check engine MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 685 of 1708

P BRAKE SYSTEM k FIRST PEDAL VACUUM GAUG DEPRESSION FORCE GAUGE POWER BRAKE UNIT Quick Inspection, On-vehicle Power brake unit function check (Simple method) ii Step 1 1. With the engine stopped, depress the pedal a few times. 2. With the pedal depressed, start the engine. 3. If immediately after the engine starts the pedal moves down slightly, the unit is operating. Step 2 1. Start the engine and let it run 1 or 2 minutes. 2. Stop the engine. 3. Depress the pedal with the usual force. 4. If the first pedal stroke is long and becomes shorter with subsequent strokes, the unit is operating. 5. If a problem is found, inspect for damage or improper connection of the check valve or vacuum hose. Repair if necessary, and inspect it once again. Step 3 1. Start the engine. 2. Depress the pedal with the usual force. 3. Stop the engine with the pedal depressed. 4. Hold the pedal down for about 30 seconds. 5. If the pedal height does not change, the unit is operating. ,, 6. If there is a problem, check for damage or improper con- nection of the check valve or vacuum hose. Repair if necessary, and check once again. If the nature of the problem is still not clear after following the 3 steps above, follow the more detailed check described in "Method using tester," below. (Method using tester) Connect the SST, vacuum gauge, and pedal depression force gauge as shown in the figure. After bleeding the air from the SST, conduct the test as described in the 3 steps below. Inspection using gauges Connect the SST gauges, a vacuum gauge (A), and a pedal depression gauge (B) as shown. Bleed the air from the SST gauges before performing the following tests. a) Checking for vacuum loss Unloaded condition 1. Start the engine. 2. Stop the engine when the vacuum gauge indicates 66.7 kPa (500 mmHg, 19.7 inHg). 3. Observe the vacuum gauge for 15 seconds. If the gauge indicates 63.4-66.6 kPa (475-500 mmHg, ,, 18.7-19.7 inHg), the unit is operating. Gartner Banana

Page 686 of 1708

BRAKE SYSTEM P (20 kgf, 44 Ibf) (20 kgf, 44 Ibf) Loaded condition 1. Start the engine. 2. Depress the brake pedal with a force of 196 N (20 kgf, 44 Ibf). 3. With the brake pedal depressed, stop the engine when the vacuum gauge indicates 66.7 kPa I500 mmHg, 19.7 inHg). 4. Observe the vacuum gauge for 15 seconds. If the gauge indicates 63.4-66.6 kPa (475--500 mmHg, 18.7-19.7 inHg), the unit is operating. b) Checking for hydraulic pressure 1. If with the engine stopped (vacuum 0 kPa (0 mmHg, 0 inHg}) the fluid pressure is within specification, the unit is operating. 1 Pedal force Fluid pressure 2. Start the engine. Depress the brake pedal when the vac- uum reaches 66.7 kPa (500 mmHg, 19.7 inHg). If the fluid pressure is within specification, the unit is operat- ing. 1 96 N {20 kgf, 44 Ibf) I Pedal force I Fluid pressure I 1,079-1,177 kPa {I 1-1 2 kgf/cm2, 156-1 71 psi) lnspection of Check Valve 196 N {20 kgf, 44 Ibf) Note There is an arrow on the hose to indicate direction of hose installation. 5,199--5,494 kPa {53-56 kgf/cm2, 754--796 psi} lnspection 1. Disconnect both ends of the vacuum hose. 2. Apply suction and pressure to the hose from the engine side. Verify that air flows only toward the engine. If air passes in both directions or not at all, replace the vac- uum hose (along with the check valve). Gartner Banana

Page 705 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) Troubleshooting procedure 2. ALTEnuAtOR TEST START mtmE (ALTWJATOR TESTED BY RWNa ENQlNE) 3. A88 SYSTEM TEST TURN IGNITION K€Y ON (00 NOT ROES EWWE) - - 1. LOCATE ABS CONTROL UNIT. 2. DISCONNECT CONTROL UNlT HARNESS CONNECTOR FROM CONTROL UNIT. 3. CONNECT ABS TESTER HARNESS TO CONTROL UNlT HARNESS CON- NECTOR. 4. TURN IGNITION KEY TO ON POSITION. TESTER WlLL RAPIDLY DISPLAY SEVERAL MESSAGES DURING AN INITIAL SEGMENT CHECK I THEN 1 I MAZDA ABS 2 TEST 1 4 I YES ENG RUN? NO 1 I MAZDA ALT TEST I CHK ALTERNATOR NO FAULT DETECTED t I TURN OFF ENGINE I TESTER WlLL RAPIDLY DISPLAY SEVERAL MESSAGES DURING AN INITIAL SEGMENT CHECK. I THEN t 1 YES ENG RUN? NO t 1 MAZDA ABS 2 TEST I Gartner Banana

Page 738 of 1708

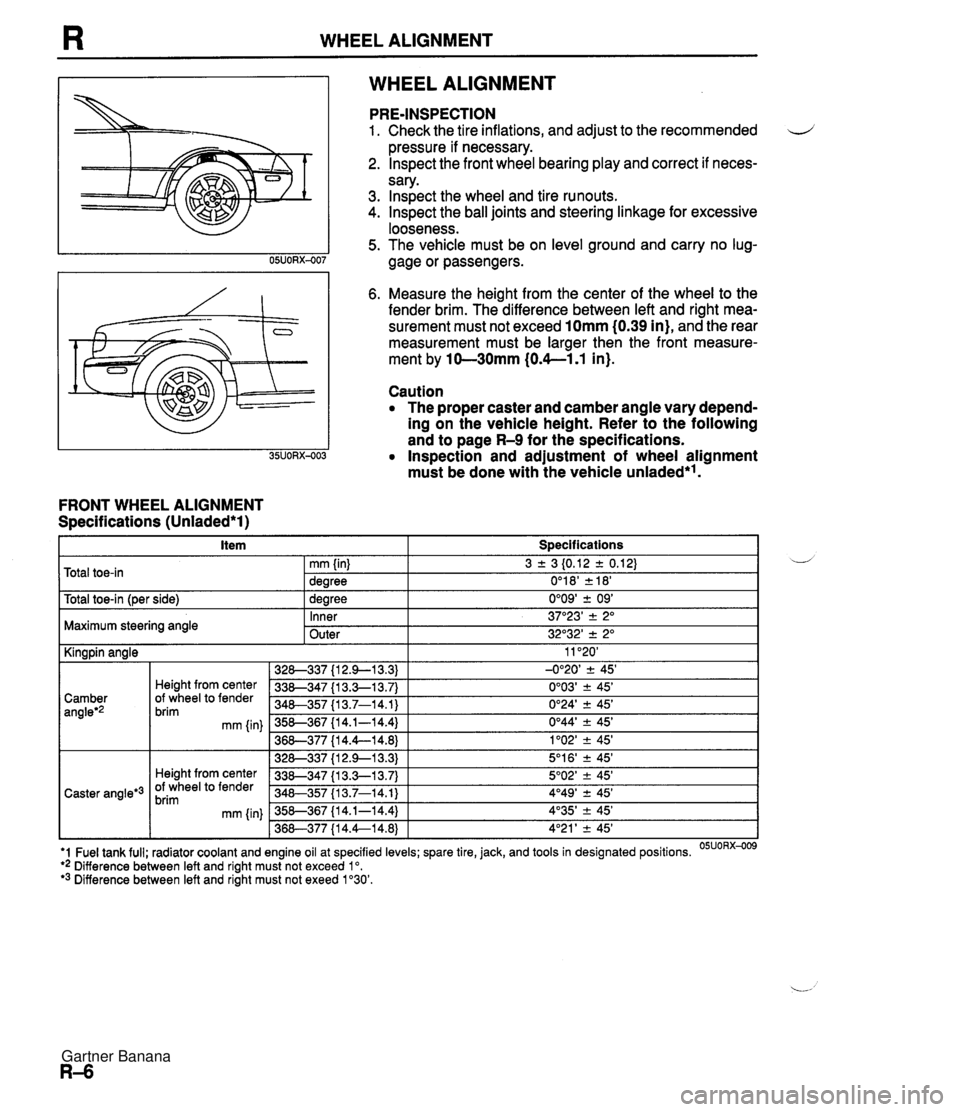

WHEEL ALIGNMENT WHEEL ALIGNMENT FRONT WHEEL ALIGNMENT Specifications (Unladed*l) PRE-INSPECTION 1. Check the tire inflations, and adjust to the recommended d pressure if necessary. 2. lnspect the front wheel bearing play and correct if neces- sary. 3. lnspect the wheel and tire runouts. 4. Inspect the ball joints and steering linkage for excessive looseness. 5. The vehicle must be on level ground and carry no lug- gage or passengers. 6. Measure the height from the center of the wheel to the fender brim. The difference between left and right mea- surement must not exceed 10mm (0.39 in), and the rear measurement must be larger then the front measure- ment by 10-30mm (0.4--1.1 in). Caution The proper caster and camber angle vary depend- ing on the vehicle height. Refer to the following and to page R-9 for the specifications. Inspection and adjustment of wheel alignment must be done with the vehicle unladed*'. . . I Y -- t~otal toe-in l~er side) I 1 dearee 0'09' + 09' I Total toe-in 3 2 3 I0.12 2 0.12) 0'1 8' 2 18' mm (in) dearee Maximum steering angle U - Inner Outer 11 '20' -0°20' 2 45' 0'03' ? 45' 0'24' 2 45' 0°44' -+ 45' 1'02' -+ 45' 5'1 6' ? 45' 5O02' -+ 45' 4O49' 2 45' 4'35' -+ 45' 4'21 ' -+ 45' I Kingpin angle 37"23' -+ 2" 32O32' 2 2" '1 Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. OSUORX-009 ** Difference between left and right must not exceed lo. '3 Difference between left and right must not exeed 1'30'. 328-337 {I 2.9-1 3.3) 338-347 {I 3.3-1 3.7) 340-357 I13.7-14.1) 358-367 {I 4.1-14.4) 36&377 {I 4.4--14.8) 328-337 {I 2.9--13.3) 338-347 {I 3.3-1 3.7) 348-357 113.7-14.1) 358-367 {I 4.1-14.4) 368-377 {I 4.4--14.8) Camber angleg2 Caster angle*3 Height from center Of wheel to fender brim mm {in) Height from center Of wheel to fender brim mm (in) Gartner Banana

Page 870 of 1708

INSTRUMENT CLUSTER T L Symptom: Tachometer does not operate. 9MUOTX-069 Step 1 - Preparation 1. Remove the instrument cluster. (Refer to page T-29.) 2. Connect a test tachometer between terminals 1 H and 2J of the harness side connector. Step 2 1. Start the engine. 2. Check that the test tachometer indicates engine speed. Indicates rpm Yes No 7 Action Replace tachometer Repair wiring harness (Instrument cluster - laniter1 Gartner Banana

Page 875 of 1708

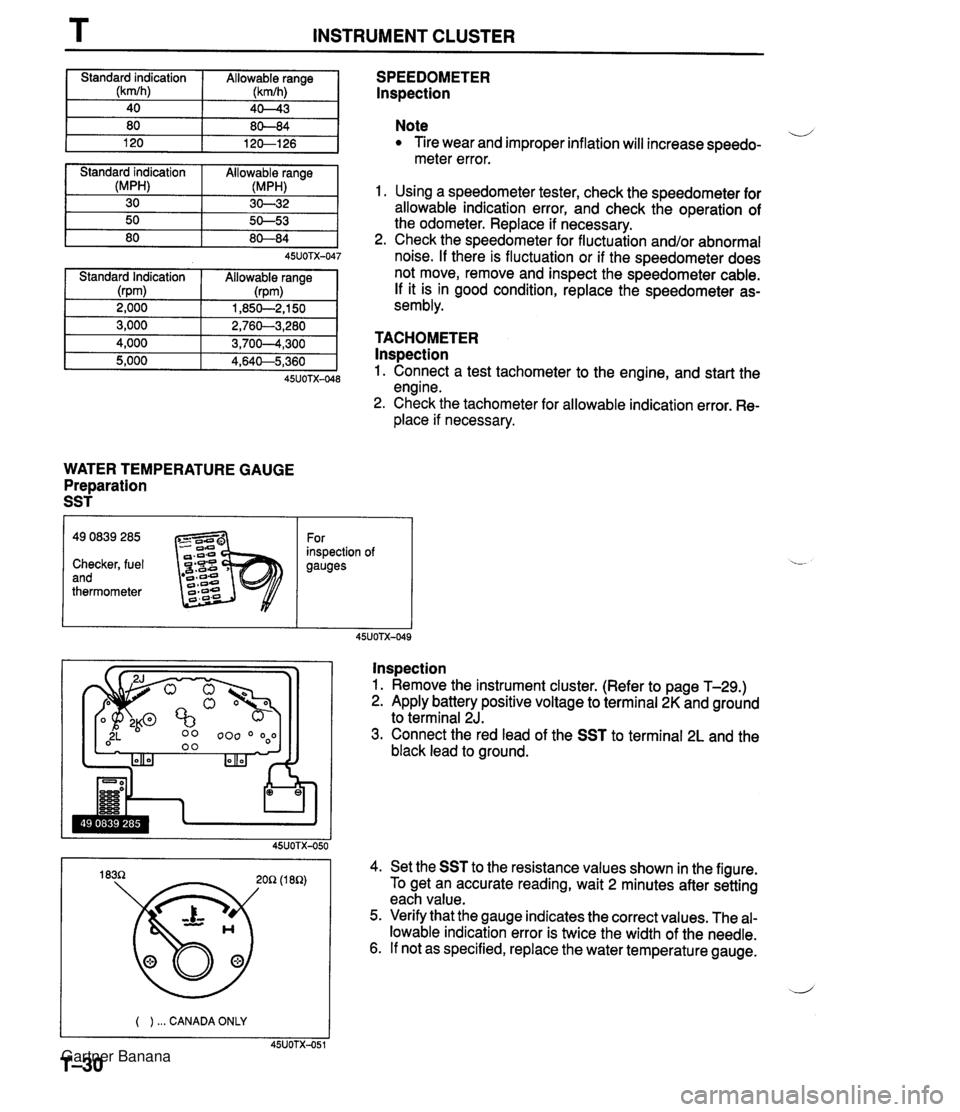

T INSTRUMENT CLUSTER Standard indication (kmlhl I 80 I 80-84 45UOTX-047 1 Standard Indication 1 Allowable ranae I Allowable range (kmlhl Standard indication (MPH) 30 WATER TEMPERATURE GAUGE Preparation SST Allowable range (MPH) 30-32 SPEEDOMETER lnspection Note .-,' Tire wear and improper inflation will increase speedo- meter error. 1. Using a speedometer tester, check the speedometer for allowable indication error, and check the operation of the odometer. Replace if necessary. 2. Check the speedometer for fluctuation and/or abnormal noise. If there is fluctuation or if the speedometer does not move, remove and inspect the speedometer cable. If it is in good condition, replace the speedometer as- sembly. TACHOMETER lnspection 1. Connect a test tachometer to the engine, and start the engine. 2. Check the tachometer for allowable indication error. Re- place if necessary. lnspection 1. Remove the instrument cluster. (Refer to page T-29.) 2. Apply battery positive voltage to terminal 2K and ground to terminal 2J. 3. Connect the red lead of the SST to terminal 2L and the black lead to ground. 49 0839 285 Checker, fuel and thermometer For inspection of gauges ( ) ... CANADA ONLY I I 45UOTX-050 183R 2on (I sn) 4. Set the SST to the resistance values shown in the figure. To get an accurate reading, wait 2 minutes after setting each value. 5. Verify that the gauge indicates the correct values. The al- lowable indication error is twice the width of the needle. 6. If not as specified, replace the water temperature gauge. -/' Gartner Banana

Page 884 of 1708

WARNING LIGHT AND SENDER UNIT T OHMMETER Washer Level Indicator lnspection 1. Disconnect the connector from the washer level sensor. 2. Jump terminal-wire L (harness side) to a body ground. 3. Start the engine and check that the WASHER indicator illuminates. 4. If there is no illumination, check the bulb, wiring harness, and sensor. Replace or repair as necessary. Washer Level Sensor lnspection 1. Connect the sensor connector (sensor side) to an ohm- meter. 2. Move the sensor float up and down. 3. Verify that there is continuity when the float is at the low- est point. BRAKE FLUID LEVEL SENSOR lnspection 1. Check for continuity of the sensor. 2. If continuity is not as specified, replace the level sensor. Float level Below MIN Above MIN BUCKLE SWITCt Continuity Yes No OHMMETER -1 PARKING BRAKE SWITCH lnspection 1. Disconnect the parking brake switch connector. 2. Check for continuity between the switch connector and ground. I Lever I Continuity I 3. If continuity is not as specified, adjust or replace the parking brake switch. (Refer to section P.) Pulled one notch Released BUCKLE SWITCH lnspection 1. Disconnect the buckle switch connector 2. Check for continuity of the switch. Yes No Seat belt I Continuity Seat belt buckled Seat belt unbuckled No Yes 3. If continuity is not as specified, replace the buckle switch. Gartner Banana

Page 918 of 1708

LIGHTING SYSTEM T Symptom: Daytime running lights (DRL) do not illuminate. (Turn signals function normally.) DRL operate with engine running and following switches are off: Headlight switch Turn signal switch (Selected turn signal light flashes, other light remains illumi- nated) Hazard warning switch Parking brake switch (Parking brake released) Step 1 1. Position the vehicle on a flat surface and block the wheels to prevent vehicle movement. 2. Turn the ignition switch to ON. 3. Measure the voltage at the following terminal wires of the DRL control unit. 4. If correct, replace the DRL control unit. B+: Battery positive voltage Step 2 1. Disconnect the parking brake switch connector. 2. Check for continuity between the terminal of the switch and a body ground. Terminal J (L) u Connected to WIPER 20A fuse I(B) B (R) C (WIR) Parking brake lever Pulled one notch Continuity Yes Released Test condition Constant GND Parking brake switch Headlight switch No I 3. If not as specified, adjust or replace the parking brake switch. 4. If correct, repair wiring harness. (DRL control unit - Parking brake switch) Specification B+ Constant Parking brake released Headlight switch off Action Repair wiring harness (WIPER 20A - DRL control unit) Other B+ Other Repair wiring harness (DRL control unit - GND) Go to Step 2 Go to Step 3 Gartner Banana

Page 944 of 1708

CRUISE CONTROL SYSTEM Step 8 - lnspection of actuator 1. Measure the cruise actuator solenoid resistance by us- ing an ohmmeter. Check terminals C-A 2. If not as soecified. redace the actuator. Resistance C-B C-D 3. If continuiiv is OK: ad to Ster, 84. Approx. 25 to 55R 4. ~isconne4 the actiator cabie from the accelerator ped- al. 5. Run the engine at idle speed. 6. Apply battery positive voltage to the following terminals, and check actuator operation. B+: Batterv aositive voltaae I Order 1 2 7. If not as specified, replace the actuator. Terminal condition AlBlClD 3 4 Step 9 - lnspection of vehicle speed sensor 1. Remove the instrument cluster. 2. Check for continuity between terminals 2D and 2F while rotating the speedometer cable. 3. If there are not four pulses per shaft rotation, replace the vehicle speed sensor. (Refer to page T-32.) 4. If there are four pulses per rotation, check the wiring har- ness. (instrument cluster - control unit). 5. If the wiring is OK, replace the cruise control unit. Operation of control cable GND GND GND - GND - - B+ B+ B+ - GND GND Pull Hold - - Extend Release Gartner Banana

Page 952 of 1708

CRUISE CONTROL SYSTEM T ACTUATOR Inspection 1. Measure the actuator solenoid resistance by using an ohmmeter. Check terminals C-A 2. If not as specified, replace the actuator. 3. Disconnect the actuator cable from the accelerator ped- al. 4. Run the engine at idle speed. 5. Apply battery positive voltage to the following terminals, and check the actuator operation. Resistance C-B C-D B+: Battery positive voltage Approx. 25 to 55hL I I I I I 1 I GND I GND I B+ I GND 1 Pull I Terminal condition AlBlClD I I I 1 I 2 1 GND I - I B+ I GND I Hold I Operation of control cable I 6. If not as specified, replace the actuator. 3 4 Removal 1. Disconnect the accelerator cable and vacuum hose from the actuator. 2. Remove the bolt and nuts and the actuator. Installation Install in the reverse order of removal. GND - - - B+ - - - Extend Release Gartner Banana