MAZDA PROTEGE 1992 Repair Manual

PROTEGE 1992

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57077/w960_57077-0.png

MAZDA PROTEGE 1992 Repair Manual

Trending: inflation pressure, fuse box location, tow, remote control, horn, engine schematic, key

Page 61 of 1164

REMOVAL Bl

Step 4 -

ATX

REPLACE

13UOBl-043

1. Speedometer cable 7. Stabilizer

2. Clutch release cylinder

8. Tie rod end

Removal Note below Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page 61-32

,...............,....................

3. Shift control rod (MTX)

4. Extension bar (MTX)

5. Shift control cable (ATX)

6. Front exhaust pipe 9. Engine mount member

Removal Note ,.......................... page Bl-32

10. Driveshaft

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . page 81-32

Removal note

13UOBl-04 .4

Clutch release cylinder (MTX)

1. Remove the release cylinder pipe bracket from the transaxle.

2. Position the release cylinder away from the transaxle for eas-

ier removal with the hose still connected.

Caution

l Do not damage the pipe or hose.

81-31

Page 62 of 1164

Bl REMOVAL

I 03UOBi-05 I

14

‘5

03UOBl-056

Bl-32

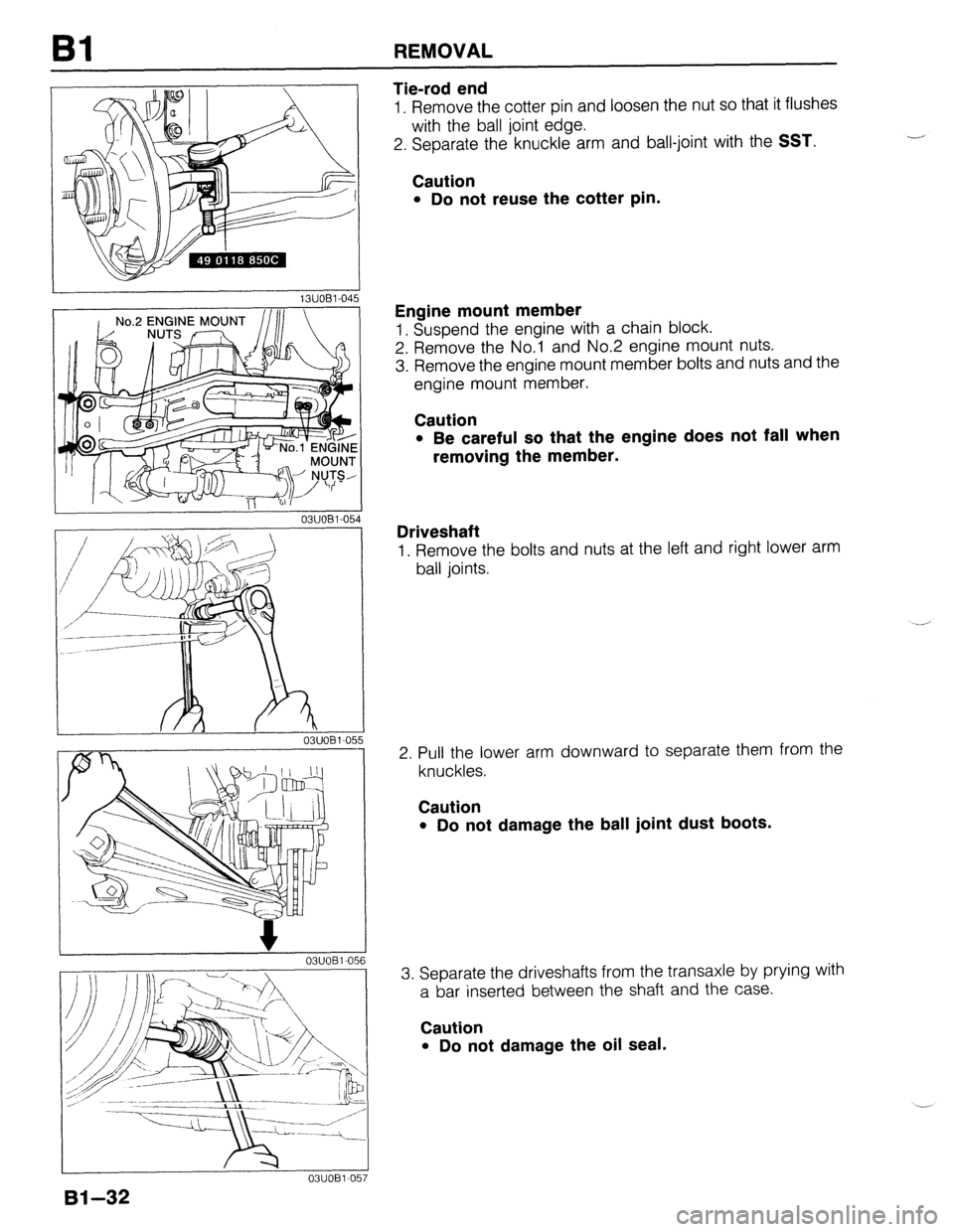

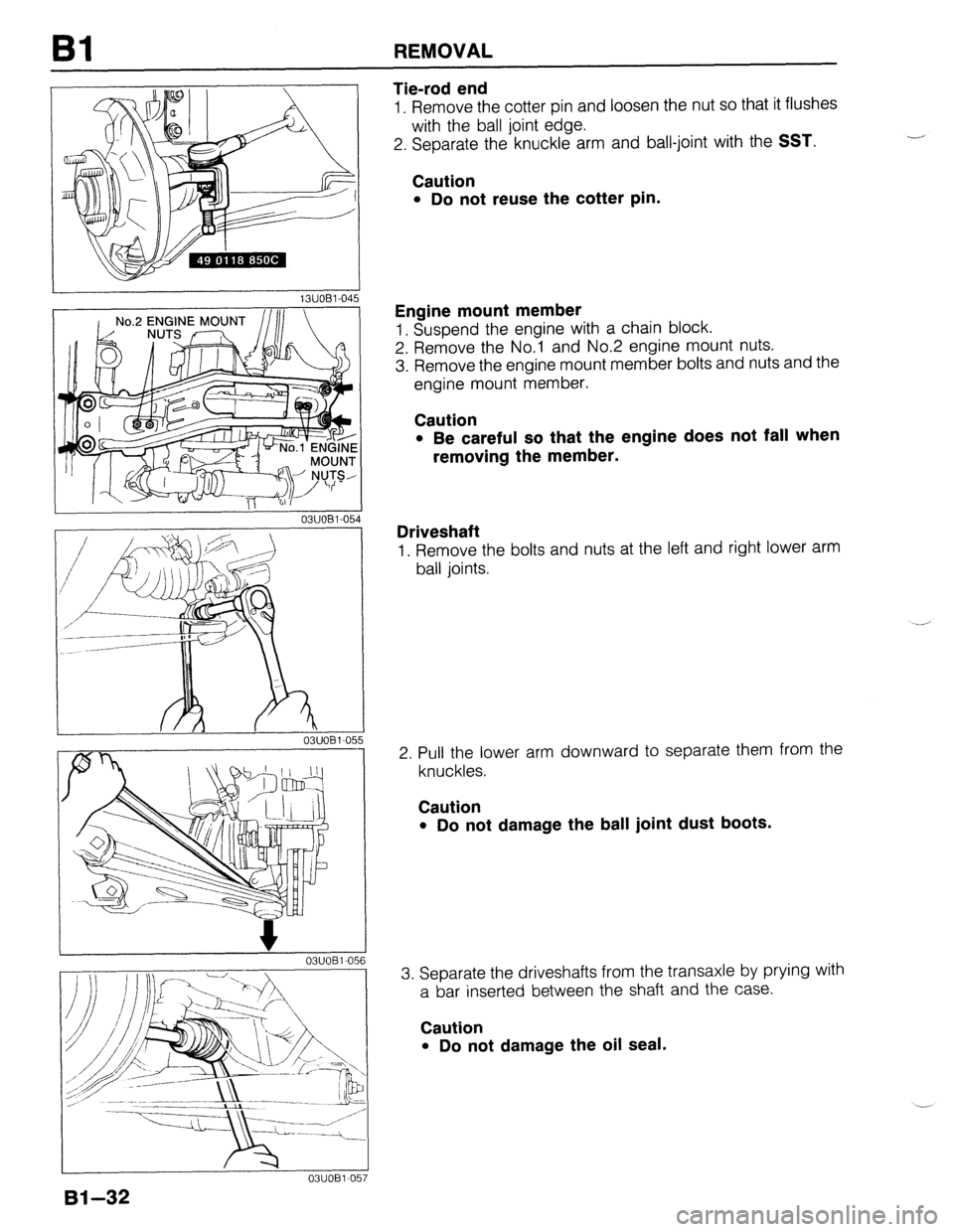

Tie-rod end

1. Remove the cotter pin and loosen the nut so that it flushes

with the ball joint edge.

2. Separate the knuckle arm and ball-joint with the

SST.

Caution

l Do not reuse the cotter pin.

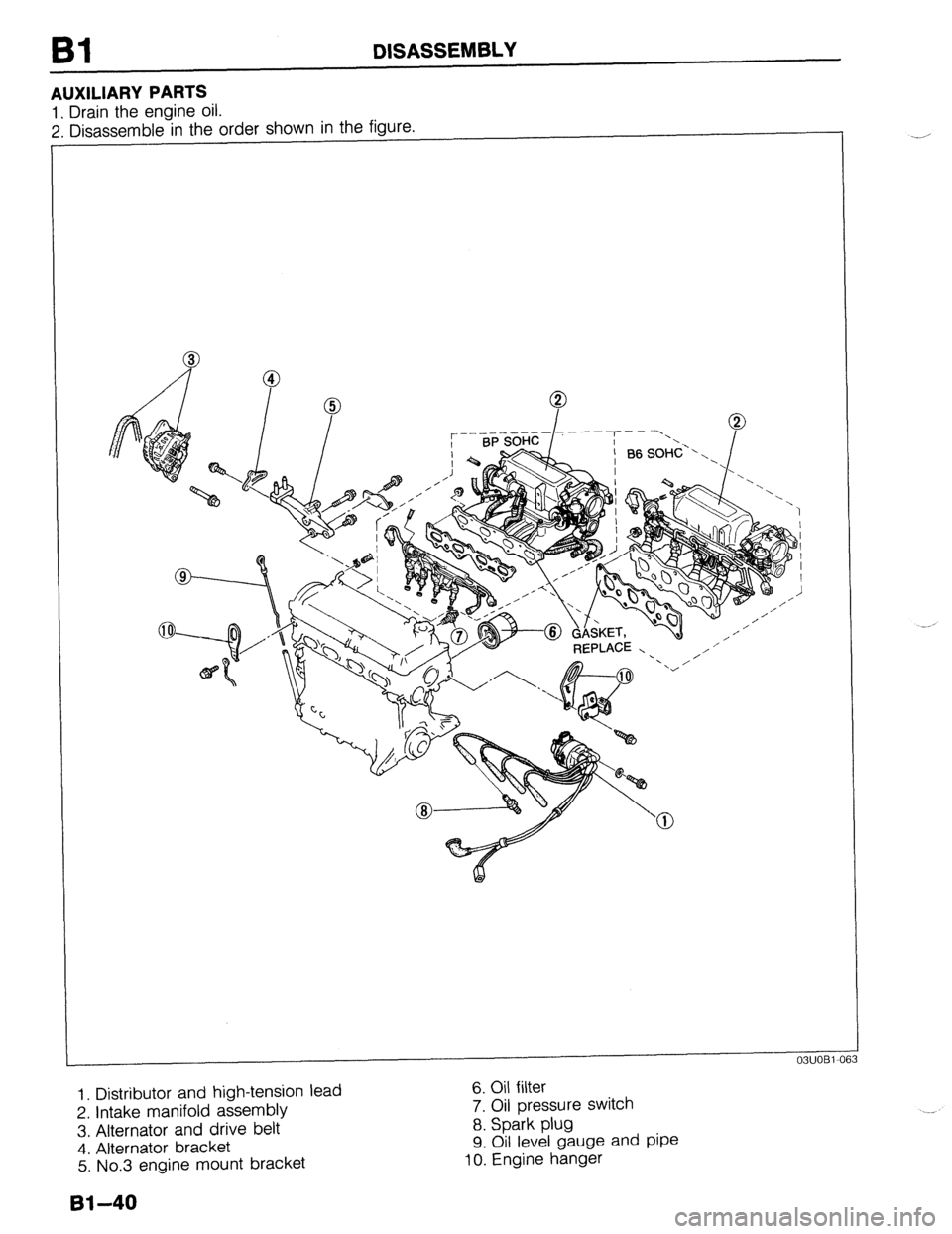

Engine mount member

1. Suspend the engine with a chain block.

2. Remove the No.1 and No.2 engine mount nuts.

3. Remove the engine mount member bolts and nuts and the

engine mount member.

Caution

l Be careful so that the engine does not fall when

removing the member.

Driveshaft

1. Remove the bolts and nuts at the left and right lower arm

ball joints.

2. Pull the lower arm downward to separate them from the

knuckles.

Caution

l Do not damage the ball joint dust boots.

3. Separate the driveshafts from the transaxle by prying with

a bar inserted between the shaft and the case.

Caution

l Do not damage the oil seal.

Page 63 of 1164

REMOVAL Bl

1 Step 5

I

1. Dynamic damper

2. No.3 engine mount rubber

3. No.4 engine mount rubber and bracket 4. Engine and transaxle assembly

Removal note . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘....... below

I 03UOBl-059

Removal note

Engine and transaxle assembly

Caution

l Do not damage any components in the engine com-

partment.

1. Lift the engine and transaxle assembly out as a unit.

Bl-33

Page 64 of 1164

REMOVAL

Step 6

Separate the engine and transaxle in the order shown in the figure.

MTX BP SOHC

ATX

BP SOHC

--

03UOB1-060

1. Intake manifold bracket 5. Integrated stiffener (B6 engine)

2. Starter and bracket 6. Torque converter nuts (ATX)

3. Throttle cable (ATX) 7. Transaxle mounting bolts

4. No.2 engine mount rubber and bracket 8. Transaxle

01-34

Page 65 of 1164

ENGINE STAND MOUNTING Bl

ENGINE STAND MOUNTING

PREPARATION

SST

49 0107 680A

49 LO10 1AO)

49 LO10 103

49 LO10 IAO)

49 LO10 105

49 LO10 IAO)

OSUOBX-O(!

m-35

Page 66 of 1164

Bl ENGINE STAND MOUNTING

PROCEDURE

Step 1

1. Remove in the order shown in the figure.

GASKET, REPLACE

I

1. Exhaust manifold insulator

2. Exhaust manifold

3. Water bypass pipe

23UOBl-03

4. A/C compressor bracket (If equipped) and idler

5. Water inlet pipe

6. Exhaust pipe bracket

‘0

Step 2

Caution

l When installing the SST (engine hanger), use the

holes shown in the figure.

Bl-36

Page 67 of 1164

ENGINE STAND MOUNTING Bl

OBUOBX-Ot

OWOBX-0; 36

ENGINE

NlJ/ WkSHER b&i THAP

2Omm (0.79 il

OWOBX-0

I

-I n)

80

OWOBX-089

1. Install the SST (arms) to the holes as shown in the figure,

and loosely tighten the SST (bolts).

2. Assemble the SST (bolts and plate) in the specified po-

sition.

3. Assemble the SST (nuts, hooks, and bolts).

4. Install the SST to the respective arms.

Note

l Adjust the SST (bolts) so that less than 20mm (0.79

in) of thread is exposed.

l Make the SST (plate and arms) parallel by adjust-

ing the SST (bolts and nuts).

5. Tighten the SST (bolts and nuts) to affix the SST firmly.

6. Mount the engine on the SST (engine stand).

81-37

Page 68 of 1164

Bl DISASSEMBLY

DISASSEMBLY

PREPARATION

SST

49 EOl 1 1AO

Ring gear brake

49 EOll 104

49 EOl 1 1 AO)

49 0636 100A

Arm, valve spring removal of valve

49 B012 006

Pivot, valve

49 8012 012

49 8012 014

49 LO11 006

Puller 84 installer

(Part of

49 LO1 1 OAO)

81-38

Page 69 of 1164

DISASSEMBLY Bl

I I

49 LO11 010

Centering tool

(Part of

49 LO1 1 OAO) For

removal I

installation of

piston pins 49 LO11 011

Holder

(Part of

49 LO1 1 OAO) For

removal I

installation of

piston pins

49 HO11 OOlA

Support block

head For

removal /

installation of

piston pins

1. Code all identical parts (such as piston, piston rings, connecting rods, and valve springs) so that they

can be reinstalled in the cylinder from which they were removed.

2. Clean the parts with a steam cleaner. Blow off any remaining water with compressed air.

Note

l During disassembly of any part or system, be sure to study its order of assembly. Also, note

any deformation, wear, or damage.

05UOBX-091

81-39

Page 70 of 1164

Bl DISASSEMBLY

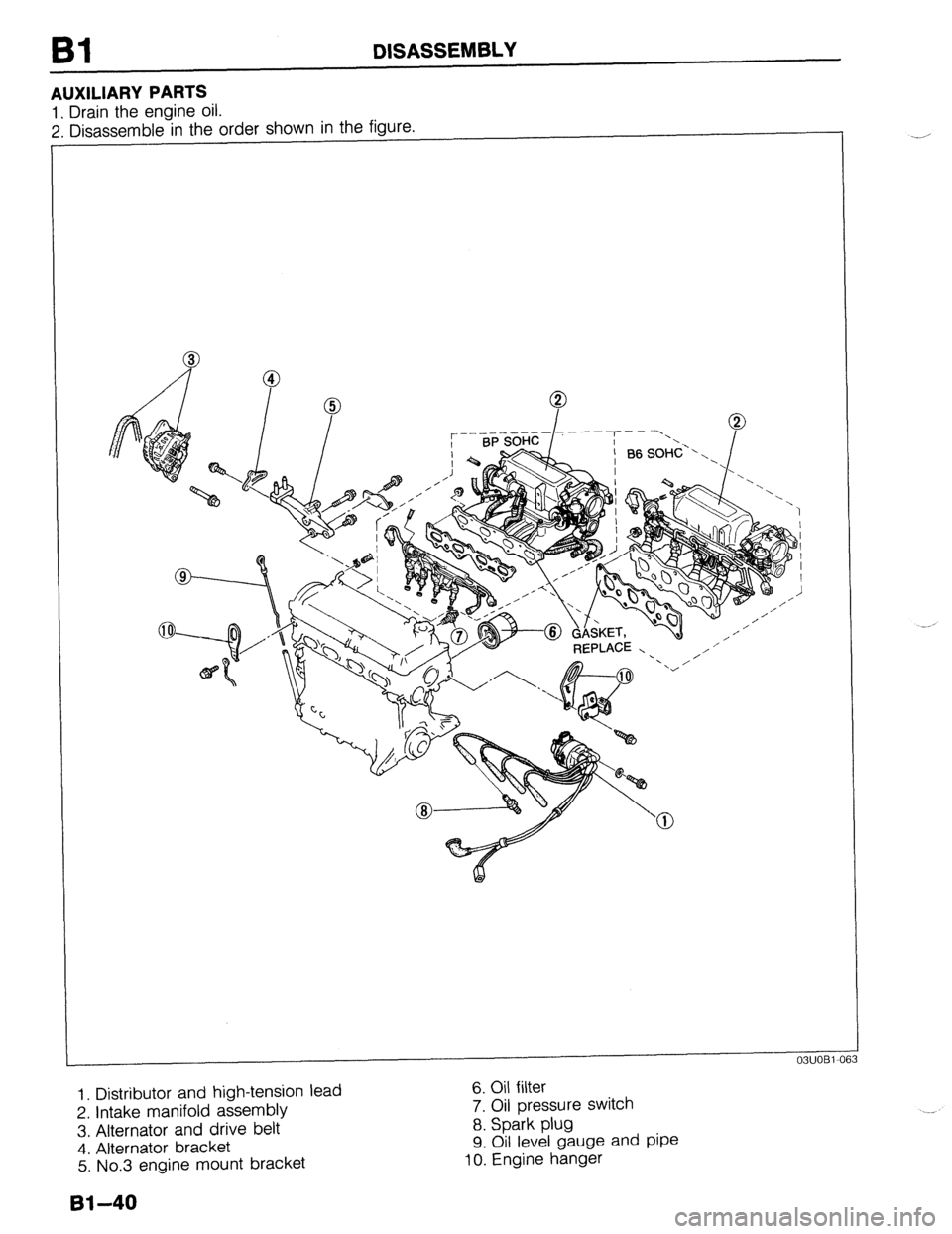

AUXILIARY PARTS

1. Drain the engine oil.

2. Disassemble in the order shown in the figure.

- REPLACE - ’ ,/ I’

1. Distributor and high-tension lead

2. Intake manifold assembly

3, Alternator and drive belt

4. Alternator bracket

5. No.3 engine mount bracket 6. Oil filter

7. Oil pressure switch

8. Spark plug

9. Oil level gauge and pipe 10. Engine hanger

61-40

Trending: check engine, charging, bolt pattern, reset, ignition, remote start, transmission oil