SECTION T MAZDA MX-5 1994 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 150 of 1708

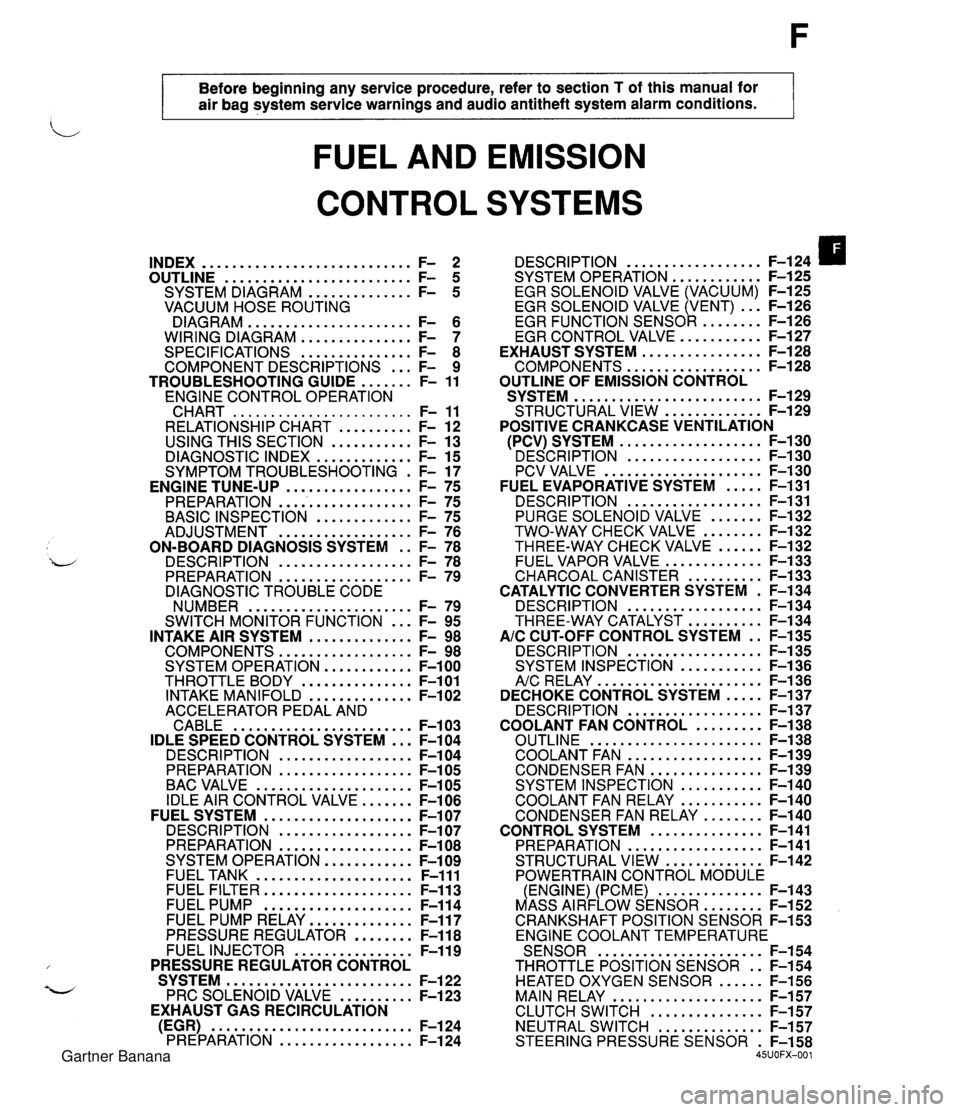

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . FUEL AND EMISSION CONTROL SYSTEMS INDEX ............................ F- 2 ......................... OUTLINE F- 5 .............. SYSTEM DIAGRAM F- 5 VACUUM HOSE ROUTING DIAGRAM ...................... F- 6 WIRING DIAGRAM ............... F- 7 SPECIFICATIONS ............... F- 8 COMPONENT DESCRIPTIONS ... F- 9 ....... TROUBLESHOOTING GUIDE F- 11 ENGINE CONTROL OPERATION CHART ........................ F- 11 RELATIONSHIP CHART .......... F- 12 USING THIS SECTION ........... F- 13 DIAGNOSTIC INDEX ............. F- 15 SYMPTOM TROUBLESHOOTING . F- 17 PREPARATION ................... F- 75 ............. BASIC INSPECTION F- 75 .................. ADJUSTMENT F- 76 ON-BOARD DIAGNOSIS SYSTEM . . F- 78 DESCRIPTION .................. F- 78 PREPARATION .................. F- 79 DIAGNOSTIC TROUBLE CODE NUMBER ...................... F- 79 ... SWITCH MONITOR FUNCTION F- 95 INTAKE AIR SYSTEM .............. F- 98 COMPONENTS .................. F- 98 SYSTEM OPERATION ............ F-100 THROTTLE BODY ............... F-101 INTAKE MANIFOLD .............. F-102 ACCELERATOR PEDAL AND CABLE ........................ F-103 IDLE SPEED CONTROL SYSTEM ... F-104 DESCRI PTlON .................. F-104 PREPARATION .................. F-105 BAC VALVE ..................... F-105 IDLE AIR CONTROL VALVE ....... F-106 FUEL SYSTEM .................... F-107 DESCRIPTION .................. F-107 PREPARATION .................. F-108 SYSTEM OPERATION ............ F-109 FUEL TANK ..................... F-111 FUEL FILTER .................... F-113 FUEL PUMP .................... F-114 FUEL PUMP RELAY .............. F-117 PRESSURE REGULATOR ........ F-118 FUEL INJECTOR ................ F-119 PRESSURE REGULATOR CONTROL SYSTEM ......................... F-122 PRC SOLENOID VALVE .......... F-123 EXHAUST GAS RECIRCULATION (EGR) ........................... F-124 PREPARATION .................. F-124 .................. DESCRIPTION F-124 SYSTEM OPERATION F-125 ............ EGR SOLENOID VALVE (VACUUM) F-125 EGR SOLENOID VALVE (VENT) ... F-126 ......... EGR FUNCTION SENSOR F-126 ........... EGR CONTROL VALVE F-127 ................ EXHAUST SYSTEM F-128 .................. COMPONENTS F-128 OUTLINE OF EMISSION CONTROL ......................... SYSTEM F-129 ............. STRUCTURAL VIEW F-129 POSITIVE CRANKCASE VENTILATION ................... (PCV) SYSTEM F-130 ' DESCRIPTION .................. F-I ..................... PCV VALVE F-1 ..... FUEL EVAPORATIVE SYSTEM F- .................. DESCRIPTION F- ....... PURGE SOLENOID VALVE F- ........ TWO-WAY CHECK VALVE F- ...... THREE-WAY CHECK VALVE F- ............. FUEL VAPOR VALVE F- .......... CHARCOAL CANISTER F- CATALYTIC CONVERTER SYSTEM . F- .................. DESCRIPTION F- .......... THREE-WAY CATALYST F- AIC CUT-OFF CONTROL SYSTEM . . F- .................. DESCRIPTION F- ........... SYSTEM INSPECTION F- ...................... A/c RELAY F-1 36 ..... DECHOKE CONTROL SYSTEM F-137 .................. DESCRIPTION F-137 ......... COOLANT FAN CONTROL F-138 ....................... OUTLINE F-138 .................. COOLANT FAN F-139 ............... CONDENSER FAN F-139 ........... SYSTEM INSPECTION F-140 ........... COOLANT FAN RELAY F-140 ........ CONDENSER FAN RELAY F-140 ............... CONTROL SYSTEM F-141 .................. PREPARATION F-141 ............. STRUCTURAL VIEW F-142 POWERTRAIN CONTROL MODULE .............. (ENGINE) (PCME) F-143 ........ MASS AIRFLOW SENSOR F-152 CRANKSHAFT POSITION SENSOR F-153 ENGINE COOLANT TEMPERATURE ...................... SENSOR F-154 THROTTLE POSITION SENSOR . . F-154 HEATED OXYGEN SENSOR ...... F-156 MAIN RELAY .................... F-157 ............... CLUTCH SWITCH F-157 NEUTRAL SWITCH .............. F-157 STEERING PRESSURE SENSOR . F-158 45UOFX-001 Gartner Banana

Page 162 of 1708

TROUBLESHOOTING GUIDE USING THIS SECTION Introduction Most of the fuel and emission control system is electrically controlled, often making it difficult to diagnose '.-/ problems in the system, especially intermittent problems. Before undertaking actual checks, take a few minutes to talk with a customer who approaches with a driveability complaint. The customer is often a good source of information on such problems, especially intermittent ones. Through talks with the cus- tomer, one can find out what the symptoms are and under what conditions they occur. Work flow CHECK IN LISTEN TO CUSTOMER COMPLAINTS REFER TO TROUBLESHOOTING PAGE THAT - - - - - - - - - - - - - - - - - - Diagnostic index CORRESPONDS TO ACTUAL SYMPTOM (Refer to page F-18) 1-CHECKFORWHATISBADINSYSTEM--------------------- Inspection CHECKFORWHATPARTISBAD----------------------- Action Diagnostic index No.: / Each troubleshooting item is as- signed a number. TROUBLESHOOTING ITEM: There are 34 troubleshooting items. Choose the item that most closely corresponds to the actual symp- ,, tom. yes 1 CHECK OUT ---- -- TROUBLESHOOTING GUIDE F DESCRIPTION: Describes each troubleshooting item. ' PAGE: Shows the reference page. Gartner Banana

Page 164 of 1708

TROUBLESHOOTING GUIDE DIAGNOSTIC INDEX Cranks normally but will not start (No com- Engine cranks at normal speed but shows no sign of bustion) I #firingN I F-17 I No. 1 TROUBLESHOOTING ITEM Will not crank or cranks slowly -- -- Cranks normally but will not start (Partial combustion) -When engine is cold Cranks normally but will not start (Partial combustion) - After warm-up Cranks normally but hard to start - Always Cranks normally but hard to start - When engine is cold - Engine cranks at normal speed but shows partial com- bustion and will not continue to run Engine cranks at normal speed but shows partial com- bustion and will not continue to run after running and hot soaked Engine cranks at normal speed but requires excessive cranking time (more than 5 sec.) before starting Same condition as No.5 when engine is cold Restarts OK after warm-up 8 DESCRIPTION Refer to Engine Electrical System Low idle speed1Rough idle - Before warm- UP Low idle speed/Rough idle -After warm-up PAGE SECTION G Cranks normally but hard to start - After warm-up Rough idle - Always Engine speed low or engine vibrates excessively at idle during warm-up Engine runs normally at idle during warm-up but vi- brates excessively after warm-up High idle speed - After warm-up Low idle speed - When NC, PIS, or EIL ON l5 1 Engine stalls at idle - Always Engine starts normally but vibrates excessively and stalls at idle in every condition I F40 1 13 14 Same condition as No.5 after running and hot soaked Starts normally when cold Engine vibrates excessively at idle in every condition Engine idle excessive for operation mode Engine speed decreases at idle when NC, PIS, or EIL is ON 18 1 Engine stalls during start-up 1 Engine unexpectedly stops running while starting I F-45 F-26 F-27 F-34 F-36 Rough idle just after starting Idle moves up and down 16 17 l9 1 Engine stalls on deceleration I Engine unexpectedly stops running while decelerating or after deceleration Engine starts normally but vibrates excessively only just after starting Engine speed up and down periodically at idle Engine stalls at idle - Before warm-up Engine stalls at idle - After warm-up Engine stalls at idle -When AIC, PIS, or EIL running at idle when 1 20 1 ON I F-50 1 F-37 F-38 I I . . I 21 1 Engine stalls suddenly (Intermittent) I Engine intermittently stops running I F-52 Engine starts normally but vibrates excessively and stalls at idle before warm-up Engine runs normally at idle during warm-up but be- comes rouclh and stalls after warm-up F-43 F-44 24 1 Lack of power Performance is poor under load Maximum speed re- 1 duced I F-57 I Hesitates/Stumbles on acceleration Surges while cruising I I I 25 / Poor acceleration I Performance is poor while accelerating 1 F-61 I Flat spot occurs just after accelerator is depressed or mild jerking occurs during acceleration Unexpected, usually repetitive change in engine speed Knocking F-53 F-55 Runs rough on deceleration1Afterburn Abnormal combustion accompanied by audible "ping- ing" noise I F-67 I Engine runs rough while decelerating and abnormal combustion in exhaust system 1 30 1 High oil consumption I Oil consumption excessive I F-70 1 F-65 28 1 Fuel odor 29 / Exhaust sulfur smell 1 31 1 Poor fuel economy I Fuel economy unsatisfactory I F-71 I Gasoline odor in cabin Exhaust gas smells abnormal (rotten egg smell) F-69 F-70 Gartner Banana

Page 166 of 1708

TROUBLESHOOTING GUIDE SYMPTOM TROUBLESHOOTING 2 CRANKS NORMALLY BUT WILL NOT START (NO COMBUSTION) Engine cranks at normal speed but shows no sign of "firing" ESCwPTION : Battery in normal condition Throttle valve not held wide open throttle while cranking Fuel in tank rROUBLESHOOTlNG HINTS] ecause of no combustion, possibly no fuel is injected to engine or no ignition at all cylinders 1 No spark O Low fuel line pressure lanition control malfunction @ Low engine compression ignition system component malfunction I No fuel injection Fuel pump does not operate Fuel injector does not operate INSPECTION ACTION :heck if strong blue spark is visible at disconnected iigh-tension lead while cranking engine :heck if "00" is displayed on Self Diagnosis Checker ~ith ignition switch ON page F-79 Sonnect data link connector terminals F/P and GND ~ith jumper wire and check for fuel pump operating sound with ignition switch ON page F-114 Yes - No - Yes No - Yes - No Go to Step 3 Go to Step 2 Check ignition system (Refer to Troubleshooting "Misfire") mf Section G Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage ojg. page F-145 Specification: Battery positive voltage (Ignition switch ON) 0 If OK, replace PCME us? page F-143 Q If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Check if engine starts in this condition 0 If starts, check fuel pump relay f@ page F-117 r3 If does not start, go to Step 5 Go to Step 4 Gartner Banana

Page 167 of 1708

F TROUBLESHOOTING GUIDE INSPECTION Check if battery positive voltage exists at fuel pump connector fuel pump positive terminal with jumper wire connected.(~tep 3 Check for fuel injector operating sound while crank- ing engine Check if battery positive voltage exists at fuel injector connector B terminal wire with ignition switch ON Connect data link connector terminals F/P and GND with jumper wire and check for correct fuel line pres- sure with ignition switch ON page F-110 Fuel Line pressure: 265--314 kPa f2.7-3.2 kgf/crn2, 38-46 psi) Check for correct engine compression Section B Engine compression: 1,255--883 kPa {12.&9.0 kgf/crn2, 182-1 28 psi)-300 rpm Check if spark plugs are OK WEAR AND CARBON BUILDUP BURNS PLUG GAP 1.0-l.lmm DAMAGE AND (0.040-0.043 in) DETERIORATION DAMAGE Try known good PCME and check if condition im- proves page F-144 - Yes - No Yes Yes - No Yes Yes - No - Yes ACTION Check continuity of fuel pump page F-114 Check fuel pump relay page F-117 Go to Step 7 Go to Step 6 Check PCME terminals 2A, 2U, 2V, 2Y and 22 voltages @3F page F-147 Check for open circuit in wiring between main relay and fuel injector page F-7 Go to next step Low pressure Check fuel line pressure while pinching fuel return hose 0 If fuel line pressure quickly increases, check pressure regulator page F-118 0 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure page F-115 Go to next step Check engine condition @3F Section B w Worn piston, piston rings or cylinder wall Defective cylinder head gasket w Distorted cylinder head Improper valve seating w Valve sticking in guide Go to next step Repair, clean, or replace Section G Gartner Banana

Page 168 of 1708

TROUBLESHOOTING GUIDE 3 CRANKS NORMALLY BUT WILL NOT START (PARTIAL COMBUSTION) -WHEN ENGINE IS COLD Engine cranks at normal speed but shows partial combustion and will not continue to run IESCRIPTION Battery in normal condition Fuel in tank TROUBLESHOOTING HINTS] B AirIFue! mixture too rich Q Low engine compression Air cleaner element clogged D AirIFuel mixture too lean Fuel injection control malfunction (Correction for coolant temperature) Low fuel line pressure Air leakage of intake air system 1 INSPECTION ACTION :heck if "00" is displayed on Self-Diagnosis Checker ~ith ignition switch ON as page F-79 Sheck if strong blue spark is visible at each discon- iected high-tension lead while cranking engine Connect data link connector terminals F/P and GND with jumper wire and check for correct fuel line pres- sure with ignition switch ON E+T page F-110 Fuel Line pressure: 265--314 kPa I2.7-3.2 kgf/cm2, 38-46 psi) INSTALL CLAPS ' Yes Yes Yes - No - Go to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage @f page F-145 Specification: Battery positive voltage (Ignition switch ON) O If OK, replace PCME page F-143 L:, If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Go to next step Check ignition system (Refer to Troubleshooting "Misfire") Section G Go to next step Low pressure Check fuel line pressure while pinching fuel return hose If fuel line pressure quickly increases, check pressure regulator page F-118 o If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure page F-115 High pressure Check if fuel return hose is clogged or restricted O If OK, replace pressure regulator page F-119 s If not OK, repair or replace Gartner Banana

Page 169 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check if PCME terminal voltages are OK (IC, 1 R, IT, 2D, 20 and 2Q) page F-146 :heck for air leakage of intake air system malfunction page F-100 :heck for EGR system malfunction page F-124 Check if mass airflow sensor US page F-152 Check for correct engine compression Section B Engine compression: 1,255-883 kPa j12.8-9.0 kgf/cm2, 182-128 psil-300 rpm Check if spark plugs are OK WEAR AND CARB/ON BUILDUP BURNS PLUG GAP 1 .O-1 .l mm (0.040-4.043 in) DAMAGE AND DETERIORATION DAMAGE - Yes Yes - No Yes - No Yes - No Yes No - Yes - No - ACTION Go to next step Check for cause (Refer to "Check Point for Each Terminal") page F-148 Repair or replace Go to next step Repair or replace Go to next step Go to next step Repair or replace page F-99 Go to next step Check engine condition Section B Worn piston, piston rings or cylinder wall Defective cylinder head gasket Distorted cylinder head Improper valve seating a Valve sticking in guide Go to next step Repair, clean, or replace @a Section G Try known good PCME and check if condition im- 3rOVeS page F-144 Gartner Banana

Page 173 of 1708

TROUBLESHOOTING GUIDE INSPECTION ACTION Check if PCME terminal voltages are OK (1 R, 1 T, ZD, 20 and 20) us page F-146 Yes Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") Djp paae F-148 Check if strong blue spark is visible at each discon. nected high-tension lead while cranking engine Yes - No Go to next step Check ignition system (Refer to Troubleshooting "Misfire") Section G Check for EGR system malfunction page F-124 Yes - No Repair or replace Go to next step Check for fuel injector operating sound at each in- Yes Go to Step 10 jector at idle No - Yes Go to Step 9 Check if battery positive voltage exists at fuel injec- tor connector B terminal with ignition switch ON Check if fuel injector resistance is OK page F-119 Resistance: 12-1 6R G If OK, check wiring between injector and PCME page F-7 o If not OK, replace injector L@? page F-119 No - Yes Check wiring between main relay and fuel injector page F-7 Go to next step Check for correct engine compression Section B Engine compression: 1,255-883 kPa I12.8-9.0 kgflcm2, 182-1 28 psi)-300 rpm Check engine condition Section B I Worn piston, piston rings or cylinder wall r Defective cylinder head gasket r Distorted cylinder head r Improper valve seating Valve sticking in guide No - Yes :heck if spark plugs PLUG GAP 1 .O-1 .l mm (0.04+0.043 in} DETERIORATION 30 to next step qepair, clean, or replace Section G Try known good PCME and check if condition im- roves @r page F-144 Gartner Banana

Page 177 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check for fuel injector operating sound at idle with sound scope or screwdriver Check if battery positive voltage exists at fuel injec- tor connector 6 terminal Disconnect each high-tension lead at idle and check if engine speed decreases equally each time - - - Check if spark plu CARBON BUILDUP PLUG GAP 1.0-1 .l mm (0.040-0.043 in) DAMAGE AND DETERIORATION Check for correct ignition timing at idle page F-76 Ignition timing: 10" +. lo BTDC Check for EGR system malfunction w page F-124 Check for correct fuel line pressure at idle * page F-110 Fuel line pressure: 26-14 kPa f2.7-3.2 kgflcm2, 38-46 psi} (Vacuum hose to pressure reaulator discon- - Yes - No - Yes No - Yes - No - Yes - No Yes No - Yes ACTION Yes - No - Go to Step 8 Go to Step 7 Check if fuel injector resistance is OK page F-119 Resistance: 12-1 632 0 If OK, check wiring between PCME and fuel injector @r page F-7 Q If not OK, replace fuel injector page F-119 Check wiring between PCME and fuel injector page F-7 Disconnect each fuel injector connector at idle and check if engine speed decreases equally each time 0 If OK, go to Step 10 o If not OK, check fuel injector for fuel leakage G= pane F-120 Go to step 9 Check for correct engine compression t@ Section B Q if OK, replace fuel injector t@ page F-119 o If not OK, check for cause (Refer to Section 6) U=S Section B Repair, clean, or replace Section G Check for correct idle speed @ page F-77 Idle speed: 850 -c 50 rpm (MT) 800 2 50 rpm (AT) 0 If OK, go to next step 0 If not OK, adjust idle speed w page F-77 Adjust page F-72 Repair or replace Go to next step Go to next step Low pressure Check fuel line pressure while pinching fuel return hose 3 If fuel line pressure quickly increases, check pressure regulator US= page F-118 3 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure E+T page F-115 Try known good PCME and check if condition im- proves w Daae F-144 Gartner Banana

Page 181 of 1708

F TROUBLESHOOTING GUIDE INSPECTION :heck for correct intake manifold vacuum at idle Vacuum: More than 450 mmHg I17.7 inHg) VACUUM GAUGE :heck if PCME terminal voltages are OK (2D, 20 and 2Q) page F-146 :heck for correct ignition timing at idle @S page F-76 Ignition timing: 10" + 1" BTDC :heck for correct fuel line pressure at idle @S page F-11 0 Fuel line pressure: 265--314 kPa f2.7-3.2 kgf/cm2,38-46 psi} (Vacuum hose to pressure regulator discon- INSTALL CLAPS ' :heck if strong blue spark is visible at each discon- iected high-tension lead while cranking engine - -- :heck for correct engine compression @S Section B Engine compression: 1,255-883 kPa (12.8-9.0 kgf/cm2, 182-128 psi)-300 rpm - Yes Yes Yes No - Yes - No - Yes No - Yes - No - ACTION Go to next step Low vacuum Check for air leakage of intake air system components page F-100 Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") page F148 Check for correct idle speed page F77 Idle speed: 850 -c 50 rpm (Mi) 800 + 50 rpm (AT) e If OK, go to next step o If not OK, adjust idle speed page F-77 Adjust page F-76 Go to next step Low pressure Check fuel line pressure while pinching fuel return hose 0 If fuel line pressure quickly increases, check pressure regulator page F-118 0 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure page F-115 Go to next step Check ignition system (Refer to Troubleshooting "Misfire") Section G Go to next step Check engine condition Section B Worn piston, piston rings or cylinder wall Defective cylinder head gasket Distorted cylinder head Improper valve seating Valve sticking in guide Gartner Banana