fuel pump MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 536 of 1865

4B EEC SYSTEM

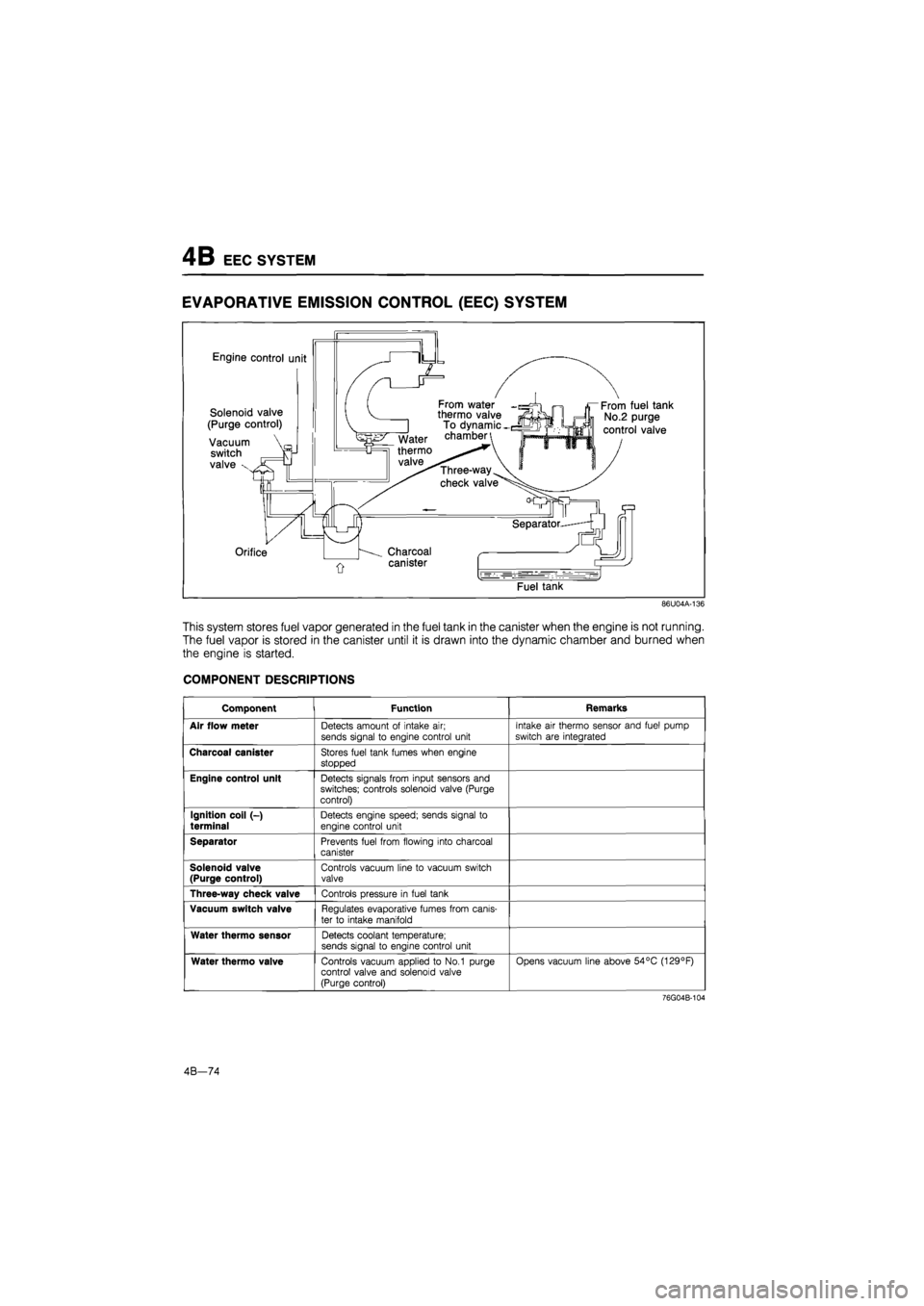

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Engine control unit

Solenoid valve

(Purge control)

Vacuum

switch

valve x

From water thermo valve To dynamic -chamber

Three-way

check valve

Orifice Charcoal

canister

From fuel tank

No.2 purge

control valve

Fuel tank

86U04A-136

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter Detects amount of intake air; sends signal to engine control unit

Intake air thermo sensor and fuel pump

switch are integrated

Charcoal canister Stores fuel tank fumes when engine

stopped

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Purge control)

Ignition coil (-)

terminal Detects engine speed; sends signal to

engine control unit

Separator Prevents fuel from flowing into charcoal canister

Solenoid valve (Purge control) Controls vacuum line to vacuum switch valve

Three-way check valve Controls pressure in fuel tank

Vacuum switch valve Regulates evaporative fumes from canis-

ter to intake manifold

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo valve Controls vacuum applied to No.1 purge control valve and solenoid valve (Purge control)

Opens vacuum line above 54°C (129°F)

76G04B-104

4B—74

Page 556 of 1865

4B CONTROL SYSTEM

AIR FLOW METER

Potentiometer

Intake air thermo

sensor Fc EI E2 VB VC VS THA

Fuel pump switch

Connector-—

I

lOQDOQOD i

69G04C-100

Inspection

1. Remove the air flow meter. (Refer to page 4B—31)

2. Check the air flow meter body for cracks.

3. Verify that the measuring plate moves smoothly.

4. Disconnect the connector from the air flow meter.

5. Using an ohmmeter, check resistance between the

terminals with the measuring plate fully closed and

fully open.

6. Connect the connector to the air flow meter after

inspecting.

76G04B-112

Terminal Resistance (Q) Terminal Fully closed | Fully open

E2<->VS More than 20

E2«VC 100-300

E2«VB 200-400

E2«THA (Intake air thermo sensor)

-20°C (—4°F) 13.6-18.4 kfi 20°C (68°F) 2.21-2.69 kfi 60°C (140°F) 493—667 0

Ei<->Fc OO 0

Note

Refer to page 4B—31 for replacement of the

air flow meter.

76G04B-113

4B—94

Page 562 of 1865

4C

FUEL AND EMISSION

CONTROL SYSTEMS

(FUEL INJECTION FE DOHC)

OUTLINE 4C— 2

COMPONENT APPLICATION 4C— 2

SYSTEM DIAGRAM 4C— 3

COMPONENT LOCATION 4C— 4

VACUUM HOSE ROUTING

DIAGRAM 4C— 7

SPECIFICATIONS 4C— 8

TROUBLESHOOTING GUIDE 4C— 9

TROUBLESHOOTING WITH SST.. 4C— 11

INSPECTION PROCEDURE 4C— 12

PRINCIPLE OF CODE CYCLE 4C— 13

CODE NUMBER 4C— 14

SWITCH MONITOR FUNCTION 4C— 25

INSPECTION PROCEDURE 4C— 26

IDLE ADJUSTMENT 4C— 29

IDLE SPEED 4C— 29

IDLE MIXTURE 4C— 30

INTAKE AIR SYSTEM 4C— 31

COMPONENT DESCRIPTION 4C— 31

REMOVAL 4C— 32

PARTS INSPECTION 4C— 33

REPLACEMENT 4C— 36

INSTALLATION 4C— 37

VARIABLE INERTIA CONTROL

(VIC) SYSTEM 4C— 39

COMPONENT DESCRIPTION 4C— 40

TROUBLESHOOTING 4C— 40

IDLE SPEED CONTROL

(ISC) SYSTEM 4C— 44

COMPONENT DESCRIPTION 4C— 45

TROUBLESHOOTING 4C— 46

REMOVAL 4C— 48

FUEL SYSTEM 4C— 49

COMPONENT DESCRIPTION 4C— 50

TROUBLESHOOTING 4C— 51

FUEL PRESSURE RELEASE AND

SERVICING FUEL SYSTEM 4C— 52

MULTI-PRESSURE TESTER 4C— 53

FUEL PUMP 4C— 56

PULSATION DAMPER 4C— 57

INJECTOR 4C— 57

TRANSFER PUMP CONTROL

SYSTEM 4C— 59

REPLACEMENT 4C— 60

FUEL TANK 4C— 65

PRESSURE REGULATOR

CONTROL (PRC) SYSTEM 4C— 68

COMPONENT DESCRIPTION 4C— 69

TROUBLESHOOTING 4C— 69

DECELERATION CONTROL

SYSTEM 4C— 72

COMPONENT DESCRIPTION 4C— 73

TROUBLESHOOTING 4C— 73

ELECTRONIC SPARK ADVANCE

(ESA) CONTROL SYSTEM 4C— 75

COMPONENT DESCRIPTION 4C— 76

TROUBLESHOOTING 4C— 76

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM 4C- 77

COMPONENT DESCRIPTION 4C— 77

TROUBLESHOOTING 4C— 78

EVAPORATIVE EMISSION

CONTROL (EEC) SYSTEM 4C— 80

COMPONENT DESCRIPTION 4C— 80

TROUBLESHOOTING 4C— 81

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM.... 4C— 86

COMPONENT DESCRIPTION 4C— 86

PCV VALVE 4C— 86

EXHAUST SYSTEM

(UNLEADED FUEL) 4C— 87

REMOVAL AND INSTALLATION.. 4C— 88

INSPECTION 4C— 88

EXHAUST SYSTEM

(LEADED FUEL) 4C— 89

REMOVAL AND INSTALLATION.. 4C— 90

CONTROL SYSTEM 4C— 91

RELATIONSHIP CHART 4C— 92

EGI MAIN FUSE 4C— 96

CONTROL RELAY 4C— 96

NEUTRAL SWITCH 4C— 97

CLUTCH SWITCH 4C— 97

P/S PRESSURE SWITCH 4C— 97

ENGINE CONTROL UNIT 4C— 98

E/L CONTROL UNIT 4C—102

AIR FLOW SENSOR 4C—103

THROTTLE SENSOR 4C—104

IDLE SWITCH 4C—106

WATER THERMO SWITCH 4C—106

WATER THERMO SENSOR 4C—107

OXYGEN SENSOR 4C—107

DISTRIBUTOR 4C—108

OXYGEN SENSOR HEATER 4C—109

KNOCK SENSOR 4C—109

INTAKE AIR THERMO SENSOR .. 4C—110

76G04C-001

Page 563 of 1865

4C OUTLINE

OUTLINE

COMPONENT APPLICATION

Item Unleaded fuel Leaded fuel

Air flow sensor (Hot wire type) O O

Dynamic chamber with vacuum chamber o o

INTAKE AIR SYSTEM Throttle body (Two bore) o o

Throttle sensor o X

Idle switch o o

Resonance chamber o o

VARIABLE INERTIA CONTROL SYSTEM o 0

IDLE SPEED CONTROL SYSTEM o o

Injector o o

Pressure regulator o o

Pulsation damper o o

FUEL SYSTEM Intank filter o o

Transfer pump 0 (4WS) O (4WS)

Transfer pump switch O (4WS) O (4WS)

Fuel pump control unit O (4WS) O (4WS)

PRESSURE REGULATOR CONTROL SYSTEM o o

Canister o x

EVAPORATIVE Three-way check valve o x

EMISSION CONTROL Two-way check valve X o SYSTEM Separator o o

Solenoid valves o x

EGR control valve o x

EGR SYSTEM EGR modulator valve o X

Solenoid valve o X

ELECTRONIC SPARK

ADVANCE CONTROL

SYSTEM

Igniter o o ELECTRONIC SPARK

ADVANCE CONTROL

SYSTEM Knock control function X o

Water thermo sensor o o

Water thermo switch o X

Intake air thermo sensor o o

Oxygen sensor o X

CONTROL SYSTEM Distributor o o CONTROL SYSTEM Ne signal o o

G signal o o

Clutch switch o o

Neutral switch o o

Knock sensor x o

FAIL-SAFE CONTROL SYSTEM o o

MONITOR FUNCTION o o

76G04C-002

4C—2

Page 564 of 1865

Fuel filter Solenoid valve *1 Solenoid valve *1

(No.2 purge control) (No.1 purge control)

Separator Three way

Injector

,Distributor

Fuel pump

In-take filter

Air flow sensor

Water thermo sensor

Knock sensor

switches

Intake air thermo sensor

— Water thermo switch *1 __ j—Ig. switch (ST) j_J,—lg. switch (ON) -A/C switch 'A/C magnet clutch P/S switch —Head light switch —Rear defroster switch —Cooling fun switch —Blower switch —Neutral and clutch

O) <

{/> H m

g >

o 3D >

^Throttle sensor *1

Air valve

Solenoid valve

(ISC)

EGR control valve *1

EGR modulator valve *1

0 1 CO

a *1...Unleaded fuel only

*2...Leaded fuel only

Oxygen

sensor *1

One-way check valve

Shutter valve actuator Catalytic

converter *1 Solenoid valve (VIC)

O c

m

o

Page 569 of 1865

4C OUTLINE

SPECIFICATIONS

Item Engine type Unleaded Fuel Leaded Fuel

Idle speed rpm 750 ± 50

Throttle body

Type Horizontal draft (2-barrel)

Throat diameter mm (in) No. 1 46 (1.8) Throat diameter mm (in) No. 2 40 (1.6)

Fuel pump

Type Impeller (in tank)

Output pressure kPa (kg/cm2, psi) Main pump: 441-588 (4.5—6.0, 64—85) Transfer pump: 20—25 (0.20—0.25, 2.8—3.6)

Feeding capacity cc (cu in)/10 sec. Main pump: More than 220 (13.4) Transfer pump: More than 190 (11.6)

Fuel filter

Type Low pressure side Nylon element Type High pressure side Paper element

Pressure regulator

Type Diaphragm

Regulating pressure kPa (kg/cm2, psi) 235-275 (2.4 -2.8, 34-40)

Injector

Type High-ohmic

Type of drive Voltage

Resistance G 12--16

Injection amount cc (cu in)/15 sec. 66-91 (4.03-5.55)

Idle speed control valve

Solenoid resistance a 6.3--9.9

Fuel tank

Capacity liters (US gal, Imp gal) 60 (15.9, 13.2), 57 (15.0, 12.5): 4-wheel steering vehicle

Air cleaner

Element type Dry

Fuel

Specification Unleaded (95 RON or more) Leaded or unleaded fuel

(95 RON or more)

76G04C-008

4C-8

Page 602 of 1865

VIC SYSTEM 4C

System Inspection

1. Warm up the engine to normal operating temper-

ature and run it at idle.

2. Check that the rod has been pulled into the ac-

tuator.

76G04C-068

3. Increase the engine speed and check that the rod

is released above specification.

Specification:

Approx. 5,200 rpm....Unleaded fuel

Approx. 5,400 rpm....Leaded fuel

76G04C-069

Shutter Valve Actuator

1. Disconnect the vacuum hose from the actuator,

and connect a vacuum pump to the actuator.

2. Apply approx. 200 mmHg (7.9 inHg) vacuum

and check that the rod is pulled into the actuator.

76G04C-070

VIC Solenoid Valve

1. Disconnect the vacuum hoses from the solenoid

valve.

2. Blow through the valve from port A and check that

air flows from port B.

76G04C-071

4C—41

Page 603 of 1865

4C VIC SYSTEM

3. Disconnect the solenoid valve connector and con-

nect 12V and a ground to the terminals of the sole-

noid valve.

4. Blow through the valve from port A and check that

air flows from the air filter.

76G04C-072

Electrical Signal

1. Connect a voltmeter to the VIC solenoid valve (O

wire).

2. Increase the engine speed and note the voltmeter

reading.

Voltmeter reading Unleaded fuel Leaded fuel

Approx. 12V Below 5,200 rpm Below 5,400 rpm

Below 2.0V Approx. 5,100 rpm Approx. 5,300 rpm

76G04C-073

Vacuum Signal

1. Disconnect the vacuum hose from the actuator.

2. Place a finger over the port opening and check

that air is pulled in at idle.

3. Increase the engine speed above specification and

check that air is not pulled in.

Specification:

Approx. 5,200 rpm Unleaded fuel

Approx. 5,400 rpm Leaded fuel

4. Connect the vacuum hose.

76G04C-074

76G04C-075

4C-42

Vacuum Chamber

1. Disconnect vacuum hose A from the dynamic

chamber.

2. Connect the vacuum pump to the dynamic

chamber.

3. Apply vacuum and check that it is held.

4. If not correct, check the one-way check valve for

vacuum leakage. (Refer to page 4C—43.)

Note

10 mm Hg (0.39 inHg) drop per 30 seconds is

allowable.

5. If the one-way check valve is good, check the dy-

namic chamber.

Page 610 of 1865

FUEL SYSTEM 4C

FUEL SYSTEM

76G04C-087

This system supplies the necessary fuel for combustion at a constant pressure to the injectors. Fuel

is metered and injected into the intake manifold according to the injection control signals from the en-

gine control unit. It consists of the fuel pump, fuel filters, delivery pipe, pulsation damper, pressure

regulator, injectors, fuel pump control unit, and the control relay.

The fuel pump is mounted in the fuel tank to minimize the operating noise of the fuel pump. The injec-

tors directly supplied with battery voltage through the control relay. The connector of the injectors is

white to distinguish the injectors for FE DOHC from those of other engines.

Due to the installation of the steering angle transfer shaft for the 4-wheel steering (4WS) the fuel tank

of 4WS vehicles is designed with separate right and left sections. A transfer pump is used to pump

fuel from the left side to the right side.

4C—49

Page 611 of 1865

4C FUEL SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Air flow sensor Detects amount of intake air;

sends signal to engine control unit

Clutch switch Detects in-gear condition; sends signal to engine control unit Switch ON when clutch pedal released

Engine control unit Detects signals from input sensors and switches; controls injector and fuel pump operations

Fuel filter Filters fuel

Fuel pump Provides fuel to injectors • Operates while engine running

• Installed in fuel tank

Fuel pump control unit (4WS) Monitors fuel level in left section; controls transfer pump operation

G signal pick-up Detects No.1 cylinder TDC; sends signal to engine control unit Installed in distributor

Idle switch Detects when throttle valve fully closed; sends signal to engine control unit Installed on throttle body

Ignition switch (ST position) Sends engine cranking signal to engine control unit

Injector Injects fuel into intake port • Controlled by signals from engine control unit • High-ohmic injector

Intake air thermo sensor Detects intake air temperature; send signal to engine control unit

Control relay Supplies electric current to injectors fuel pump and engine control unit

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to engine control unit Installed in distributor

Neutral switch Detects in-gear condition; sends signal to engine control unit

Switch ON when in gear

Oxygen sensor (Unleaded fuel) Detects oxygen concentration; sends signal to engine control unit

• Zirconia ceramic and platinum coating • Integrated heater coil

Pressure regulator Adjusts fuel pressure supplied to injectors

Pulsation damper Absorbs fuel pulsation

Throttle sensor Detects throttle valve opening angle;

sends signal to engine control unit

Installed on throttle body

Transfer pump (4WS) Pumps fuel from the left to the right side Controlled by fuel pump control unit

Transfer pump switch (4WS) Detects fuel level in left section;

sends signal to control unit

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch (Unleaded fuel) Detects radiator coolant temperature; sends signal to engine control unit ON: above 17°C (63°F)

76G04C-088

4C-50