MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: wiper fluid, engine coolant, brakes, oil viscosity, fuel pressure, height, alternator belt

Page 801 of 1865

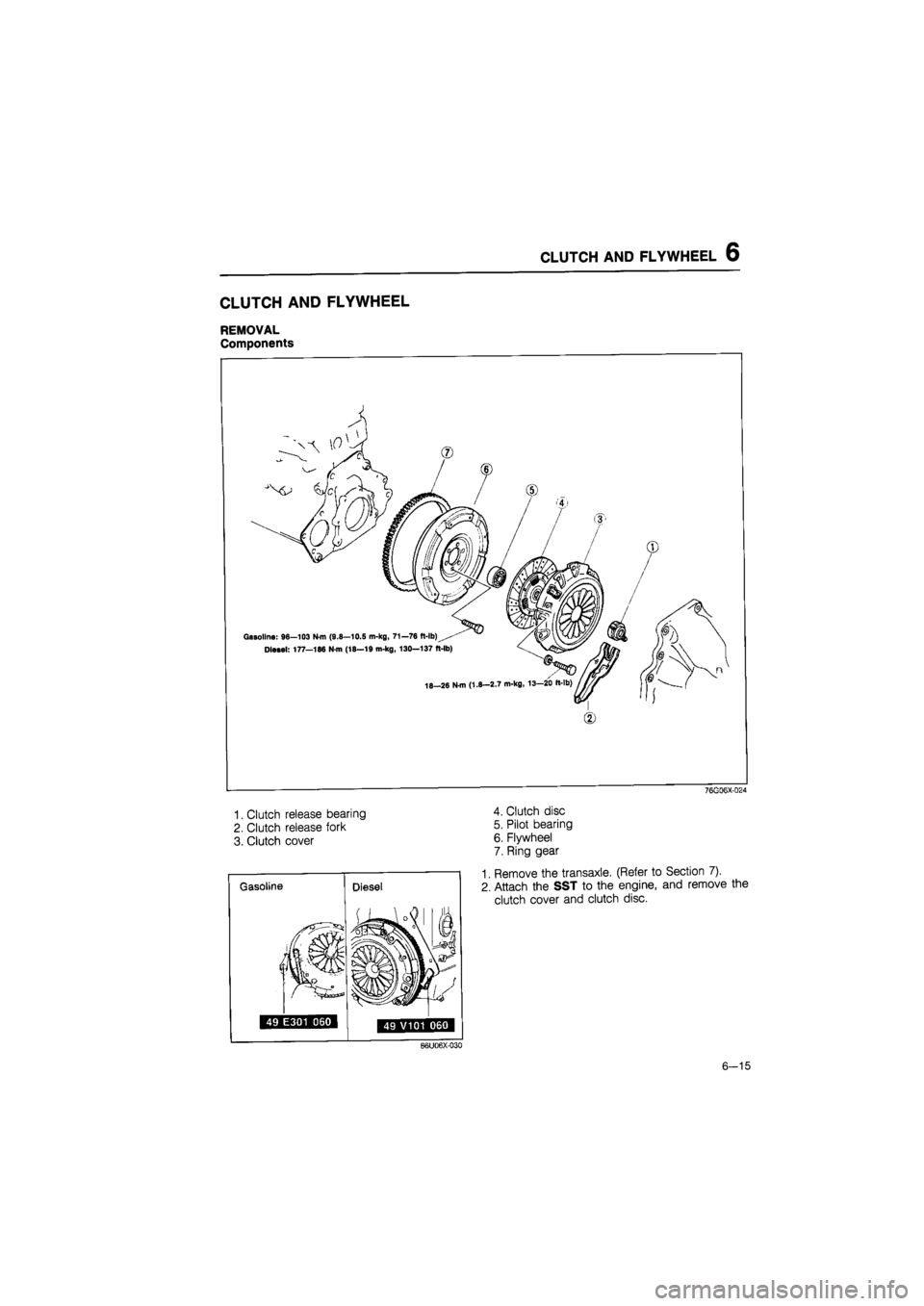

CLUTCH AND FLYWHEEL 6

CLUTCH AND FLYWHEEL

REMOVAL

Components

Gasoline: 96—103 N-m (9.8—10.5 m-kg, 71—76 ft-lb)

Diesel: 177—186 N-m (18—19 m-kg, 130—137 ft-lb)

18-26 N-m (1.8—2.7 m-kg, 13—20 ft-lb)

1. Clutch release bearing

2. Clutch release fork

3. Clutch cover

76G06X-024

4. Clutch disc

5. Pilot bearing

6. Flywheel

7. Ring gear

1. Remove the transaxle. (Refer to Section 7).

2. Attach the SST to the engine, and remove the

clutch cover and clutch disc.

B6U06X-030

6-15

Page 802 of 1865

6 CLUTCH AND FLYWHEEL

3. Remove the pilot bearing from the crankshaft with

the SST.

Note

Do not remove the bearing if it is not neces-

sary.

86U06X-031

4. Remove the flywheel.

86U06X-032

5. Remove the release bearing.

6. Remove the release fork.

86U06X-033

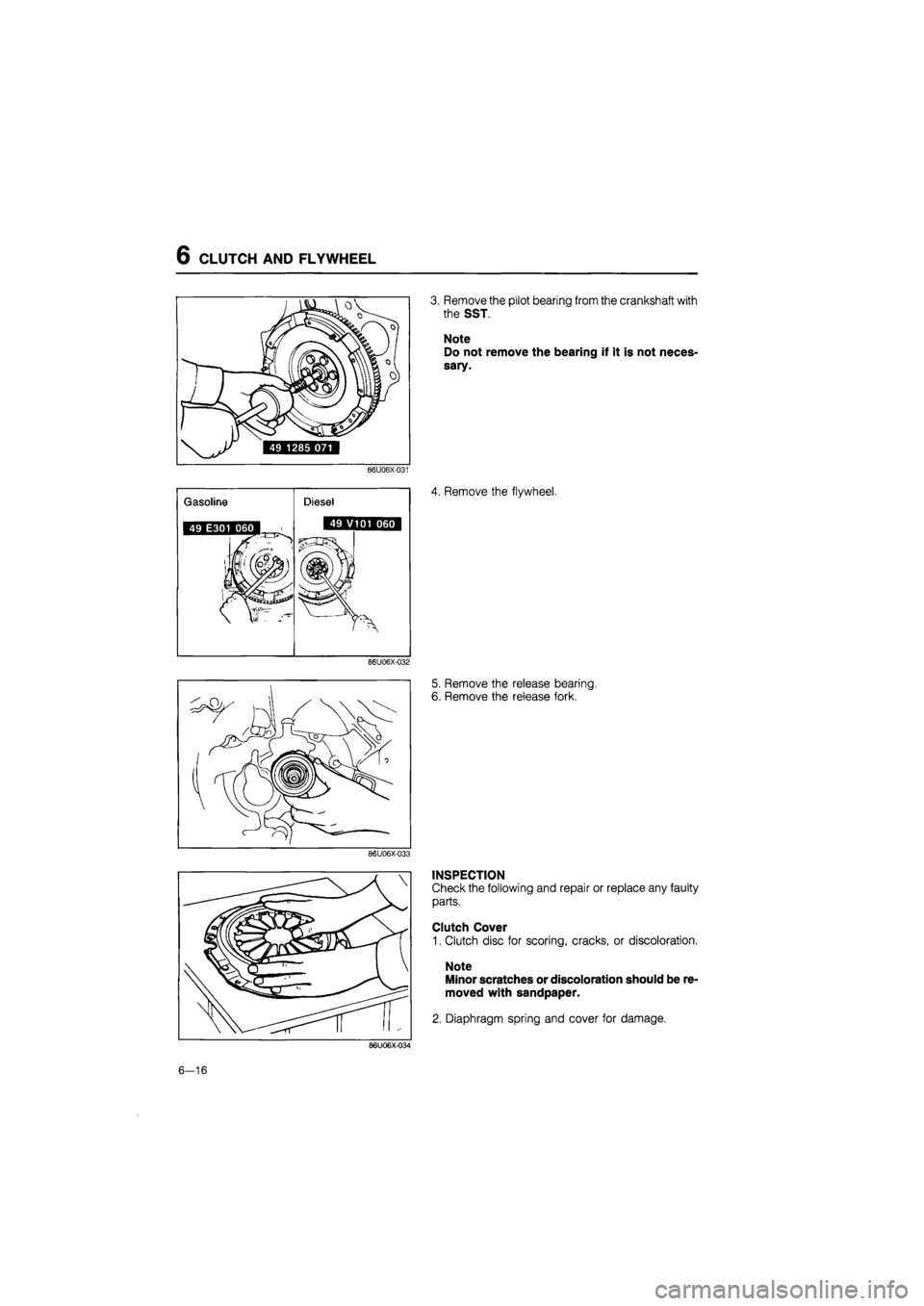

INSPECTION

Check the following and repair or replace any faulty

parts.

Clutch Cover

1. Clutch disc for scoring, cracks, or discoloration.

Note

Minor scratches or discoloration should be re-

moved with sandpaper.

2. Diaphragm spring and cover for damage.

86U06X-034

6-16

Page 803 of 1865

CLUTCH AND FLYWHEEL 6

86U06X-035

86U06X-036

76G06X-025

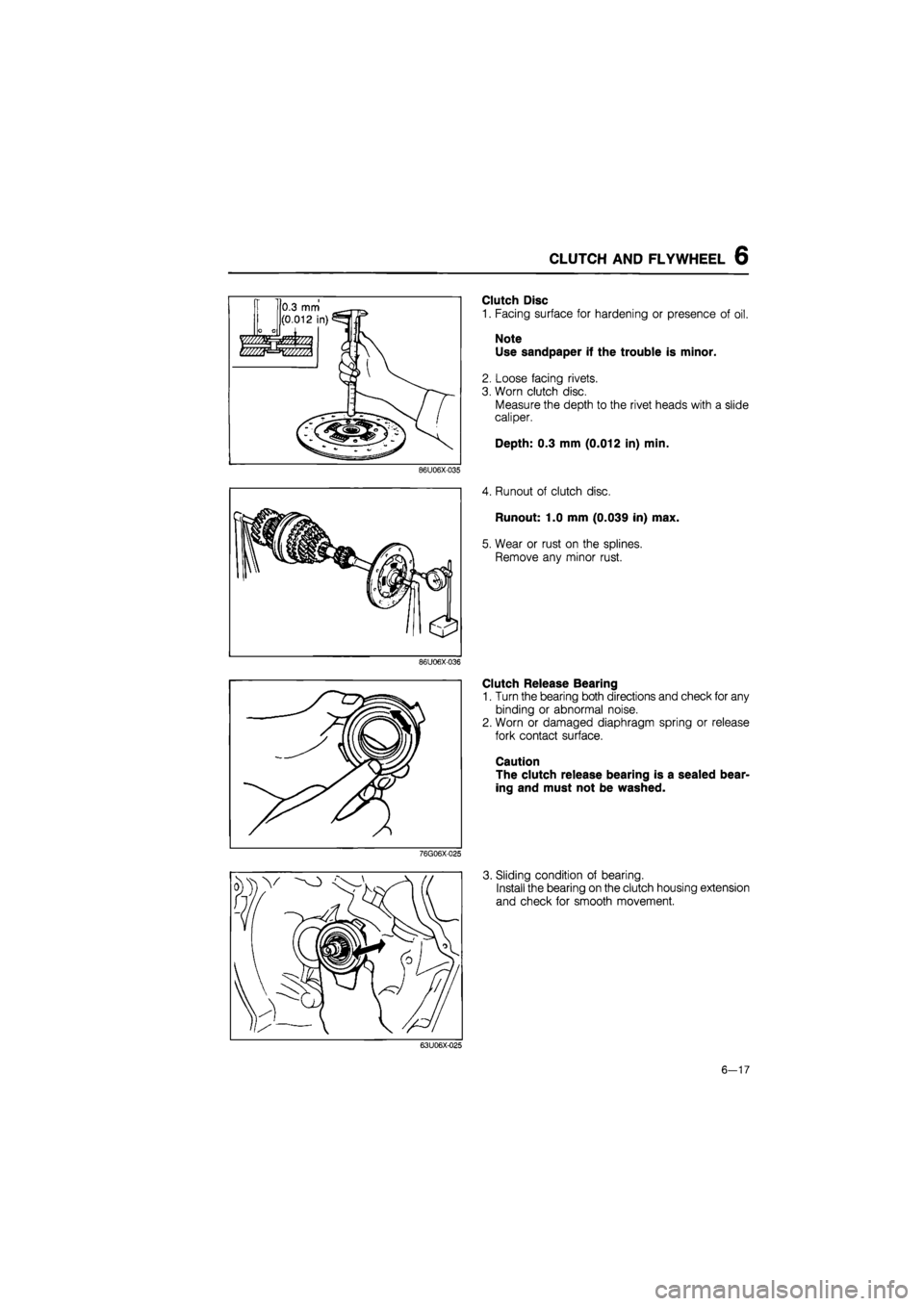

Clutch Disc

1. Facing surface for hardening or presence of oil.

Note Use sandpaper if the trouble is minor.

2. Loose facing rivets.

3. Worn clutch disc.

Measure the depth to the rivet heads with a slide

caliper.

Depth: 0.3 mm (0.012 in) min.

4. Runout of clutch disc.

Runout: 1.0 mm (0.039 in) max.

5. Wear or rust on the splines.

Remove any minor rust.

Clutch Release Bearing

1. Turn the bearing both directions and check for any

binding or abnormal noise.

2. Worn or damaged diaphragm spring or release

fork contact surface.

Caution

The clutch release bearing is a sealed bear-

ing and must not be washed.

3. Sliding condition of bearing.

Install the bearing on the clutch housing extension

and check for smooth movement.

63U06X-025

6-17

Page 804 of 1865

6 CLUTCH AND FLYWHEEL

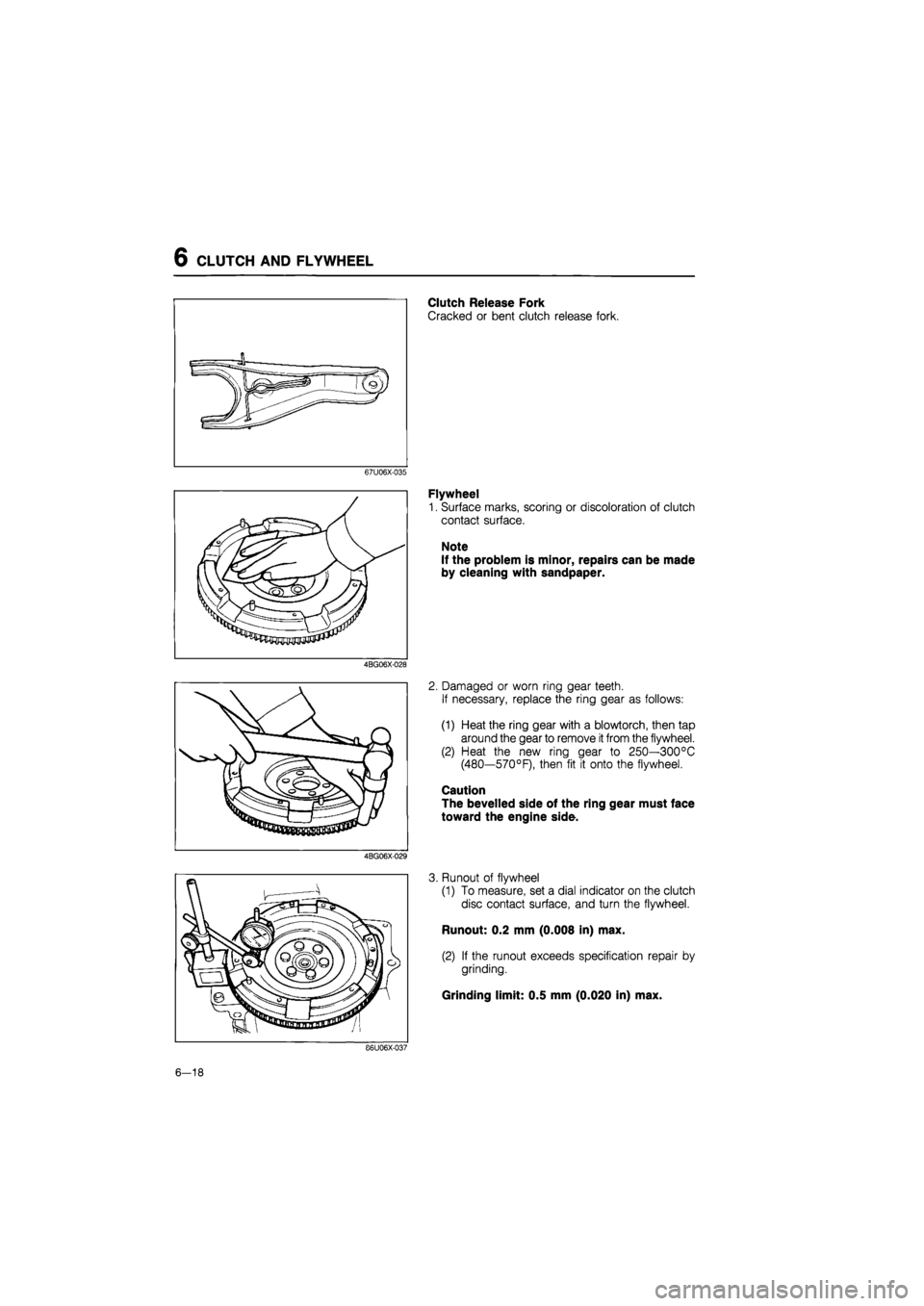

Clutch Release Fork

Cracked or bent clutch release fork.

67U06X-035

4BG06X-028

4BG06X-029

Flywheel

1. Surface marks, scoring or discoloration of clutch

contact surface.

Note

If the problem is minor, repairs can be made

by cleaning with sandpaper.

2. Damaged or worn ring gear teeth.

If necessary, replace the ring gear as follows:

(1) Heat the ring gear with a blowtorch, then tap

around the gear to remove

it

from the flywheel.

(2) Heat the new ring gear to 250—300°C

(480—570°F), then fit it onto the flywheel.

Caution

The bevelled side of the ring gear must face

toward the engine side.

3. Runout of flywheel

(1) To measure, set a dial indicator on the clutch

disc contact surface, and turn the flywheel.

Runout: 0.2 mm (0.008 in) max.

(2) If the runout exceeds specification repair by

grinding.

Grinding limit: 0.5 mm (0.020 in) max.

86U06X-037

6-18

Page 805 of 1865

CLUTCH AND FLYWHEEL 6

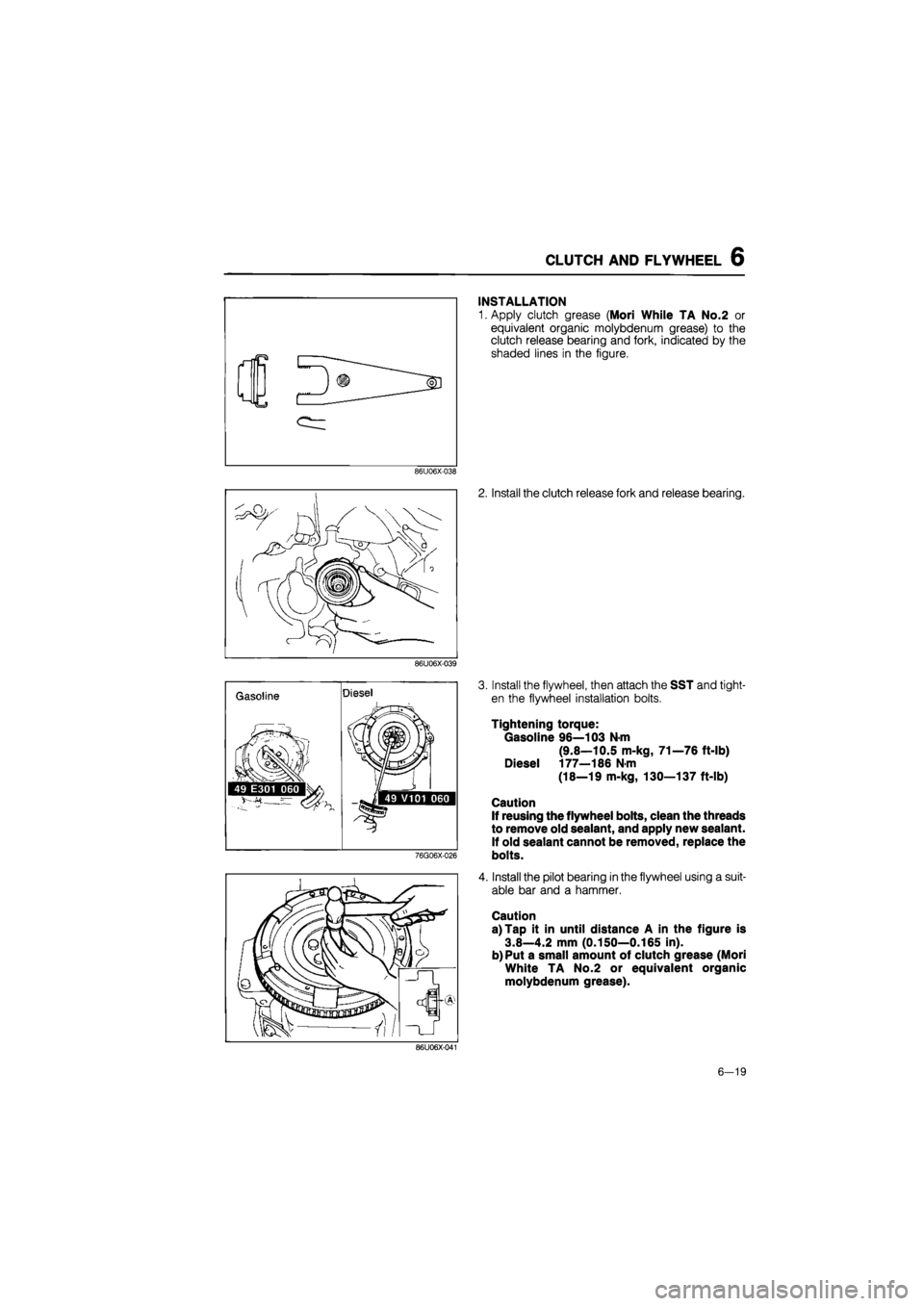

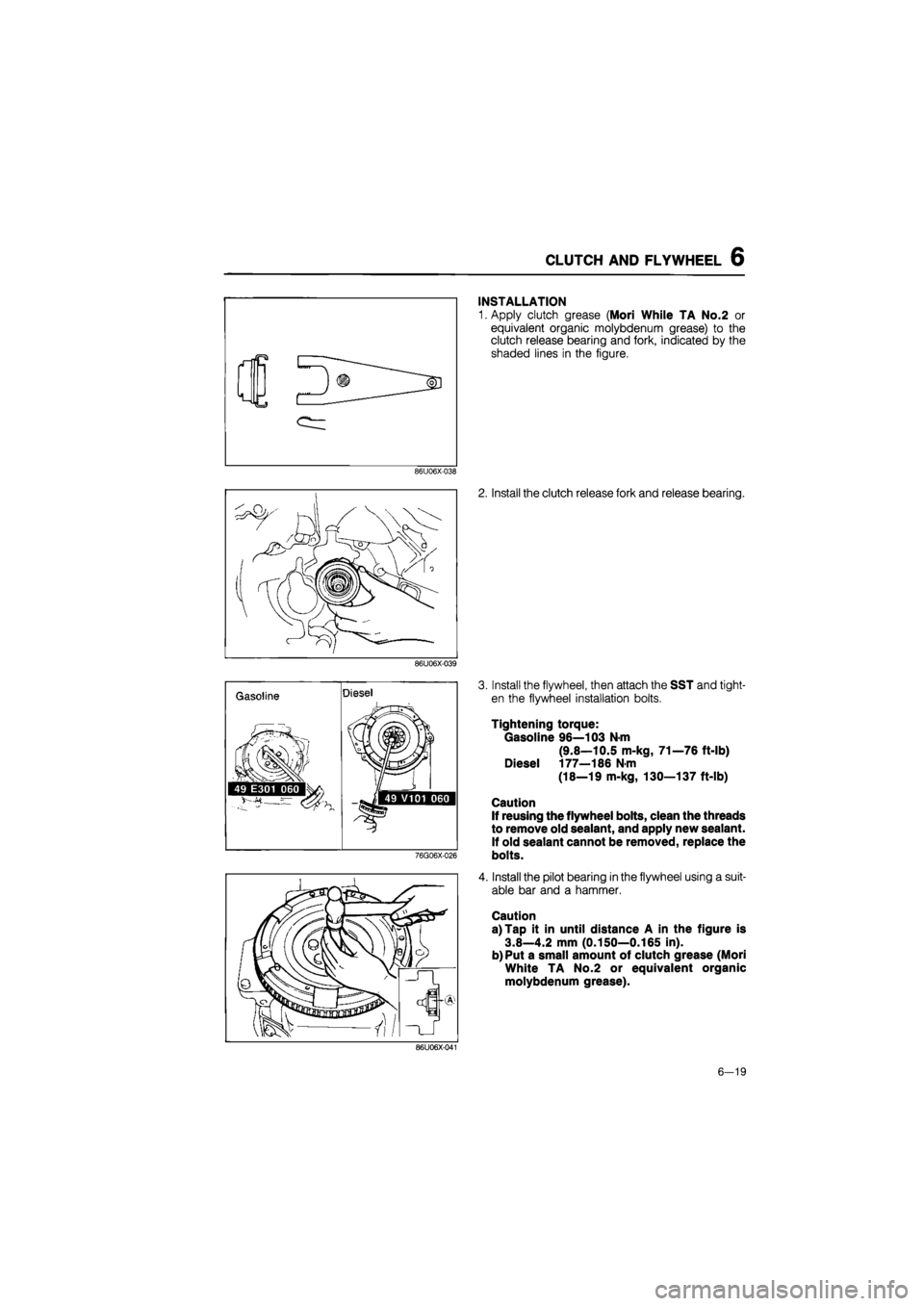

INSTALLATION

1. Apply clutch grease (Mori While TA No.2 or

equivalent organic molybdenum grease) to the

clutch release bearing and fork, indicated by the

shaded lines in the figure.

86U06X-038

2. Install the clutch release fork and release bearing.

86U06X-039

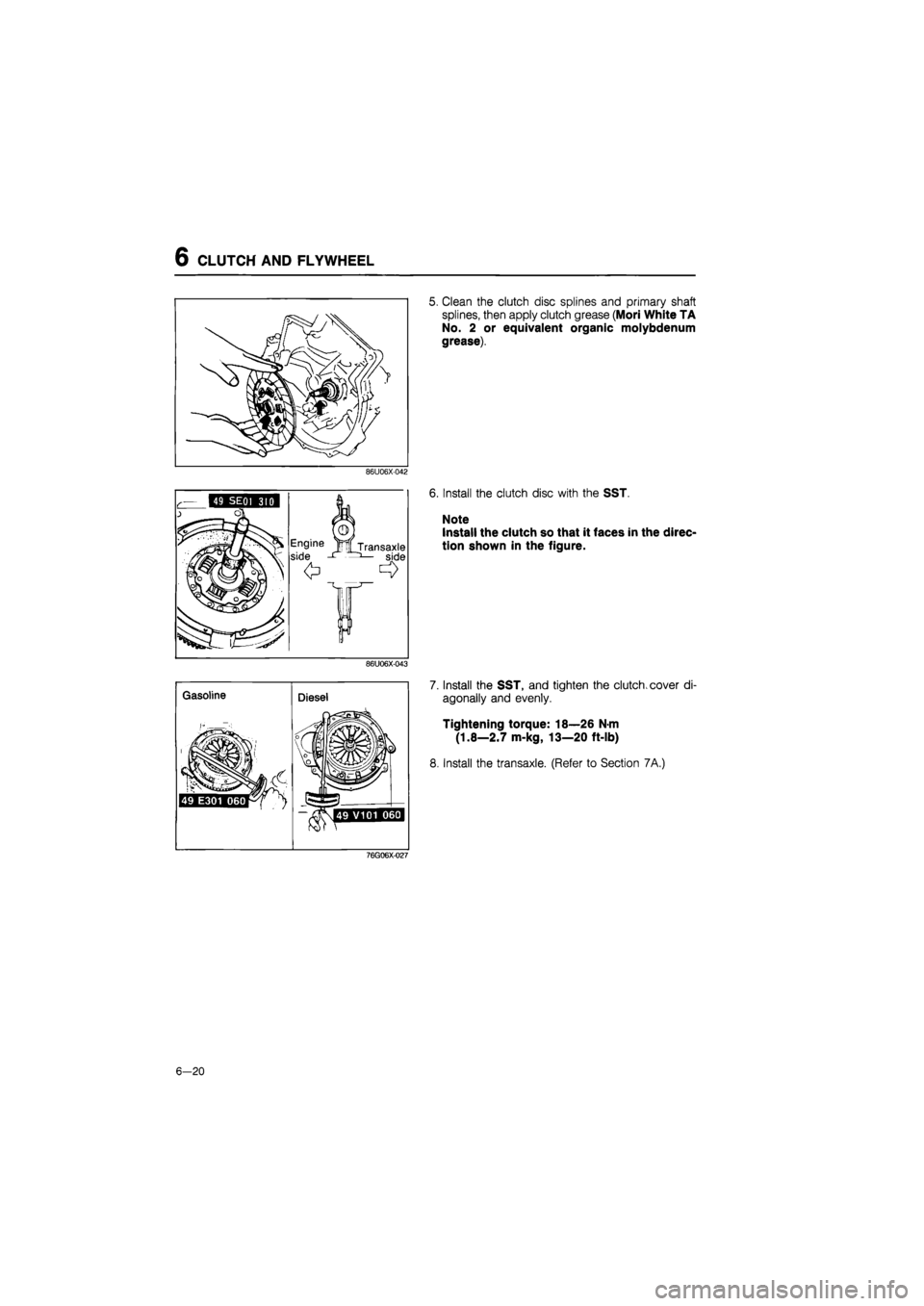

Gasoline Diesel

}

.iSlf

49 E301 060 g^M 1/ j> •«] 49 V101 060

76G06X-026

3. Install the flywheel, then attach the SST and tight-

en the flywheel installation bolts.

Tightening torque:

Gasoline 96—103 N-m

(9.8—10.5 m-kg, 71—76 ft-lb)

Diesel 177—186 N-m

(18—19 m-kg, 130—137 ft-lb)

Caution

If reusing the flywheel bolts, clean the threads

to remove old sealant, and apply new sealant.

If old sealant cannot be removed, replace the

bolts.

4. Install the pilot bearing in the flywheel using a suit-

able bar and a hammer.

Caution

a) Tap it in until distance A in the figure is

3.8—4.2 mm (0.150—0.165 in).

b) Put a small amount of clutch grease (Mori

White TA No.2 or equivalent organic

molybdenum grease).

86U06X-041

6—19

Page 806 of 1865

6 CLUTCH AND FLYWHEEL

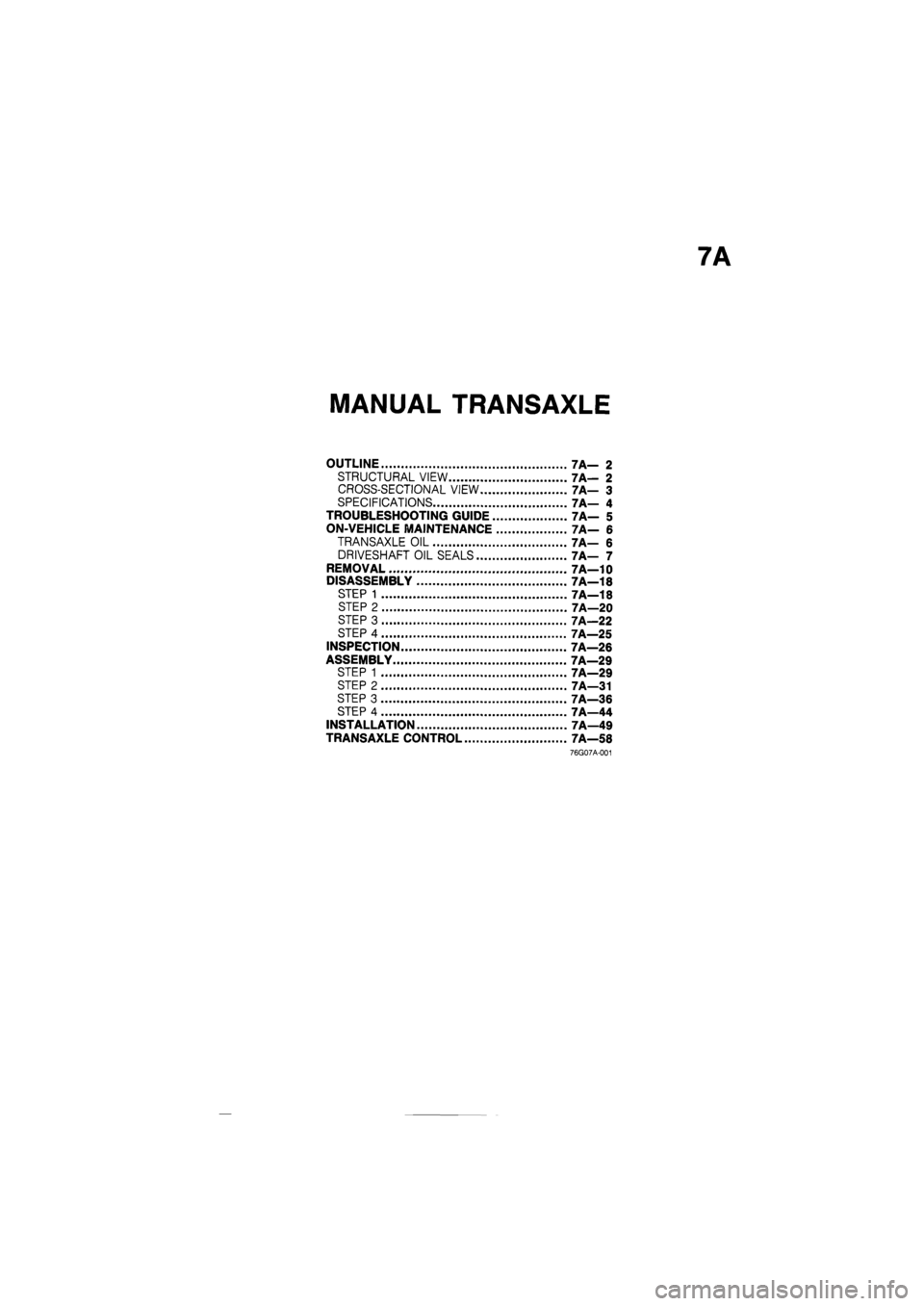

86U06X-042

86U06X-043

5. Clean the clutch disc splines and primary shaft

splines, then apply clutch grease (Mori White TA

No. 2 or equivalent organic molybdenum

grease).

6. Install the clutch disc with the SST.

Note

Install the clutch so that it faces in the direc-

tion shown in the figure.

7. Install the SST, and tighten the clutch, cover di-

agonally and evenly.

Tightening torque: 18—26 N-m

(1.8—2.7 m-kg, 13—20 ft-lb)

8. Install the transaxle. (Refer to Section 7A.)

76G06X-027

6-20

Page 807 of 1865

MANUAL TRANSAXLE

OUTLINE 7 A— 2

STRUCTURAL VIEW 7A— 2

CROSS-SECTIONAL VIEW 7A— 3

SPECIFICATIONS 7A— 4

TROUBLESHOOTING GUIDE 7A— 5

ON-VEHICLE MAINTENANCE 7A— 6

TRANSAXLE OIL 7A— 6

DRIVESHAFT OIL SEALS 7A— 7

REMOVAL 7A—10

DISASSEMBLY 7A—18

STEP 1 7A—18

STEP 2 7A—20

STEP 3 7A—22

STEP 4 7A—25

INSPECTION 7A—26

ASSEMBLY 7A—29

STEP 1 7A—29

STEP 2 7A—31

STEP 3 7A—36

STEP 4 7A—44

INSTALLATION 7A—49

TRANSAXLE CONTROL 7A—58

76G07A-001

Page 808 of 1865

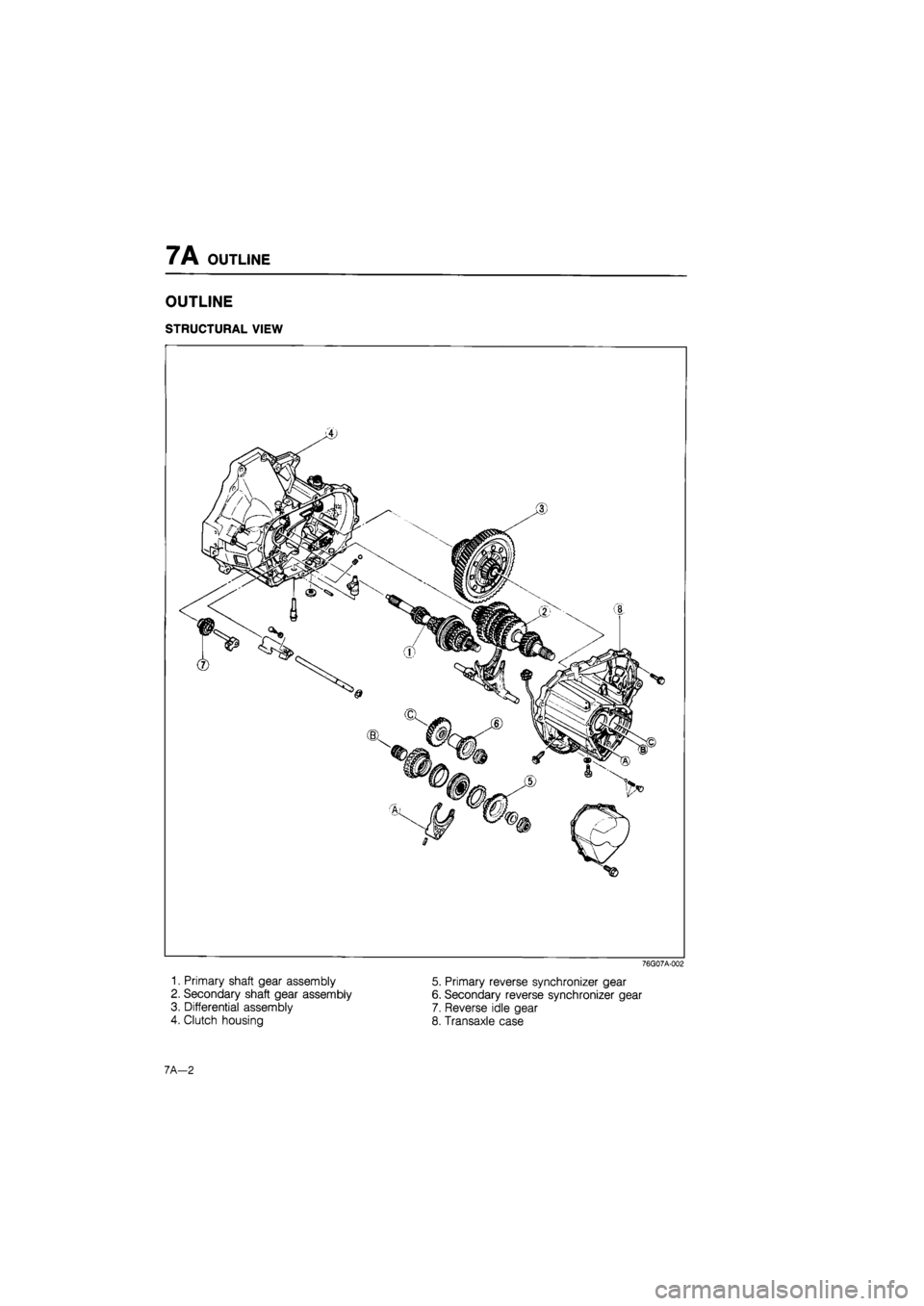

7A OUTLINE

OUTLINE

STRUCTURAL VIEW

76G07A-002

1. Primary shaft gear assembly

2. Secondary shaft gear assembly

3. Differential assembly

4. Clutch housing

5. Primary reverse synchronizer gear

6. Secondary reverse synchronizer gear

7. Reverse idle gear

8. Transaxle case

7A—2

Page 809 of 1865

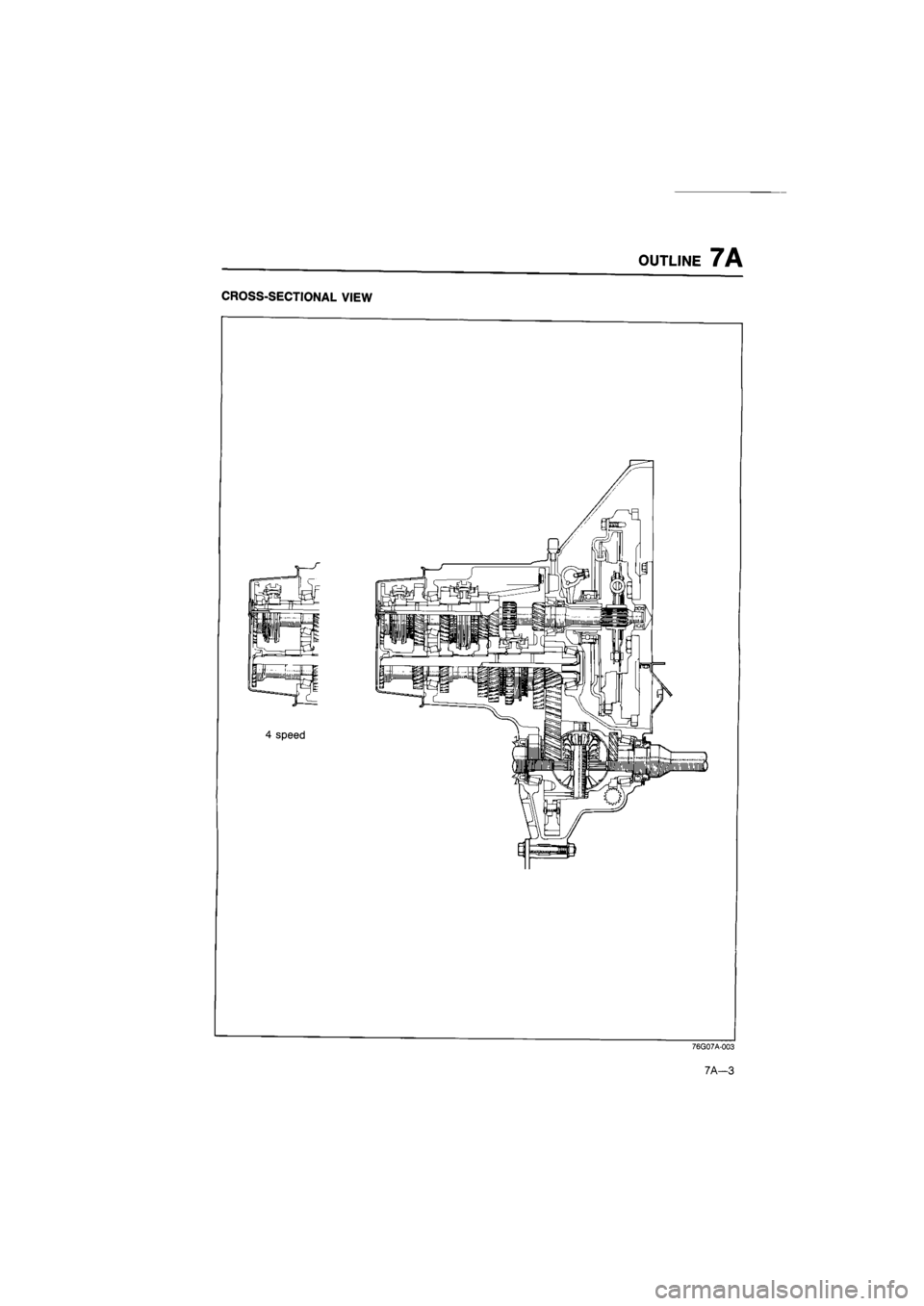

CROSS-SECTIONAL VIEW

OUTLINE 7 A

4 speed

76G07A-003

7A—3

Page 810 of 1865

7A OUTLINE

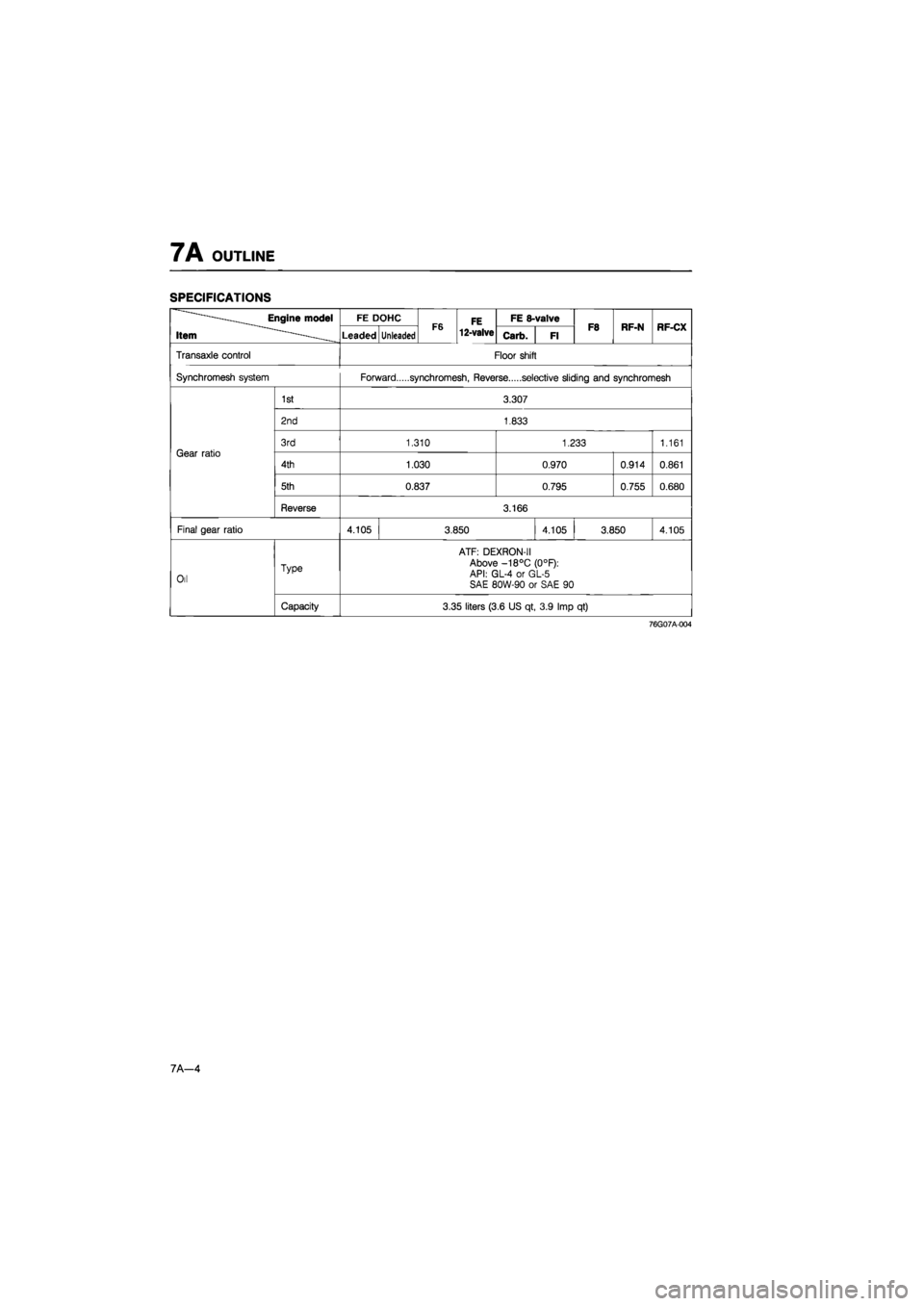

SPECIFICATIONS

•Engine model

Item ——

FE DOHC F6 FE 12-valve

FE 8-valve F8 RF-N RF-CX •Engine model

Item —— Leaded Unleaded F6 FE 12-valve Carb. Fl F8 RF-N RF-CX

Transaxle control Floor shift

Synchromesh system Forward synchromesh, Reverse selective sliding and synchromesh

Gear ratio

1st 3.307

Gear ratio

2nd 1.833

Gear ratio 3rd 1.310 1.233 1.161 Gear ratio

4th 1.030 0.970 0.914 0.861

Gear ratio

5th 0.837 0.795 0.755 0.680

Gear ratio

Reverse 3.166

Final gear ratio 4.105 3.850 4.105 3.850 4.105

Oil Type

ATF: DEXRON-II Above -18°C (0°F): API: GL-4 or GL-5 SAE 80W-90 or SAE 90 Oil

Capacity 3.35 liters (3.6 US qt, 3.9 Imp qt)

76G07A-004

7A—4

Trending: spark plugs, inflation pressure, oil pressure, child lock, fuel type, steering, seats