MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: fuel cap release, audio, service interval, tire pressure reset, check oil, tow, check engine

Page 251 of 1865

DISASSEMBLY (INJECTION PUMP) 1 C

INJECTION PUMP

76G01C-082

1. No.3 engine mount and idler

2. Injection pipe

3. Injection pump

4. Oil level gauge and stay

5. Oil pipe

6. Fuel feed pipe

7. Oil pressure switch

8. Water pipe

9. Water pump

Disassembly Note

Injection pump

Remove the injection pump with its brackets.

If separate them, adjust the injection timing after in-

stalling the timing belt referring to Section 4D.

76G01C-083

1C-39

Page 252 of 1865

1 C DISASSEMBLY (CYLINDER HEAD)

CYLINDER HEAD

76G01C-079

1. Thermostat cover

2. Thermostat

3. Thermostat case

4. Front and rear engine

hanger

5. Fuel leak pipe

6. Injection nozzle

7. Glow cord

8. Glow plug

9. Camshaft cap

10. Oil seal

11. Camshaft

12. Cylinder head bolt

13. Cylinder head and gasket

14. Tappet and adjusting disc

15. Valve keepers

16. Upper spring seat

17. Valve spring

18. Valve

19. Lower spring seat

20. Valve seal

21. Valve guide and clip

1C-40

Page 253 of 1865

DISASSEMBLY (CYLINDER HEAD) 1 C

76G01C-085

76G01C-086

76G01C-087

A.

Disassembly Note

Camshaft

During disassembly, clean the bearings and journals,

and measure the following:

1. Camshaft end play. (Refer to page 1C—55)

2. Camshaft journal oil clearance . (Refer to page

1C—54)

Camshaft cap

Loosen the camshaft cap nuts in two or three steps

in the order shown in the figure.

Cylinder head bolt

1. Loosen the cylinder head bolts in two or three steps

in the order shown in the figure.

2. Remove the cylinder head by tapping the cylinder

head with a plastic hammer.

Adjusting disc and tappet

Remove the adjusting discs and tappets as a set.

Caution

All adjusting discs and tappets should be dis-

assembled in a way so that correct reassem-

bly can be performed.

4BG01B-094

1C—41

Page 254 of 1865

1 C DISASSEMBLY (CYLINDER HEAD)

Valve spring

Remove the valve, spring seats and valve keepers

from the cylinder head with the SST.

76G01C-088

Valve seal

After removing the lower spring seats, remove the

valve seals with the SST.

76G01C-089

Ball

_ Combustion

"X^ chamber

Glow plug hole

Combustion chamber insert

Caution

Do not remove the combustion chamber in-

sert as the cylinder head and the combustion

chamber insert are machined together, re-

place the combustion chamber insert and cyl-

inder head as an assembly.

76G01C-090

1C-42

Page 255 of 1865

DISASSEMBLY (CYLINDER BLOCK) 1 C

CYLINDER BLOCK—I

76G01C-091

1. Clutch cover

2. Clutch disc

3. Flywheel

4. End plate

5. Oil pan

6. Oil strainer

7. Stiffener (RF-CX)

8. Rear cover

9. Timing belt pulley

10. Oil pump assembly

Flywheel

1. Install the SST to the flywheel.

2. Remove the clutch cover, clutch disc and flywheel.

Timing belt pulley

1. Reverse the direction of the SST.

2. Remove the timing belt pulley.

76G01C-092

1C—43

Page 256 of 1865

1 C DISASSEMBLY (CYLINDER BLOCK)

Oil pan

1. Remove the oil pan mounting bolts.

2. Insert a scraper or a suitable tool between the oil

pan and the stiffener to separate them.

Caution

Do not bend the oil pan when prying loose.

3. Remove the oil pan.

86U01X-072

1C—44

Page 257 of 1865

DISASSEMBLY (CYLINDER BLOCK) 1 C

CYLINDER BLOCK—II

76G01C-093

1. Connecting rod cap

2. Connecting rod bearing

3. Connecting rod and piston

4. Piston ring

5. Snap ring

6. Piston pin

7. Main bearing cap

8. Crankshaft

9. Main bearing

10. Pilot bearing

11. Oil jet

12. Cylinder block

Disassembly Note

Connecting rod and cap

During disassembly, clean the bearing, connecting

rod, and crankpin, and measure the following:

1. Connecting rod side clearance. (Refer to page

1C-67.)

2. Crankpin oil clearance.(Refer to page 1C—66.)

76G01C-094

1C-45

Page 258 of 1865

1 C DISASSEMBLY (CYLINDER BLOCK)

Piston and connecting rod

1. Before disassembling the piston and connecting

rod, check the oscillation torque as shown in the

figure. If the large end does not drop by its own

weight, replace the piston or the piston pin.

76G01C-095

2. Remove the snap rings from the piston.

3. Remove the piston pin with the SST.

76G01C-249

76G01C-096

Main bearing cap

During disassembly, clean the bearings, main jour-

nals, and caps, and measure the following:

1. Crankshaft end play. (Refer to page 1C—65.)

2. Main journal oil clearance. (Refer to page 1C—64.)

Pilot bearing

Remove the pilot bearing from the crankshaft with the

SST.

76G01C-097

1C—46

Page 259 of 1865

INSPECTION AND REPAIR 1C

INSPECTION AND REPAIR

1. Clean all parts, taking care to remove any gasket fragments, dirt, oil or grease, carbon, moisture

residue, or other foreign materials.

2. Inspect and repair must be performed in the order specified.

Caution

Be careful not to damage the joints or friction surfaces of aluminum alloy components (such

as the cylinder head or pistons).

86U01X-077

Cylinder Head

1. Inspect the cylinder head for damage, cracks, and

leakage of water or oil. Replace if necessary.

2. Measure the cylinder head distortion in the seven

directions shown in the figure.

Distortion: 0.10 mm (0.004 in) max.

76G01C-098

3. If the cylinder head distortion exceeds specificati-

on replace the cylinder head.

Height:

133.9—134.1 mm (5.272—5.280 in)

Caution

Do not attempt to repair a cylinder head by

milling or grinding.

76G01C-099

4. Measure the manifold contact surface distortion in

the three directions shown in the figure.

Distortion: 0.20 mm (0.008 in) max.

5. If distortion exceeds specification replace the cyl-

inder head.

76G01C-100

1C—47

Page 260 of 1865

1C INSPECTION AND REPAIR

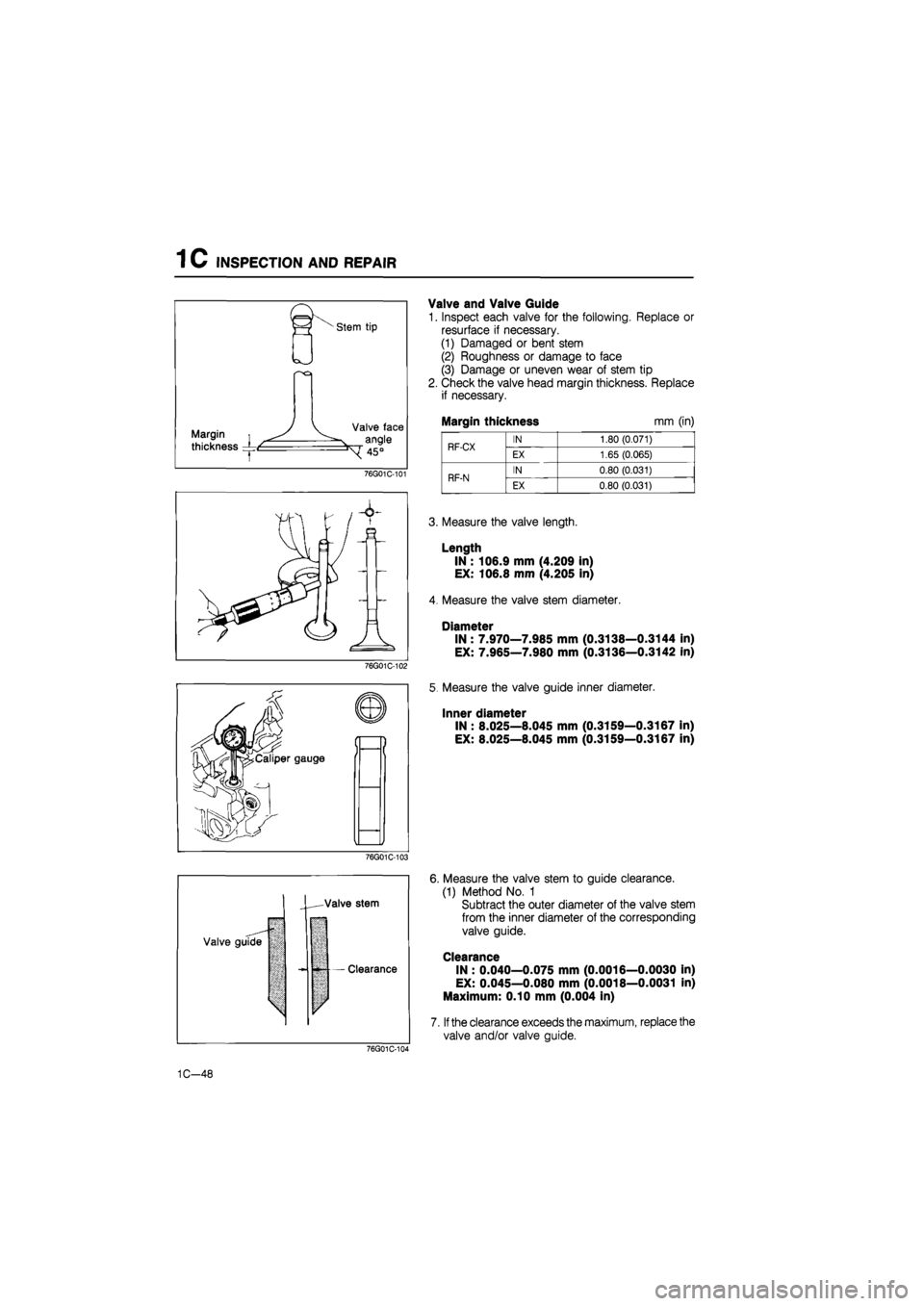

Stem tip

Margin i

thickness

T

Valve face

angle

^45°

76G01C-101

76G01C-102

" & ©

JMFc

•^Caliper gauge

^V^r "M

m

Valve and Valve Guide

1. Inspect each valve for the following. Replace or

resurface if necessary.

(1) Damaged or bent stem

(2) Roughness or damage to face

(3) Damage or uneven wear of stem tip

2. Check the valve head margin thickness. Replace

if necessary.

Margin thickness mm (in)

RF-CX IN 1.80 (0.071) RF-CX EX 1.65 (0.065)

RF-N IN 0.80 (0.031) RF-N EX 0.80 (0.031)

3. Measure the valve length.

Length

IN : 106.9 mm (4.209 in)

EX: 106.8 mm (4.205 in)

4. Measure the valve stem diameter.

Diameter

IN : 7.970—7.985 mm (0.3138—0.3144 in)

EX: 7.965—7.980 mm (0.3136—0.3142 in)

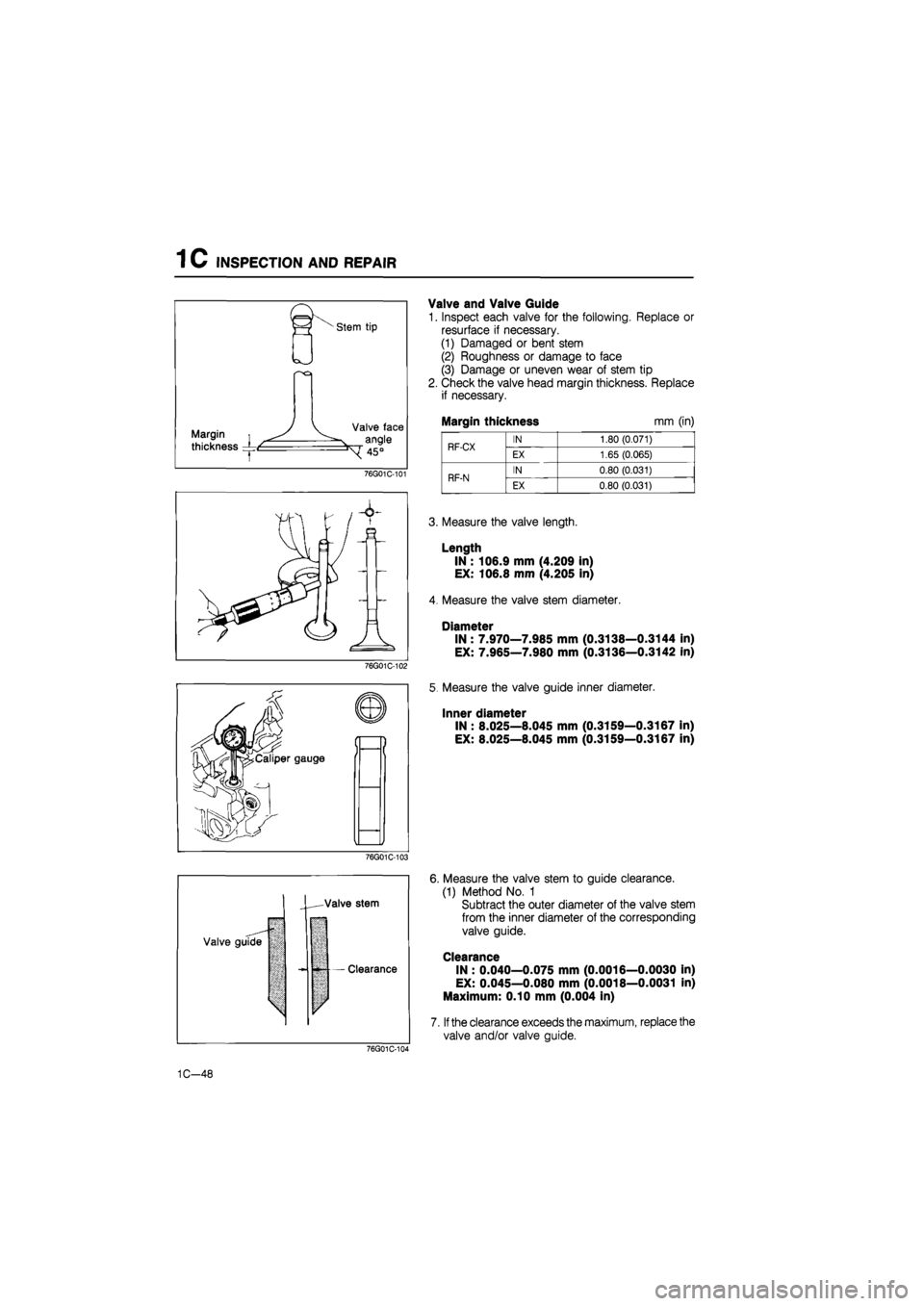

5. Measure the valve guide inner diameter.

Inner diameter

IN : 8.025—8.045 mm (0.3159—0.3167 in)

EX: 8.025—8.045 mm (0.3159—0.3167 in)

76G01C-103

-Valve stem

Valve guide

Clearance

V

6. Measure the valve stem to guide clearance.

(1) Method No. 1

Subtract the outer diameter of the valve stem

from the inner diameter of the corresponding

valve guide.

Clearance

IN : 0.040—0.075 mm (0.0016—0.0030 in)

EX: 0.045—0.080 mm (0.0018—0.0031 in)

Maximum: 0.10 mm (0.004 in)

7.

If

the clearance exceeds the maximum, replace the

valve and/or valve guide.

76G01C-111

1C-48

Trending: catalytic converter, maintenance, fuse diagram, cooling, bonnet, sunroof, coolant reservoir