MAZDA 626 1987 Manual Online

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 81 of 1865

INSPECTION AND REPAIR 1 A

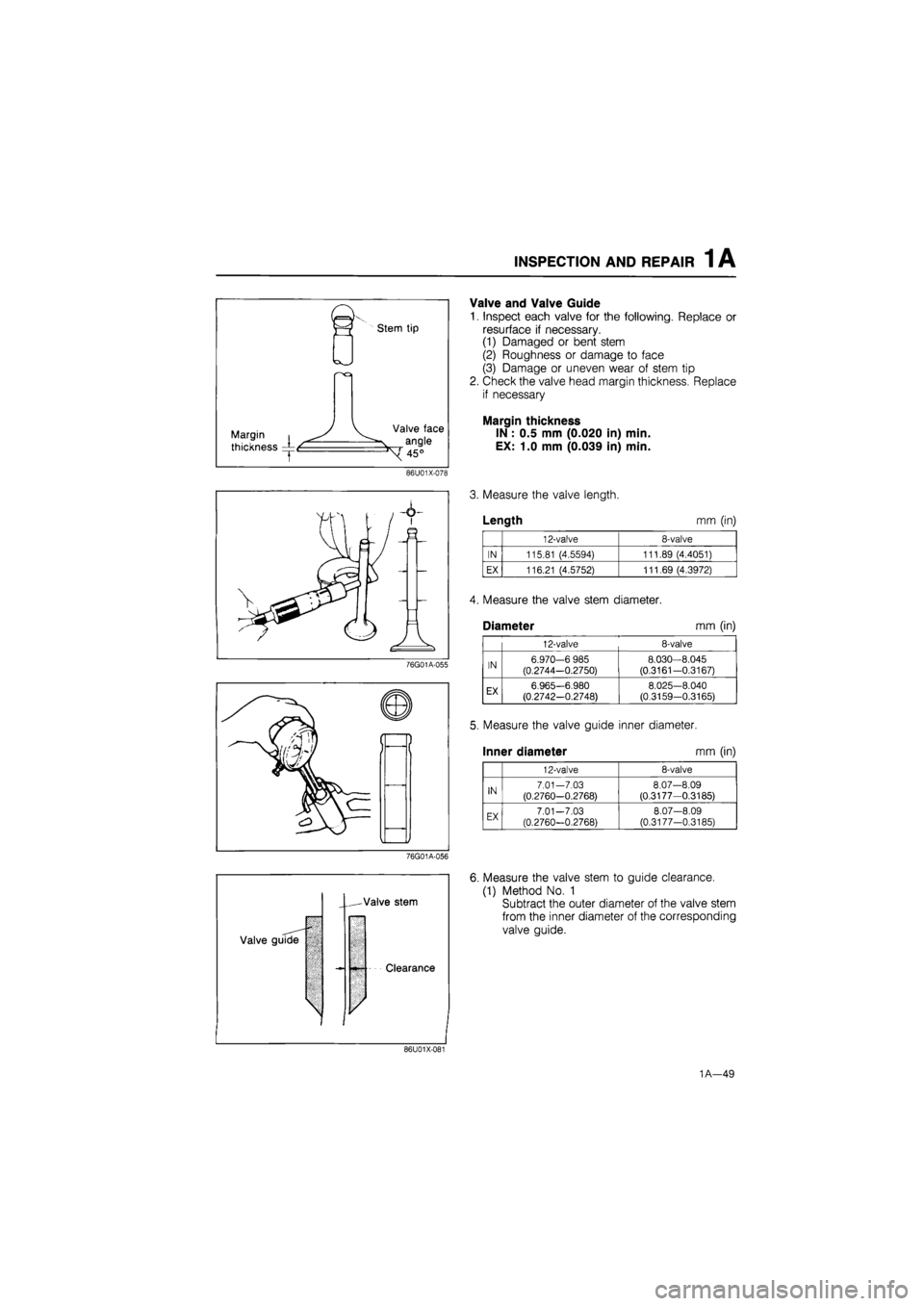

Stem tip

Margin

thickness

Valve face

angle

45°

86U01X-078

76G01A-055

(

—SY/ in

76G01A-056

Valve guide

-Valve stem

Clearance

V

Valve and Valve Guide

1. Inspect each valve for the following. Replace or

resurface if necessary.

(1) Damaged or bent stem

(2) Roughness or damage to face

(3) Damage or uneven wear of stem tip

2. Check the valve head margin thickness. Replace

if necessary

Margin thickness

IN : 0.5 mm (0.020 in) min.

EX: 1.0 mm (0.039 in) min.

3. Measure the valve length.

Length mm (in)

12-valve 8-valve

IN 115.81 (4.5594) 111.89 (4.4051)

EX 116.21 (4.5752) 111.69 (4.3972)

Measure the valve stem diameter.

Diameter mm (in)

12-valve 8-valve

IN 6.970-6 985

(0.2744-0.2750)

8.030—8.045

(0.3161-0.3167)

EX 6.965-6.980 (0.2742-0.2748) 8.025-8.040 (0.3159-0.3165)

5. Measure the valve guide inner diameter.

Inner diameter mm (in)

12-valve 8-valve

IN 7.01-7.03 (0.2760—0.2768) 8.07—8.09

(0.3177—0.3185)

EX 7.01-7.03

(0.2760-0.2768)

8.07-8.09

(0.3177-0.3185)

6. Measure the valve stem to guide clearance.

(1) Method No. 1

Subtract the outer diameter of the valve stem

from the inner diameter of the corresponding

valve guide.

86U01X-117

1A—49

Page 82 of 1865

INSPECTION AND REPAIR 1 A

86U01X-082

Valve guide

Cylinder head

76G01A-057

(2) Method No. 2

Measure the valve stem play at a point close

to the valve guide with the valve lifted slightly

off the valve seat.

Clearance

IN : 0.025—0.060 mm (0.0010—0.0024 in)

EX: 0.030—0.065 mm (0.0012—0.0026 in)

Maximum: 0.20 mm (0.0079 in)

7. If the clearance exceeds the maximum, replace the

valve and/or valve guide.

8. Check that the valve guide projection height

(dimension A in the figure). Replace if necessary.

Height:

19.8—20.3 mm (0.780—0.799 in)... 12-valve

19.1—19.6 mm (0.752—0.772 in)...8-valve

Replacement of valve guide

Note

Although the shapes of the intake and exhaust

valve guides are different, use the exhaust

valve guide on both sides as a replacement.

86U01X-214

Removal

1. Gradually heat the cylinder head in water to ap-

prox. 90°C (194°F).

76G01A-131

1A—50

Page 83 of 1865

INSPECTION AND REPAIR 1 A

12-valve:

8-valve:

49 0249 01 OA

49 0221 251A

76G01A-058

76G01A-059

V

86U01X-087

2. Remove the valve guide from the side opposite the

combustion chamber with the SST.

3. Remove the valve guide clip (8-valve).

Installation

1. Fit the clip onto the valve guide (8 valve).

2. Gradually heat the cylinder head in water to ap-

prox. 90°C (194°F).

3. Tap the valve guide in from the side opposite the

combustion chamber with the SST until the projec-

tion height is as specified.

Valve Seat

1. Inspect the contact surface of the valve seat and

valve face for the following.

(1) Roughness

(2) Damage

2. If necessary, resurface the valve seat with a 45°

valve seat cutter and/or resurface the valve face.

3. Apply a thin coat of prussian blue to the valve face.

4. Check the valve seating by rotating the valve

against the seat.

(1) If blue does not appear 360° around the valve

face, replace the valve.

(2) If blue does not appear 360° around the valve

seat, resurface the seat.

79G01C-053

1A—51

Page 84 of 1865

1A INSPECTION AND REPAIR

76G01A-128

86U01X-088

5. Check the seat contact width.

Width: 1.2—1.6 mm (0.047—0.063 in)

6. Check that the valve seating position is at the cen-

ter of the valve face.

(1) If the seating position is too high, correct the

valve seat with a 60° cutter and a 45° cutter.

(2) If the seating position is too low, correct the

valve seat with a 35° (IN) or 15° (EX) cutter

and a 45° cutter.

7. Seat the valve to the valve seat with a lapping

compound.

76G01A-060

8. Check the sinking of the valve seat.

Measure protruding length (dimension L) of each

valve stem.

Dimension L: 50.2 mm (1.976 in).... 12-valve

46.5 mm (1.831 in).... 8-valve

(1) If L is as below, it can be used as it is.

50.2—51.0 mm (1.976—2.008 in)..12-valve

46.5—48.0 mm (1.831—1.890 in).. 8-valve

(2) If L is as below, insert a spacer between the

spring seat and cylinder head to adjust.

51.0—51.7 mm (2.008—2.035 in)..12-valve

48.0—48.7 mm (1.890—1.917 in).. 8-valve

(3) If L is more than as below, replace the cylin-

der head.

51.7 mm (2.035 in) or more 12-valve

48.7 mm (1.917 in) or more 8-valve

1A—52

Page 85 of 1865

INSPECTION AND REPAIR 1 A

76G01A-062

86U01X-092

76G01A-063

A vl^k

L^-X

B As^

Valve Spring

1. Inspect each valve spring for cracks or damage.

2. Check the free length and angle. Replace if

necessary.

Free length mm (in)

Standard Minimum

12-valve IN 49.5 (1.949) 49.0 (1.929) 12-valve EX 50.4 (1.984) 48.7 (1.917)

I FE.Middle Outer 51.2 (2.016) 50.6 (1.992)

8-valve East General Inner 45.7 (1.799) 43.7 (1.720) 8-valve

Others Outer 52.0 (2.047) 51.5 (2.028) 8-valve

Others Inner 44.0 (1.732) 43.3 (1.705)

Angle: 1.8 mm (0.071 in) max.

Camshaft

1. Set the front and rear journals on V-blocks.

Check the camshaft runout. Replace if necessary.

Runout: 0.03 mm (0.0012 in) max.

2. Check the cam for wear or damage. Replace if

necessary.

3. Check the cam lobe height at the two points as

shown in the figure.

Height mm (in)

Standard Minimum

12-valve IN 41.340 (1.6276) 41.14 (1.620) 12-valve EX 41.847 (1.6476) 41.65 (1.640)

8-valve IN 38.157 (1.5022) 37.96 (1.494) 8-valve EX 38.160 (1.5024) 37.96 (1.494)

4. Measure wear of the journals in X and Y directions

at the two points as shown in the figure.

Diameter mm (in)

12-valve 8-valve

No. 1,5 31.940-31.965 (1.2575-1.2585) 31.940-32.035 (1.2575-1.2612)

No. 2,3,4 31.910-31.935 (1.2563-1.2573) 31.910-32.065 (1.2563—1.2624)

Out-of-round: 0.05 mm (0.002 in) max.

76G01A-129

1

A—53

Page 86 of 1865

INSPECTION AND REPAIR 1 A

mjjm

H D f IT~inr

86U01X-095

5. Measure the oil clearance of the camshaft and

camshaft caps.

(1) Remove any oil, or dirt from the journals and

bearing surface.

(2) Set the camshaft onto the cylinder head.

(3) Position plasti-gauge on top of the journals in

the axial direction.

(4) Place the camshaft caps and rocker arm shafts

in position, and tighten them to the specified

torque.

Tightening torque:

18—26

N

m (1.8—2.7 m-kg, 13—20 ft-lb)

(5) Remove the camshaft caps and measure the

oil clearance at each cap.

Oil clearance

Front and rear:

0.035—0.085 mm (0.0014—0.0033 in)

Center three journals:

0.065—0.115 mm (0.0026—0.0045 in)

Maximum: 0.15 mm (0.0059 in)

(6) If the oil clearance exceeds the maximum, re-

place the cylinder head.

86U01X-096

6. Measure the camshaft end play. If it exceeds the

maximum, replace the camshaft and/or the cylin-

der head.

End play:

0.08—0.16 mm (0.003—0.006 in)

Maximum: 0.20 mm (0.008 in)

86U01X-097

76G01A-131

1A—54

Rocker Arm and Rocker Arm Shaft

1. Check for wear or damage to the contact surface

of the rocker arm shaft and the rocker arm. Re-

place if necessary.

2. Check the oil clearance between the rocker arm

and shaft. Replace if necessary.

(1) Measure the rocker arm inner diameter.

Diameter:

19.000—19.033 mm (0.7480—0.7493 in)

...12-valve

16.000—16.027 mm (0.6299—0.6310 in)

... 8-valve

Page 87 of 1865

INSPECTION AND REPAIR 1 A

76G01A-065

76G01A-066

86U01X-100

(2) Measure the rocker arm shaft diameter.

Diameter:

18.959—18.980 mm (0.7464—0.7472 in)

...12 valve

15.966—15.984 mm (0.6286—0.6293 in)

... 8 valve

(3) Subtract the shaft diameter from the rocker arm

diameter.

Oil clearance mm (in)

Standard Maximum

12-valve 0.020-0.074

(0.0008-0.0029) 0.10 (0.0039)

8-valve 0.016-0.061 (0.0006-0.0024) 0.10 (0.0039)

Hydraulic Lash Adjuster (12-valve)

Check the HLA face for wear or damage. Replace

if necessary.

Caution

Do not remove the HLA unless necessary to

prevent damaging the O-ring.

Cylinder Block

1. Check the cylinder block. Repair or replace if

necessary.

(1) Leakage damage

(2) Cracks

(3) Scoring of wall

2. Measure the distortion of the top surface of the cyl-

inder block in the six directions as shown in the

figure.

Distortion: 0.15 mm (0.006 in) max.

3. If the distortion exceeds the maximum, repair by

grinding, or replace the cylinder block.

Grinding limit: 0.20 mm (0.008 in) max.

86U01X-117

1A—55

Page 88 of 1865

INSPECTION AND REPAIR 1 A

76G01A-067

4. Measure the cylinder bore in directions X and Y

at three levels in each cylinder as shown.

Cylinder bore mm (in)

Size Bore

FE

F8

Standard 86.000-86.019 (3.3858-3.3866) FE

F8 0.25 (0.010) oversize 86.250-86.269 (3.3957-3.3964) FE

F8 0.50 (0.020) oversize 86.500-86.519 (3.4055-3.4062)

F6

Standard 81.000-81.019 (3.1890-3.1897)

F6

0.25 (0.010) oversize 81.250-81.269 (3.1988-3.1996)

F6 0.50 (0.020) oversize 81.500-81.519 (3.2087-3.2094) F6

0,75 (0.030) oversize 81.750-81.769 (3.2185-3.2192)

F6

1.00 (0.039) oversize 82.000-82.019 (3.2283-3.2291)

(1) If the difference between the measurement A

and C exceeds the maximum taper, rebore the

cylinder to oversize.

Taper: 0.019 mm (0.0007 in) max.

79G01C-071

O ^ ^ o

^^——

(2) If the difference between the measurement X

and Y exceeds the maximum out-of-round, re-

bore the cylinder to oversize.

Out-of-round: 0.019 mm (0.0007 in) max.

Caution

The boring size should be based on the size

of an oversize piston and be the same for all

cylinders.

79G01C-072

5. If the upper part of the cylinder wall shows uneven

wear, remove the ridge with a ridge reamer.

86U01X-117

1A—56

Page 89 of 1865

INSPECTION AND REPAIR 1A

76G01A-068

Piston

1. Inspect the outer circumferences of all pistons for

seizure or scoring. Replace if necessary.

2. Measure the outer diameter of each piston at a right

angle (90°) to the piston pin, 18 mm (0.709 in)

below the oil ring land lower edge.

Piston diameter mm (in)

Size Diameter

LU

OO LL LL Standard 85.944-85.964 (3.3836-3.3844)

LU

OO LL LL 0.25 (0.010) oversize 86.194-86.214 (3.3935-3.3942)

LU

OO LL LL

0.50 (0.020) oversize 86 444-86.464 (3.4033-3.4041)

F6

Standard 80 944-80.964 (3.1868-3.1876)

F6

0.25 (0.010) oversize 81.194-81.214 (3.1966-3.1974)

F6 0.50 (0.020) oversize 81.444-81.464 (3.2065-3.2072) F6

0.75 (0.030) oversize 81.694-81.714 (3.2163-3.2171)

F6

1.00 (0.039) oversize 81.944-81.964 (3.2261-3,2269)

3. Check the piston to cylinder clearance.

ClGdrsncG1

0.036—0.075 mm (0.0014—0.0030 in)

Maximum: 0.15 mm (0.0059 in)

4. If the clearance exceeds the maximum, replace the

piston or rebore the cylinders to fit oversize pistons.

Caution

If the piston is replaced, replace the piston

rings also.

76G01A-130

Piston and Piston Ring

1. Measure the piston ring to ring land clearance

around the entire circumference using a new pis-

ton ring.

Clearance (Top and Second):

0.03—0.07 mm (0.001—0.003 in)

Maximum: 0.15 mm (0.006 in)

2. If the clearance exceeds the maximum, replace the

piston.

69G01A-125

1A—57

Page 90 of 1865

INSPECTION AND REPAIR 1 A

JT

I0J

'r-Sj&f-;:*::;^

.^Piston ring

'r-Sj&f-;:*::;^

.^Piston ring

'r-Sj&f-;:*::;^

.^Piston ring

86U01X-104

76G01A-069

86U01X-106

3. Inspect the piston rings for damage, abnormal

wear, or breakage. Replace if necessary.

4. Insert the piston ring into the cylinder by hand and

push it to the bottom of the ring travel in using the

piston.

5. Measure each piston ring end gap with a feeler

gauge. Replace if necessary.

End gap

Top : 0.20—0.35 mm (0.008—0.014 in)

Second: 0.15—0.30 mm (0.006—0.012 in)

Oil rail : 0.20—0.70 mm (0.008—0.028 in)

Maximum: 1.0 mm (0.039 in)

Piston and Piston Pin

1. Measure the piston pin hole diameter in X and Y

directions at four points.

Diameter:

21.988—21.998 mm (0.8657—0.8661 in)

2. Measure the piston pin diameter.

Diameter:

21.974—21.980 mm (0.8651—0.8654 in)

3. Determine the piston pin to piston clearance by

subtracting the two figures.

Clearance:

0.008—0.024 mm (0.0003—0.0009 in)

4. If the clearance exceeds the specification, replace

the piston and/or piston pin.

86U01X-117

1A—58