brake sensor MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 743 of 909

P–10

OUTLINE , GENERAL PROCEDURES

SUPPLEMENTAL SERVICE INFORMATIONA6E690201020205•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Power brake unit

•Removal/installation procedure has been modified.

Vacuum switch (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Vacuum pump (MZR-CD (RF Turbo))

•Inspection procedure has been added.

•Removal/installation procedure has been added.

Front brake (disc)

•Inspection procedure has been modified.

•Removal/installation procedure has been modified.

Disc pad (front)

•Replacement procedure has been modified.

Parking brake (lever type)

•Adjustment procedure has been modified.

DSC HU/CM

•Inspection procedure has been modified.

Combine sensor (Forward-G sensor)

•Inspection procedure has been modified.

On-board diagnostic (ABS/TCS)

•4WD and MZR-CD (RF Turbo) have been added.

End Of Sie

PRECAUTION (BRAKES)A6E691001020201Wheels and Tires Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}.

Brake Lines Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

•If any brake line has been disconnected anytime during the procedure, add brake fluid, bleed the brakes,

and inspect for leakage after the procedure has been completed.

Connectors Disconnection

1. Disconnect the negative battery cable before doing any work that requires handling of connectors. Reconnect

the negative battery cable only after the work is completed.

ABS, ABS/TCS, or DSC Components Operations

1. Make sure that there are no DTCs in the ABS, ABS/TCS, or DSC memory after working on ABS, ABS/TCS or

DSC components.

•If there are any DTCs in the memory, clear them.

End Of Sie

OUTLINE

GENERAL PROCEDURES

Page 750 of 909

PARKING BRAKE SYSTEM, DYNAMIC STABILITY CONTROL

P–17

P

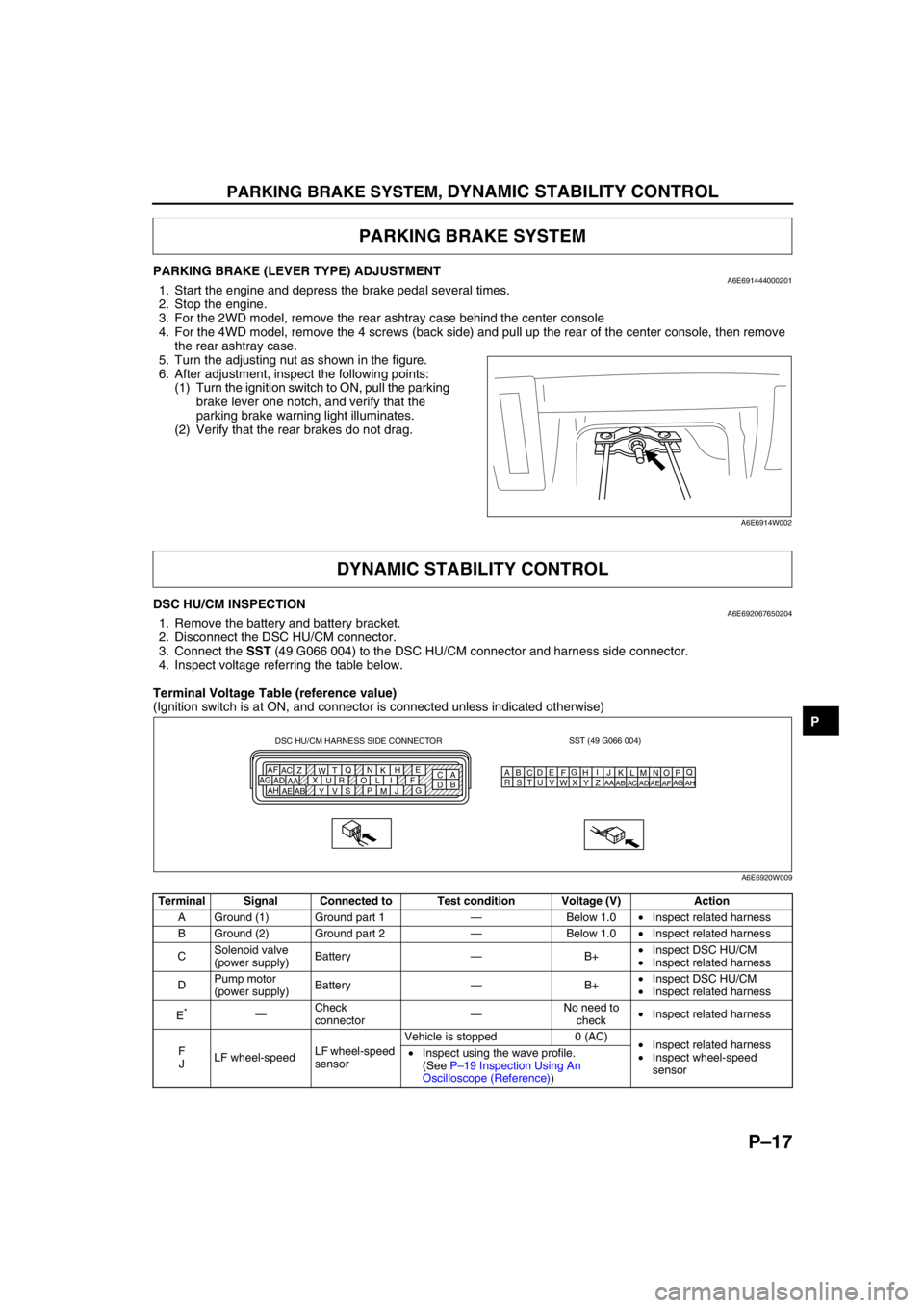

PARKING BRAKE (LEVER TYPE) ADJUSTMENTA6E6914440002011. Start the engine and depress the brake pedal several times.

2. Stop the engine.

3. For the 2WD model, remove the rear ashtray case behind the center console

4. For the 4WD model, remove the 4 screws (back side) and pull up the rear of the center console, then remove

the rear ashtray case.

5. Turn the adjusting nut as shown in the figure.

6. After adjustment, inspect the following points:

(1) Turn the ignition switch to ON, pull the parking

brake lever one notch, and verify that the

parking brake warning light illuminates.

(2) Verify that the rear brakes do not drag.

End Of Sie

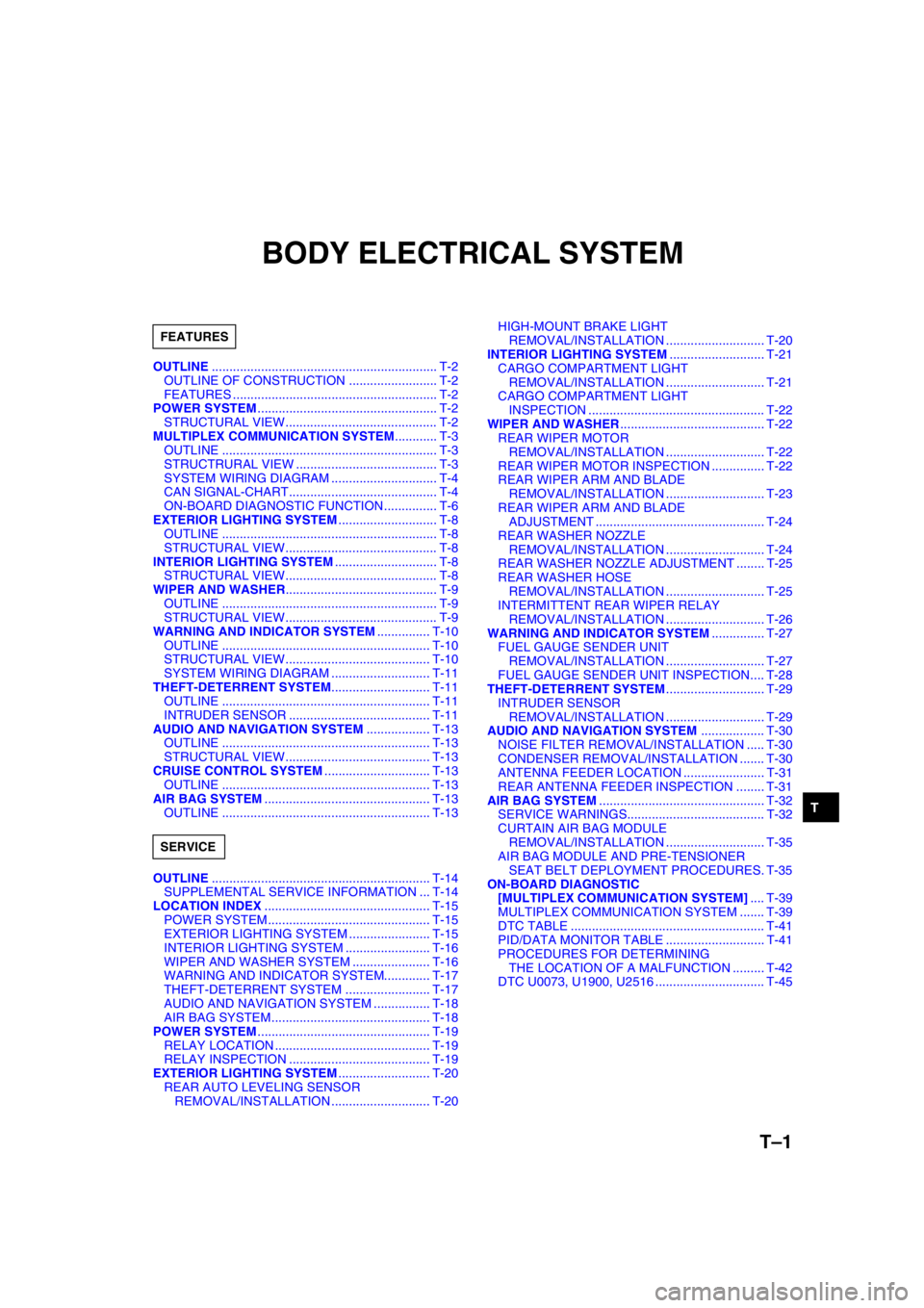

DSC HU/CM INSPECTIONA6E6920676502041. Remove the battery and battery bracket.

2. Disconnect the DSC HU/CM connector.

3. Connect the SST (49 G066 004) to the DSC HU/CM connector and harness side connector.

4. Inspect voltage referring the table below.

Terminal Voltage Table (reference value)

(Ignition switch is at ON, and connector is connected unless indicated otherwise)

PARKING BRAKE SYSTEM

A6E6914W002

DYNAMIC STABILITY CONTROL

Terminal Signal Connected to Test condition Voltage (V) Action

A Ground (1) Ground part 1—Below 1.0•Inspect related harness

B Ground (2) Ground part 2—Below 1.0•Inspect related harness

CSolenoid valve

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

DPump motor

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

E

*—Check

connector—No need to

check•Inspect related harness

F

JLF wheel-speedLF wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

A6E6920W009

Page 751 of 909

P–18

DYNAMIC STABILITY CONTROL

K

HRR wheel-speedRR wheel-

speed sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

M

IRF wheel-speedRF wheel-

speed sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

Q

NLR wheel-speedLR wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

G Battery (IG) Ignition switch Ignition switch ON B+•Inspect related harness

•Inspect ignition switch

L Brake switch Brake switchWhen brake pedal is

depressed10—14•Inspect related harness

•Inspect brake switch

OLateral-G

(lateral-G signal)Combine

sensorVehicle is stopped 2.2—2.8

•Inspect related harness

•Inspect combine sensor Left corneringFluctuation

between

2.5—4.0 V

Right corneringFluctuation

between

1.0—2.5 V

PCombine sensor

power outputCombine

sensorIgnition switch ON 4.75—5.25•Inspect related harness

•Inspect combine sensor

RSteering angle

(ground)Steering angle

sensor—Below 1.0•Inspect related harness

•Inspect steering angle

sensor

S Combine sensorCombine

sensor—3.5—5.0•Inspect related harness

•Inspect combine sensor

TYaw rate

(yaw rate signal)Combine

sensorVehicle is stopped 2.2—2.8

•Inspect related harness

•Inspect yaw rate sensor Right corneringFluctuation

between

2.5—4.62 V

Left corneringFluctuation

between

2.5—0.33 V

USteering angle

(neutral signal)Steering angle

sensorSteering position:

center position 25°—29°Below 1.0•Inspect related harness

•Inspect steering angle

sensor

Except above condition Approx. 4

VForward-G

(forward-G signal)Combine

sensorVehicle is stopped 2.2—2.8

•Inspect related harness

•Inspect combine sensor AccelerationFluctuation

between

2.5—4.0 V

Deceleration Fluctuation

between

1.0—2.5 V

WSteering angle

(steering angle

signal 2)Steering angle

sensor•Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))•Inspect related harness

•Inspect steering angle

sensor

XSteering angle

(steering angle

signal 1)Steering angle

sensor•Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))•Inspect related harness

•Inspect steering angle

sensor

YCombine sensor

(ground)Combine

sensor—Below 1.0•Inspect related harness

•Inspect combine sensor

AA DSC OFF switchDSC OFF

switchWhen switch is pressed Below 1.0

•Inspect related harness

•Inspect DSC OFF switch

When switch is not pressed B+

AB OBDKLN terminal of

DLC-2It cannot be determined with terminal

voltage whether the condition is good or bad

because advanced function diagnostic

output is performed with serial

communication. Inspect with service codes.•Inspect related harness

•Inspect DSC HU/CM Terminal Signal Connected to Test condition Voltage (V) Action

Page 754 of 909

ON-BOARD DIAGNOSTIC

P–21

P

DSC ON-BOARD DIAGNOSISA6E697067650201DTC Table

Note

•There is no change except for the code marked with an asterisk *

ON-BOARD DIAGNOSTIC

DTC

Diagnosis system component

WDS or

equivalent

B1318 DSC power supply

B1342 DSC HU/CM

B1483 Stop switch signal (with DSC only)

B1484 Stop switch signal (with DSC only)

B1486 Stop switch signal (with DSC only)

B1627 Reverse signal (with DSC only)

B2477 Module configuration (with DSC only)

C1095 Motor relay, pump motor

C1096 Motor relay, pump motor

C1119* Engine control system

C1125 Brake fluid level sensor (with DSC only)

C1140 DSC HU (pump) (with DSC only)

C1145 Right front wheel-speed sensor

C1148 Right front wheel-speed sensor/sensor rotor

C1155 Left front wheel-speed sensor

C1158 Left front wheel-speed sensor/sensor rotor

C1165 Right rear wheel-speed sensor

C1168 Right rear wheel-speed sensor/sensor rotor

C1175 Left rear wheel-speed sensor

C1178 Left rear wheel-speed sensor/sensor rotor

C1186 Fail-safe relay

C1194 Left front pressure reduction solenoid valve

C1198 Left front pressure retention solenoid valve

C1210 Right front pressure reduction solenoid valve

C1214 Right front pressure retention solenoid valve

C1233 Left front wheel-speed sensor/sensor rotor

C1234 Right front wheel-speed sensor/sensor rotor

C1235 Right rear wheel-speed sensor/sensor rotor

C1236 Left rear wheel-speed sensor/sensor rotor

C1242 Left rear pressure reduction solenoid valve

C1246 Right rear pressure reduction solenoid valve

C1250 Left rear pressure retention solenoid valve

C1254 Right rear ABS pressure retention solenoid valve

C1266 Fail-safe relay

C1280 Combine sensor (with DSC only)

C1400 Right front traction switch solenoid valve (with DSC only)

C1410 Left front traction switch solenoid valve (with DSC only)

C1414 DSC HU/CM (with DSC only)

C1507 DSC control (with DSC only)

C1508 TCS control

C1510 Right front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1511 Left front solenoid valve, motor or wheel-speed sensor/sensor rotor

C1512 Right rear solenoid valve, motor or wheel-speed sensor/sensor rotor

C1513 Left rear solenoid valve, motor or wheel-speed sensor/sensor rotor

Page 755 of 909

P–22

ON-BOARD DIAGNOSTIC

PID/DATA Monitor Table

Note

•There is no change except for the PID marked with an asterisk *

C1730 Combine sensor (with DSC only)

C1949* Combine sensor (with DSC only)

C1950* Combine sensor (with DSC only)

C1951 Combine sensor (with DSC only)

C1952 Combine sensor (with DSC only)

C1953 Brake fluid pressure sensor (with DSC only)

C1954 Brake fluid pressure sensor (with DSC only)

C1955 Steering angle sensor (with DSC only)

C1956 Steering angle sensor (with DSC only)

C1957 Right front DSC switch solenoid valve (with DSC only)

C1958 Left front DSC switch solenoid valve (with DSC only)

C1959 Combine sensor (with DSC only)

U1900 CAN communication

U2021 Invalid/fault data received

U2511* CAN communication

U2516 CAN communicationDTC

Diagnosis system component

WDS or

equivalent

PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

RPM

(Engine speed signal input)RPM•Engine is stopped: 0 RPM

•Engine is running: Indicates

engine speedInspect PCM.—

TRANSGR

*

(with DSC only)

(Transaxle gear position)FN4A-EL:

R/N/D/S/L

JA5AX-EL:

R/N/D•Selector lever position is

displayed

—R: R

—N: N

—D: D

—S: SInspect PCM, TR

switch, or DSC HU/

CM.

—

TRAC_SW

(TCS OFF switch input)ON/OFF•TCS (DSC) OFF switch is

depressed: ON

•TCS (DSC) OFF switch is

released: OFFInspect TCS (DSC)

OFF switch.

AA

TC LVAL (with DSC only)

(Traction switch solenoid valve

(LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

TC RVAL (with DSC only)

(Traction switch solenoid valve

(RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

L_DSC O (with DSC only)

(Stability control solenoid

valve (LF-RR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

R_DSC O (with DSC only)

(Stability control solenoid

valve (RF-LR))ON/OFF•Solenoid valve is activated:

ON

•Solenoid valve is

deactivated: OFFInternal fault of DSC

HU/CM. Replace DSC

HU/CM.—

CCNTABS

(Number of continuous codes)—DTC is detected: 1—255

DTC is not detected: 0Perform inspection

using appropriate

DTC.—

Page 756 of 909

ON-BOARD DIAGNOSTIC

P–23

P

PMPSTAT

(Pump motor output state)ON/OFF•Pump motor is activated:

ON

•Pump motor is deactivated:

OFFInspect DSC HU/CM

—

BRK_FLUID (with DSC only)

(Brake fluid level sensor input)OK/LOW•Brake fluid is above LOW:

OK

•Brake fluid is below LOW:

LOWInspect brake fluid

level.

Inspect brake fluid

level sensor.—

BOO_ABS

(Brake pedal switch input)ON/OFF•Brake pedal is depressed:

ON

•Brake pedal is released:

OFFInspect brake switch.

ABS (ABS/

TCS): Y

DSC: L

ABS_LAMP

(ABS warning light driver

output state)ON/OFF•ABS warning light is

illuminated: ON

•ABS warning light is not

illuminated: OFFInspect ABS warning

light.

—

BRAKE_LMP

(BRAKE system warning light

output state)ON/OFF•BRAKE system warning

light is illuminated: ON

•BRAKE system warning

light is not illuminated: OFFInspect BRAKE

system warning light.

—

ABSRR_O

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_O

(Left rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRF_O

(Right front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLF_O

(Left front ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSRR_I

(Right rear ABS pressure

reduction solenoid valve

output state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLR_I

(Left rear ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS or EBD control:

ON/OFF

(solenoid valve is activated/

deactivated)

•Not ABS and EBD control:

OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.— PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 757 of 909

P–24

ON-BOARD DIAGNOSTIC

ABSRF_I

(Right front ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSLF_I

(Left front ABS pressure

retention solenoid valve output

state)ON/OFF•During ABS control: ON/

OFF

(solenoid valve is activated/

deactivated)

•Not ABS control: OFF

(solenoid valve is

deactivated)Internal fault of ABS

(ABS/TCS) or DSC

HU/CM. Replace ABS

(ABS/TCS) or DSC

HU/CM.—

ABSVLVRLY

(Fail-safe relay output state)ON/OFF•Fail-safe relay is

activated: ON

•Fail-safe relay is

deactivated: OFFInspect ABS (ABS/

TCS) or DSC HU/CM.

—

ABSPMPRLY

(Motor relay output state)ON/OFF•Motor relay is activated: ON

•Motor relay is deactivated:

OFFInspect ABS (ABS/

TCS) or DSC HU/CM.—

SWA POS (with DSC only)

(Steering angle sensor input)ANGLE•Steering wheel is in neutral

position: 0 DEG

•Steering wheel is turned to

left: Changes between

0 DEG and -1,638.40 DEG

•Steering wheel is turned to

right: Changes between

0 DEG and 1,638.35 DEGInspect steering angle

sensor.

R, U, W, X

LF_WSPD

(Left front wheel-speed sensor

input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): E, I

DSC: F, J

RF_WSPD

(Right front wheel-speed

sensor input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): D, G

DSC: I, M

LR_WSPD

(Left rear wheel-speed sensor

input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): C, F

DSC: N, Q

RR_WSPD

(Right rear wheel-speed

sensor input)SPEED•Vehicle is stopped: 0 KPH

{0 MPH}

•Vehicle is driving: Indicates

vehicle speedInspect wheel-speed

sensor/sensor rotor.ABS (ABS/

TCS): A, B

DSC: H, K

LAT ACC (with DSC only)

(Lateral-G sensor input)ACCELERATION•Vehicle is stopped or driving

straight: 0 G

•Cornering to left: Changes

between 0 G and 1.27 G

•Cornering to right: Changes

between 0 G and -1.28 GInspect ABS wheel-

speed sensor/sensor

rotor.

O

YAW_RATE (with DSC only)

(Yaw rate sensor input)ACCELERATION•Vehicle is stopped or driving

straight: 0 DG/S

•Cornering to left: Changes

between 0 DG/S and 127

DG/S

•Cornering to right: Changes

between 0 DG/S and -128

DG/SInspect combine

sensor.

T

MCYLI P (with DSC only)

(Brake fluid pressure sensor

input)PRESSURE•Brake pedal is released:

0 MPa

•Brake pedal is depressed:

Changes between 0 MPa

and 25.5 MPaInspect DSC HU/CM.

— PID Name

(Definition)Unit/Condition Condition/Specification ActionABS (ABS/

TCS) HU/CM or

DSC HU/CM

terminal

Page 777 of 909

REAR SUSPENSION

R–15

R

.

1

2

93.2—131.4

{9.51—13.39, 68.75—96.91}

86.2—116.6

{8.80—11.88,

63.58—85.99}

7

5

C

C

A

A

B

B

D

D

E

E

4

6

3

18.6—25.5

{1.90—2.60,

13.8—18.8}

18.6—25.5

{1.90—2.60,

13.8—18.8}

86.2—116.6

{8.80—11.88,

63.58—85.99}86.2—116.6

{8.80—11.88,

63.58—85.99}

N·m {kgf·m, ft·lbf}

A6E74162008

1 ABS wheel-speed sensor

2 Parking brake cable

3 Bolt (shock absorber lower side)

4 Bolt (trailing link front side)

(See R–16 Bolt (Trailing Link Front Side) Removal

Note)

(See R–16 Bolt (Trailing Link Front Side) Installation

Note)5 Bolt (Lateral link outer side)

(See R–16 Bolt (Lateral Link Outer Side) Removal

Note)

(See R–16 Bolt (Lateral Link Outer Side) Installation

Note)

6 Toe link bracket

7 Trailing link

Page 812 of 909

T–1

T

TBODY ELECTRICAL SYSTEM

OUTLINE................................................................ T-2

OUTLINE OF CONSTRUCTION ......................... T-2

FEATURES .......................................................... T-2

POWER SYSTEM................................................... T-2

STRUCTURAL VIEW........................................... T-2

MULTIPLEX COMMUNICATION SYSTEM............ T-3

OUTLINE ............................................................. T-3

STRUCTRURAL VIEW ........................................ T-3

SYSTEM WIRING DIAGRAM .............................. T-4

CAN SIGNAL-CHART.......................................... T-4

ON-BOARD DIAGNOSTIC FUNCTION............... T-6

EXTERIOR LIGHTING SYSTEM............................ T-8

OUTLINE ............................................................. T-8

STRUCTURAL VIEW........................................... T-8

INTERIOR LIGHTING SYSTEM............................. T-8

STRUCTURAL VIEW........................................... T-8

WIPER AND WASHER........................................... T-9

OUTLINE ............................................................. T-9

STRUCTURAL VIEW........................................... T-9

WARNING AND INDICATOR SYSTEM............... T-10

OUTLINE ........................................................... T-10

STRUCTURAL VIEW......................................... T-10

SYSTEM WIRING DIAGRAM ............................ T-11

THEFT-DETERRENT SYSTEM............................ T-11

OUTLINE ........................................................... T-11

INTRUDER SENSOR ........................................ T-11

AUDIO AND NAVIGATION SYSTEM.................. T-13

OUTLINE ........................................................... T-13

STRUCTURAL VIEW......................................... T-13

CRUISE CONTROL SYSTEM.............................. T-13

OUTLINE ........................................................... T-13

AIR BAG SYSTEM............................................... T-13

OUTLINE ........................................................... T-13

OUTLINE.............................................................. T-14

SUPPLEMENTAL SERVICE INFORMATION ... T-14

LOCATION INDEX............................................... T-15

POWER SYSTEM.............................................. T-15

EXTERIOR LIGHTING SYSTEM ....................... T-15

INTERIOR LIGHTING SYSTEM ........................ T-16

WIPER AND WASHER SYSTEM ...................... T-16

WARNING AND INDICATOR SYSTEM............. T-17

THEFT-DETERRENT SYSTEM ........................ T-17

AUDIO AND NAVIGATION SYSTEM ................ T-18

AIR BAG SYSTEM............................................. T-18

POWER SYSTEM................................................. T-19

RELAY LOCATION ............................................ T-19

RELAY INSPECTION ........................................ T-19

EXTERIOR LIGHTING SYSTEM.......................... T-20

REAR AUTO LEVELING SENSOR

REMOVAL/INSTALLATION ............................ T-20HIGH-MOUNT BRAKE LIGHT

REMOVAL/INSTALLATION ............................ T-20

INTERIOR LIGHTING SYSTEM........................... T-21

CARGO COMPARTMENT LIGHT

REMOVAL/INSTALLATION ............................ T-21

CARGO COMPARTMENT LIGHT

INSPECTION .................................................. T-22

WIPER AND WASHER......................................... T-22

REAR WIPER MOTOR

REMOVAL/INSTALLATION ............................ T-22

REAR WIPER MOTOR INSPECTION ............... T-22

REAR WIPER ARM AND BLADE

REMOVAL/INSTALLATION ............................ T-23

REAR WIPER ARM AND BLADE

ADJUSTMENT ................................................ T-24

REAR WASHER NOZZLE

REMOVAL/INSTALLATION ............................ T-24

REAR WASHER NOZZLE ADJUSTMENT ........ T-25

REAR WASHER HOSE

REMOVAL/INSTALLATION ............................ T-25

INTERMITTENT REAR WIPER RELAY

REMOVAL/INSTALLATION ............................ T-26

WARNING AND INDICATOR SYSTEM............... T-27

FUEL GAUGE SENDER UNIT

REMOVAL/INSTALLATION ............................ T-27

FUEL GAUGE SENDER UNIT INSPECTION.... T-28

THEFT-DETERRENT SYSTEM............................ T-29

INTRUDER SENSOR

REMOVAL/INSTALLATION ............................ T-29

AUDIO AND NAVIGATION SYSTEM.................. T-30

NOISE FILTER REMOVAL/INSTALLATION ..... T-30

CONDENSER REMOVAL/INSTALLATION ....... T-30

ANTENNA FEEDER LOCATION ....................... T-31

REAR ANTENNA FEEDER INSPECTION ........ T-31

AIR BAG SYSTEM............................................... T-32

SERVICE WARNINGS....................................... T-32

CURTAIN AIR BAG MODULE

REMOVAL/INSTALLATION ............................ T-35

AIR BAG MODULE AND PRE-TENSIONER

SEAT BELT DEPLOYMENT PROCEDURES. T-35

ON-BOARD DIAGNOSTIC

[MULTIPLEX COMMUNICATION SYSTEM].... T-39

MULTIPLEX COMMUNICATION SYSTEM ....... T-39

DTC TABLE ....................................................... T-41

PID/DATA MONITOR TABLE ............................ T-41

PROCEDURES FOR DETERMINING

THE LOCATION OF A MALFUNCTION ......... T-42

DTC U0073, U1900, U2516 ............................... T-45 FEATURES

SERVICE

Page 813 of 909

T–2

OUTLINE, POWER SYSTEM

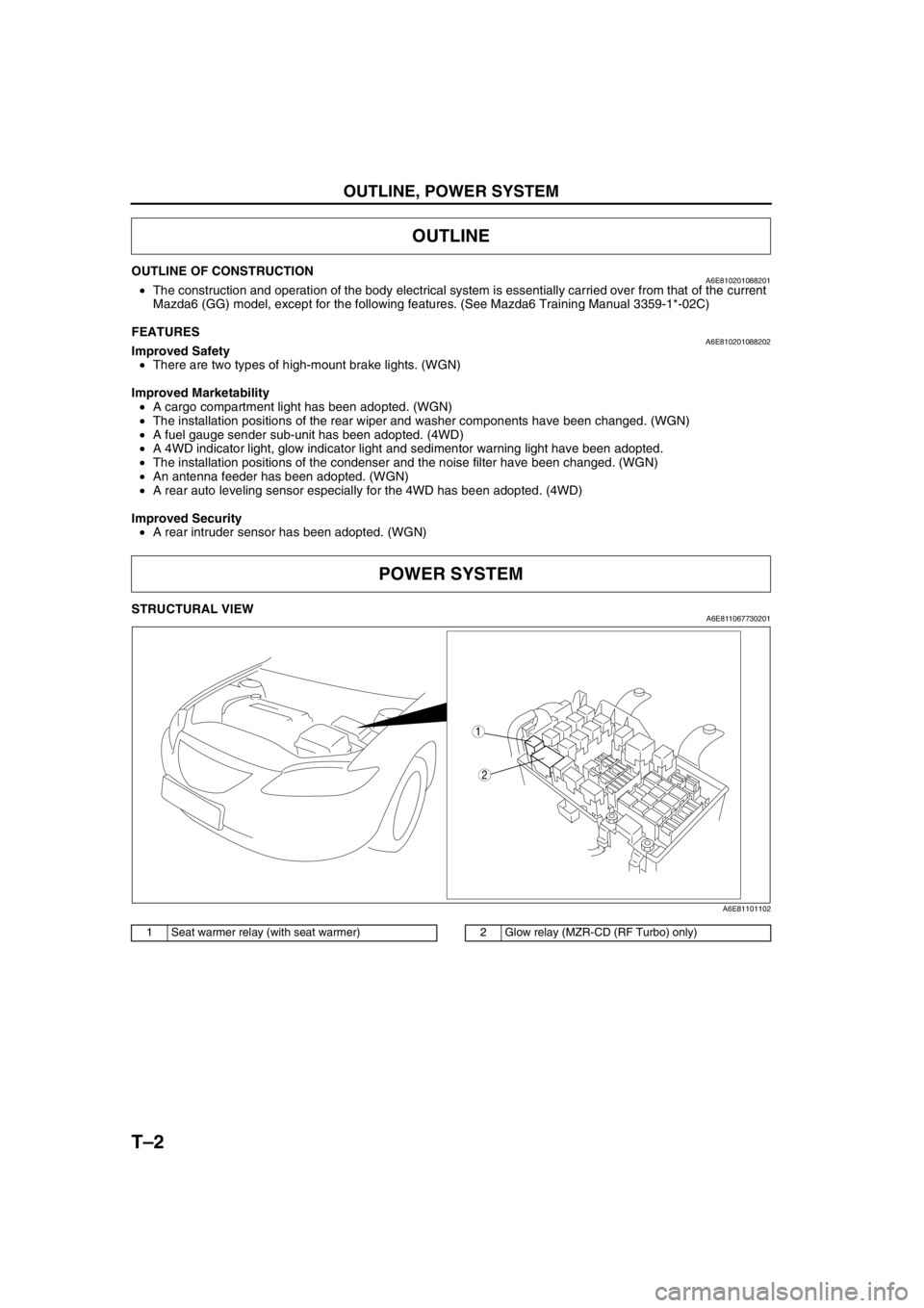

OUTLINE OF CONSTRUCTIONA6E810201088201•The construction and operation of the body electrical system is essentially carried over from that of the current

Mazda6 (GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C)

End Of Sie

FEATURESA6E810201088202Improved Safety

•There are two types of high-mount brake lights. (WGN)

Improved Marketability

•A cargo compartment light has been adopted. (WGN)

•The installation positions of the rear wiper and washer components have been changed. (WGN)

•A fuel gauge sender sub-unit has been adopted. (4WD)

•A 4WD indicator light, glow indicator light and sedimentor warning light have been adopted.

•The installation positions of the condenser and the noise filter have been changed. (WGN)

•An antenna feeder has been adopted. (WGN)

•A rear auto leveling sensor especially for the 4WD has been adopted. (4WD)

Improved Security

•A rear intruder sensor has been adopted. (WGN)

End Of Sie

STRUCTURAL VIEWA6E811067730201

.

End Of Sie

OUTLINE

POWER SYSTEM

2

1

A6E81101102

1 Seat warmer relay (with seat warmer)2 Glow relay (MZR-CD (RF Turbo) only)