MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 261 of 1865

1C INSPECTION AND REPAIR

76G01C-105

Replacement of valve guide

Caution

When the valve guide is replaced, check the

gap between the valve and guide once again.

The valve seal should be installed after in-

spection and repair of the valve seat.

Don't misassemble the valve guides because

intake and exhaust valve guides have a differ-

ent seat.

Intake side valve guide longer

Exhaust side valve guide shorter

Removal

1. Gradually heat the cylinder head in water to ap-

prox. 90°C (194°F).

76G01C-106

2. Remove the valve guide from the side opposite the

combustion chamber with the SST.

86U01X-084

Installation

1. Gradually heat the cylinder head in water to ap-

prox. 90°C (194°F).

76G01C-111

1C-49

Page 262 of 1865

1C INSPECTION AND REPAIR

76G01C-103

76G01C-104

76G01C-110

2. Fit the clip onto the valve guide.

3. Tap the valve guide in from the side opposite the

combustion chamber with the SST until the clip

contacts the cylinder head.

4. Check the guide protrusion height (dimension A

in the figure) is as specified.

Height:

8.3—8.8 mm (0.327—0.346 in)

Valve Seat

1. Inspect the contact surface of the valve seat and

valve face for the following.

(1) Roughness

(2) Damage

2. If necessary, resurface the valve seat to the speci-

fied angle with valve seat cutter and/or resurface

the valve face.

Angle

RF-CX IN 60° RF-CX EX 45°

RF-N IN 45° RF-N EX 45°

3. Apply a thin coat of prussian blue to the valve face.

4. Check the valve seating by pressing the valve

against the seat.

(1) If blue does not appear 360° around the valve

face, replace the valve.

(2) If blue does not appear 360° around the valve

seat, resurface the seat.

76G01C-111

1C-50

Page 263 of 1865

INSPECTION AND REPAIR 1C

76G01C-112

76G01C-113

76G01C-114

5. Check the seat contact width.

Width mm (in)

RF-CX IN 1.4-1.8 (0.055-0.071) RF-CX EX 1.64-2.04 (0.065-0.080)

RF-N IN 1.7—2.3 (0.067-0.091) RF-N EX 1.7—2.3 (0.067—0.091)

6, Check that the valve seating position is at the cen-

ter of the valve face.

(1) If the seating position is too high, correct the

valve seat as below.

Angle

- - • -1st 2nd

RF-CX IN 75° 60° RF-CX EX 60° 45°

RF-N IN 60° 45° RF-N EX 60° 45°

(2) If the seating position is too low, correct the

valve seat as below.

Angle

1st 2nd

RF-CX IN 15° 45° RF-CX EX 30° 45°

RF-N IN 30° 45° RF-N EX 30° 45°

7. Seat the valve to the valve seat with a lapping

compound.

Caution

Do not let compound adhere to the valve

stem.

8. Measure the receded amount from the cylinder

head surface by using a feeler gauge.

Recession-

0.75—1.05 mm (0.030—0.041 in)

Maximum: 2.55 mm (0.100 in)

(1) If the receded amount is 1.55—2.55 mm

(0.061—0.100 in), install the washer into the

valve spring seat area.

The washer thickness should be equal to the

amount subtracted 1 mm (0.04 in) from the

receded amount.

(2) If the receded amount exceeds 2.55 mm

(0.100 in), replace the cylinder head.

76G01C-144

1C-51

Page 264 of 1865

INSPECTION AND REPAIR 1C

76G01C-116

76G01C-117

—Angle limit

S//////A 777;////////

Combustion Chamber Insert

1. Inspect the combustion chamber insert for damage

or crack, replace if necessary.

2. Mesure the receded or projected amount of com-

bustion chamber insert from cylinder head surface.

Recession: 0.020 mm (0.0008 in) max.

Projection: 0.005 mm (0.0001 in) max.

If it exceeds the specification, replace the combus-

tion chamber insert and the cylinder head as an as-

sembly.

Valve Spring

1. Inspect each valve spring for cracks or damage.

2. Check the free length and angle. Replace if

necessary.

Free length: 45.11 mm (1.776 in)

Minimum: 44.8 mm (1.764 in)

Angle: 1.6 mm (0.06 in) max.

76G01C-118

Tappet

1. Check the tappet to tappet hole clearance.

(1) Measure the tappet outer diameter.

Diameter:

34.95—34.97 mm (1.3764—1.3768 in)

76G01C-144

1C-52

Page 265 of 1865

INSPECTION AND REPAIR 1C

(2). Measure the inner diameter of the tappet hole

in the cylinder head.

Hole diameter:

34.99—35.01 mm (1.3776—1.3787 in)

2. Calculate the difference (clearance) between the

tappet diameter and hole inner diameter.

If the clearance exceeds the specification , replace

the tappet or the cylinder head.

Clearance: 0.10 mm (0.004 in) max.

76G01C-120

76G01C-121

76G01C-122

Camshaft

1. Set the front and rear journals on V-blocks.

Check the camshaft runout. Replace if necessary.

Runout: 0.10 mm (0.004 in) max.

2. Check the cam for wear or damage. Replace if

necessary.

3. Check the cam lobe height at the two points as

shown in the figure.

Height mm (in)

' " " Standard Mimimum

RF-CX IN 42.521 (1.6741) 42.11 (1.658) RF-CX EX 45.300 (1.7835) 44.90 (1.768)

RF-N IN 44.306 (1.7443) 43.90 (1.728) RF-N EX 45.300 (1.7835) 44.90 (1.768)

4. Measure wear of the journals in X and Y directions

at the two points as shown in the figure.

Diameter:

31.959—31.975 mm (1.2582—1.2589 in)

Out-of-round: 0.05 mm (0.002 in) max.

76G01C-144

1C-53

Page 266 of 1865

INSPECTION AND REPAIR 1C

n a. n _ n

76G01C-124

76G01C-250

76G01C-125

5. Measure the oil clearance of the camshaft.

(1) Remove the tappets and adjusting discs from

the cylinder head, and separate them by

cylinder.

(2) Clean the camshaft and cylinder head journal.

(3) Install the camshaft into position.

(4) Set a Plasti-gauge on the camshaft journal in

the axial direction.

(5) Install the camshaft caps according to the num-

ber and arrow marks.

(6) Tighten the camshaft caps evenly and in ord-

er shown in the figure.

Tighten torque:

20—26 Nm (2.0—2.7 m-kg, 14—20 ft-lb)

(7) Remove the camshaft caps and measure the

oil clearance.

Oil clearance:

0.025—0.066 mm (0.0010—0.0026 in)

Maximum: 0.10 mm (0.004 in)

(8) If the oil clearance exceeds the maximum,

replace the cylinder head or camshaft.

76G01C-144

1C-54

Page 267 of 1865

INSPECTION AND REPAIR 1C

76G01C-127

76G01C-128

Feeler gauge

76G01C-129

6. Measure the camshaft end play. If it exceeds the

maximum, replace the camshaft and/or the cylin-

der head.

End play:

0.02—0.15 mm (0.0008—0.0059 in)

Maximum: 0.20 mm (0.008 in)

Cylinder Block

1. Check the cylinder block. Repair or replace if

necessary.

(1) Leakage damage

(2) Cracks

(3) Scoring of wall

2. Measure the distortion of the top surface of the cyl-

inder block in the six directions as shown in the

figure.

Distortion: 0.10 mm (0.004 in) max.

3. If the distortion exceeds the maximum, replace the

cylinder block.

Caution

Do not grind the surface of the cylinder block.

4. Measure the cylinder bore in directions X and Y

at three levels in each cylinder as shown.

Cylinder bore mm (in)

Size Bore

Standard 86.000-86.022 (3.3858—3.3867)

0.25 (0.010) oversize 86.250—86.272 (3.3957—3.3965)

0.50 (0.020) oversize 86.500-86.522 (3.4055—3.4064)

76G01C-144

1C-55

Page 268 of 1865

1C INSPECTION AND REPAIR

(1) If the difference between the measurement A

and C exceeds the maximum taper, rebore the

cylinder to oversize.

Taper: 0.022 mm (0.0009 in) max.

76G01C-131

Ot?

a

—-]

^y A

o ^r c^

O

n r

(2) If the difference between the measurement X

and Y exceeds the maximum out-of-round, re-

bore the cylinder to oversize.

Out-of-round: 0.022 mm (0.0009 in) max.

Caution

The boring size should be based on the size

of an oversize piston and be the same for all

cylinders.

76G01C-132

5. If the upper part of the cylinder wall shows uneven

wear, remove the ridge with a ridge reamer.

86U01X-102

Piston

1. Inspect the outer circumferences of all pistons for

seizure or scoring. Replace if necessary.

2. Measure the outer diameter of each piston at a right

angle (90°) to the piston pin, 19 mm (0.75 in)

above the bottom of piston.

Piston diameter mm (in)

Size Diameter

Standard 85.957-85.983 (3.3841-3.3852)

0.25 (0.010) oversize 86.207-86.233 (3.3940-3.3950)

0.50 (0.020) oversize 86.457-86.483 (3.4038-3.4048)

76G01C-133

1C—56

Page 269 of 1865

INSPECTION AND REPAIR 1C

-Clearance

3. Check the piston to cylinder clearance.

Clearance-

0.032—0.050 mm (0.0013—0.0020 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Note

If the piston is replaced, replace the piston

rings also.

76G01C-134

69G01A-125

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top)

RF-CX: 0.18—0.22 mm (0.0071—0.0087 in)

RF-N : 0.05—0.09 mm (0.0020—0.0035 in)

Clearance (Second):

0.04—0.08 mm (0.0016—0.0031 in)

Maximum: 0.2 mm (0.008 in)

2.

If

the clearance exceeds the maximum, replace the

piston.

3. Inspect the piston rings for damage, abnormal

wear, or breakage. Replace if necessary.

4. Insert the piston ring into the cylinder by hand and

push it to the bottom of the ring travel in using the

piston.

86U01X-104

5. Measure each piston ring end gap with a feeler

gauge. Replace if necessary.

End gap (Top and second)

RF-CX: 0.20—0.35 mm (0.008—0.014 in)

RF-N : 0.20—0.40 mm (0.008—0.016 in)

End gap (Oil rail):

0.20—0.40 mm (0.008—0.016 in)

Maximum: 1.0 mm (0.039 in)

76G01C-144

1C-57

Page 270 of 1865

INSPECTION AND REPAIR 1C

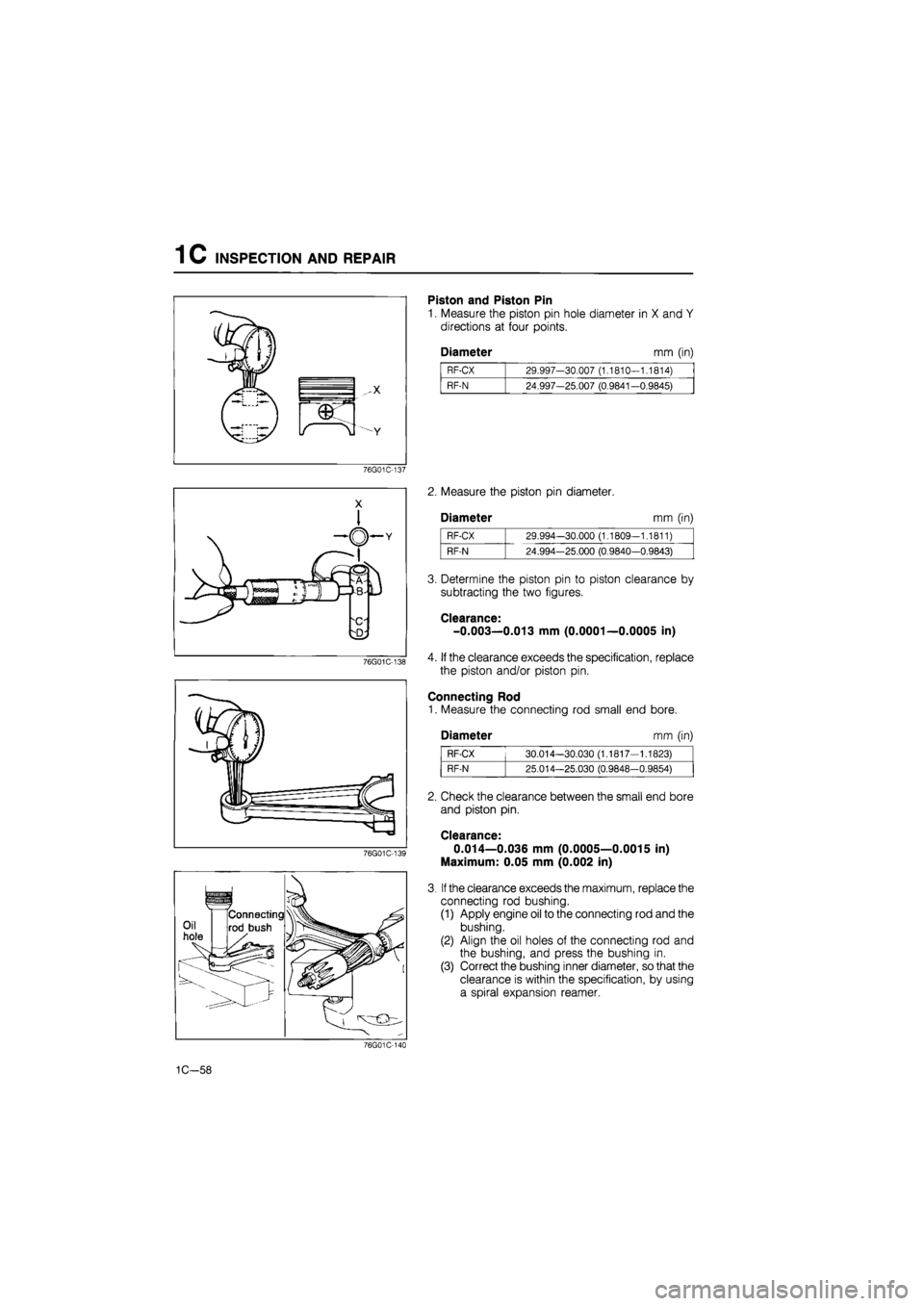

Piston and Piston Pin

1. Measure the piston pin hole diameter in X and Y

directions at four points.

Diameter mm (in)

RF-CX 29.997-30.007 (1.1810-1.1814)

RF-N 24.997-25.007 (0.9841-0.9845)

76G01C-137

76G01C-139

2. Measure the piston pin diameter.

Diameter mm (in)

RF-CX 29.994-30.000 (1.1809-1.1811)

RF-N 24.994-25.000 (0.9840-0.9843)

3. Determine the piston pin to piston clearance by

subtracting the two figures.

Clearance-

-0.003—0.013 mm (0.0001—0.0005 in)

4. If the clearance exceeds the specification, replace

the piston and/or piston pin.

Connecting Rod

1. Measure the connecting rod small end bore.

Diameter mm (in)

RF-CX 30.014-30.030 (1.1817-1.1823)

RF-N 25.014-25.030 (0.9848-0.9854)

2. Check the clearance between the small end bore

and piston pin.

Clearance*

0.014—0.036 mm (0.0005—0.0015 in)

Maximum: 0.05 mm (0.002 in)

3. If the clearance exceeds the maximum, replace the

connecting rod bushing.

(1) Apply engine oil to the connecting rod and the

bushing.

(2) Align the oil holes of the connecting rod and

the bushing, and press the bushing in.

(3) Correct the bushing inner diameter, so that the

clearance is within the specification, by using

a spiral expansion reamer.

76G01C-144

1C-58