MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 121 of 1865

ASSEMBLY (AUXILIARY PARTS) 1 A

86U01X-171

76G01A-090

76G01A-091

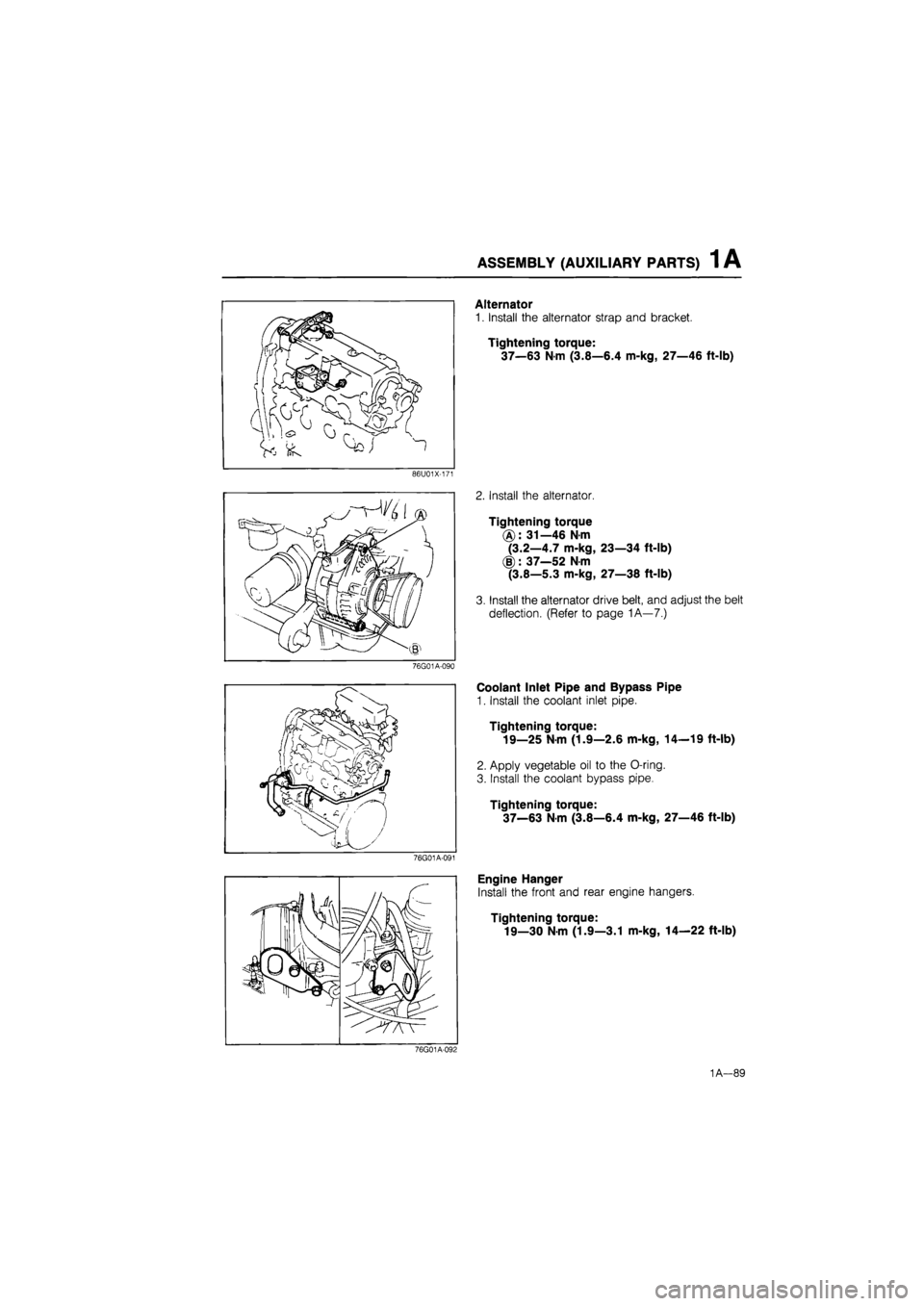

Alternator

1. Install the alternator strap and bracket.

Tightening torque:

37—63 Nm (3.8—6.4 m-kg, 27—46 ft-lb)

2. Install the alternator.

Tightening torque

(A): 31—46 Nm

(3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

3. Install the alternator drive belt, and adjust the belt

deflection. (Refer to page 1A—7.)

Coolant Inlet Pipe and Bypass Pipe

1. Install the coolant inlet pipe.

Tightening torque:

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

2. Apply vegetable oil to the O-ring.

3. Install the coolant bypass pipe.

Tightening torque:

37—63

N

m (3.8—6.4 m-kg, 27—46 ft-lb)

Engine Hanger

Install the front and rear engine hangers.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

76G01A-092

1A—89

Page 122 of 1865

1 A ASSEMBLY (AUXILIARY PARTS)

76G01A-093

76G01A-094

76G01A-095

Exhaust Manifold Assembly

1. Place the new gaskets in position with the ridge

facing the cylinder head.

2. Install the exhaust manifold assembly.

3. Tighten the nuts in two or three steps.

Tightening torque:

34—49

N

m (3.5—5.0 m-kg, 25—36 ft-lb)

Exhaust Manifold Insulator

Install the exhaust manifold insulator.

Tightening torque:

19—30

N

m (1.9—3.1 m-kg, 14—22 ft-lb)

EGR Pipe

Install the EGR pipe.

Tightening torque:

34—44 Nm (3.5—4.5 m-kg, 25—33 ft-lb)

Secondary Air Pipe Assembly

Install the secondary air pipe assembly.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

P/S Oil Pump Bracket

Install the P/S oil pump bracket.

Tightening torque:

37—63 Nm (3.8—6.4 m-kg, 27—46 ft-lb)

86U01X-178

1A—90

Page 123 of 1865

INSTALLATION 1A

INSTALLATION

TRANSAXLE ASSEMBLY

Assemble the transaxle to the engine in the sequence shown in the figure referring to the installation note.

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

8—11 N-m (80-110 cm-kg, 69-95 In-lb) (2)

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb) (3.) B9—117 N-m (9.1—11.9 m-kg, 66—86 ft-lb)

76G01A-143

1. Transaxle

2. Clutch under cover

3. Gusset plate

4. Starter

Installation Note

Clutch under cover

Before installation, fill the notches with silicon as

shown in the figure.

76G01A-096

1A—91

Page 124 of 1865

1A INSTALLATION

ENGINE INSTALLATION

Install the engine and transaxle assembly.

Warning: Be sure the vehicle is securely supported.

Torque Specifications

16—27 N-m (1.6—2.8 m-kg, 12—20 ft-lb)

.OT-

9

85—117 N-m (6.7-11.9 m-kg, 63—86 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 In-lb)

44—64 N-m I (4.5—6.5 m-kg,

_

33-47 ft-lb)

16—27 N-m (1.6—2.8 m-kg, 12—20 ft-lb)

/ 64—89 N-m (6.5—9.1 m-kg, 47—66 ft-lb)

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

31—46 N-m (3.2-4.7 m-i 23—34 ft-lb)

39—59 N-m _ (4.0—6.0 m-kg, 29—43 ft-lb)

19—25 N-m (1.9—2.6 m-kg, 14—1S ft-lb)

36-54 N-m (3.7—5.5 m-kg, 27—40 ft-lb)

16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

5—7 N-m (50—70 cm-kg, 43—61 In-lb)

-31—46 N-m (3.2—4.7 m-kg, 23—34 ft-lb)

9—13 N m (90—130 cm-kg, 78—113 ft-lb)

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

8-11 N-m (80—110 cm-kg, 69—95

31—46 N-m (3.2—4.7 m-kg.

8—11 N-m (80

16—23

88—118 N-m (9.0—12.0 m-kg, 65—87 ft-lb)

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

8—11 N-m (80—110 cm-kg, 69—95 In-lb)

86U01X-180

1A—92

Page 125 of 1865

INSTALLATION 1A

Engine Mount

Install the engine mount.

76G01A-096

86U01X-181

Exhaust Pipe

1. Install the exhaust pipe.

Tightening torque

31—46

N

m

(3.2—4.7 m-kg, 23—34 ft-lb)

(§): 64—89

N

m

(6.5—9.1 m-kg, 47—66 ft-lb)

2. Tighten the bracket bolt.

Tightening torque:

19—25 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

Extension Bar (MTX)

Install the extension bar to the transaxle.

Tightening torque:

31—46

N

m (3.2—4.7 m-kg, 23—34 ft-lb)

Change Rod (MTX)

Install the change rod to the transaxle.

Tightening torque:

16—23 Nm (1.6—2.3 m-kg, 12—17 ft-lb)

1A—93

Page 126 of 1865

1A INSTALLATION

Driveshaft

1. Apply grease to the end of the driveshaft.

2. Install the driveshaft and a new clip.

Caution

a) When installing the driveshaft, be careful

not to damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft is securely

held by the clip.

86U01X-184

Lower Arm

Install the lower arm ball-joint to the knuckle; then tight-

en the lock nut.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

86U01X-185

Tie-Rod End

1. Install the tie-rod end to the knuckle.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

2. Install the cotter pin.

86U01X-186

Stabilizer Control Rod

Install and adjust the front stabilizer control rods.

Dimension A: 20.1 mm (0.79 in)

Tightening torque: 16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

Install the front wheel.

Tightening torque:

88—118

N

m (9.0—12.0 m-kg, 65—87 ft-lb)

1A—94

Page 127 of 1865

INSTALLATION 1A

86U01X-188

86U01X-189

P/S Oil Pump

1. Install the P/S oil pump.

Tightening torque:

31—46 N m (3.2—4.7 m-kg, 23—34 ft-lb)

2. Tighten the pulley lock nut.

Tightening torque:

39—59

N

m (4.0—6.0 m-kg, 29—43 ft-lb)

A/C Compressor

1. Install the A/C compressor strap to the P/S oil pump

bracket.

Tightening torque:

19—25 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

2. Install the A/C compressor bracket.

Tightening torque:

37—63 Nm (3.8—6.4 m-kg, 27—46 ft-lb)

3. Install the A/C compressor.

4. Install the A/C compressor upper bracket.

Tightening torque:

37—63

N

m (3.8—6.4 m-kg, 27—46 ft-lb)

5. Tighten to the lock nut and mounting bolts.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

86U01X-190

Drive Belt

Install the drive belt and adjust the belt deflection. (Re-

fer to page 1A—7.)

76G01A-096

1A—95

Page 128 of 1865

1A INSTALLATION

Clutch Release Cylinder (MTX)

1. Set the pipe bracket in position.

Tightening torque:

8—11 Nm (80—110 cm-kg, 69—95 in-lb)

2. Install the clutch release cylinder.

Tightening torque:

19—25 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

86U01X-192

Control Cable (ATX)

Install the control cable and adjust the shift selector

position. (Refer to Section 7.)

Tightening torque

@: 44—64

N

m

(4.5—6.5 m-kg, 33—47 ft-lb)

(§): 16—23

N

m

(1.6—2.3 m-kg, 12—17 ft-lb)

Speedometer Cable

Install the speedometer cable.

76G01A-097

Three-Way Solenoid Assembly

Install the three-way solenoid assembly.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

76G01A-098

Brake Vacuum Hose

Connect the brake vacuum hose.

Canister Hose

Connect the canister hoses.

86U01X-180

1A—96

Page 129 of 1865

INSTALLATION 1A

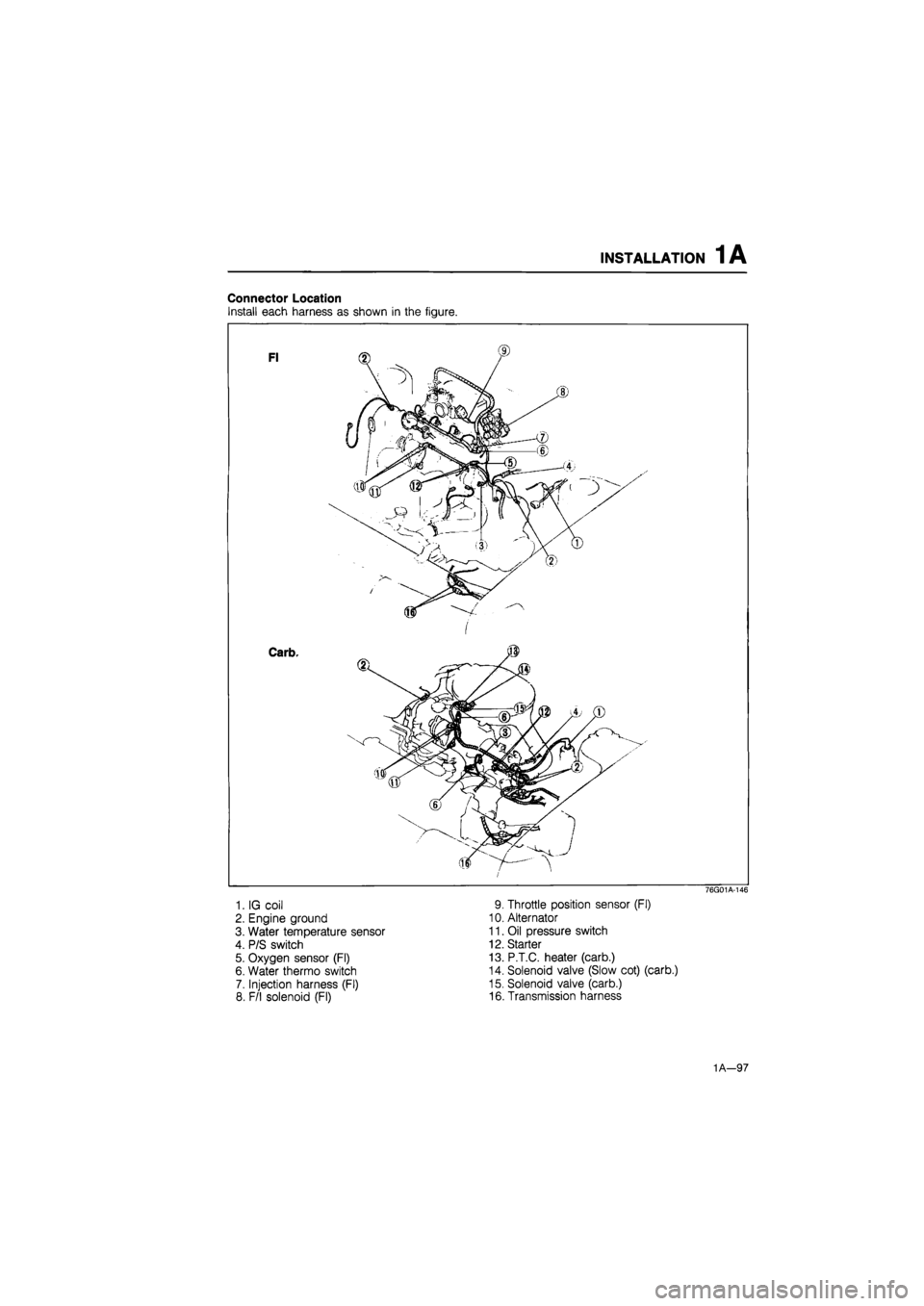

Connector Location

Install each harness as shown in the figure.

1. IG coil

2. Engine ground

3. Water temperature sensor

4. P/S switch

5. Oxygen sensor (Fl)

6. Water thermo switch

7. Injection harness (Fl)

8. F/l solenoid (Fl)

76G01A-146

9. Throttle position sensor (Fl)

10. Alternator

11. Oil pressure switch

12. Starter

13. P.T.C. heater (carb.)

14. Solenoid valve (Slow cot) (carb.)

15. Solenoid valve (carb.)

16. Transmission harness

1A—97

Page 130 of 1865

1A INSTALLATION

76G01A-147

86U01X-199

86U01X-200

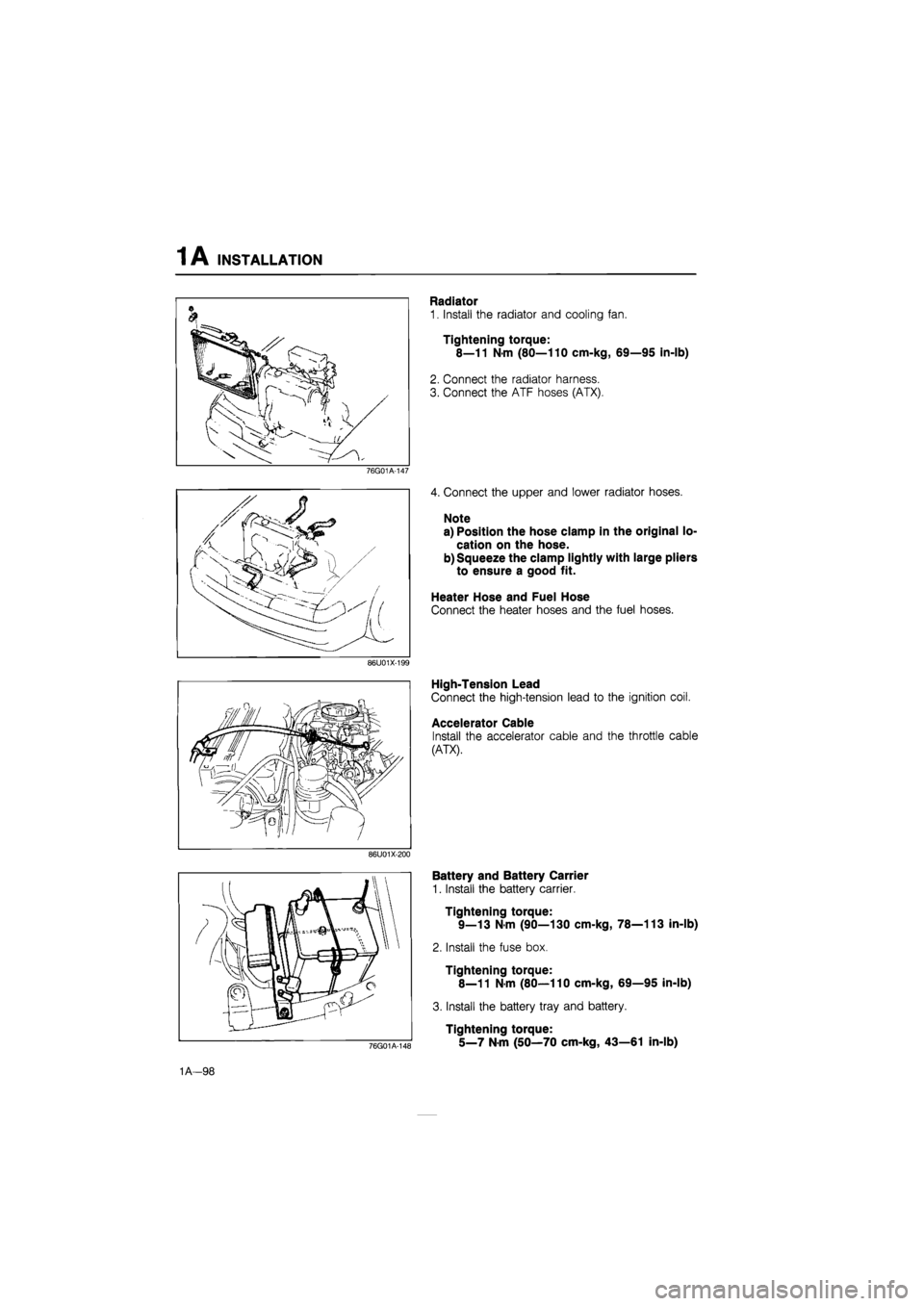

Radiator

1. Install the radiator and cooling fan.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

2. Connect the radiator harness.

3. Connect the ATF hoses (ATX).

4. Connect the upper and lower radiator hoses.

Note

a) Position the hose clamp in the original lo-

cation on the hose.

b) Squeeze the clamp lightly with large pliers

to ensure a good fit.

Heater Hose and Fuel Hose

Connect the heater hoses and the fuel hoses.

High-Tension Lead

Connect the high-tension lead to the ignition coil.

Accelerator Cable

Install the accelerator cable and the throttle cable

(ATX).

76G01A-148

Battery and Battery Carrier

1. Install the battery carrier.

Tightening torque:

9—13 N-m (90—130 cm-kg, 78—113 in-lb)

2. Install the fuse box.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

3. Install the battery tray and battery.

Tightening torque:

5_7 Nm (50—70 cm-kg, 43—61 in-lb)

1A—98