lock MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 988 of 1164

CHARGING HOSE

CLOSED

CLOSED

23UOUX-061

CHARGING HOSE

CHARGING VALVE CLOSED 0

23UOUX.061

3. Connect high-and low-pressure side charging hoses and

stop valves to the refrigerant system service valves.

23UOUX-062

FREON (REFRIGERANT RECOVERY

ND RECYCLING

CONTAINER

VALVE

Manifold gauge set/Stop valve installation

Caution

l Connect all charging hoses via stop valves to avoid

venting the refrigerant remaining in the hoses into

the atomosphere. _A

l Do not disconnect the stop valve from the charg-

ing hose when there is refrigerant remaining in the

hose.

1. Turn the knob counterclockwise to close the stop valve.

2. Install the stop valve to the end of the charging hose of the

manifold gauge set.

Caution

l Verify that high-and low-pressure side valves of the

manifold gauge set are fully closed before connect-

ing the charging hose and stop valve to the refriger-

ant system service valve.

23UOUX-063 Evacuation/Airtiahtness test

1. Connect the manifold gauge set and stop valves to the

refrigerant system service valves.

2. Connect the center hose of the manifold gauge set to the

vacuum pump inlet.

3. Prepare as follows according to the charging method.

Charging from service container.

Connect the charging hose and service container valve to the

manifold gauge set air purge valve.

I

23UOUX-06

U-32

4

Refrigerant recovery operation.

Remove the refrigerant from the refrigerant system by using

a freon (refrigerant) recovery and recycling system.

Caution

. Never vent the refrigerant into the atomosphere.

l When using a freon recovery and recycling system,

follow the operation instructions provided by the

equipment manufacturer.

_-,

Page 996 of 1164

U AIR CONDITIONER

OFF

03UOUX-06

03UOUX-06,

03UOUX-06

On-vehicle Inspection

Thermoswitch

1. Remove the glove box.

2. Run the engine at idle.

3. Turn OFF the A/C switch and set the blower switch to the

highest position to operate the blower fan for a few minutes.

4. After a few minutes, turn OFF the blower switch and stop

the engine.

5. Disconnect the thermoswitch connector and check for con-

tinuity between terminals of the switch.

Terminals Continuity

a-b Yes

6. If not as specified, replace the thermoswitch.

Note

l The thermoswitch contacts will be open if the

evaporator temperature is below 0.4 f 0.7OC (32.7

z!z 1.3OF).

Inspection

Thermoswitch

1. Immerse the sensing bulb in a container of ice water.

2. Check continuity between terminals of the switch as

specified.

Terminals

a-b Temperature Continuity

Above 5°C Yes

Below 0% No

3. If not as specified, replace the thermoswitch

Evaporator

1. Check the evaporator fins for blockage. If the fins are

clogged, clean them with compressed air.

Caution

l Never use water to clean the evaporator.

2. Check the fittings for cracks and other damage.

Replace the evaporator if necessary.

u-40

Page 1003 of 1164

AIR CONDITIONER U

r 23UOUX-036

L 23UOUX.03

I

L

23UOUX-03 7

Shaft Seal Replacement

1. Remove the armature plate.

Note

l Removal of the clutch pulley and coil is not

necessary.

2. Remove the felt seal and snap ring.

3. Remove the shim(s).

4. Insert the

SST into the compressor aligning the cutout of

the

SST with the groove of the seal plate.

5. Rotate the

SST counterclockwise to make sure that the

cutout is engaged with the seal plate.

6. Pull out the seal plate.

7. Insert the

SST into the compressor aligning the cutout of

the

SST with the metal pawl of the shaft seal.

8. Rotate the

SST counterclockwise to make sure that the cut-

off is engaged with the metal pawl.

9. Pull out the shaft seal.

u-47

Page 1017 of 1164

TECHNICAL DATA TD

Item Engine

B6 SOHC BP SOHC

Valve seat

IN

45O

Seat angle

EX 45O

Seat contact width IN

mm 04 EX 1.1-l .7 (0.043-0.067) 0.8-l .4 (0.031-0.055)

1.1-l .7 (0.043-0.067) 0.8-l .4 (0.031-0.055)

IN Standard 39 (1.5354) 42.5 (1.673)

Seat sinking mm (in) Maximum 40.5 (1.594) 44.0 (1.732)

EX Standard 39 (1.5354) 41.0 (1.614)

Maximum 40.5 (1.594) 42.5 (1.673) Valve spring

Standard mm (in) 43.66 (1.7188) 46.12 (1.8157)

IN

Minimum N (kg, Ib)/mm (in) 224-253 (22.8-25.8, 205-231 (20.9-4X3.5,

Free length 50--57)/35.5 (1.398) 46-52)/39 (1.535)

Standard mm (in) 43.66 (1.7188) 43.61 (1.7169)

EX

Minimum N (kg, Ib)/mm (in) 224-253 (22.8-25.8, 129-147 (13.1-15.0,

50-57)/35.5 (1.398) 29-33)/37.5 (1.476)

Out-of-square mm (in) 1 Maximum 1.52 (0.060) IN...l.61 (0.063) EX...1.52 (0.060)

Lobe height mm (in) IN

EX Standard 36.451 (1.4351) 35.993 (1.4170)

Wear limit 36.251 (1.4272) 35.793 (1.4092)

Standard 36.451 (1.4351) 36.273 (1.4281)

Wear limit 36.251 (1.4272) 36.073 (1.4202)

Front 43.440-43 ,460 No.1 & 43.440-43.460

(1.7102-l .7 ‘110) No.5 (1.7102-1.7110)

43.430-43 ,445 No.2 & 43.425-43.450

mm (in) Center

(1.7098-l .7 ‘108) No.4 (1.7096-l .7106)

. , L

Rear 43.440-43.460 No’3 43.41 o-43.435

(1.7102-l .7110) (1.7091-1.7100)

1 Out-of-round 0.05 (0.002) max.

Front 0.055-0.095 No.1 & 0.040-0.075

(0.0021-0.0037) No.5 (0.0016-0.0030)

e--I-.. 0.060-O. 105 No.2 84 0.035-0.080

1041) No.4

“.“-.-..“” (O.OOi 4-0.0031)

Rear 0.055-0.095 0.050-0.095

(0.0021-0.0037) No.3

(0.0020-0.0037)

1 Maximum

0.15 (0.006)

0.01 (0.0004)

0.03 (0.0012)

0.05-0.18 (0.0020-0.0071) 0.06-0.19 (0.0024-0.0075)

n ‘1 m *no Journal diameter

Camshaft hearinn nil cIewanr.F? mm tin I b,er’Ler I (0.0023--0.c

Camshaft runout mm (in) Maximum

Camshaft end play mm (in) Standard

Maximum

I Rocker arm and rocker arm shaft

Rocker arm inner diameter mm (in) 18.000-18.027 (

Rocker arm shaft diameter mm (in)

17 9.59-17 981) I “.L ~“.““O,

lN...19.000--19.027 (0.7480-0.7491)

o.7087-o’70g7) EX...19.000-19.033 (0.7480-0.7493)

I .““” -- -

0 7070-0.7079) 18.959-18.980 (0.7464-0.7472)

lN...0.020-0.068 (0.0008-0.0027)

Rnrkx arm tn shaft clearance

mm (in Standard

I .Y”,.VG 11.,, .” -,,-.. “,“-.“, .I”

““” ,“‘I o.020-o.068 (“~ooo8-o~oo27) EX...O.020-0.074 (0.0008-0.0029)

Maximum 0.10 (0.004) Cylinder block

Height mm (in) 221.5 (8.720)

Distortion mm (in) 0.15 (0.006) max.

Grinding mm (in) 0.20 (0.008) max.

^. , ,

78.006-78.013 (3.0711-3.0714) 183.006-83.013 (3.2679-3.2682)

-.n nr,. -,n fin,% ,n nnnr

” nn’n’ ’ “- T)cc 83.263 (3.2778-3.2781) Cylinder bore diameter stanaara size

mm (in) 0.25 (0.010) oversize IU.L3cl-/U.dDJ (J.uouu-J.uo IL) 1 OJ.LJU--

0.50 (0.020) oversize 78.506-78.513 (3.0908-3.0911) ) 83.506-

Cylinder bore taper and out-of-round mm (in) 0.019 (0.0007) ma: 83.513 i3.2876-3.2879)

I(.

TD-3

Page 1020 of 1164

TD TECHNICAL DATA

Item Engine

BP DOHC

Guide projection (Height “A”) IN

mm (in) EX 18.3-l 8.9 (0.720-0.744)

_-j

18.3-l 8.9 (0.720-0.744)

Valve seat

Seat angle

Seat contact width IN 45O

EX 45O

IN

mm (in) EX 0.8-l .4 (0.031-0.055)

0.8-l .4 (0.031-0.055)

Seat sinking

Valve spring

Free length

Out-of-square

Camshaft IN Standard 45.0 (1.7716)

mm (in) Maximum 46.5 (1.831)

EX Standard 45.0 (1.7716)

Maximum 46.5 (1.831)

Standard mm (in) 46.26 (1.821)

Minimum N (kg, Ib)/mm (in) 224-253 (22.8-25.8, 50--57)/39.5 (1.555)

mm (in) 1.62 (0.064) max.

I C+^~rl^.A

44.094 (1.7360)

43.894 (1.7281)

44.600 (1.7560)

44.400 (1.7480) IN 3Ldl l”dl u

Cam height mm (in) Wear limit

EX Standard

Wear limit

Standard

Journal diameter mm (in) (No.l-No.5) 25.940-25.965 (1.0213-l .0222)

Out-of-round 0.03 (0.001) max.

Standard

Camshaft bearing oil clearance mm (in) (No-1-No.5) 0.035-0.081 (0.0014-0.0032)

Maximum 0.15 (0.006)

Camshaft runout mm (in) 0.03 (0.0012) ma

IX.

Camshaft end play mm (in) ’ Standard 0.07-O. 19 (0.0028-0.0075)

Maximum I

I n 9 m mm “.L \“.“““,

Cylinder block

Height

Distortion

Grinding mm (in) 221.5 (8.720)

mm (in) 0.15 (0.006) max.

mm (in) 0.20 (0.008) max.

Cylinder bore diameter Standard size 83.006-83.013 (3.2679-3.2682)

mm (in) 0.25 (0.010) c oversize 83.256-83.263 (3.2778-3.2781)

n.vl IO0701 I -.--

\-----I Jversize 83.506-83.513 (3.2876-3.2879)

Cylinder bore taper and out-of-round mm (in) 0.019 (0.0007) max.

Piston

I

I I

Piston diameter 82.954-82.974 (3.2659-3.2667)

Measured at 90” to pin

bore axis and 16.5mm

83.21 l-83.21 7 (3.2760-3.2763)

(0.650 in) below oil ring

groove

mm fin) 0.50 (0.020) oversize 83.461-83.467 (3.2859-3.2861)

r~ Piston to cylinder clearance

mm On) (Standaid 0.039-0.052 (0.0015-0.0020)

Piston ring

Thickness

End gap

(Measured in the cylinder) mm (in) ‘W

Second

Top

Second

mm (in) Oil (rail)

Maximum

Too I .‘t, - I .ct3 (“.“a, 3-u

1.47-l .49 (0.0579-C

0.1%0:30 (0.006--C

0.15-0.30 (0.006-C

I I.01 2)

0.20-0.70 (0.008-0.028)

1.0 (0.039)

1,520-l

,535 (0.0598-0.0604)

1.52-l .54 (0.0598-0.0606)

3.02-3.04 (0.1189-O. 1197)

I Ring groove width in piston mm (In) n

;_A

TD-6

Page 1029 of 1164

TECHNICAL DATA TD

Item

Carrier hub

Sun gear drum

Small sun gear TransaxlelEngine

Clearance between pinion washer

and planet carrier mm (in) Maximum

Bushing inner diameter

mm (in) Maximum

Bushing inner diameter

mm (in) Maximum F4A-EL

B6 SOHC BP SOHC BP DOHC

0.2-0.7 (0.008-0.028)

30.425 (1.198)

21.021 (0.828)

Gear assembly

Total end play

End play adjust race

Idle gear bearing preload

Preload

adjust shims

Output gear bearing preload

Preload adjust shims

Differential

Bearing preload

Preload

adjust shims

Backlash of side gear and pinion mm (in)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

N.m (cm-kg, in-lb)

mm (in)

mm (in) Standard

Maximum 0.25-0.50 (0.010-0.020)

1.2 (0.047) 1.4 (0.055), 1.6 (0.063)

1.8 (0.071) 2.0 (0.079) 2.2 (0.087)

-

0.03-0.9 (0.3-9.0, 0.26-7.8)

3.80 (0.150) 3.85 (0.152) 3.90 (0.154) 3.95

(0.156)

4.00 (0.158) 4.05 (0.159) 4.10 (0.161) 4.15 (0.163)

4.20 (0.165) 4.25 (0.167) 4.30 (0.169) 4.35 (0.171)

4.40 (0.173), 4.45 (0.175) 4.50 (0.177) 4.55

(0.179)

4.60 (0.181) 4.65 (0.183) 4.70 (0.185) 4.75 (0.187)

0.03-0.9 (0.3-9.0, 0.26-7.8)

0.50 (0.020) 0.55 (0.022) 0.60 (0.024) 0.65

(0.026).

0.70 (0.028) 0.75 (0.030) 0.80 (0.032) 0.85

(0.034)

0.90 (0.035) 0.95 (0.037) 1.00 (0.039) 1.05 (0.041)

1.10 (0.043) 1.15 (0.045) 1.20 (0.047) 1.25 (0.049)

1.30 (0.051), 1.35 (0.053) 1.40 (0.055) 1.45

(0.057)

2.9-3.9 (30-40, 26-35)

0.50 (0.020) 0.55 (0.022) 0.60 (0.024) 0.65

(0.026)

0.70 (0.028) 0.75 (0.030) 0.80 (0.032) 0.85 (0.034)

0.90 (0.035) 0.95 (0.037) 1.00 (0.039), 1.05 (0.041)

1.10 (0.043) 1.15 (0.045) 1.20 (0.047). 1.25 (0.049)

1.30 (0.051) 1.35 (0.053) 1.40 (0.055), 1.45 (0.057)

0.025-0.1 (0.001-0.004)

0.5 (0.020)

Torque converter

Bushing inner diameter mm (in) Standard 1 53.030-53.075 (2.088-2.090)

Maximum 1 53.075 (2.090)

Spring Specification

Spring name Outer diameter Free length

No. of coil Wire diameter

mm (in) mm (in) mm (in)

Throttle modulator 8.1 I I--.._ ^^^1-^1 1 spring 1 (0.319)

1 43.4 (1.709) 1 10.5 1 0.8 (0.031)

1

” cJIJtz:I li”I IL, “I

valve body Throttle spring

Throttle assist spring 1 5.4 (0.213) 46.2 (1.819) 1 29.0

0.88 (0.035)

1 5.15 (0.203)

26.88 (1.058) 1 16.2 0.6 (0.024)

,

^ -- ,^ ^^^

Mnin contrnl I Low reducina sprina I 7.9 (0.311) .._... __.._. -

valve body

-. .- \“---I 29.98 (1.180) 10.0

0.8 (0.03lj

1 3-4

shift spring / 7.4 (0.291) I 36.6 (1.441)

12.0 0.8 (0.031)

B6 SOHC

23.0

Bypass spring BP

SOHC 4.9 (0.193) 27.6 (1.087) 0.55 (0.022)

Premain control BP

DOHC 4.9 (0.193) 30.5 (1.201) 23.0

0.55 (0.022)

valve body

2-3 shift spring 7.4 (0.291) 36.6 (1.441)

12.0 0.8 (0.031)

Converter relief spring

8.6 (0.339) 68.4 (2.693) 27.5

1.2 (0.057)

Lockup control spring

5.0 (0.197) 30.1 (1.185) 21.5 0.55 (0.022)

Control valve body Throttle relief spring

6.6 (0.260) 21.6 (0.850) 11.5

0.8 (0.031)

Oil

pump Spring

13.0 (0.512) 53.0 (2.087)

12.0 1.2 (0.047)

TD-15

Page 1030 of 1164

TD TECHNICAL DATA

Spring name

2-3 accumulator

small spring Outer diameter Free length Wire diameter

mm (in) mm (in) No. of coil

mm (in) BP DOHC 11.6 (0.457)

59.7 (2.350)

16.9 1.8 (0.071)

56 SOHC

BP SOHC 10.0 (0.394) 71.8

(2.827) 24.2 1.4 (0.055)

2-3 accumulator BP DOHC 15.0

(0.591) 71.8 (2.827) 9.8

1.2 (0.047)

large spring B6 SOHC

BP SOHC 15.0 (0.591)

71.8 (2.827)

15.8 2.0 (0.079)

l-2 accumulator small spring

11.2 (0.441)

84.7 (3.335)

25.5 1.5 (0.059)

BP DOHC

- - -

-

l-2 accumulator

Accumulator large spring B6 SOHC

BP SOHC 16.0 (0.630)

84.7 (3.335) 19.5

1.9 (0.075)

B6 SOHC 10.8 (0.425) 101.2 (3.984)

28.2

1.2 (0.047)

N-D Accumulator

small spring BP SOHC

BP DOHC

10.8 (0.425) 101.2 (3.984)

28.2

1.2 (0.047)

B6 SOHC

15.0 (0.591) 94.2 (3.709)

16.5

1.6 (0.063)

N-D Accumulator

large spring BP SOHC

BP DOHC 15.0 (0.591) 94.2

(3.709) 16.5

1.6 (0.063)

N-R Accumulator small spring

9.8 (0.386)

93.2 (3.669) 31.5

1.3 (0.051)

N-R Accumulator large spring

14.0 (0.551) 106.5 (4.193)

23.0 1.7 (0.067)

3-4 clutch

Return spring

74.4 (2.929)

40.5 (1.594) 1 .o

5.0 (0.197)

Coasting clutch

Return spring

7.3 (0.287) 20.45 (0.805)

10.0 1 .o (0.039)

Low and reverse

brake Return

spring 5.55 (0.219)

14.3 (0.563)

12.0 0.75 (0.030)

Servo

Return spring

27.7 (1.091) 43.25 (1.703)

4.5

3.2 (0.126)

Vehicle Speed at Shift point Table -

lode

- -

angc

-

D Throttle condition

(Throttle sensor

voltage)

Fully opened

(4.0 volt)

Half throttle

(1.6-2.2 volt)

/ &%L) j 3 1 850-2,500 2,100-2,650 2,300-3,000 74-100 (46-62) 91-116 (56-72) 93-120 (58-74

Lock-up

[1,850-2,20011,950-2.550(2,300-2,700/74-88 (46--55)185-110 (53-68)(93-108 (58-67)1

Kir.kdnwn OD -+ DI

1,05U

%lly opened

i4.0 volt)

Half throttle

s2 -+ s3 5,000-5,45c

s3 -+ s2 2,900

S2 -+ ST 2,300-2,6OC

SI * 52

2.500-3.35C

(1.6-2.2 volt)

s2 -+ s3 v, v...

Fully opened Ll + L2 5,150-5,75(

w-dt I7w-ln

nlf throttle 6-7 7 vnltl I Ll + L2 (2.500-3.350(2,850-3,8OOj3.300-4.300125-34 (16-21$1-41 (19-25)j33-43 (20-27)1

TD-16

Page 1031 of 1164

TECHNICAL DATA TD

1 Throttle condition 1

nrllm pn-t

Mode Rr _ me/ flhrottle sensor 1 Shift 1 -.- -*r2d rpm

Vehicle speed I km/h (mohl , . ,

I

ioltage) 1 B6 sot

iC 1 BP SOHC 1 BP DOHC

66 SOHC 1 BP SOHC 1 BP

I I I

’ ni - n9 I’) 7nn-1 “50 2,500-3,05012,700-3.3001 I I DOHC

Fully opened 27-33 (17-201

3 D (4.0 volt) 50 2,050-2,55012,200-2,750]

40-50 i25-31 j

e I 300-500 1 450-650 / Q-15 16-9) 112-18 (7-111

00 3,250-3,45013,550-3.800~91-97 f56-60&G10’4 (61-64)hOO-106;62-&\I

s

i- f Fully closed

(0.5 volt)

YI -l&c

L, r vv-“,L

Dz + D3 2,150-2,7

D3 -+ DI 300--5O(

S3 -+ S2 3,200-3,4

’ L2 -+ LI 2,350-2,65012,200-2,50012,350-2.7001

43-49 ;27--3b1 ’ ‘I

M. FRONT AND REAR AXLES -

Item

Driveshaft Engine/Transaxle BP SOHC BP DOHC

Joint type

Length of shaft

Shaft diameter Front axle

Bearing play axial direction Rear axle

Bearing play axial direction Inside Tripod joint

Outside Ball joint

Right

919.3 (36.19) 918.7 (36.17) 630.7 (24.83)

mm (in) Left

637.8 (25.11) 640.2 (25.20) 621.2

637.1

(24.46) (25.08)

21.5 (0.85) 23.0 (0.91)

mm (in) 1 0.05 (0.002)

mm (in) I 0.05 (0.002)

N. STEERING SYSTEM Steering wheel

Outer diameter Item Specifications 370 (14.57)

Lock-to-lock I Steering gear

--

Type

Steering gear ratio

Backlash between rack and pinion mm (in)

N.r ’ ’ ” ’ n (cm-Kg, in-01

Preload measured by torque

*rrv~rrdl Rack and pinion

Infinite (00)

0 (0)

M/S : 0.9-l .3 (Q-13, 7.8-l 1.3)

P/S : 1.0-1.3 (10-14, 8.7-12)

Pinion preload ““l~jll~,,

9 (0.4

Preload measured by pull

scale with attachment

Limit of rack housing movement mm (in)

Distance between left and right brackets mm (in)

Rack stroke mm (in M/S : 900-l ,300 (31.8-45.9)

P/S : l,OOO-1,400 (35.3-49.4)

1.5 (0.06)

298.5 (11.75)

140 (5.511

Lubricant type (power steering)

Oil capacity (power steering) Drive belt

liter (US qt, Imp qt) I ATF: M-III or DexronW

0.8 (0.85, 0.70)

I New belt: 8-Q (0.31-0.35)

Deflection with force of 98 N (10 kg, 22 lb) mm (in) Used belt: 9-10 (0.35-0.39)

I imit: 11.5 (0.461

TD-17

Page 1034 of 1164

TD TECHNICAL DATA

Coil Spring Specifications (See page R-5 for coil spring applications)

*’ Main identification mark color: Indicated on second coil from bottom. l * Auxiliary identification mark color: Indicated on third coil from bottom.

T. BODY ELECTRICAL SYSTEM

Item

Headlight

Frnnt tl wn sinnnl/Pnrkinn linht

Specification (W) (Bulb Trade number)

65145 (9004)

2718 II I 571

I

“‘VW, I u”“y’ 1. I” \’ ‘V’,

uinh mount stoplight 18.4 (1141)

turn single light 27 (1156)

Y-,-~p light 27 (1156)

Rear side marker light (Sedan) 3.8 (194)

License plate light 7.5 (89) [PROTEGE], 5 (168) [3HBl

Interior 10

Interior and spot lamp

spot 6

Interior lamp 10

‘i--” Spot lamp (in overhead console)

8 (67)

Cargo room lamp 5 (168)

Trunk room lamp 5 (168)

I I

ntminr Iamnc

I

Curtesy lamp

High beam

Turn light

Brake

Hold

) Charge 5 (168)

3.4

3.4

3

3 (158)

i

Oil pressure

Washer

Seat belt

Malfunction

Fuel

illumination 3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3 (158)

3.4 Indicator and

warning lamps

Check 3 (158)

Dif. lock

I 3 (158) .-

,

-.-’

I

I

TD-20

Page 1039 of 1164

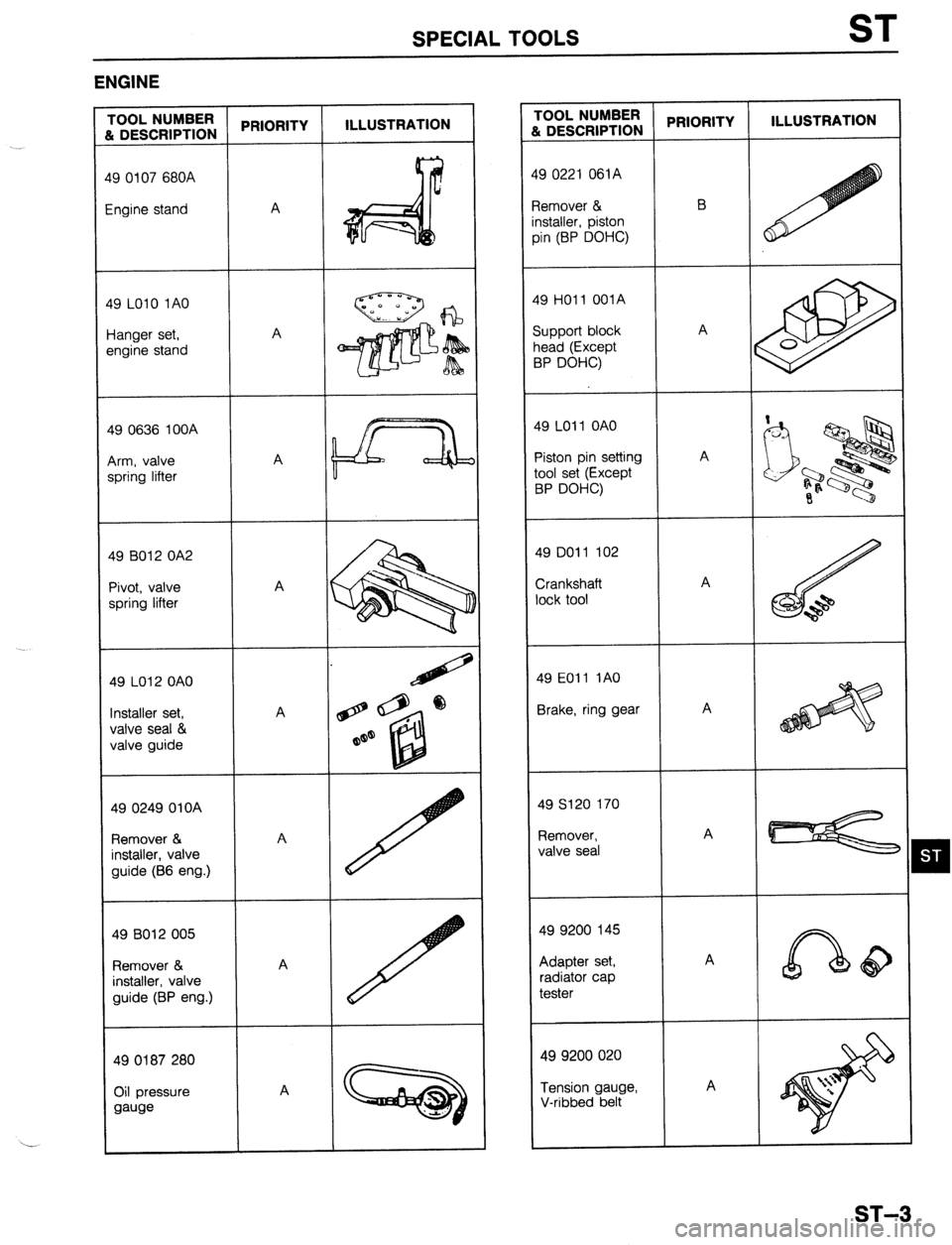

SPECIAL TOOLS ST

.._ ENGINE

9 LO10 1AO

,9 0636 100A

19 B012 OA2

19 LO12 OAO

nstaller set,

/alve seal &

$9 0249 OlOA

3emover &

nstaller, valve

49 8012 005

Remover &

installer, valve

49 0187 280

Oil pressure ‘OOL NUMBER

: DESCRIPTION PRIORITY ILLUSTRATION

9 0221 061A

:emover & B

Istaller, piston

in (BP DOHC)

4 9 HO11 OOlA

s iupport block

h lead (Except

E )P DOHC)

.9 LO1 1 OAO

‘iston pin setting A

DOI set (Except

3P DOHC) 4

F

tl

E

L

(

II

1

I

I I9 DO11 102

;rankshaft

ock tool

19 EOI 1 1AO

3rake, ring gear

49 s120 170

Remover,

valve seal A

@ 0

A

49 9200 145

Adapter set,

radiator cap A cl3JQ

tester

49 9200 020

Tension gauge,

V-ribbed belt A

ST-3