MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 101 of 1164

ASSEMBLY

f

05UOW18

THRUST BEARING

OYJOBX-18

05UOBX-18

23UOBl-04

OWOBX-181

Crankshaft

1. Before installing the crankshaft, inspect the main bearing

oil clearances as follows.

Oil clearance inspection

(1) Remove all foreign material and oil from the journals and

bearings.

Caution

l Install the grooved upper main bearings in the cyl-

inder block.

l Install the thrust bearings with the oil groove fac-

ing the crankshaft.

(2) Install the upper main bearings and thrust bearings.

(3) Set the crankshaft in the cylinder block.

Caution

l Do not rotate the crankshaft when measurlng the

oil clearances.

(4) Position Plastigage atop the journals in the axial di-

rection.

(5) Install the lower main bearings and the main bearing

caps according to the cap number and + mark.

(6) Tighten the main bearing cap bolts in two or three steps

in the order shown in the figure.

Tightening torque:

54-59 N-m (5.5-6.0 m-kg, 40-43 ft-lb)

(7) Remove the main bearing caps, and measure the P lasti-

gage at each journal at the widest point for the smallest

clearance and at the narrowest point for the largest

clearance.

(8) If the oil clearance exceeds specification, grind the

crankshaft and use undersize main bearings.

(Refer to page Bl-64.)

Oil clearance: 0.016-0.036mm (0.0007-0.0014 in)

Maximum: O.lOmm (0.004 in)

2. Apply a liberal amount of clean engine oil to the main bear-

ings, thrust bearings and main journals.

3. Install the crankshaft and the main bearing caps accord-

ing to the cap number and + mark.

61-71

Page 102 of 1164

Bl ASSEMBLY

05UOBX-18s

WIDTH

05lJOBX-l!

, MATCHING MARKS’,

03UOBl-1;

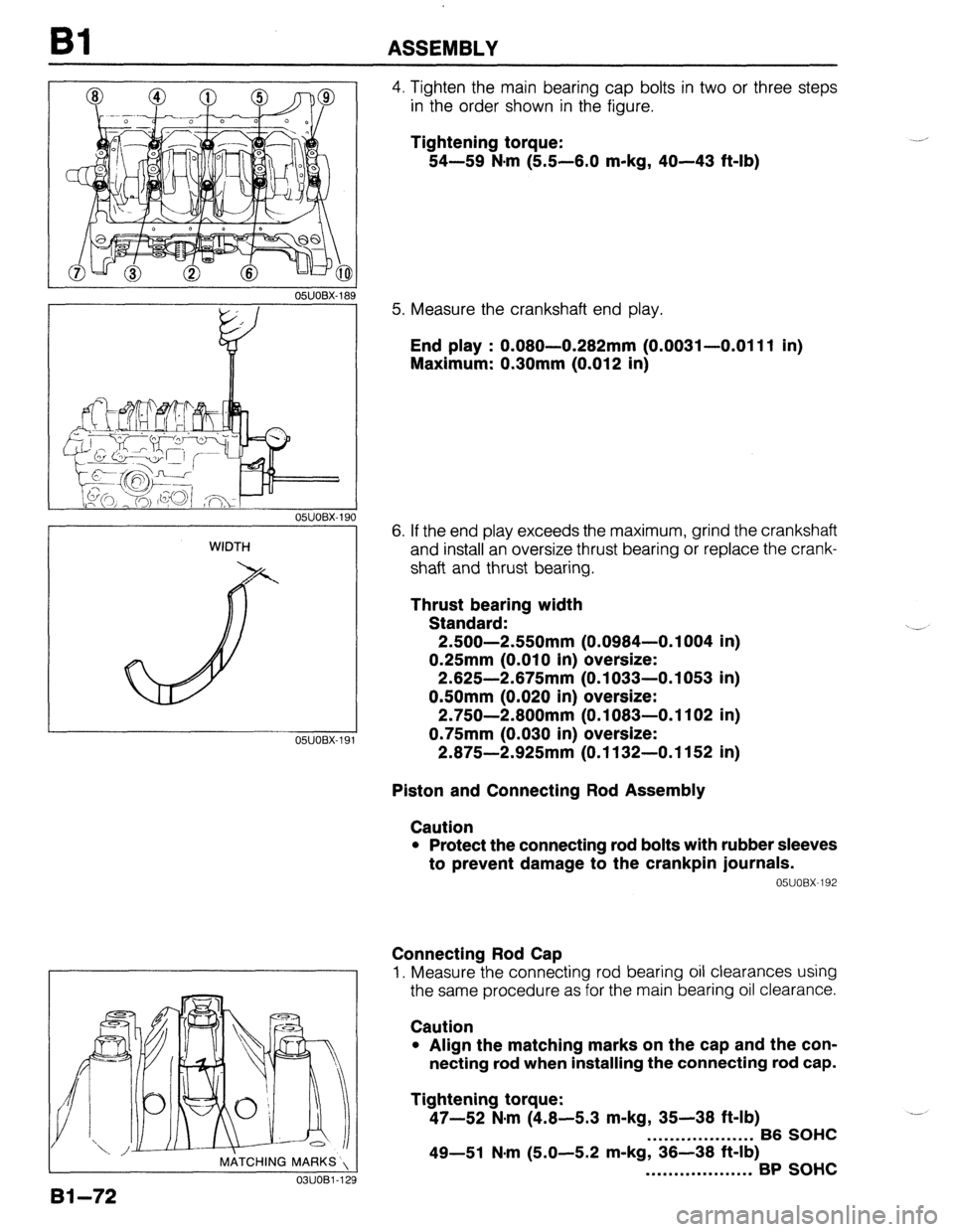

4. Tighten the main bearing cap bolts in two or three steps

in the order shown in the figure.

Tightening torque:

54-59 N.m (5.5-6.0 m-kg, 40-43 ft-lb)

5. Measure the crankshaft end play.

End play : 0.060-0.262mm (0.0031-0.0111 in)

Maximum: 0.30mm (0.012 in)

6. If the end play exceeds the maximum, grind the crankshaft

and install an oversize thrust bearing or replace the crank-

shaft and thrust bearing.

Thrust bearing width

Standard:

2.500-2.550mm (0.0964-0.1004 in)

0.25mm (0.010 in) oversize:

2.625-2.675mm (0.1033-0.1053 in)

0.50mm (0.020 in) oversize:

2.750-2.600mm (0.1063-0.1102 in)

0.75mm (0.030 in) oversize:

2.675-2.925mm (0.1132-0.1152 in)

Piston and Connecting Rod Assembly

Caution

l Protect the connecting rod bolts with rubber sleeves

to prevent damage to the crankpin journals.

OSUOBX-192

Connecting Rod Cap

1. Measure the connecting rod bearing oil clearances using

the same procedure as for the main bearing oil clearance.

Caution

l Align the matching marks on the cap and the con-

necting rod when installing the connecting rod cap.

Tightening torque:

47-52 N-m (4.6-5.3 m-kg, 35-36 ft-lb)

. . . . . . . . . . . . . . . . . . .

B6 SOHC

49-51 N.m (5.0-5.2 m-kg, 36-36 ft-lb)

. . . . . . . . . . . . . . . . . . . BP SOHC .-’

Bi-72

Page 103 of 1164

ASSEMBLY Bl

23UOEl-04

03UOBl-1:

MATCHING MARKS

‘\, 1

0311081.132

Oil clearance: 0.028-0.068mm (0.001 l-0.0027 in)

Maximum: O.lOmm (0.004 in)

2. If the oil clearance exceeds the maximum, grind the crank-

shaft and use undersize bearings. (Refer to page Bl-64.)

3. Measure the connecting rod side clearances.

Side clearance: 0.11 O-0.262mm (0.0043-0.0103 in)

Maximum: 0.30mm (0.012 in)

4. If the clearance exceeds the maximum, replace the con-

necting rod and cap.

5. Apply a liberal amount of clean engine oil to the crankpin

journals and connecting rod bearings.

6. Install the connecting rod caps with the matching marks

aligned.

7. Tighten the connecting rod cap nuts in two or three steps.

Tightening torque:

47-52 N-m (4.8-5.3 m-kg, 35-38 ft-lb)

. . . . . . . . . . . . . . . . . . . 66 SOHC

49-51 N*m (5.0-5.2 m-kg, 36-38 ft-lb)

. . . . . . . . . . . . . . . . . . . BP SOHC

Bl-73

Page 104 of 1164

Bl ASSEMBLY

CYLINDER BLOCK (EXTERNAL PARTS)

Torque Specifications

19-25

(1.9-2.6, 14-19)

GASKET, NEW

OIL SEAL,

NEW

7.6-11 N.m

(60-l 10 cm-kg,

69-95 in-lb)

GASKET, NE

16-21 (1.6-2.1, 12--15)-j

R

A -22% / 7.6-11 N.m

(60-110 cm-kg, 69-95 in-lb) 6-103 w

,..6-10.6,

71-76) 16-26

(1.6-2.7, 13-20)

7.6-11 N-m

(60-110 cm-kg, 69-95 in-lb)

N.m (m-kg, R-lb)

Bl-74

OWOBX-201 0

Rear Cover

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be pressed in until it is flush with

the edge of the rear cover.

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 1OOmm (3.94 in)

4. Apply silicone sealant to the shaded area shown in the

figure.

Page 105 of 1164

ASSEMBLY Bl

OWOBX-20

23UOBl-049

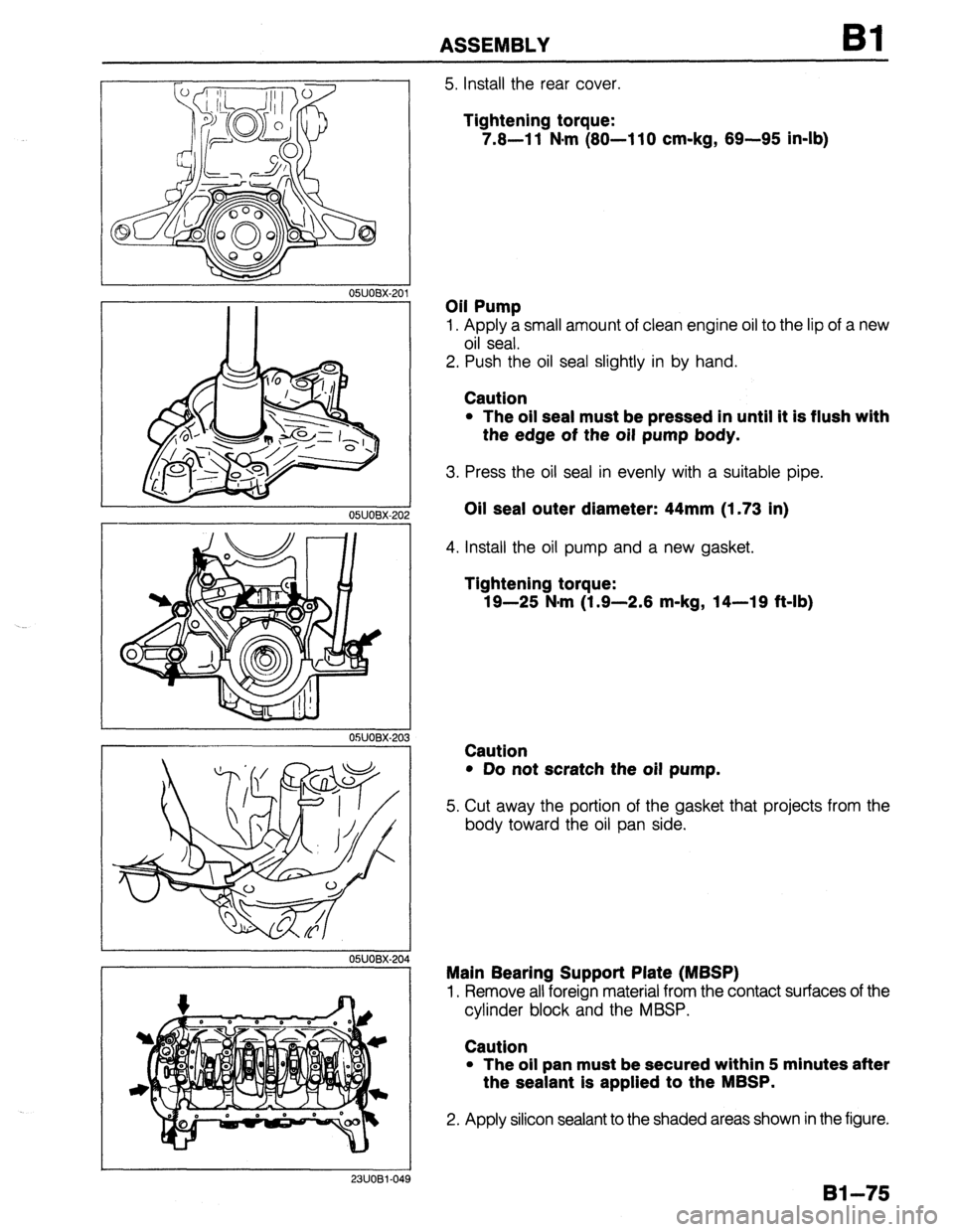

5. Install the rear cover.

Tightening torque:

7.8-l 1 N*m (80-l 10 cm-kg, 89-95 in-lb)

Oil Pump

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be pressed in until it is flush with

the edge of the oil pump body.

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 44mm (1.73 in)

4. Install the oil pump and a new gasket.

Tightening torque:

19-25 N-m (1.9-2.8 m-kg, 14-19 ft-lb)

Caution

l Do not scratch the oil pump.

5. Cut away the portion of the gasket that projects from the

body toward the oil pan side.

Main Bearing Support Plate (MBSP)

1, Remove all foreign material from the contact surfaces of the

cylinder block and the MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply silicon sealant to the shaded areas shown in the figure.

81-75

Page 106 of 1164

Bl ASSEMBLY

3. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes,

4. Install the MBSP onto the cylinder block.

5. Tighten the MBSP bolts in two or three steps in the order

shown in the figure.

Tightening torque:

16-21 N.m (1.6-2.1 m-kg, 12-15 ft-lb)

Oil Strainer

1. Install the oil strainer and a new gasket.

Tightening torque:

7.6-11 N.m (60-110 cm-kg, 69-95 in-lb)

Oil Pan

1. Remove all foreign material from the contact surfaces.

2. Apply silicone sealant to the shaded areas shown in the

figure.

-137 3. Install new gaskets onto the oil pump body and the rear

cover with the projections in the notches shown in the figure.

81-76

Page 107 of 1164

ASSEMBLY Bl

05UOBX.21’

OYJOBX-21

23UOBl-07

23UOBl-Ot

4. Apply a continuous bead of silicone sealant to the oil pan

along the inside of the bolt holes and overlap the ends.

5. Install the oil pan.

Tightening torque:

7.8-l 1 N,m (80-l 10 cm-kg, 89-95 in-lb)

End Plate

1. Install the end plate.

Tightening torque:

7.8-l 1 N,m (80-l 10 cm-kg, 89-95 in-lb)

Flywheel (MTX)

1, Remove the sealant from the flywheel bolt holes in the crank-

shaft and from the flywheel bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the flywheel onto the crankshaft.

3. Apply sealant to the flywheel bolts and install them.

4. Hold the flywheel with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown.

Tightening torque:

98-103 N+m (9.8-10.5 m-kg, 71-78 ft-lb)

Clutch Disc and Clutch Cover (MTX)

1. Install the clutch disc and clutch cover using the SST or

equivalent. (Refer to Section H.)

Tightening torque:

18-28 N.m (1.8-2.7 m-kg, 13-20 ft-lb)

B-l -77

Page 108 of 1164

ASSEMBLY

23UOBi-08

0311081-14

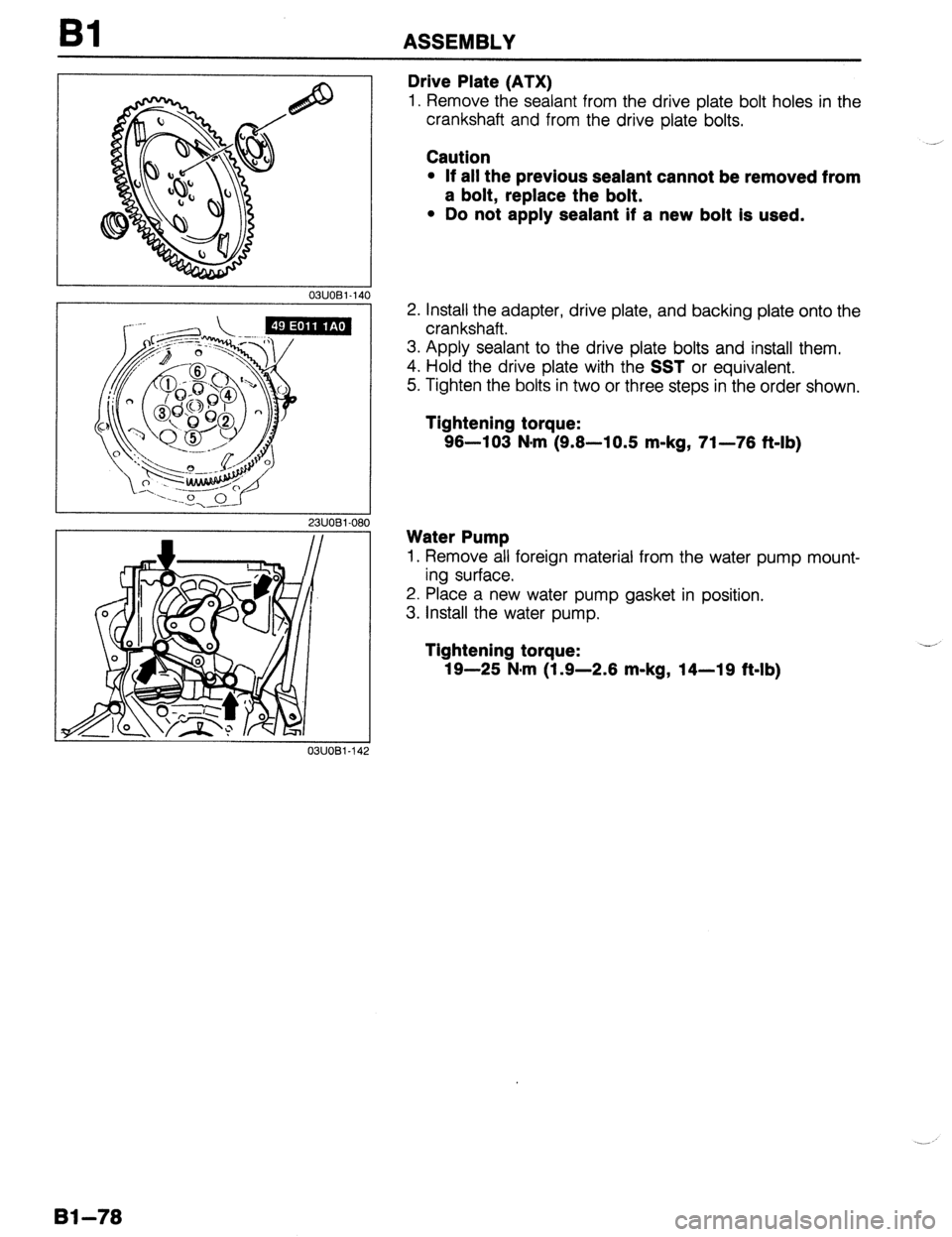

Drive Plate (ATX)

1. Remove the sealant from the drive plate bolt holes in the

crankshaft and from the drive plate bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Install the adapter, drive plate, and backing plate onto the

crankshaft.

3. Apply sealant to the drive plate bolts and install them.

4. Hold the drive plate with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown.

Tightening torque:

96-103 N-m (9.6-10.5 m-kg, 71-76 ft-lb)

Water Pump

1. Remove all foreign material from the water pump mount-

ing surface.

2. Place a new water pump gasket in position.

3. Install the water pump.

Tightening torque:

19-25 N,m (1.9-2.6 m-kg, 14-19 ft-lb)

81-78

Page 109 of 1164

ASSEMBLY Bl

CYLINDER HEAD

Torque Specifications

I

36 SOHC 1

GASKET, NEW

,-’

/

76-81

, /

--.

/

(2.2-2.9, 16-21)

“,A

OIL SEAL,

NEW 49-61

(5.0-6.2, 36-45)

P- (80-110 cm-kg, 69-95 in-lb)

w GA&ET, NEW -

19-25 ;1.9-2.6, 14-19) 6.4-9.3 N.m

19-25

(65-95 cm-kg, 56-82 in-lb)

(1.9-2.6, 14-19)

N.m (m-kg, ft-lb

03UOBl-I(

1)

-I 43

81-79

Page 110 of 1164

Bl ASSEMBLY

BP SOHC

4.9-8.8 N.m

(50-90 cm-kg, 43-76 in-lb)

76-61

(7.7-8.3, 56-60)

49-61

(5.0-6.2, 36-45)

OIL SEAL, -‘L-l

3

NEW

/

I - GASKET, NEW

19-25 (1.9-2.6, 14-19) 6.4-9.3 N-m

(65-95 cm-kg, 56-62 in-lb) I

19-25

(1.9-2.6, 14-19)

N.m (m-kg, ft-lb)

03UOBl-211 3

Valve Seal

BP SOHC

1. Install the new valve seal onto the valve guide by hand.

2. After installation adjust the protrusion A to specification.

Protrusion

IN : 19.6-20.2mm (0.772-0.795 in)

EX: 18.1-l 8.7mm (0.713-0.736 in)