MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1411 of 1865

MASTER CYLINDER 1 1

76G11X-015

76G11X-016

76G11X-017

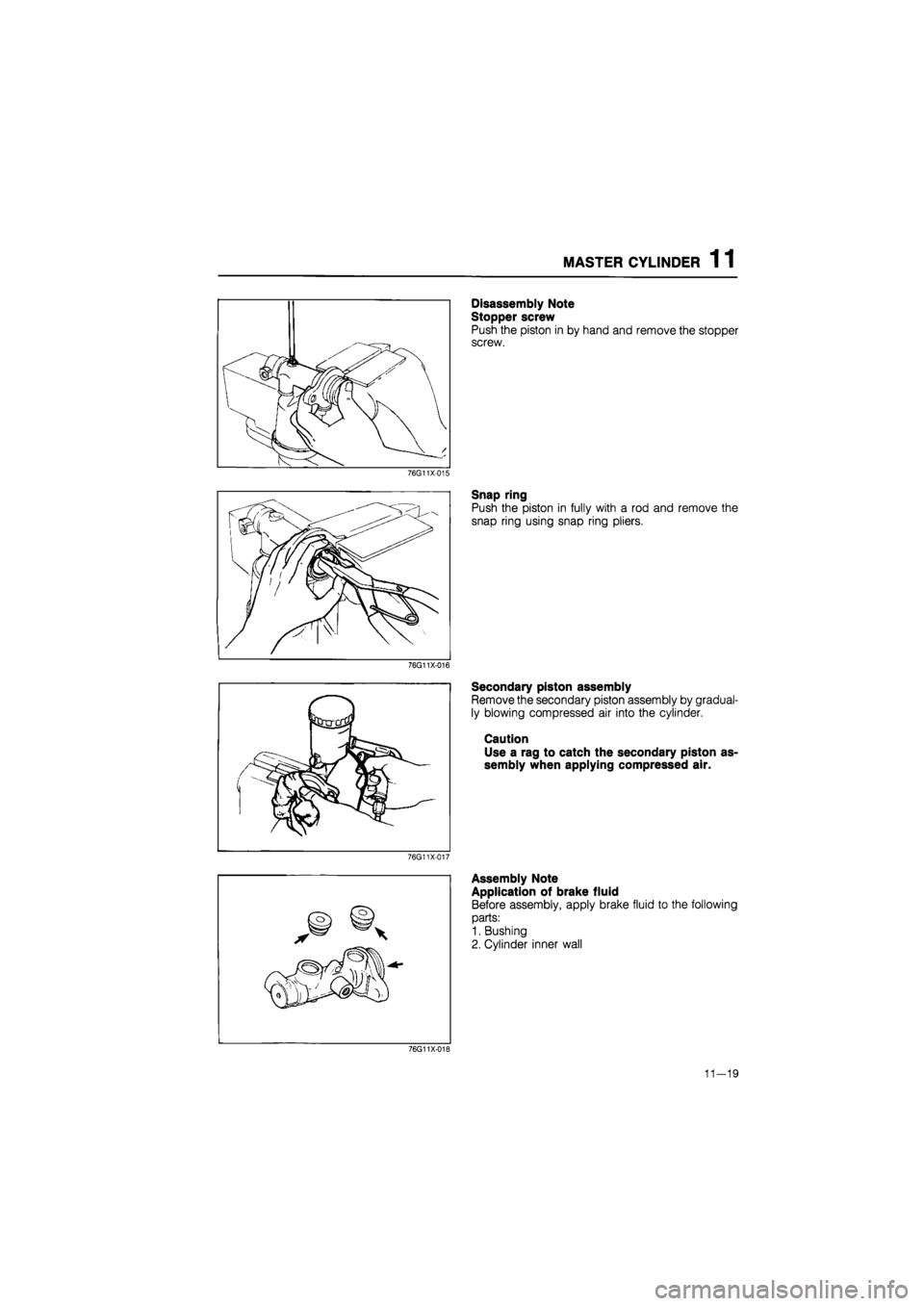

Disassembly Note

Stopper screw

Push the piston in by hand and remove the stopper

screw.

Snap ring

Push the piston in fully with a rod and remove the

snap ring using snap ring pliers.

Secondary piston assembly

Remove the secondary piston assembly by gradual-

ly blowing compressed air into the cylinder.

Caution

Use a rag to catch the secondary piston as-

sembly when applying compressed air.

Assembly Note

Application of brake fluid

Before assembly, apply brake fluid to the following

parts:

1. Bushing

2. Cylinder inner wall

76G11X-018

11—19

Page 1412 of 1865

1 1 MASTER CYLINDER

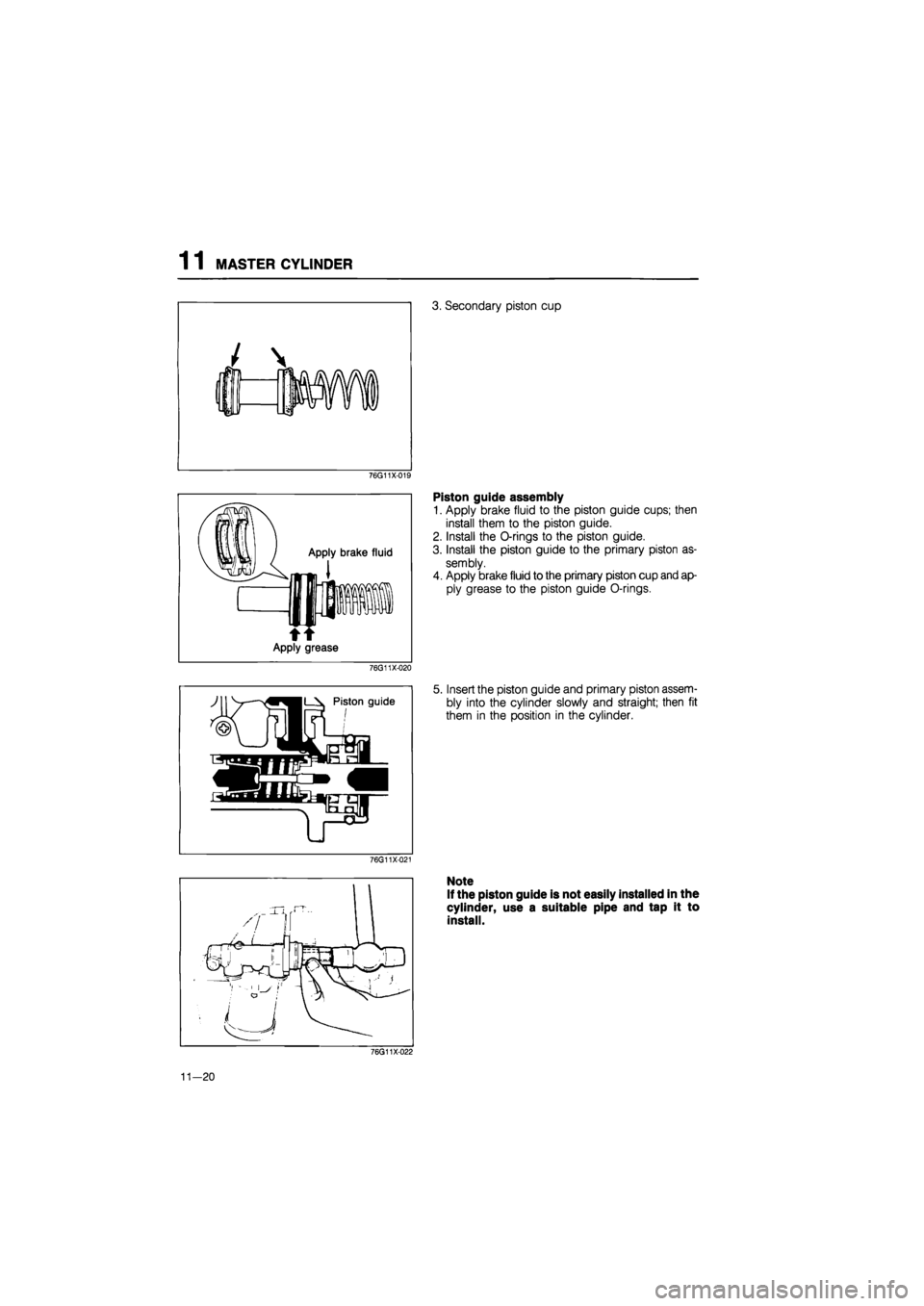

3. Secondary piston cup

76G11X-019

Apply brake fluid

t Apply grease

76G11X-020

Piston guide assembly

1. Apply brake fluid to the piston guide cups; then

install them to the piston guide.

2. Install the O-rings to the piston guide.

3. Install the piston guide to the primary piston as-

sembly.

4. Apply brake fluid to the primary piston cup and ap-

ply grease to the piston guide O-rings.

5. Insert the piston guide and primary piston assem-

bly into the cylinder slowly and straight; then fit

them in the position in the cylinder.

76G11X-021

Note

If the piston guide is not easily installed in the

cylinder, use a suitable pipe and tap it to

install.

76G11X-022

11—20

Page 1413 of 1865

MASTER CYLINDER 1 1

86U11X-031

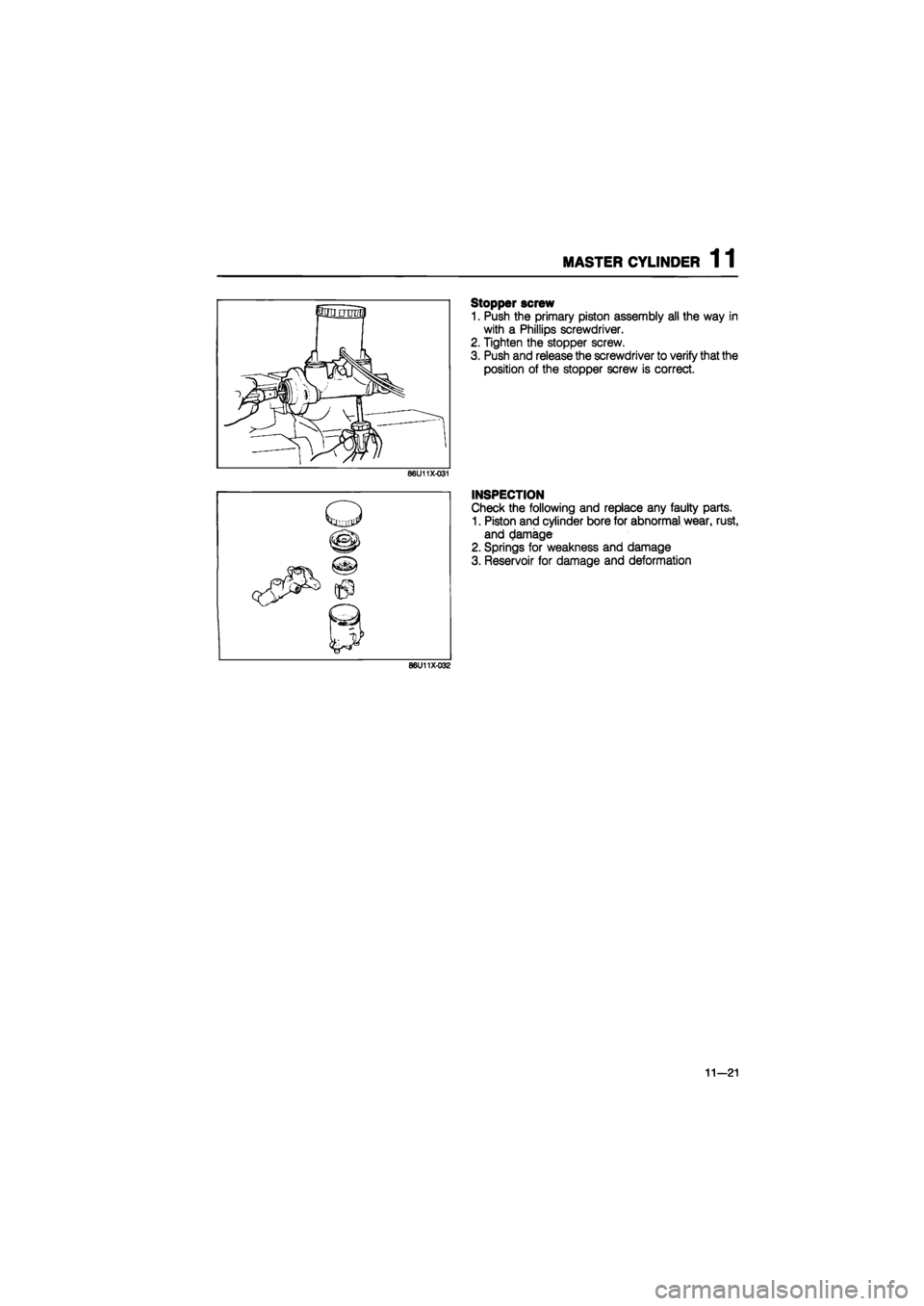

Stopper screw

1. Push the primary piston assembly all the way in

with a Phillips screwdriver.

2. Tighten the stopper screw.

3. Push and release the screwdriver to verify that the

position of the stopper screw is correct.

INSPECTION

Check the following and replace any faulty parts.

1. Piston and cylinder bore for abnormal wear, rust,

and damage

2. Springs for weakness and damage

3. Reservoir for damage and deformation

86U11X-032

11—21

Page 1414 of 1865

1 1 MASTER CYLINDER

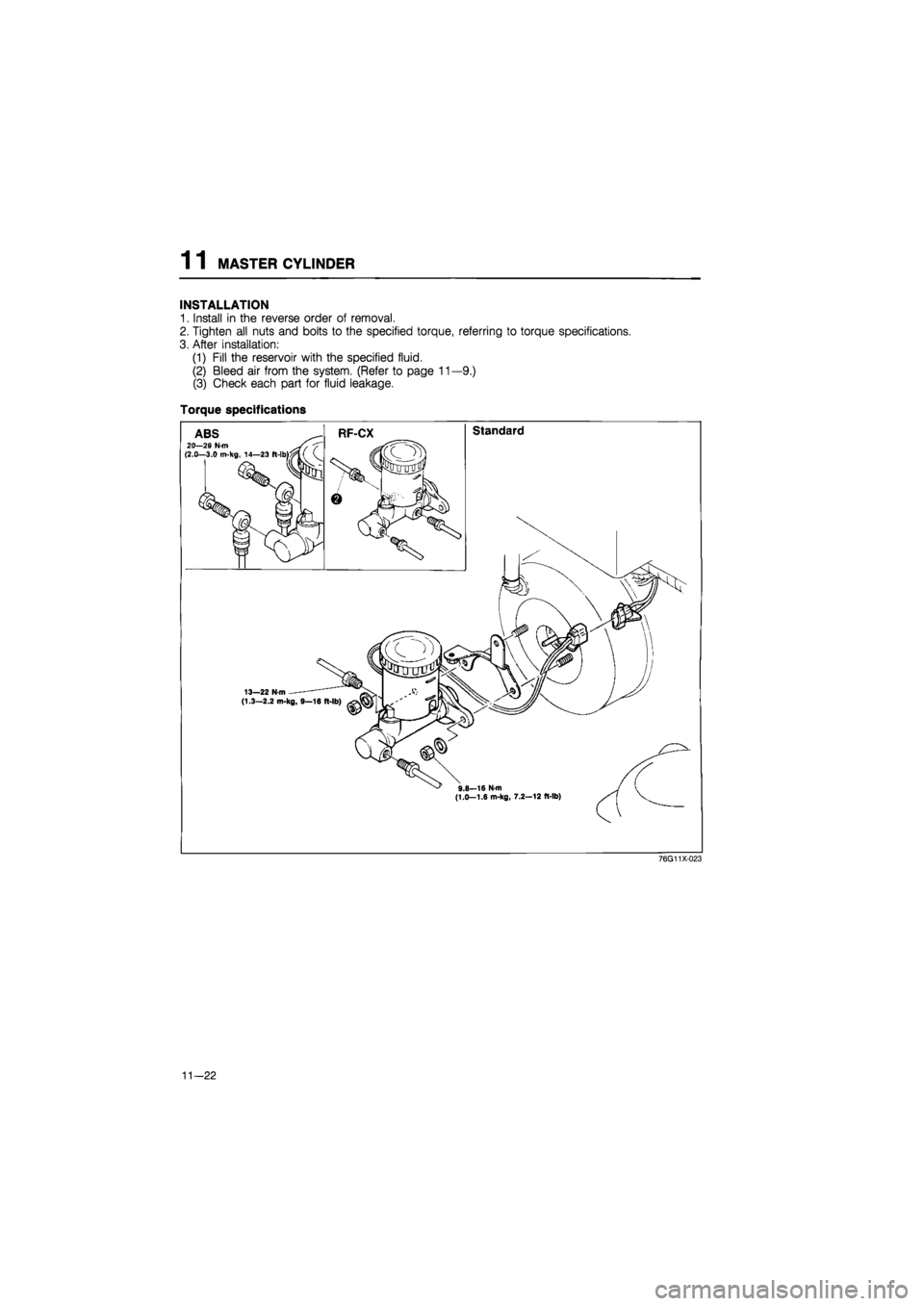

INSTALLATION

1. Install in the reverse order of removal.

2. Tighten all nuts and bolts to the specified torque, referring to torque specifications.

3. After installation:

(1) Fill the reservoir with the specified fluid.

(2) Bleed air from the system. (Refer to page 11—9.)

(3) Check each part for fluid leakage.

Torque specifications

11—22

Page 1415 of 1865

MASTER CYLINDER 1 1

Installation Note

Piston to push rod clearance adjustment

(Except RHD DOHC TURBO)

Before installing the master cylinder, check the clear-

ance between the piston of the master cylinder and

the push rod of the power brake unit as follows.

1. Place the SST on the top of the master cylinder;

then turn the adjust bolt until it contacts the bot-

tom of the push rod hole in the piston.

76G11X-024

2. Apply 500 mmHg (19.7 inHg) vacuum to the pow-

er brake unit with a vacuum pump.

76G11X-100

——x y V \ ''/v'/

\

i By Adjust bolt

86U11X-036

Locknut IV"

\ i i '

3. Invert the SST used in step 1, and place it on the

power brake unit.

4. Check the clearance between the adjust bolt and

the push rod of the power brake unit. If it is not

0 mm, loosen the push rod locknut and turn the

push rod to adjust.

76G11X-101

11-23

Page 1416 of 1865

1 1 MASTER CYLINDER

76G11X-025

II

L

\ Clearance (B)

Clearance (A) , j Adjust nut

•I

76G11X-026

Clearance (B)

49 B043 001

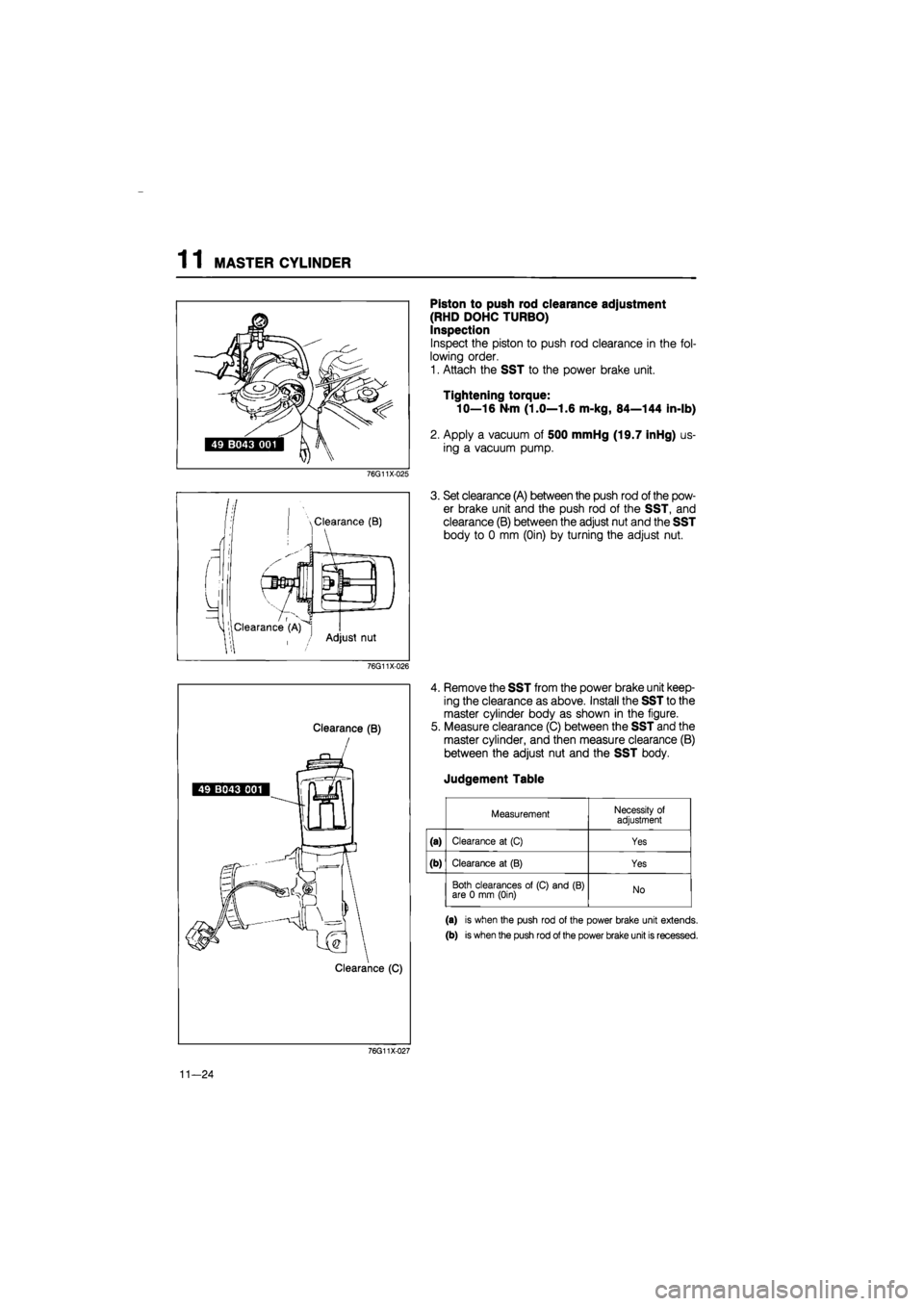

Piston to push rod clearance adjustment

(RHD DOHC TURBO)

Inspection

Inspect the piston to push rod clearance in the fol-

lowing order.

1. Attach the SST to the power brake unit.

Tightening torque:

10—16 N-m (1.0—1.6 m-kg, 84—144 in-lb)

2. Apply a vacuum of 500 mmHg (19.7 inHg) us-

ing a vacuum pump.

3. Set clearance (A) between the push rod of the pow-

er brake unit and the push rod of the SST, and

clearance (B) between the adjust nut and the SST

body to 0 mm (Oin) by turning the adjust nut.

4. Remove the SST from the power brake unit keep-

ing the clearance as above. Install the SST to the

master cylinder body as shown in the figure.

5. Measure clearance (C) between the SST and the

master cylinder, and then measure clearance (B)

between the adjust nut and the SST body.

Judgement Table

Measurement Necessity of adjustment

(a) Clearance at (C) Yes

(b) Clearance at (B) Yes

Both clearances of (C) and (B) are 0 mm (Oin) No

(a) is when the push rod of the power brake unit extends.

(b) is when the push rod of the power brake unit is recessed.

76G11X-027

11-24

Page 1417 of 1865

MASTER CYLINDER 1 1

Adjustment

Adjust the piston to push rod clearance in the follow-

ing order.

1. For (a) of judgement table

(1) Measure the height of (D) and record after

removing the SST from the master cylinder.

76G11X-028

Adjust nut

(2) Install the SST again to the master cylinder,

and turn the adjust nut so that clearance (C)

between the SST and the master cylinder is

0 mm (Oin).

(3) Measure the height of (E) when clearance (C)

is 0 mm (Oin).

(E) — (D) = Projecting amount of the power

brake unit push rod

76G11X-029

(4) Remove the push rod from the power brake

unit.

63G11X-349

(5) Make the piston to push rod clearance 0 mm

(Oin) by turning the push rod and shortening

the push rod length by the amount of (E) — (D).

Note

The threads of the push rod are specially

designed so that the push rod bolt becomes

harder to turn past a certain point to prevent

loosening of the bolt. Turn the push rod bolt

only within this range when adjusting.

76G11X030

11—25

Page 1418 of 1865

1 1 MASTER CYLINDER

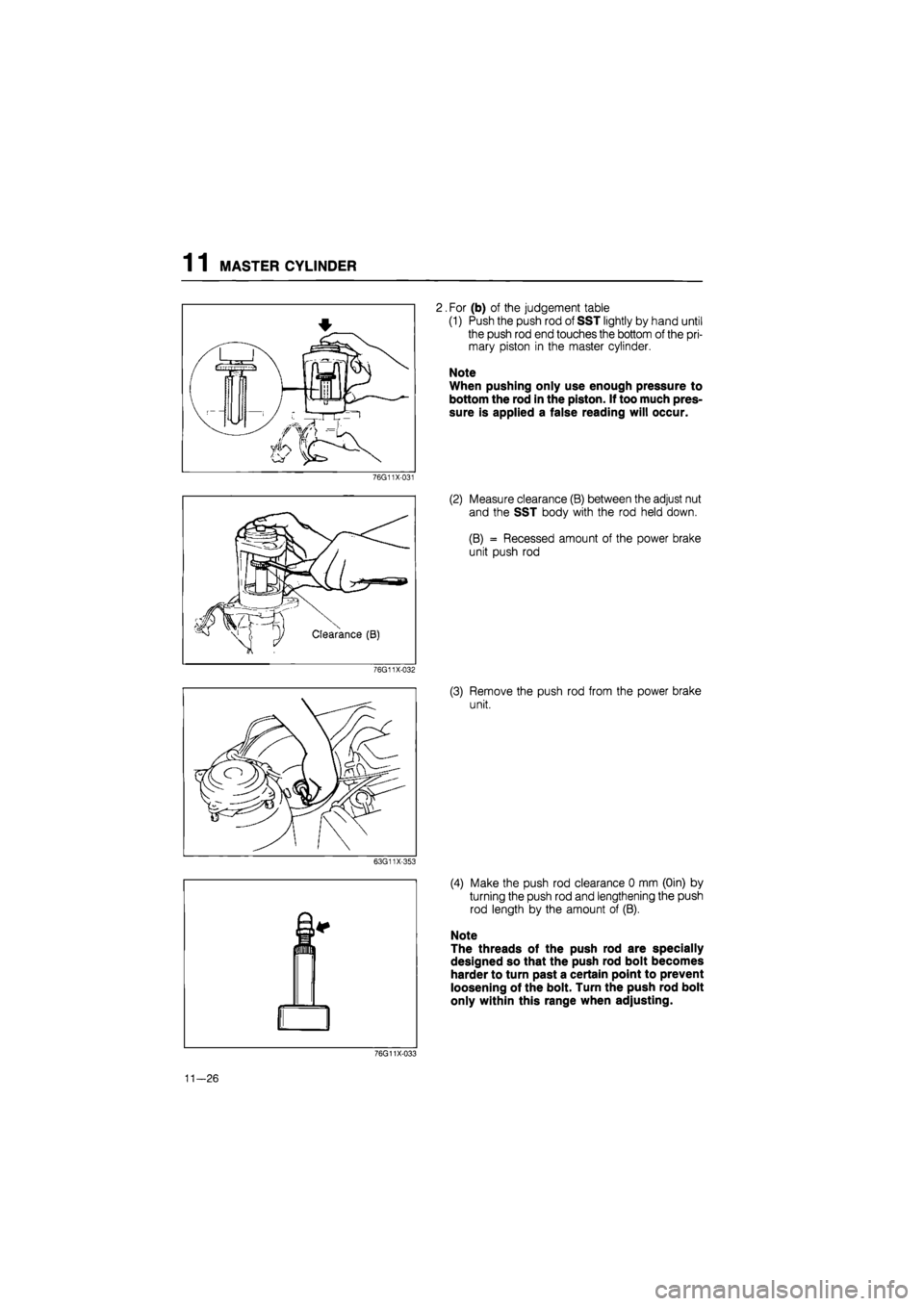

2. For (b) of the judgement table

(1) Push the push rod of SST lightly by hand until

the push rod end touches the bottom of the pri-

mary piston in the master cylinder.

Note

When pushing only use enough pressure to

bottom the rod in the piston. If too much pres-

sure is applied a false reading will occur.

76G11X-031

(2) Measure clearance (B) between the adjust nut

and the SST body with the rod held down.

(B) = Recessed amount of the power brake

unit push rod

76G11X-032

(3) Remove the push rod from the power brake

unit.

63G11X-353

(4) Make the push rod clearance 0 mm (Oin) by

turning the push rod and lengthening the push

rod length by the amount of (B).

Note

The threads of the push rod are specially

designed so that the push rod bolt becomes

harder to turn past a certain point to prevent

loosening of the bolt. Turn the push rod bolt

only within this range when adjusting.

76G11X-033

11—26

Page 1419 of 1865

POWER BRAKE UNIT 1 1

86U11X-038

0

o

X

\ V^ Third

Second

^ First

86U11X-039

O X

fiSy

V

86U11X-040

Pedal-depression Pre!tur!9au9e

force gauge

^Intake manifold

86U11X-041

POWER BRAKE UNIT

FUNCTION CHECK

Simple Method

First step

1. With the engine stopped, depress the pedal a few

times.

2. With the pedal depressed, start the engine

3. If immediately after the engine starts the pedal

moves down slightly, the unit is operating.

Second step

1. Start the engine.

2. Stop the engine after it has run for

1

or 2 minutes.

3. Depress the pedal with the usual force.

4.

If

the first pedal stroke is long and becomes short-

er with subsequent strokes, the unit is operating.

5. If a problem is found, inspect for damage of the

check valve or vacuum hose, and examine the in-

stallation condition. Repair if necessary, and inspect

it once again.

Third step

1. Start the engine.

2. Depress the pedal with the usual force.

3. Stop the engine with the pedal still depressed.

4. Hold the pedal down for about 30 seconds.

5. If the pedal height does not change, the unit is

operating.

6. If there is a problem, check for damage to the

check valve or vacuum hose, and check the con-

nection. Repair if necessary, and check once

again.

If the nature of the problem is still not clear after fol-

lowing the 3 steps above, follow the more detailed

check described in "Method using tester".

Method Using Tester

Connect a pressure gauge, vacuum gauge, and ped-

al depression force gauge as shown in the figure. Af-

ter bleeding the air from the pressure gauge, conduct

the test as described in the 3 steps below.

Note

Use commercially available gauges and ped-

al depression force gauge.

11—27

Page 1420 of 1865

1 1 POWER BRAKE UNIT

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading

reaches 500 mmHg (19.7 inHg).

3. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X-065

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a force of 196 N (20

kg, 44 lb).

3. With the brake pedal depressed, stop the engine

when the vacuum gauge reading reaches 500

mmHg (19.7 inHg).

4. Observe the vacuum gauge for 15 seconds.

If

the

gauge shows 475—500 mmHg (18.7—19.7

inHg), the unit is operating.

76G11X066

b) Checking for hydraulic pressure

1. If with the engine stopped (when vacuum is 0

mmHg) the relation between pedal force and fluid

pressure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) | 1,177 kPa (12 kg/cm2, 171 psi) mia

76G11X-067

2. Start the engine. Depress the brake pedal when

the vacuum reaches 500 mmHg (19.7 inHg).

If the relation between pedal force and fluid pres-

sure is within specification, the unit is operating.

Pedal force Fluid pressure

196 N (20 kg, 44 lb) 7,063 kPa (72 kg/cm2, 1,024 psi) min.

76G11X068

11-28