ignition MAZDA PROTEGE 1992 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 345 of 1164

ENGINE TUNE-UP F

03UOFX.051

03UOFX-051

- w4TEN I

Air Cleaner Element

Inspection

1. Check the air cleaner element for excessive dirt, damage,

or oil.

Caution

l Do not use compression air to clean the element.

2. Replace the element if necessary.

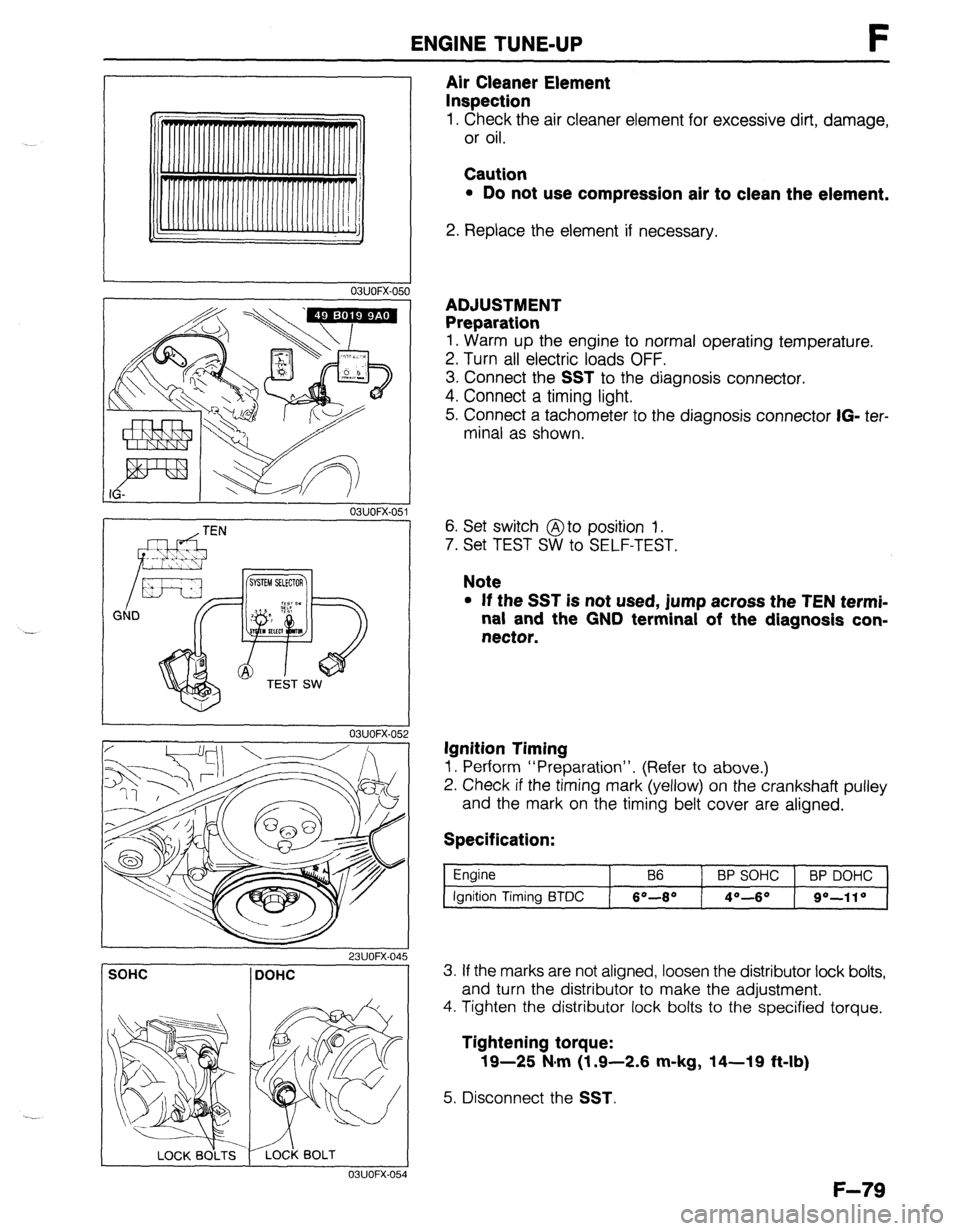

ADJUSTMENT

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect a timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

1. Perform “Preparation”. (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Specification:

Engine

Ignition Timing BTDC B6 BP SOHC BP DOHC

6O-8* 4O--6O go-110

SOHC DOHC

I 03UOFX-054

3. If the marks are not aligned, loosen the distributor lock bolts,

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

F-79

Page 348 of 1164

F SELF-DIAGNOSIS FUNCTION

SELF-DIAGNOSIS FUNCTION

DESCRIPTION

The engine control unit (integrated with the EC-AT control unit) has built-in Self-Diagnosis function the same

as for the previous models. When trouble occurs in the main input devices or output devices, they are indi-

cated and retrieved from the engine control unit (ECU) as service code numbers.

When inspecting for service code(s) memorized in the ECU use the Self-Diagnosis checker and system selector

(SST).

Note

l The ECU constantly checks for malfunction of the in put devices. But, the ECU checks for

malfunction of output devices only in a three second period after the ignition switch is turned

ON and the TEN terminal of the diagnosis connector is grounded.

-

-

INPUT =

SIGNALS-

-

-

- SELF-

DIAGNOSTIC

L!

I-

FUNCTION ENGINE CONTROL

UNIT

j FAIL-SAFE

FUNCTION

I

SYSTEM SELF-DIAGNOSIS

SELECTOR

CHECKER

MIL

(MALFUNCTION

INDICATOR LAMP)

Page 349 of 1164

SELF-DIAGNOSIS FUNCTION F

PREPARATION

SST

49 6019 9AO

System Selector For

diagnosis 49 HO18 9Al

Self-Diagnosis

Checker For

diagnosis

SERVICE CODE NUMBER

Inspection Procedure

1. Connect the SST to the diagnosis connector.

2. Set switch @to position 1.

3. Set TEST SW to SELF-TEST position.

23UOFX-048

03UOFX.059

I

4. Connect the SST to the System Selector and a ground

5. Set the select switch to position A.

6. Turn the ignition switch to ON.

7. Verify that 88 flashes on the digital display and the buzzer

sounds for 3 sec. after turning the ignition switch ON.

8. If 88 does not flash, check the main relay (FUEL INJ relay)

(Refer to page F-172) power supply circuit, and diagno-

sis connector wiring.

9. If 88 flashes and the buzzer sounds continuously for more

than 20 sec., check for a short circuit between the engine

control unit terminal 1 F and the diagnosis connector. Re-

place the engine control unit if necessary and perform Steps

3 and 7 again.

23UOFX-049 IO. Note any code numbers and check for the causes by refer-

ring to the check sequences shown on pages F-88

through F-103. Repair as necessary.

Note

l Cancel the code numbers by performing the after-

repair procedure following repairs.

(Refer to page F-104.)

I 23UOFX-050

F--83

Page 351 of 1164

SELF-DIAGNOSIS FUNCTION F

:ODE LOCATION OF

NO.

MALFUNCTION

26 Solenoid valve ON

(purge control)

OFF OUTPUT SIGNAL PATTERN nnnnnll 1 SELF4IAGNOSIS

Open or

short circuit FAIL-SAFE

-

ON

34

ISC valve

OFF u 1 llllJlll r -

41 Solenoid valve ON

(WCS)

[DOHC]

OFF -

Pulse ON No input signal Shifting performed in

55*

i nnnnn

from pulse accordance with signals

generator

OFF generator from vehicle speed

sensor

Open or Solenoid valve(s)

60* 1-2 shift ON

short circuit

solenoid valve

uuuuul performs the shifting with

as little interference as

OFF

possible with driving

performance

2-3 shift ON Lockup not provided

61*

solenoid valve

OFF

UUUI n

3-4 shift ON

62’

solenoid valve

OFF u u u u inn

1.6 sec. 4 sec.

63* Lockup solenoid

valve

u u&m I- Shifting performed

normally

Lockup not provided

0.4 sec.

0.4 sec.

*If the marked code numbers appeor, refer to Section K

Note

l The HOLD indicator does not flash the service code numbers.

l If there is more than one failure present, the code numbers will be indicated in numerical or-

der, lowest number first.

* After repairing a problem, turn the ignition switch OFF and disconnect the negative battery

cable at least 20 seconds to erase the service code numbers from the engine control unit (ECU)

memory.

23UOFX-051

F-85

Page 367 of 1164

SELF-DIAGNOSIS FUNCTION F

TEP

6

7

8

9

IO

11 INSPECTION

Check for correct fuel line pressure at idle

IV page F-122

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 38-46 psi)

(Vacuum hose to pressure regulator

disconnected)

Check intake air system components for air

leakage

Check for misfire of dead cylinder from Step 5

inspection

Check for injector operating sound at idle of

dead cylinder from Step 5 inspection -

Replace injector at dead cylinder from Step 5 in-

spection

CI page F-131

Check if same Code No. is present following

performing after-repair procedure

CT page F-104

Try known good ECU and check if condition

Improves

CT page F-149 Yes

No

Yes If not clogged, check fuel pump

maximum pressure

Go to Step 11

No Replace

--

Yes Repair or replace ignition system

No

Yes

No

Yes

No

T L ACTION

Go to next step

Low pressure

Check fuel line pressure while pinching

fuel return hose

~3 If fuel line pressure quickly in-

creases, check pressure regulator

v page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

regulator

CT page F-126

Go to next step

Go to next step

Check for battery voltage at injector

connector terminal-wire (W/R)

L3 If Yes, replace injector c7 page F-131

+ If No, check wire harness for short

or open

Go to next step

Removed injector at fault

Circuit Diagram

ATX

OXYGENSENSOR

R/L

ECU

-------------- ---

BILG

23UOFX-07

F-10'

Page 368 of 1164

SELF-DIAGNOSIS FUNCTION

:ODE No. 1 25 (SOLENOID VALVE - PRESSUREREGULATORCONTROL)-BPENGINE

r (

TEP

1

-

2

-

3 I

INSPECTION

Disconnect connector from ECU and check if

battery voltage exists at ECU terminal 2T (MTX)

3M (ATX) wire (G/O) with ignition switch ON

In same condition as Step 1, check if battery

voltage exists at solenoid valve connector

terminal-wire (G/O) ACTION

Yes Check ECU terminal connector for poor -

connection

* If OK, replace ECU CT page F-149

+

If not OK, repair or replace connector

No Go to next step

Yes Repair or replace wire (G/O)

No Go to next step

Check if solenoid valve is OK Yes Check for short or open circuit in wiring

w page F-135 from main relay (FUEL INJ relay) to

solenoid valve

No Replace solenoid valve

I I I

23UOFX-077

:ODE No. 26 (SOLENOID VALVE - PURGE CONTROL)

STEP INSPECTION

Disconnect connector from ECU and check if

battery voltage exists at ECU terminal 2X (MTX)

20 (ATX) wire harness (W/L) with ignition switch

ON Yes

No

In same condition as Step 1, check if battery

Yes

voltage exists at solenoid valve connector

terminal-wire (W/L)

No

Check if solenoid valve is OK

Yes

w page F-140

t- No

--

4 ACTION

Check ECU terminal connector for poor

connection

ti If OK, replace ECU c;p page F-149

e

If not OK, repair or replace connector

Go to next step

Repair or replace wire harness (W/L)

Go to next step

Check for short or open circuit in wiring

from main relay (FUEL INJ relay) to

Circuit Diagram

MTX

I-

FROM

BATTERY

FROM

23UOFX-07 9

F-l 02

Page 369 of 1164

SELF-DIAGNOSIS FUNCTION F

1

CODE No. 34 (ISC VALVE)

1 ACTION

Yes Check ECU terminal connector for poor

connection INSPECTION

Disconnect connector from ECU and check if

battery voltage exists at ECU terminal 2W (MTX)

3Q (ATX) wire (L/O) with ignition switch ON

c3 If OK, replace ECU

+ If not OK, repair or replace con-

nector w page F-149

No Go to next step

In same condition as Step 1, check if battery

voltage exists at ISC valve connector terminal.

wire (L/O) Yes ) Repair or replace wire (L/O)

No Go to next step

Yes Check for short or open circuit in wiring

from main relay (FUEL INJ relay) to ISC

valve

No Replace ISC valve Check ISC valve for correct resistance

w page F-i 16

Resistance: 1 l-130 [at 20°C(68”F) ]

I 23UOFX-08( I

r C :ODE No. )

41 (SOLENOID VALVE - VICSbDOHC

I

ii

T

I

INSPECTION

ACTION

Check ECU terminal connector for poor

connection

in’

I

* If OK, replace ECU w page F-149

c3 If not OK, repair or replace con-

nector

No Go to next step Disconnect connector from ECU and check if

battery voltage exists at ECU

terminal 2S (MTX)

31 (ATX) wire (B/R) with ignition switch ON

2 In same condition as Step 1, check if battery voltage exists at solenoid valve connector

terminal-wire (B/R)

Check if solenoid valve is OK

w page F-l 18 Yes Repair or replace wire (B/R)

No Go to next step

Yes Check for short or open circuit in wiring

from main relay to solenoid valve

No

Replace solenoid valve

23UOFX-081 3

Circuit Diagram

ATX

ISC VALVE

FROM

BATTERY 4

FROM

L

IGNITION d++n.D,,

SWITCH

MAIN RELAY

(FUEL INJ RELAY) S

4\ ECU

SOLENOID VALVE

i(VICS) [DOHC]

W/R ,,

\

SOLENOID VALVE ,

(PURGE CONTROL)

23UOFX-082

F-i 03

Page 370 of 1164

F SELF-DIAGNOSIS FUNCTION

23UOFX-08: 3

03UOFX.086

i:a pj

MONITOR

SELECT El

03UOFX-:6

7

I

7

After-repair Procedure

1. Cancel the memory of malfunctions by disconnecting the

negative battery cable for

at least 20 seconds. Reconnect

the negative battery cable.

2. Connect the

SST (System Selector) to the diagnosis con-

nector.

3. Set the switch @to position 1.

4. Set TEST SW to SELF-TEST.

5. Connect the

SST (Self-Diagnosis Checker) to the System

Selector and a ground.

6. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

7. Turn the ignition switch ON.

8. Start and warm up the engine, then run it at

2,000 rpm for

three minutes.

9. Verity that no code numbers are displayed.

F-l 04

Page 371 of 1164

SELF-DIAGNOSIS FUNCTION F

SWITCH MONITOR FUNCTION

Individual switches can be inspected by the SST (Self-Diagnosis checker).

Note

l The TEN terminal of the diagnosis connector must be grounded and the ignition switch ON

(engine stopped).

l If either of the switches remain activated, the monitor lamp will be illuminated.

ECU

NEUTRAL SWITCH (MTX)

CLUTCH SWITCH (MTX)

=d-’ 1

BATTERY

INHIBITOR SWITCH (ATX)

STOPLIGHT SWITCH (MTX)

HEADLIGHT SWITCH MONITER LAMP

REAR WINDOW (SELF-DIAGNOSIS CHECKER)

DEFROSTER SWITCH

AIC SWITCH

BLOWER SWITCH

THROTTLE SENSOR asp-

- _

COOLING FAN SWITCH

03UOFX

Switch

Clutch switch

Neutral switch (MW

(M-W Self-Diagnosis Checker (Monitor lamp)

Light ON Light OFF Pedal released Pedal depressed

In gear Neutral Remark In gear

Clutch pedal released

Inhibitor switch

(ATX) L, S, D or R range

N or P range -

Throttle sensor Pedal depressed (Not fully) Pedal released/fully depressed -

Stoplight switch

Pedal depressed Pedal released -

Headlight switch

ON

OFF Headlights/parking lights: ON

Blower switch

ON

OFF Blower switch at 2nd or

above position

AIC switch

ON OFF Fan speed control at 1st po-

sition

Rear window defroster

switch ON

OFF -

Water thermoswitch Fan operating Fan not operating -

23UOFX-084

F-l 05

Page 372 of 1164

SELF-DIAGNOSIS FUNCTION

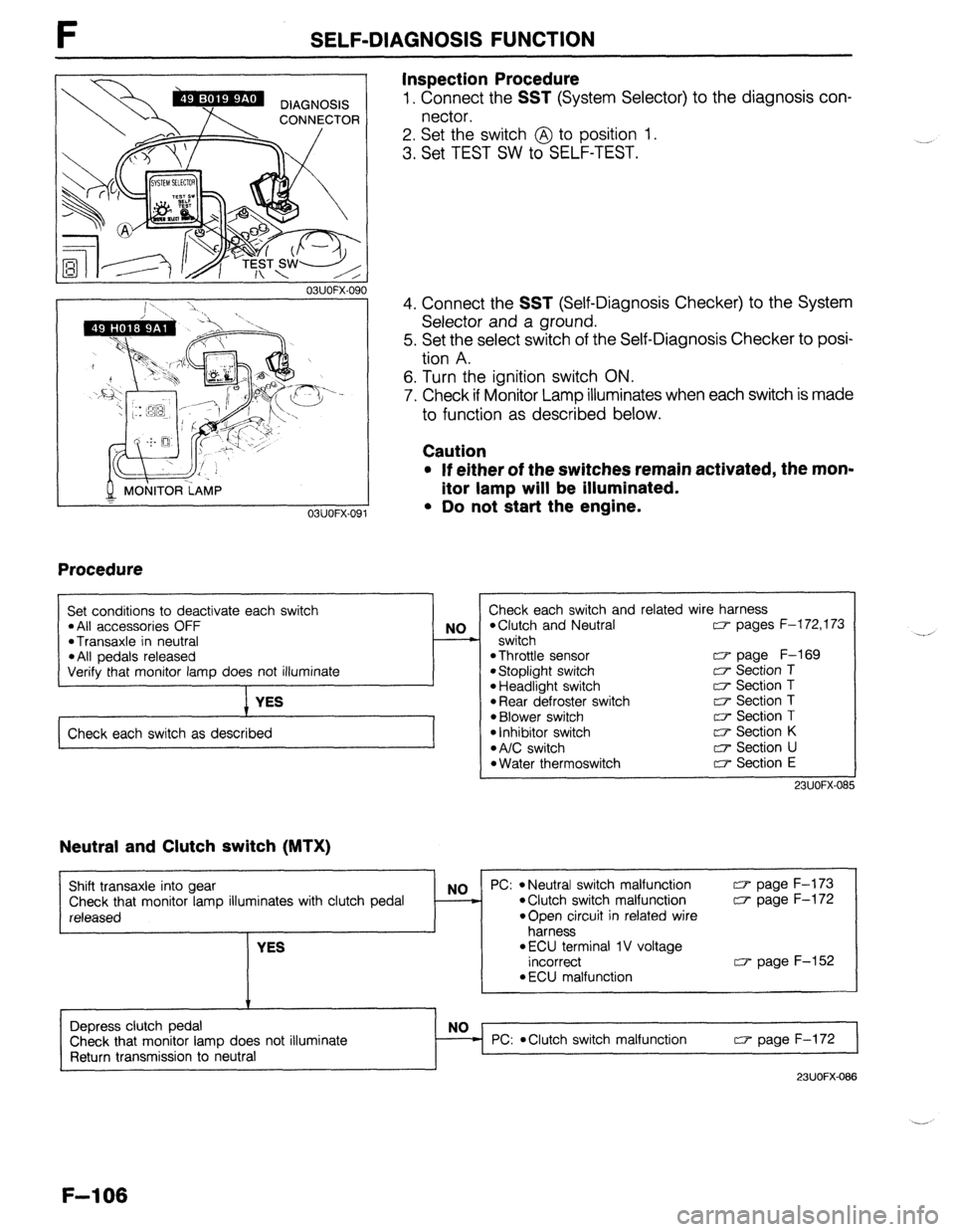

Inspection Procedure

1. Connect the SST (System Selector) to the diagnosis con-

nector.

2. Set the switch @ to position 1.

3. Set TEST SW to SELF-TEST.

03UOFX.090

MONITOR LAMP

T

03UOFX-091

Procedure

4. Connect the SST (Self-Diagnosis Checker) to the System

Selector and a ground.

5. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

6. Turn the ignition switch ON.

7. Check if Monitor Lamp illuminates when each switch is made

to function as described below.

Caution

* If either of the switches remain activated, the mon-

itor lamp will be illuminated.

l Do not start the engine.

I

I Set conditions to deactivate each switch l All accessories OFF l Transaxle in neutral l All pedals released NO

-

Verify that monitor lamp does not illuminate

YES

Check each switch as described Check each switch and related wire harness

*Clutch and Neutral CT- pages F-l 72,173

switch

*Throttle sensor w page F-169 l Stoplight switch c7 Section T l Headlight switch c7 Section T l Rear defroster switch T;P Section T l Blower switch [r+ Section T

l Inhibitor switch a Section K l A/C switch 0 Section U l Water thermoswitch c7 Section E

23UOFX-OS!

Neutral and Clutch switch (MTX)

Shift transaxle into gear

Check that monitor lamp illuminates with clutch pedal

released

YES NO PC: l Neutral switch malfunction a page F-173 l Clutch switch malfunction w page F-172

*Open circuit in related wire

harness

l ECU terminal 1 V voltage

incorrect w page F-152

l ECU malfunction

Depress clutch pedal

Check that monitor lamp does not illuminate

Return transmission to neutral PC:

*Clutch switch malfunction w page F-172

23UOFX-088

F-l 06