sensor MAZDA MX-5 1994 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 594 of 1708

FRONT AXLE M Hub bolts Note The hub bolts do not need to be removed unless you are replacing them. Remove the hub bolts with a press. Assembly note Hub bolts Install the new hub bolts with a press. Sensor rotor (ABS) Install a new sensor rotor by using the SST and a press. Inspection Front wheel hub assembly Inspect for damage. Gartner Banana

Page 596 of 1708

REAR AXLE M DISC BRAKE TYPE Inspection 1 Removal 1 Installation 1. lnspect wheel bearing play, referring to Inspection. 2. Remove in the order shown in the figure, referring to Removal Note. 3. lnspect all parts and repair or replace as necessary. 4. Install in the reverse order of removal, referring to Installation Note. 5. After installation, adjust the rear wheel alignment. (section R.) @ REPLACE 21 6294 {2230,159-217) N.m {kgf m, Rlbf) 1. Rear wheel 2. Brake caliper assembly Removal Note . . . . . . . . . . . . . page M-12 3. Disc plate 4. Locknut Installation Note . . . . . . . . . . . page M-12 5. Wheel speed sensor (ABS) 6. Sensor bracket 7. Knuckle, wheel hub, and dust cover lnspect knuckle for cracks and damage lnspect wheel hub for cracks and damage lnspect dust cover for damage and distortion Disassembly / Inspection / Assembly . . . . . . . . . . . . . . . . page M-13 Gartner Banana

Page 604 of 1708

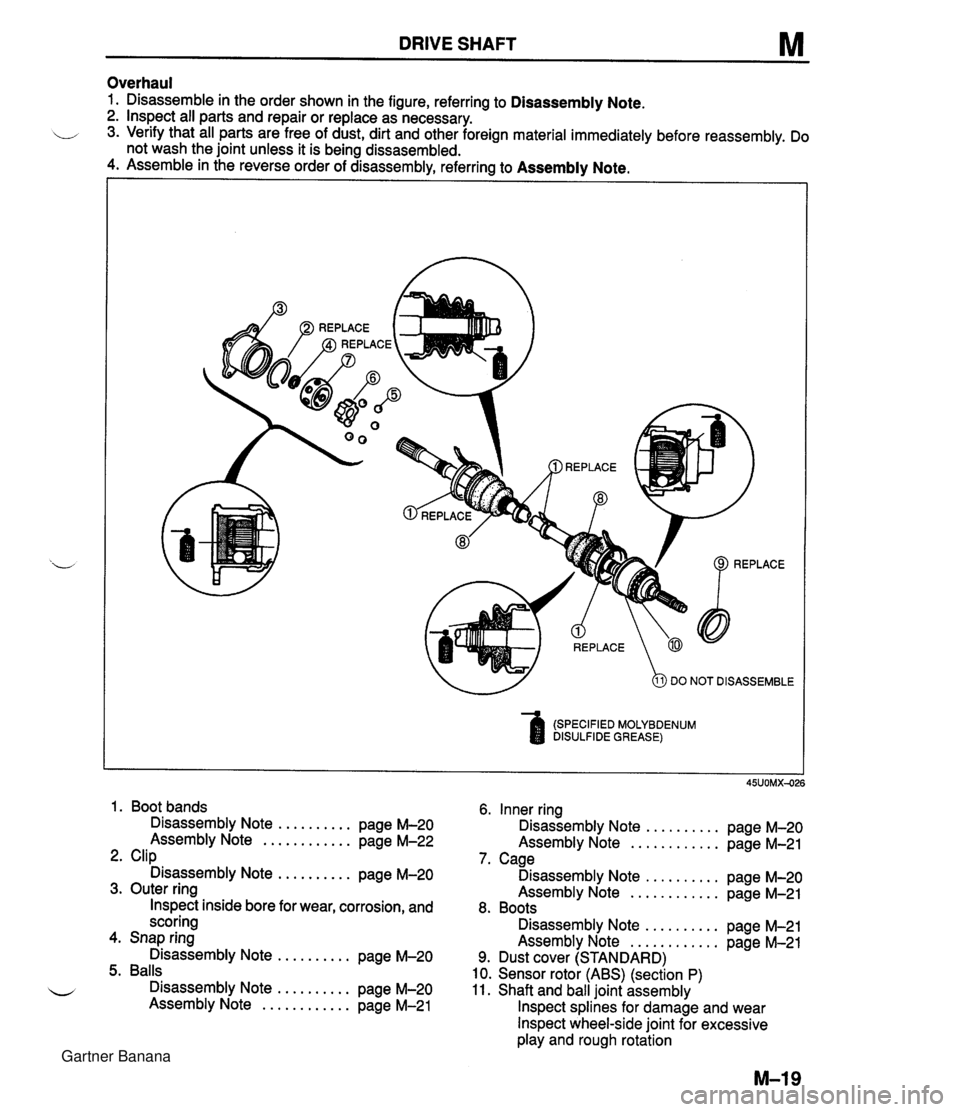

DRIVE SHAFT M Overhaul 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. lnspect all parts and repair or replace as necessary. -- 3. Verify that all parts are free of dust, dirt and other foreign material immediately before reassembly. Do not wash the joint unless it is being dissasembled. 4. Assemble in the reverse order of disassembly, referring to Assembly Note. 1. Boot bands 9 REPLACE J r DISASSEMBLE w DO NO' (SPECIFIED MOLYBDENUM DlSULFlDE GREASE) Disassembly Note .......... page M-20 Assembly Note ............ page M-22 2. Clip Disassembly Note .......... page M-20 3. Outer ring lnspect inside bore for wear, corrosion, and scoring 4. Snap ring Disassembly Note .......... page M-20 5. Balls .......... u Disassembly Note page M-20 Assembly Note ............ page M-21 45UOMX426 6. Inner rina ~isasiembl~ Note .......... page M-20 Assembly Note ............ page M-21 7. Cage Disassembly Note .......... page M-20 Assembly Note ............ page M-21 8. Boots Disassembly Note .......... page M-21 Assembly Note ............ page M-21 9. Dust cover (STANDARD) 10. Sensor rotor (ABS) (section P) 11. Shaft and ball joint assembly lnspect splines for damage and wear lnspect wheel-side joint for excessive play and rough rotation Gartner Banana

Page 614 of 1708

DIFFERENTIAL M t- 900mm (35.43 in) 10. Remove the transmission-side bolts, and remove the PPF. Do not remove the spacers from the PPF. If they are removed, replace the PPF as an assembly. Drive shaft Mark the drive shaft and output shaft for proper installa- tion. Differential 1. Support the differential with a jack. 2. Lower the differential and move it forward. Note If the drive shaft will not separate easily from the out- put shaft, remove a bolt and nut from one side of the upper arm. 3. Separate the driveshaft from the output shaft. 4. To prevent damaging the fire wall, crank angle sensor, and engine mount, support the transmission as follows. (1) Prepare a steel plate (as shown in the figure), a wooden block, bolts (M8 x 1.25), and washers. (2) Install the parts as shown in the figure. Gartner Banana

Page 666 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . BRAKING SYSTEM INDEX ....................................... P- 2 OUTLINE ..................................... P- 4 SPEClFlCATlONS ........................... P- 4 BRAKE SYSTEM ............................. P- 5 PREPARATION ............................. P- 5 TROUBLESHOOTING GUIDE ................ P- 6 AIR BLEEDING ............................. P- 7 BRAKE HYDRAULIC LINE ................... P- 7 BRAKE FLUID .............................. P- 8 ............................. BRAKE PEDAL P- 9 MASTER CYLINDER (STANDARD) ............ P-11 MASTER CYLINDER (ABS) .................. P-14 POWER BRAKE UNIT ....................... P-20 PROPORTIONING BYPASS VALVE ........... P-23 FRONT BRAKE (DISC) ...................... P-25 CALIPER ................................... P-28 REAR BRAKE (DISC) ........................ P-29 CALIPER ................................... P-32 PARKING BRAKE SYSTEM .................... P-34 TROUBLESHOOTING GUIDE ................ P-34 PARKING BRAKE LEVER .................... P-34 PARKING BRAKE CABLE .................... P-36 ANTILOCK BRAKE SYSTEM (ABS) ............ P-37 DESCRIPTION .............................. P-37 PREPARATION ............................. P-37 TROUBLESHOOTING GUIDE ................ P-38 CIRCUIT DIAGRAM ......................... P-52 HYDRAULIC UNIT ........................... P-53 ........................ ABS CONTROL UNIT P-55 RELAYS .................................... P-56 ABS WHEEL SPEED SENSOR (FRONT) ....... P-58 ABS SENSOR ROTOR (FRONT) .............. P-59 ABS WHEEL SPEED SENSOR (REAR) ........ P-60 ABS SENSOR ROTOR (REAR) ............... P-61 25UOPX-001 Gartner Banana

Page 668 of 1708

INDEX P ANTILOCK BRAKE SYSTEM (ABS) 1. Hydraulic unit 5. ABS sensor rotor (front) Removal / Installation ......... page P-53 Removal / Ins~ection / ................. Disassembly / Assembly ...... page P-54 Installation page P-59 2. ABS control unit 6. ABS wheel-speed sensor (rear) Removal I Installation ......... page P-55 Removal 1 Inspection I ................. 3. Relays Installation page P-60 Removal / Inspection / 7. ABS sensor rotor (rear) ......... ................. w Installation page P-56 Removal / Inspection page P-61 .................. 4. ABS wheel-speed sensor (front) Installation page P-62 Removal / Inspection / ................. Installation page P-58 Gartner Banana

Page 669 of 1708

OUTLINE OUTLINE SPECIFICATIONS Item TY ~e Specifications Suspended Pedal level ratio Maximum stroke mm (in) 4.1 : I 1 20 14.72) - -- TY ~e Bore mm (in) Pad dimensions (area x thickness) mm2 x mm {in2 x in) Tandem (with level sensor) 22.22 (0.875) -- - TY ~e Cylinder bore mm (in) Disc plate dimension (effective diame- ter x thickness) mm {in) Disc (ventilated) 51.1 (2.01) Pad dimensions (area x thickness) mm2 x mm (in2 x in) Cylinder bore mm {in) Disc plate dimensions (effective diameter x thickness) mm (in) Disc (solid) 31.75 (1.25) Size mm {in) Vacuum multiplier 21 4 (8) Proportioning bypass valve (PBV) FMVSS 11 6: DOT-3 Brake fluid Mechanical, two rear brakes Hand lever Parking brake TY Pe - Operation system Gartner Banana

Page 676 of 1708

BRAKE SYSTEM P MASTER CYLINDER (STANDARD) Removal / Installation 1 lnspection 1. Remove in the order shown in the figure, referring to Removal Note. ,, 2. Install in the reverse order of removal, referring to Installation Note. 3. After installation, add brake fluid, bleed the brakes, and check for fluid leakaae. 1. Fluid level sensor connector 5. Proportioning bypass valve and bracket Inspection ................... page P-13 6. Master cylinder 2. Brake pipe Installation Note ............. page P-12 Removal Note ............... page P-12 Disassembly 1 Assembly I 3. Connector bolt Inspection ................. page P-18 4. Nut and washer Gartner Banana

Page 678 of 1708

BRAKE SYSTEM CLEARANCE JSH ROD 2. By making'the above adjustment, the clearance between . the push rod and piston (after installation of the brake mas- ter cylinder and the power brake unit) will be as shown in the table below. - Clearance When vacuum applied to unit is approx. 0.1 -4.4mm 66.7 kPa (500 mmHg, 19.7 inHg) (0.004--0.016 in) Inspection Fluid level sensor connec 1. Disconnect the sensor connector. 2. Connect an ohmmeter to the connector. 3. Starting with the fluid level above the MIN mark on the reservoir, verify that there is no continuity. 4. Remove the brake fluid and verify continuity when the level is below the MIN mark. 5. Replace the sensor if necessary. Gartner Banana

Page 679 of 1708

BRAKE SYSTEM MASTER CYLINDER (ABS) Removal / Installation / lnspection 1. Remove in the order shown in the figure, referring to Removal Note. 2. Install in the reverse order of removal, referring to Installation Note. 3. After installation, add brake fluid, bleed air, and check for fluid leakage. Caution Brake fluid will damage painted surfaces. If it does get on a painted surface, wipe it off immedi- Fluid level sensor connector 5. Proportioning bypass valve and bracket Inspection ................... page P-17 6. Master cylinder Brake pipe Installation Note ............. page P-15 Removal Note ............... page P-15 Disassembly 1 Assembly 1 Connector bolt Inspection ................. page P-18 Nut and washer Gartner Banana