lock MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 857 of 1164

BODY ELECTRICAL SYSTEM

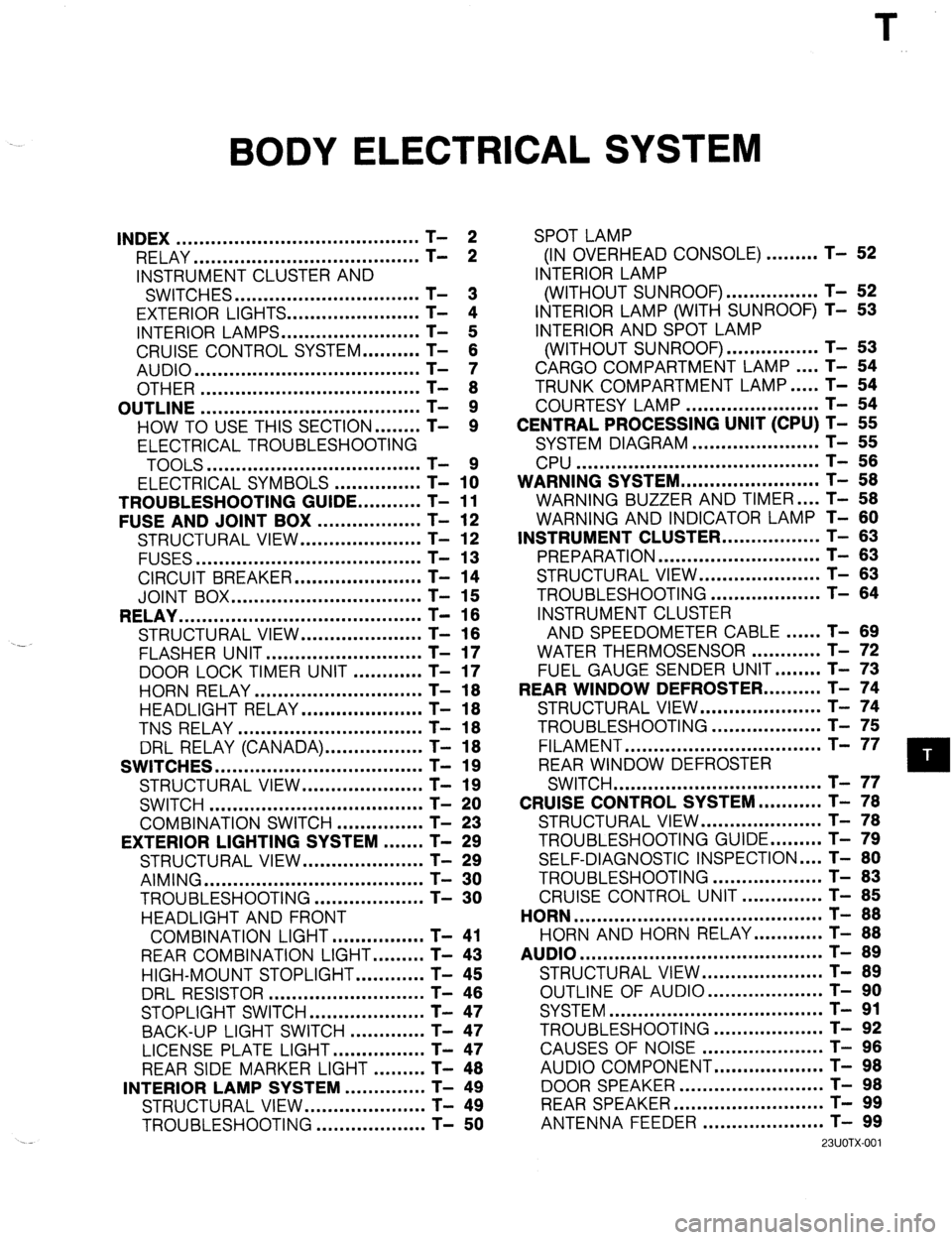

INDEX .......................................... T- 2

RELAY ....................................... T- 2

INSTRUMENT CLUSTER AND

SWITCHES ................................ T- 3

EXTERIOR LIGHTS.. ..................... T- 4

INTERIOR LAMPS.. ...................... T- 5

CRUISE CONTROL SYSTEM.. ........ T- 6

AUDIO ....................................... T- 7

OTHER ...................................... T- 8

OUTLINE ...................................... T- 9

HOW TO USE THIS SECTION.. ...... T- 9

ELECTRICAL TROUBLESHOOTING

TOOLS .....................................

ELECTRICAL SYMBOLS - ............... T- 1x

TROUBLESHOOTING GUIDE.. .........

T- 11

FUSE AND JOINT BOX ..................

T- 12

STRUCTURAL VIEW.. ...................

T- 12

FUSES ....................................... T- 13

CIRCUIT BREAKER.. ....................

T- 14

JOINT BOX ................................. T- 15

RELAY .......................................... T- 16

STRUCTURAL VIEW.. ...................

T- 16

.-

FLASHER UNIT ........................... T- 17

DOOR LOCK TIMER UNIT ............

T- 17

HORN RELAY ............................. T- 18

HEADLIGHT RELAY.. ................... T- 18

TNS RELAY ................................ T- 18

DRL RELAY (CANADA). ................ T- 18

SWITCHES .................................... T- 19

STRUCTURAL VIEW.. ................... T- 19

SWITCH ..................................... T- 20

COMBINATION SWITCH ...............

T- 23

EXTERIOR LIGHTING SYSTEM ....... T- 29

STRUCTURAL VIEW.. ...................

T- 29

AIMING ...................................... T- 30

TROUBLESHOOTING.. .................

T- 30

HEADLIGHT AND FRONT

COMBINATION LIGHT.. ..............

T- 41

REAR COMBINATION LIGHT.. ....... T- 43

HIGH-MOUNT STOPLIGHT.. .......... T- 45

DRL RESISTOR ........................... T- 46

STOPLIGHT SWITCH.. .................. T- 47

BACK-UP LIGHT SWITCH ............. T- 47

LICENSE PLATE LIGHT.. ..............

T- 47

REAR SIDE MARKER LIGHT ......... T- 48

INTERIOR LAMP SYSTEM ..............

T- 49

STRUCTURAL VIEW.. ...................

T- 49

TROUBLESHOOTING ...................

T- 50 SPOT LAMP

(IN OVERHEAD CONSOLE) ......... T- 52

INTERIOR LAMP

(WITHOUT SUNROOF). ............... T- 52

INTERIOR LAMP (WITH SUNROOF) T- 53

INTERIOR AND SPOT LAMP

(WITHOUT SUNROOF). ............... T- 53

CARGO COMPARTMENT LAMP.. .. T- 54

TRUNK COMPARTMENT LAMP.. ... T- 54

COURTESY LAMP ....................... T- 54

CENTRAL PROCESSING UNIT (CPU) T- 55

SYSTEM DIAGRAM ...................... T- 55

CPU .......................................... T- 56

WARNING SYSTEM.. ...................... T- 58

WARNING BUZZER AND TIMER .... T- 58

WARNING AND INDICATOR LAMP T- 60

INSTRUMENT CLUSTER.. ............... T- 63

PREPARATION ............................ T- 63

STRUCTURAL VIEW ..................... T- 63

TROUBLESHOOTING ................... T- 64

INSTRUMENT CLUSTER

AND SPEEDOMETER CABLE.. .... T- 89

WATER THERMOSENSOR ............ T- 72

FUEL GAUGE SENDER UNIT.. ...... T- 73

REAR WINDOW DEFROSTER.. ........ T- 74

STRUCTURAL VIEW.. ................... T- 74

TROUBLESHOOTING ................... T- 75

FILAMENT .................................. T- 77

REAR WINDOW DEFROSTER

SWITCH .................................... T- 77

CRUISE CONTROL SYSTEM.. ......... T- 78

STRUCTURAL VIEW.. ................... T- 78

TROUBLESHOOTING GUIDE.. ....... T- 79

SELF-DIAGNOSTIC INSPECTION .... T- 80

TROUBLESHOOTING ................... T- 83

CRUISE CONTROL UNIT .............. T- 85

HORN ........................................... T- 88

HORN AND HORN RELAY.. .......... T- 88

AUDIO .......................................... T- 89

STRUCTURAL VIEW.. ................... T- 89

OUTLINE OF AUDIO.. .................. T- 90

SYSTEM ..................................... T- 91

TROUBLESHOOTING ................... T- 92

CAUSES OF NOISE ..................... T- 96

AUDIO COMPONENT.. ................. T- 98

DOOR SPEAKER .........................

REARSPEAKER .......................... ;-

- !3;

ANTENNA FEEDER ..................... T- 99

23UOTX-001

Page 858 of 1164

T INDEX

INDEX

RELAY

ION 8

1. Flasher unit

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page T-i 7

2. Door lock timer unit

Inspection . . . . . . . . . . . . . . . . . ..l.........I..... page T-l 7

3. Horn relay

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page T-l 8

4. DRL control unit (Canada)

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .

page T-33

T-2

13UOTX-00:

5. DRL relay (Canada)

inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page T-l 8

6. TNS relay

Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page T-l 8

7. Headlight relay

Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page T-l 8

Page 869 of 1164

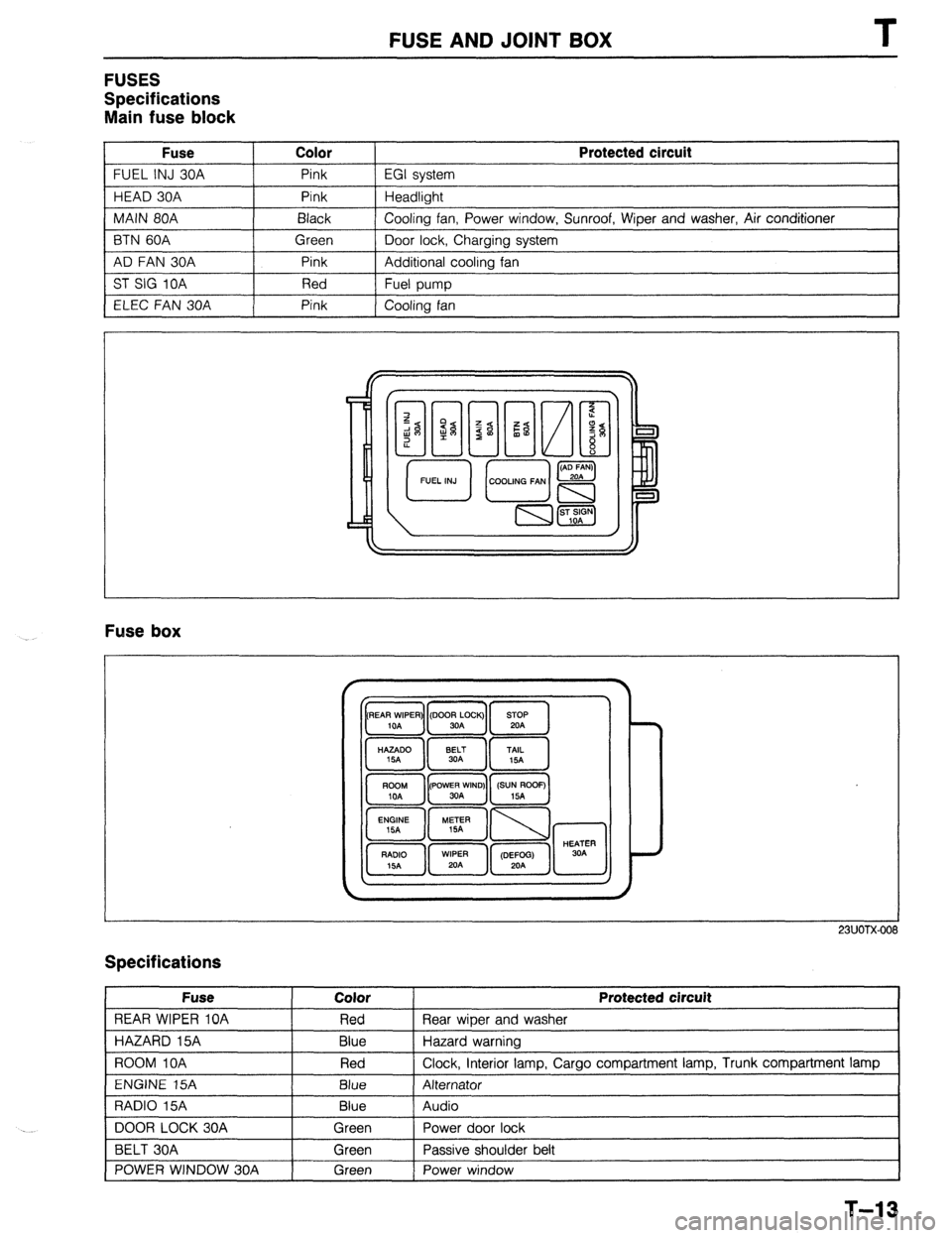

FUSE AND JOINT BOX

FUSES

Specifications

Main fuse block

Fuse Color

FUEL INJ 30A Pink

HEAD 30A Pink

MAIN 80A Black

BTN 60A Green

AD FAN 30A Pink

ST SIG 10A Red

ELEC FAN 30A Pink Protected circuit

EGI system

Headlight

Cooling fan, Power window, Sunroof, Wiper and washer, Air conditioner

Door lock, Charging system

Additional cooling fan

Fuel pump

Cooling fan

Fuse box

23UOTX-001

Specifications

Fuse

REAR WIPER 10A

HAZARD 15A

ROOM IOA

ENGINE 15A

RADIO 15A

DOOR LOCK 30A

BELT 30A

POWER WINDOW 30A Color

Red

Blue

Red

Blue

Blue

Green

Green

Green Protected circuit

Rear wiper and washer

Hazard warning

Clock, interior lamp, Cargo compartment lamp, Trunk compartment lamp

Alternator

Audio

Power door lock

Passive shoulder belt

Power window

1

T-13

Page 872 of 1164

T RELAY

RELAY

STRUCTURAL VIEW

:TION S

1 SUOTX-01:

1. Flasher unit

5. DRL relay (Canada)

Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page

T-l 7 2. Door lock timer unit

inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . .

T-l 7

3. Horn relay page

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T-l 8 4.

DRL control unit (Canada) page

Troubleshooting .,..........,..,.......... page T-33 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TNS relay page

T-l 8

Inspection .I..............,.................. page T-l 8

7. Headlight relay

Inspection ,,,,....,.,.,......,~~,...~.....,.~ page T-i 8

T-l 6

Page 873 of 1164

RELAY

h f d

OWOTX-01;

OWOTX-01’

23UOTX-00

FLASHER UNIT

Inspection

1. Check for continuity between terminals of the flasher unit.

0: Indicates continuity X: No continuity

Note

l Set the tester to the xl,OOOQ range.

2. If continuity is not as specified, replace the switch.

DOOR LOCK TIMER UNIT

inspection

1. Check for continuity between terminals.

a-h X c-e 0 e-h 0

b-c X c-f 0 f-h X

0: Continuity X: Non-continuity

Note

l Set the tester to x1000Q range.

l Continuity includes the state with resistance, and

Non-continuity means insulated.

2. Connect the battery voltage to the “b” terminal and the

ground to the “a” terminal. Then, short circuit the “h” and

“d” terminals between the “h” and “c” terminals, and check

that the relay clicks.

T-17

Page 895 of 1164

EXTERIOR LIGHTING SYSTEM T

Stoplight

Circuit diaaram

GTOPLIGHTS F-2

SHIFT-LOCK

BLUB TRADE NUMBER

STOPLIGHT: 1157 (27W)

HIGH MOUNT

STOPLIGHT: 921 (18.4W) G (F) *ENGINE CONTROL UNIT

(SECTION B- lc;26)

G (F) *CRUISE CONTROL UNIT

(SECTION 01)

WITH REAR SPOILER

HIGH MOUNl-

STOPLIGHT

STOPLIGHT STOPLIGHT

-06 STOPLIGHT

SWITCH (F) F-07 HIGH MOUNT STOP-E-12 STOPLIGHT LH(R) E-13 STOPLIGHT RH(R)

LIGHT (R3)

WITH

REAR SPOILER---+ (R2)

03UOTX-057

T-39

Page 931 of 1164

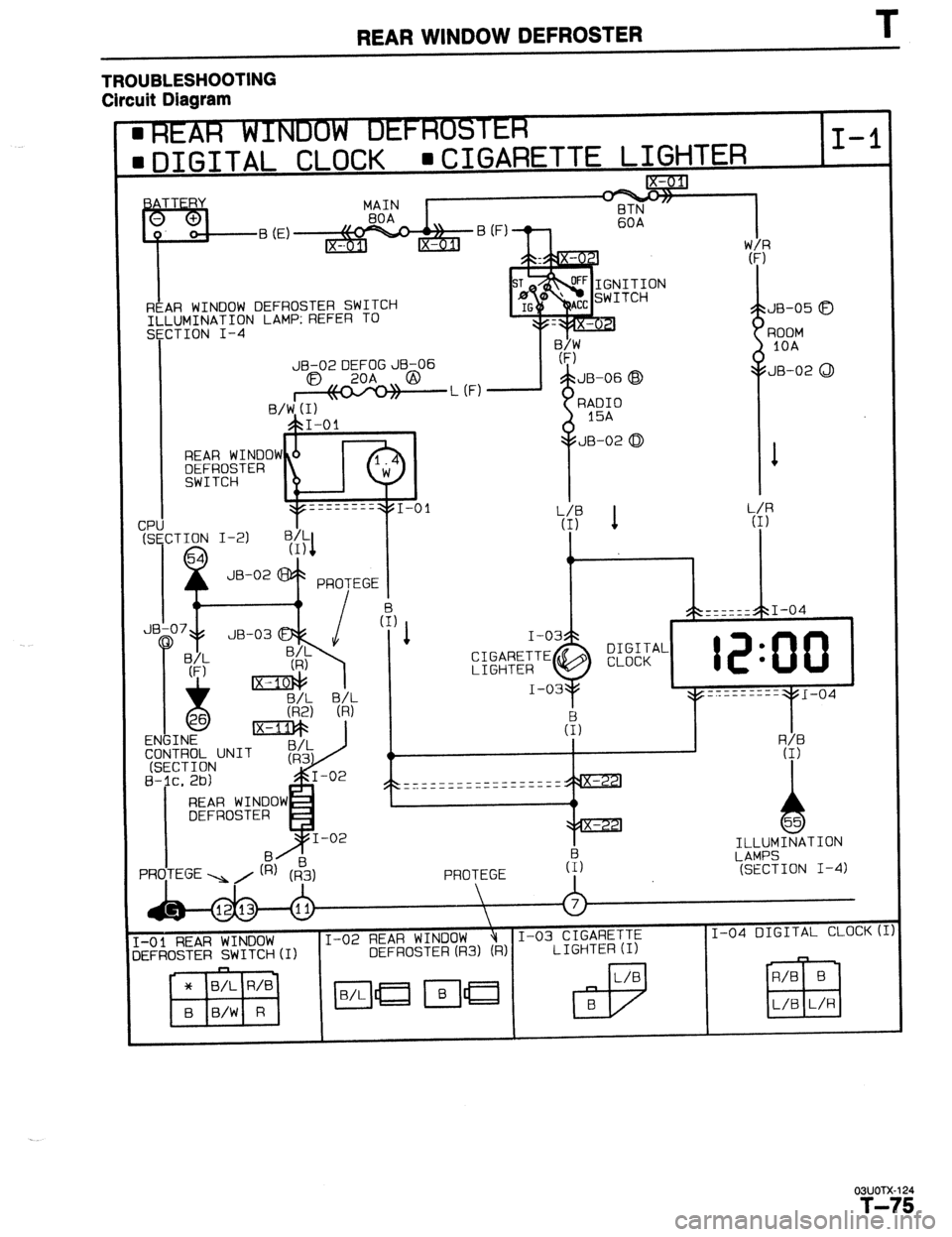

REAR WINDOW DEFROSTER T

TROUBLESHOOTING

Circuit Diagram

. .-

m DIGITAL CLOCK WXGARETTE LIGHTER I-l

f$pjg

MAIN

BOA BTN

60A v v

0. o! B (E)

l- IX-0 lJ

Ix-u REAR WINDOW DEFROSTER SWITCH TI LUMINATION LAMP: REFER TO JB-05 a

CTION I-4

I nnnt.,4

.L (F)

SE

JB-02LJ:t=;GJB-06

a3 ,, ,, @

I \\- //

B/W (I)

ET?-- (F)

5 JB-06 @

RADIO

15A

JB-02 0

1 ,“Yll IOA

JB-02 0

REAR WINDOW

m&R;~TER I

4 JB-02 @+ PRTEGE i

IV

tr I

I+ LA.“, I I\-1 I

I - -

_--___---

_._- ------

I 2s 1 w

rzlznl+ I I (3

I I -. .--. .- tNGlNt CONTROL UNIT

(SECTION

B-;c. 2b)

REAR WINDOW

DEFROSTER

PRO,TEGE ,/ ILLUMINATION

LAMPS

(SECTION I-4)

‘-01

REAR WINDOW I-02 REAR WINDOW I-03 CIGARETTE

jEFROSTER SWITCH (1)

* B/L R/B

B B/W R

03UOTX-124

T-75

Page 974 of 1164

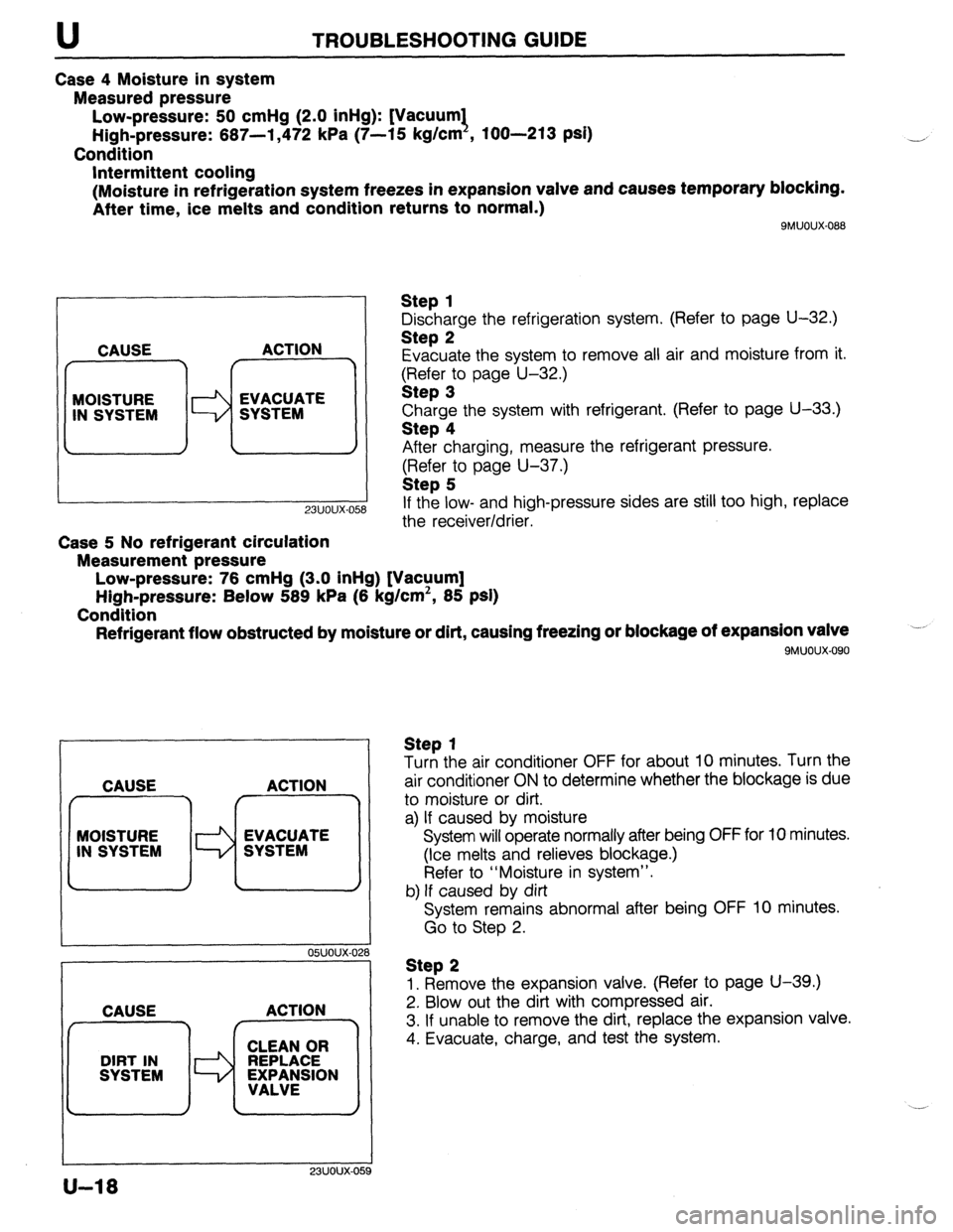

U TROU6LESHOOTlNG GUIDE

Case 4 Moisture in system

Measured pressure

Low-pressure: 50 cmHg (2.0 inHg): [Vacuum1

High-pressure: 667-l ,472 kPa (7-15 kg/cm , loo-213 psi)

Condition

Intermittent cooling

(Moisture in refrigeration system freezes in expansion valve and causes temporary blocking.

After time, ice melts and condition returns to normal.)

SMUOUX-088

CAUSE ACTION

7 r

MOISTURE

IN SYSTEM WW;MTE

-

23uoux-O!

Case 5 No refrigerant circulation

Measurement pressure

Low-pressure: 76 cmHg (3.0 inHg) [Vacuum]

High-pressure: Below 589 kPa (6 kg/cm’, 85 psi)

Condition

Refrigerant flow obstructed by moisture or dirt, causing freezing or blockage of expansion valve

9MUOUX.090

Step 1

Discharge the refrigeration system, (Refer to page U-32.)

Step 2

Evacuate the system to remove all air and moisture from it.

$?&$r:o page U-32.)

Charge the system with refrigerant. (Refer to page U-33.)

Step 4

After charging, measure the refrigerant pressure.

(Refer to page U-37.)

Step 5

If the low- and high-pressure sides are still too high, replace

the receiver/drier.

CAUSE ACTION

f r^‘---7

MOISTURE

Id EVACUATE

IN SYSTEM SYSTEM

I I

05UOUX-02

CAUSE ACTION

23UOUX-OE

Step 1

Turn the air conditioner OFF for about 10 minutes. Turn the

air conditioner ON to determine whether the blockage is due

to moisture or dirt.

a) If caused by moisture

System will operate normally after being OFF for 10 minutes.

(Ice melts and relieves blockage.)

Refer to “Moisture in system”.

b) If caused by dirt

System remains abnormal after being OFF 10 minutes.

Go to Step 2.

Step 2

1. Remove the expansion valve. (Refer to page U-39.)

2. Blow out the dirt with compressed air.

3. If unable to remove the dirt, replace the expansion valve.

4. Evacuate, charge, and test the system.

U-18

Page 977 of 1164

HEATER U

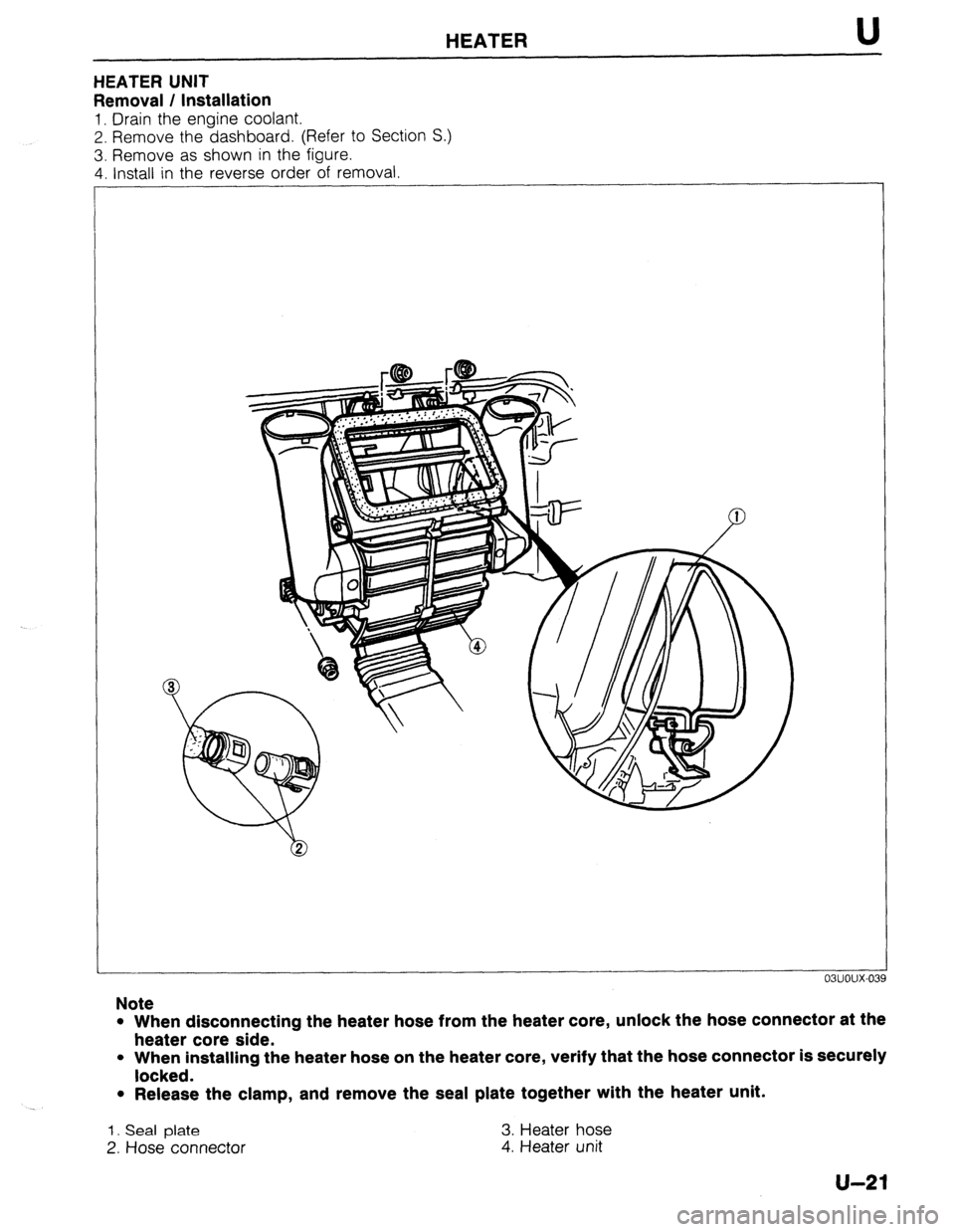

HEATER UNIT

Removal / Installation

1. Drain the engine coolant.

2. Remove the dashboard. (Refer to Section S.)

3. Remove as shown in the figure.

4. Install in the reverse order of removal

Note

l When disconnecting the heater hose from the heater core, unlock the hose connector at the

heater core side.

l When installing the heater hose on the heater core, verify that the hose connector is securely

locked.

l Release the clamp, and remove the seal plate together with the heater unit.

1. Seal plate 3. Heater hose

2. Hose connector

4. Heater unit

u-21

Page 987 of 1164

AIR CONDITIONER U

REFRIGERANT SYSTEM

Safety Precaution

1. R-12 liquid refrigerant is highly volatile. A drop of it on the

skin could result in localized frostbite. When handling the

refrigerant, be sure to wear gloves.

2. If the refrigerant splashes into the eyes, wash them with clean

water immediately. Always wear goggles or glasses to pro-

tect the eyes.

9MUOUX-125 3. The R-12 container is a highly pressurized vessel.

Never subject it to high heat, and be sure that the temper-

ature where it is stored is below 52OC

(125.6OF).

4. A halide leak detector is often used to check the system

for refrigerant leakage. R-l 2, upon coming into contact with

the flame, produces phosgene, a toxic gas. Always provide

adequate ventilation.

o3uoux-11 4

9MUOUX-12

Refrigerant System Service Basics

Refrigerant container service valve

1. Turn the handle fully counterclockwise before connecting

the valve to the refrigerant container.

2. Turn the outlet valve counterclockwise until it reaches its

highest position.

3. Turn the outlet valve fully clockwise by hand. Connect the

center hose to the valve fitting.

4. Turn the handle clockwise to puncture the sealed can.

5. Turn the handle fully counterclockwise to fill the center hose.

Do not open the high- or low-pressure manual valves.

6. Loosen the hose nut connected to the center fitting of the

manifold gauge. Allow air to escape. Then retighten the nut.

13uoux-012

u-31