

Disc plate dimensions

(outer diameter × thickness)

280 {11.0} × 10.0 {0.39}

(mm {in})

Power brake

unitType Vacuum multiplier, single diaphragm

Diameter (mm {in}) 279 {10.9}

Braking force

control deviceTypeWith ABS: EBD (Electronic Brakeforce Distribution)

Without ABS: Dual proportioning valve

Parking brakeType Mechanical two-rear-wheel control

Operation system Center lever type

Brake fluid TypeEuropean (L.H.D. U.K.) specs.: SAE J1703, FMVSS116 DOT3 OR DOT4

GCC specs.: SAE J1703, FMVSS116 DOT3

Page 736 of 909

OUTLINE

P–3

P

STRUCTURAL VIEWA6E690201020204

.

End Of Sie

7

53

1

2

6

7

53

6

89

4

4

8

10

15

14

15

14

12

13

13

12

11

11

16

16

A6E6902W201

1L.H.D.

2 R.H.D.

3 Brake pedal

4 Master cylinder

5 Power brake unit

6 Front brake (disc)

7 Rear brake (disc)

8 Vacuum pump9 Without ABS

10 Dual proportioning valve

11 ABS (ABS/TCS) or DSC HU/CM

12 ABS wheel-speed sensor (front)

13 ABS sensor rotor (front)

14 ABS wheel-speed sensor (rear)

15 ABS sensor rotor (rear)

16 Combine sensor

Page 737 of 909

P–4

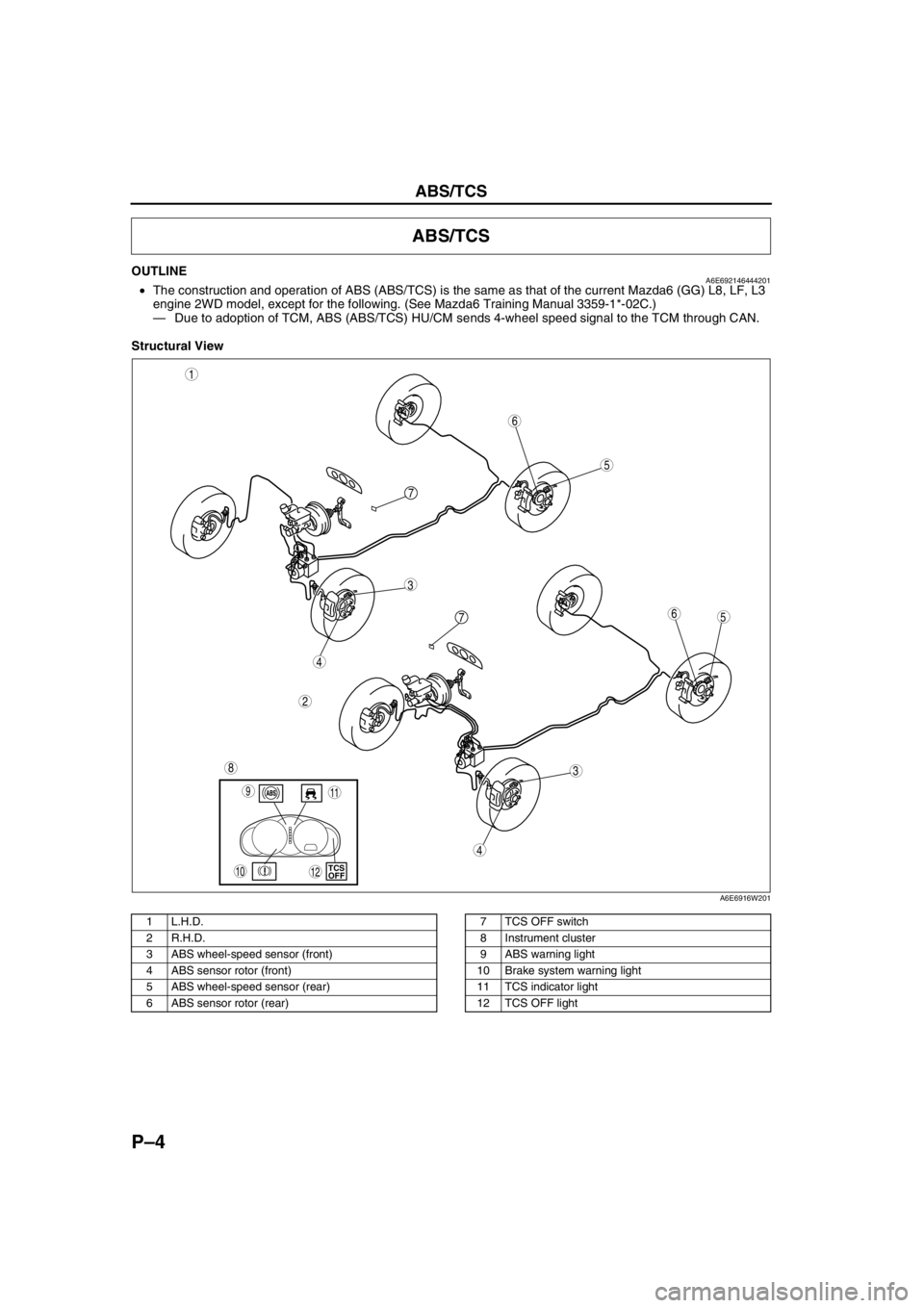

ABS/TCS

OUTLINEA6E692146444201•The construction and operation of ABS (ABS/TCS) is the same as that of the current Mazda6 (GG) L8, LF, L3

engine 2WD model, except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

—Due to adoption of TCM, ABS (ABS/TCS) HU/CM sends 4-wheel speed signal to the TCM through CAN.

Structural View

.

ABS/TCS

5

3

1

2

6

7

5

3

6

8

4

4

7

9

10TCS

OFF

11

12

A6E6916W201

1 L.H.D.

2 R.H.D.

3 ABS wheel-speed sensor (front)

4 ABS sensor rotor (front)

5 ABS wheel-speed sensor (rear)

6 ABS sensor rotor (rear)7 TCS OFF switch

8 Instrument cluster

9 ABS warning light

10 Brake system warning light

11 TCS indicator light

12 TCS OFF light

Page 738 of 909

ABS/TCS

P–5

P

System Diagram

.

End Of Sie

9

9

8

7

5

43

12

6

18

17

15

16

14

13

11

12

RF

FL

RR

RL

PCMG

E

FI Z

U

D

A

B

C

Y

AC

X

V O

R ADAB AA

ABS/TCS HU/CM

pP

9

10

19

920

A6E6921W201

1 IG switch

2SUS 15 A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 TCS OFF light

8 TCS indicator light

9CAN driver

10 Brake light11 Cruise actuator

12 TCS OFF switch

13 DLC-2

14 CAN-H

15 CAN-L

16 ABS Wheel-speed sensor

17 Battery

18 Brake switch

19 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

20 TCM, 4WD CM

Page 739 of 909

P–6

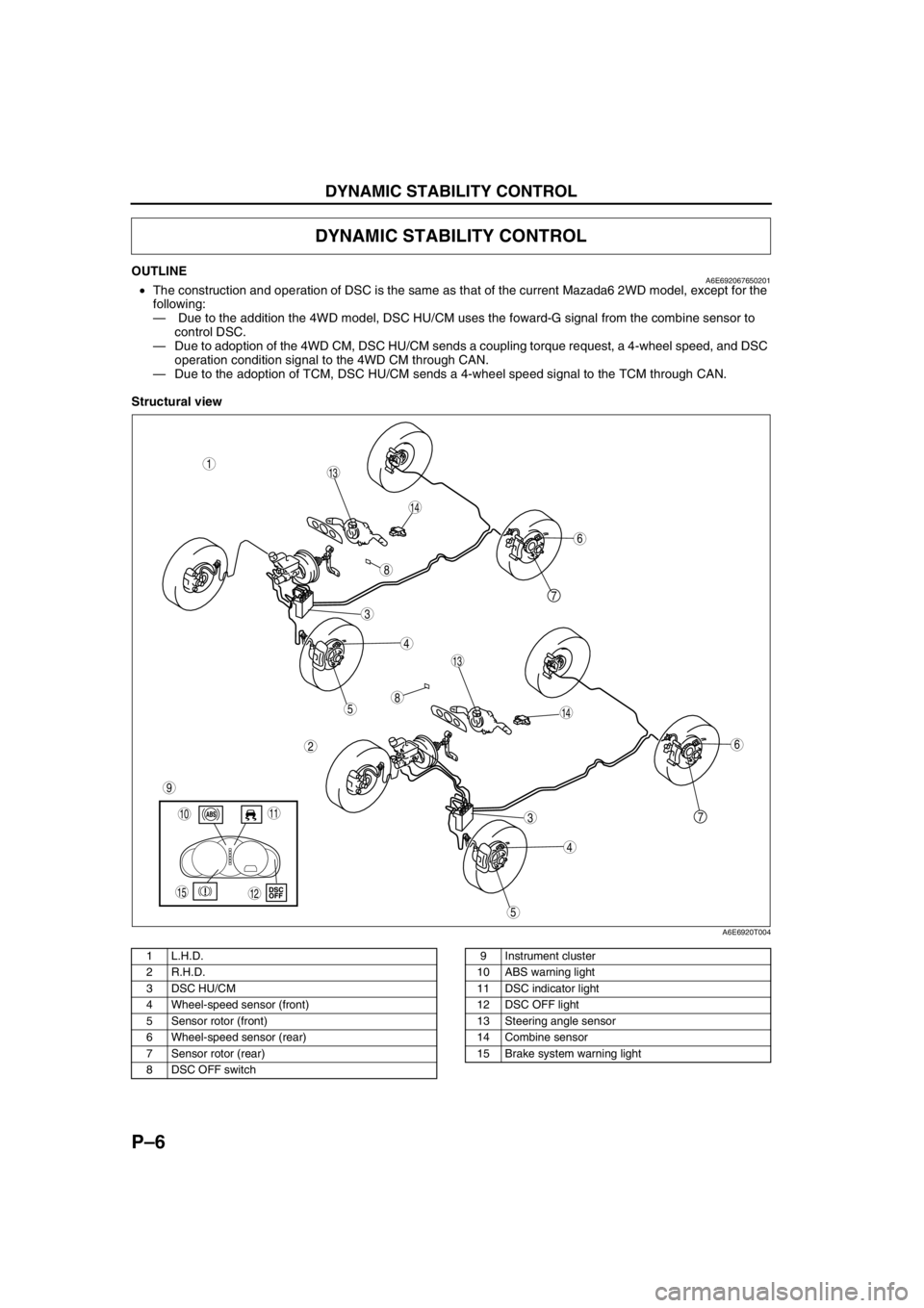

DYNAMIC STABILITY CONTROL

OUTLINEA6E692067650201•The construction and operation of DSC is the same as that of the current Mazada6 2WD model, except for the

following:

— Due to the addition the 4WD model, DSC HU/CM uses the foward-G signal from the combine sensor to

control DSC.

—Due to adoption of the 4WD CM, DSC HU/CM sends a coupling torque request, a 4-wheel speed, and DSC

operation condition signal to the 4WD CM through CAN.

—Due to the adoption of TCM, DSC HU/CM sends a 4-wheel speed signal to the TCM through CAN.

Structural view

.

DYNAMIC STABILITY CONTROL

7

5

4

3

1

2

14

13

6

13

12

5

4

3

7

6

1011

9

14

8

8

15

A6E6920T004

1 L.H.D.

2 R.H.D.

3 DSC HU/CM

4 Wheel-speed sensor (front)

5 Sensor rotor (front)

6 Wheel-speed sensor (rear)

7 Sensor rotor (rear)

8 DSC OFF switch9 Instrument cluster

10 ABS warning light

11 DSC indicator light

12 DSC OFF light

13 Steering angle sensor

14 Combine sensor

15 Brake system warning light

Page 740 of 909

DYNAMIC STABILITY CONTROL

P–7

P

Wiring Diagram

.

9

RF

FL

RR

RL

PCM

G

E

M

I

F

K

H

Q

NJ

P

S

T

V

O

Y

X

W

U

R

L

Z

AC

D

B

AG

AF

AE

AC

AA

AB

C

F

D

A

B

EDSC HU/CM

A

B

C

D

F

1

3

2

8

7

5

4

6

9

9

9

10

11

13

12

15

14

18

17

16

1920

2122

24

23

A6E6921W203

1 IG switch

2SUS 15A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 DSC OFF light

8 DSC indicator light

9CAN driver

10 Battery

11 Cruise actuator

12 DSC OFF switch13 DLC-2

14 CAN-H

15 CAN-L

16 Wheel-speed sensor

17 Combine sensor

18 Steering angle sensor

19 Brake switch

20 Brake light

21 Back-up light switch (MTX only)

22 Back-up light (MTX only)

23 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

24 TCM, 4WD CM

Page 742 of 909

ON-BOARD DIAGNOSTIC

P–9

P

OUTLINEA6E697043000201•The operation of the on-board diagnostic system for ABS (ABS/TCS) or DSC is the same as that of the current

Mazda6 (GG) L8, LF, L3 engine 2WD model, except for the following. (See Mazda6 Training Manual

3359-1*-02C.)

— Due to the addition of the 4WD model, DTCs and PID data monitor has been added.

—Due to the addition of the MZR-CD (RF Turbo) engine model, the DTC C1119 fail-safe function and the

detection condition have been changed.

Fail-safe Function

Fail-safe function table

*1: When engine speed signal through CAN is out of specification, the light illuminates.*2: When engine speed signal through CAN is out of specification, the system is suspended.*3: When engine speed signal value through CAN is invalid, only brake TCS is available.*4: When fuel injection information through CAN is out of specification or invalid, only brake TCS is available.*5: When engine speed signal value through CAN is invalid, only brake DSC is available.*6: When the engine control system has a malfunction, only brake DSC is available.

PID/DATA Monitor Table

End Of Sie

ON-BOARD DIAGNOSTIC

Malfunc-

tion

locationDTC Fail-safe function

WDS

or

equiva-

lentWarning light illumination condition Control condition

ABS

warning

lightBRAKE

system

warning

light

(when

parking

brake is

released)DSC

(TCS)

OFF lightDSC

(TCS)

indicator

light ABS

controlEBD

controlTCS

controlDSC

controlBrake

assist

control

PCM and/

or engine

speed

signal lineC1119Not

Illuminated Not

Illuminated Not

Illuminated

*1Illuminated Available AvailableAvailable*2, *3, *4Available*2, *5, *6Available

Combine

sensor

(forward-

G) lineC1949

Illuminated Not

Illuminated Illuminated IlluminatedNot

availableAvailable—Not

availableNot

available

C1950

CAN line U2511Not

Illuminated Not

Illuminated Not

Illuminated Illuminated Available Available—Available Available

PID name input/output part Operation/unit

ACCLMTR Accelerometer ACCELERATION