MERCEDES-BENZ SPRINTER 2006 Service Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 2231 of 2305

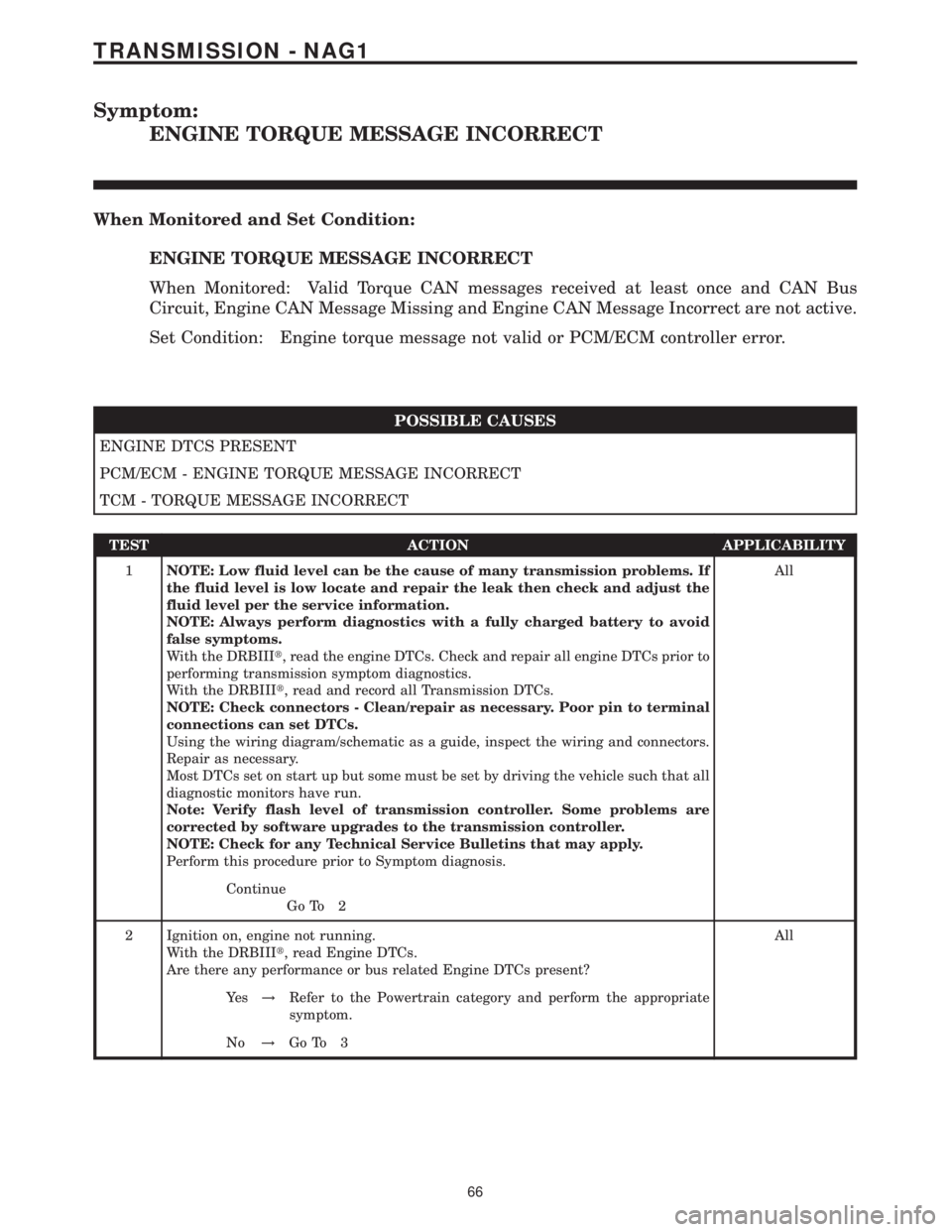

Symptom:

ENGINE TORQUE MESSAGE INCORRECT

When Monitored and Set Condition:

ENGINE TORQUE MESSAGE INCORRECT

When Monitored: Valid Torque CAN messages received at least once and CAN Bus

Circuit, Engine CAN Message Missing and Engine CAN Message Incorrect are not active.

Set Condition: Engine torque message not valid or PCM/ECM controller error.

POSSIBLE CAUSES

ENGINE DTCS PRESENT

PCM/ECM - ENGINE TORQUE MESSAGE INCORRECT

TCM - TORQUE MESSAGE INCORRECT

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 Ignition on, engine not running.

With the DRBIIIt, read Engine DTCs.

Are there any performance or bus related Engine DTCs present?All

Ye s!Refer to the Powertrain category and perform the appropriate

symptom.

No!Go To 3

66

TRANSMISSION - NAG1

Page 2232 of 2305

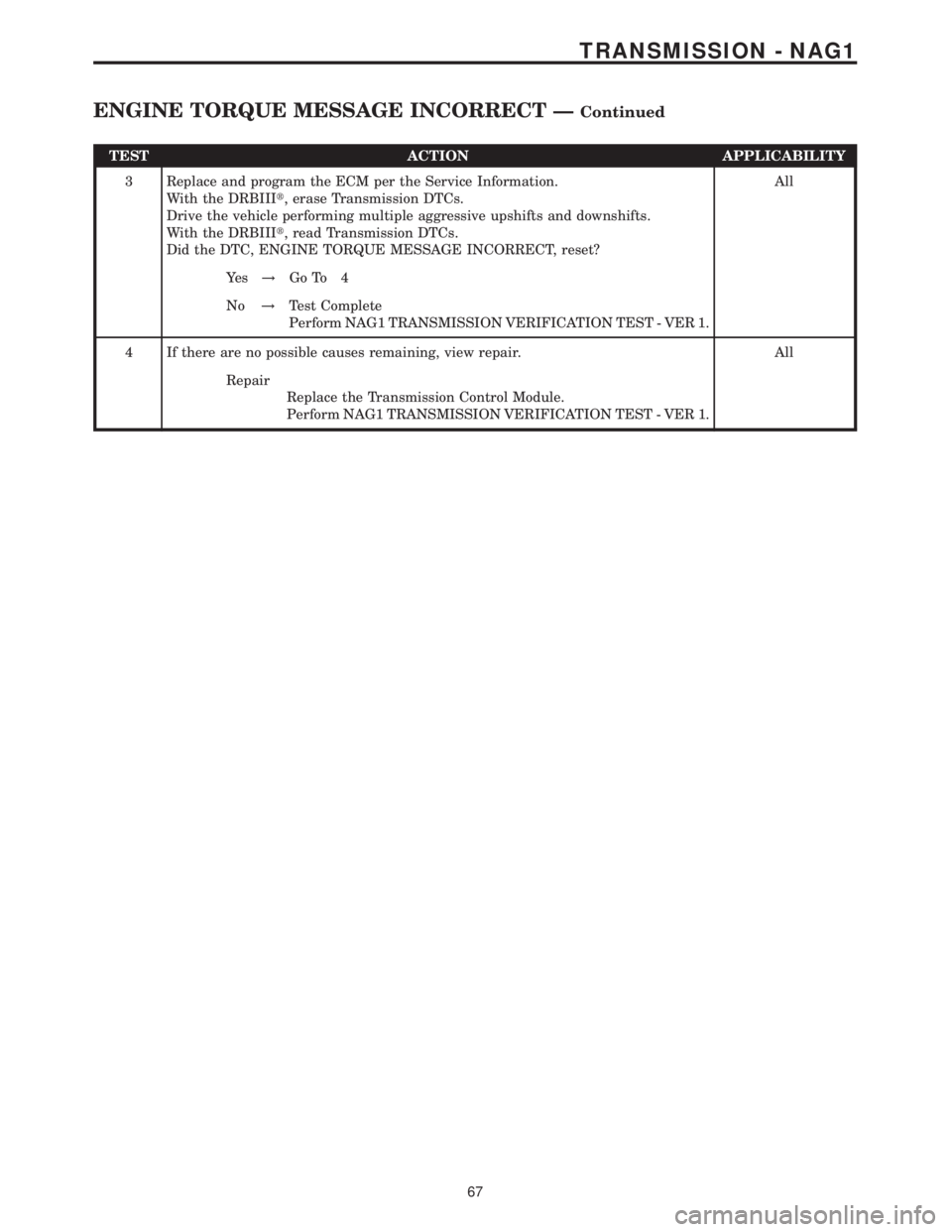

TEST ACTION APPLICABILITY

3 Replace and program the ECM per the Service Information.

With the DRBIIIt, erase Transmission DTCs.

Drive the vehicle performing multiple aggressive upshifts and downshifts.

With the DRBIIIt, read Transmission DTCs.

Did the DTC, ENGINE TORQUE MESSAGE INCORRECT, reset?All

Ye s!Go To 4

No!Test Complete

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

4 If there are no possible causes remaining, view repair. All

Repair

Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

67

TRANSMISSION - NAG1

ENGINE TORQUE MESSAGE INCORRECT ÐContinued

Page 2233 of 2305

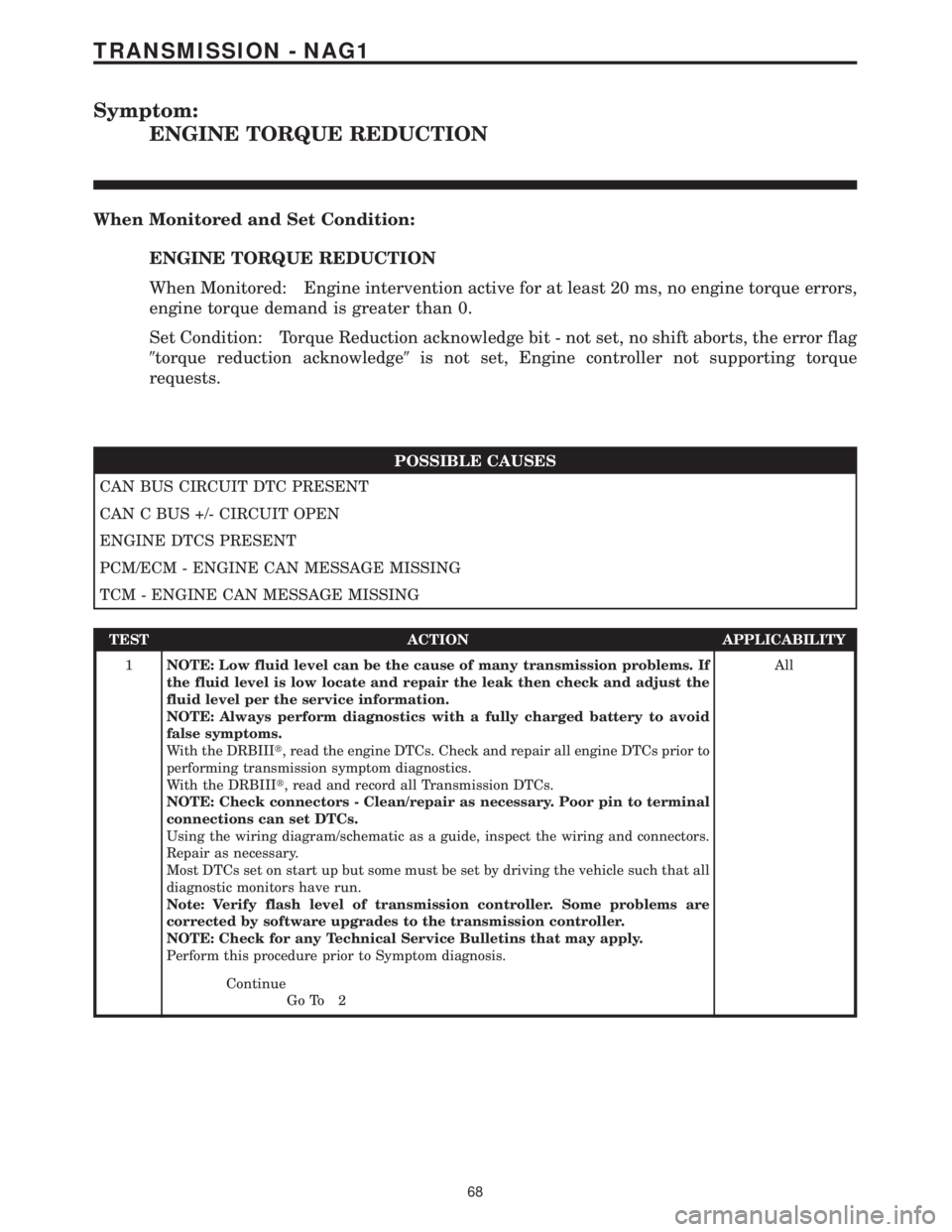

Symptom:

ENGINE TORQUE REDUCTION

When Monitored and Set Condition:

ENGINE TORQUE REDUCTION

When Monitored: Engine intervention active for at least 20 ms, no engine torque errors,

engine torque demand is greater than 0.

Set Condition: Torque Reduction acknowledge bit - not set, no shift aborts, the error flag

9torque reduction acknowledge9is not set, Engine controller not supporting torque

requests.

POSSIBLE CAUSES

CAN BUS CIRCUIT DTC PRESENT

CAN C BUS +/- CIRCUIT OPEN

ENGINE DTCS PRESENT

PCM/ECM - ENGINE CAN MESSAGE MISSING

TCM - ENGINE CAN MESSAGE MISSING

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

68

TRANSMISSION - NAG1

Page 2234 of 2305

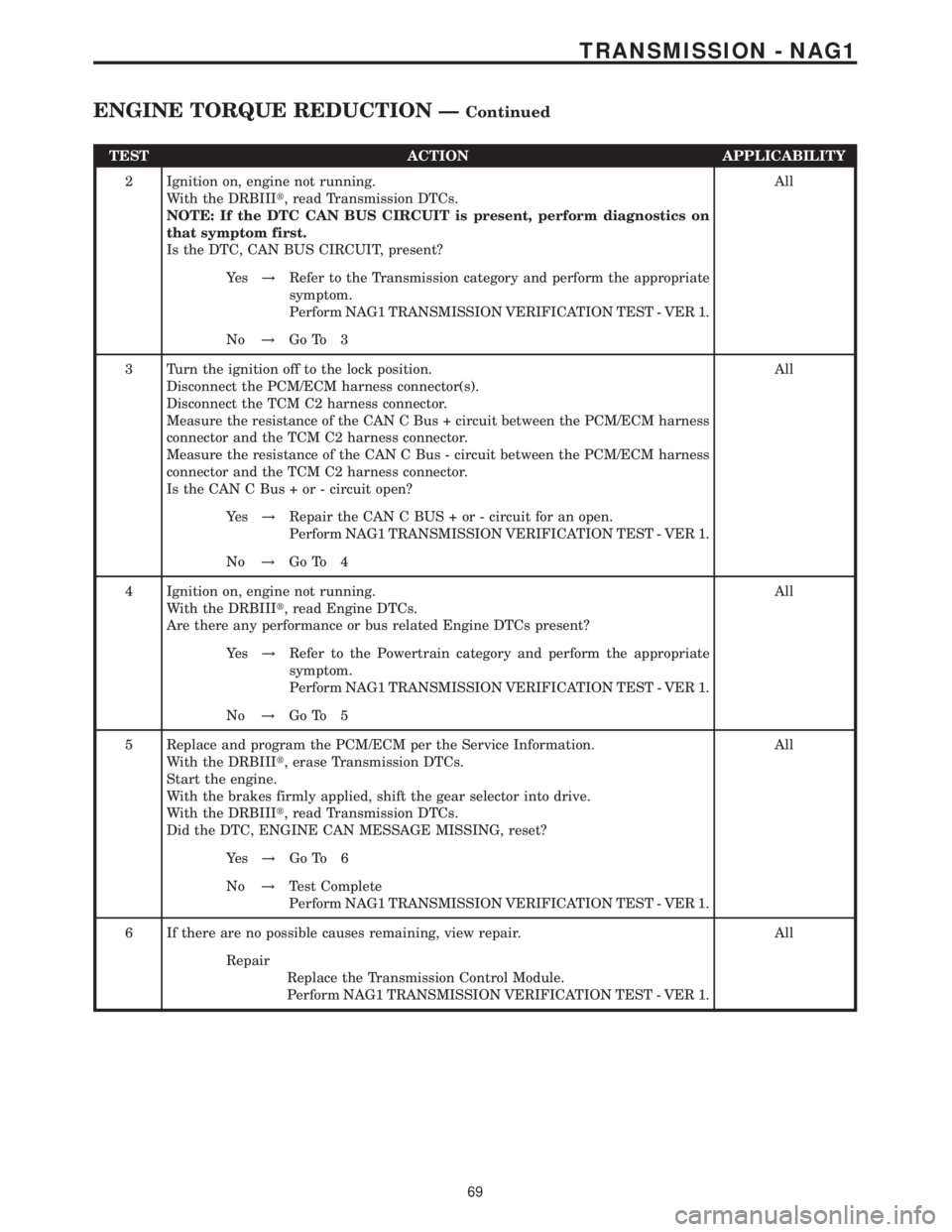

TEST ACTION APPLICABILITY

2 Ignition on, engine not running.

With the DRBIIIt, read Transmission DTCs.

NOTE: If the DTC CAN BUS CIRCUIT is present, perform diagnostics on

that symptom first.

Is the DTC, CAN BUS CIRCUIT, present?All

Ye s!Refer to the Transmission category and perform the appropriate

symptom.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off to the lock position.

Disconnect the PCM/ECM harness connector(s).

Disconnect the TCM C2 harness connector.

Measure the resistance of the CAN C Bus + circuit between the PCM/ECM harness

connector and the TCM C2 harness connector.

Measure the resistance of the CAN C Bus - circuit between the PCM/ECM harness

connector and the TCM C2 harness connector.

Is the CAN C Bus + or - circuit open?All

Ye s!Repair the CAN C BUS + or - circuit for an open.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 4

4 Ignition on, engine not running.

With the DRBIIIt, read Engine DTCs.

Are there any performance or bus related Engine DTCs present?All

Ye s!Refer to the Powertrain category and perform the appropriate

symptom.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 5

5 Replace and program the PCM/ECM per the Service Information.

With the DRBIIIt, erase Transmission DTCs.

Start the engine.

With the brakes firmly applied, shift the gear selector into drive.

With the DRBIIIt, read Transmission DTCs.

Did the DTC, ENGINE CAN MESSAGE MISSING, reset?All

Ye s!Go To 6

No!Test Complete

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

6 If there are no possible causes remaining, view repair. All

Repair

Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

69

TRANSMISSION - NAG1

ENGINE TORQUE REDUCTION ÐContinued

Page 2235 of 2305

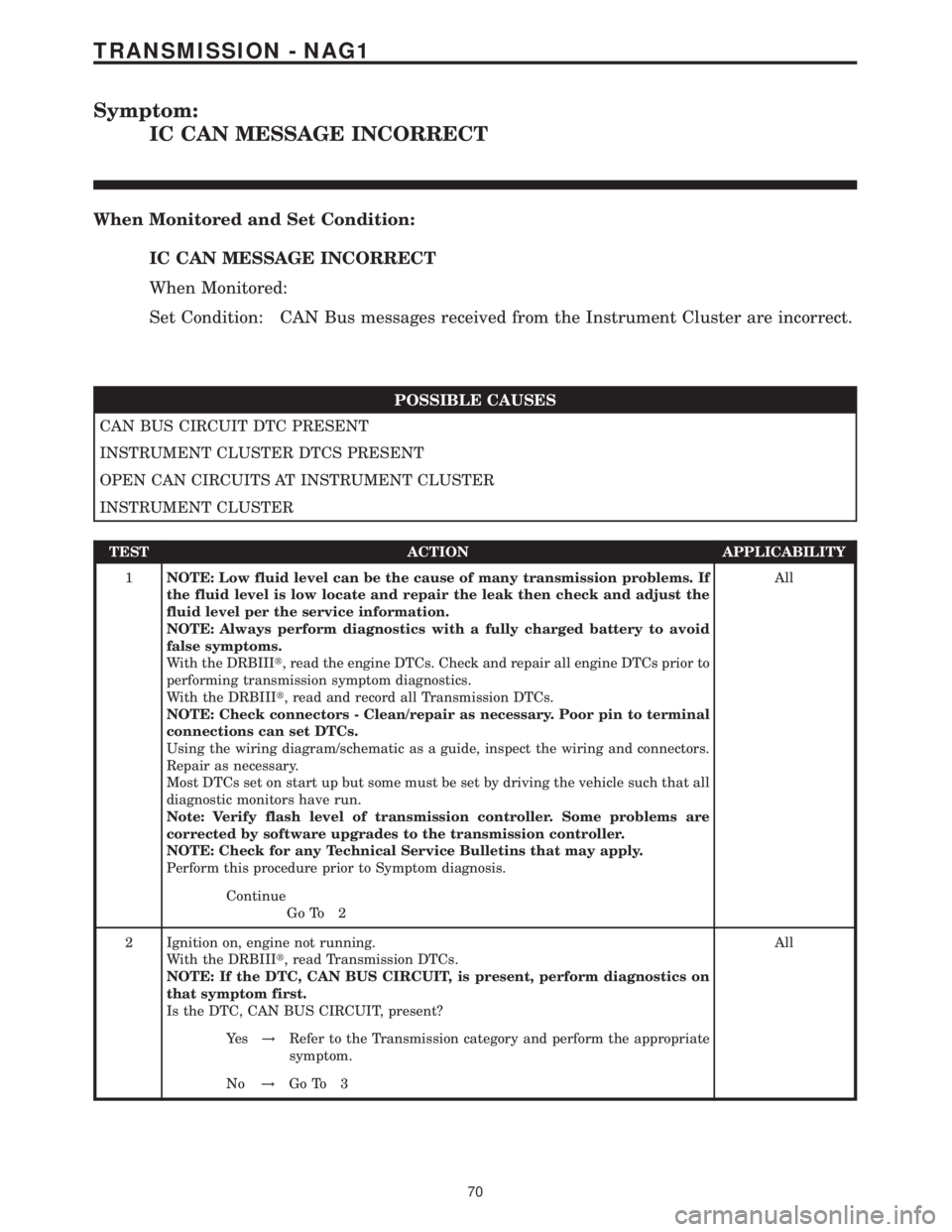

Symptom:

IC CAN MESSAGE INCORRECT

When Monitored and Set Condition:

IC CAN MESSAGE INCORRECT

When Monitored:

Set Condition: CAN Bus messages received from the Instrument Cluster are incorrect.

POSSIBLE CAUSES

CAN BUS CIRCUIT DTC PRESENT

INSTRUMENT CLUSTER DTCS PRESENT

OPEN CAN CIRCUITS AT INSTRUMENT CLUSTER

INSTRUMENT CLUSTER

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 Ignition on, engine not running.

With the DRBIIIt, read Transmission DTCs.

NOTE: If the DTC, CAN BUS CIRCUIT, is present, perform diagnostics on

that symptom first.

Is the DTC, CAN BUS CIRCUIT, present?All

Ye s!Refer to the Transmission category and perform the appropriate

symptom.

No!Go To 3

70

TRANSMISSION - NAG1

Page 2236 of 2305

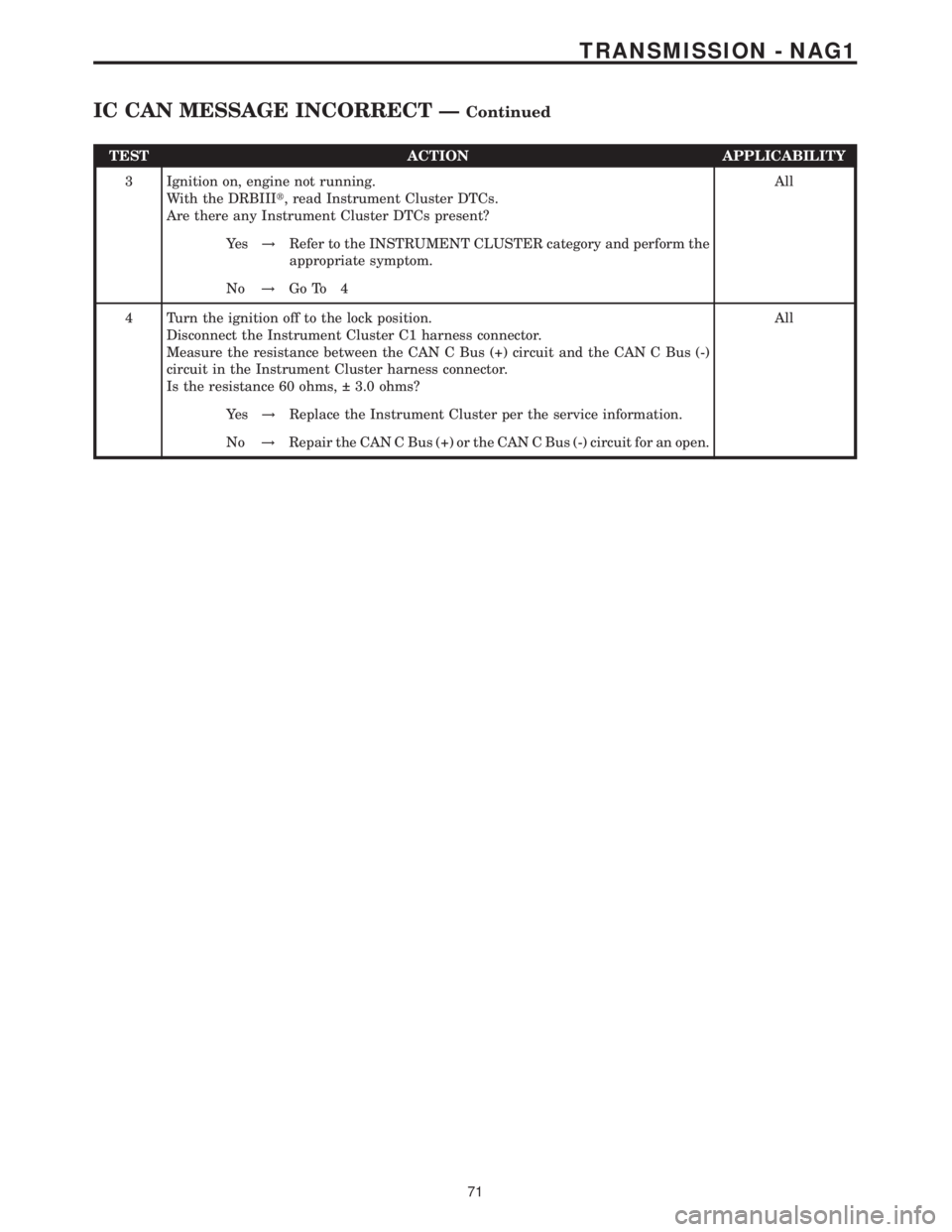

TEST ACTION APPLICABILITY

3 Ignition on, engine not running.

With the DRBIIIt, read Instrument Cluster DTCs.

Are there any Instrument Cluster DTCs present?All

Ye s!Refer to the INSTRUMENT CLUSTER category and perform the

appropriate symptom.

No!Go To 4

4 Turn the ignition off to the lock position.

Disconnect the Instrument Cluster C1 harness connector.

Measure the resistance between the CAN C Bus (+) circuit and the CAN C Bus (-)

circuit in the Instrument Cluster harness connector.

Is the resistance 60 ohms, 3.0 ohms?All

Ye s!Replace the Instrument Cluster per the service information.

No!Repair the CAN C Bus (+) or the CAN C Bus (-) circuit for an open.

71

TRANSMISSION - NAG1

IC CAN MESSAGE INCORRECT ÐContinued

Page 2237 of 2305

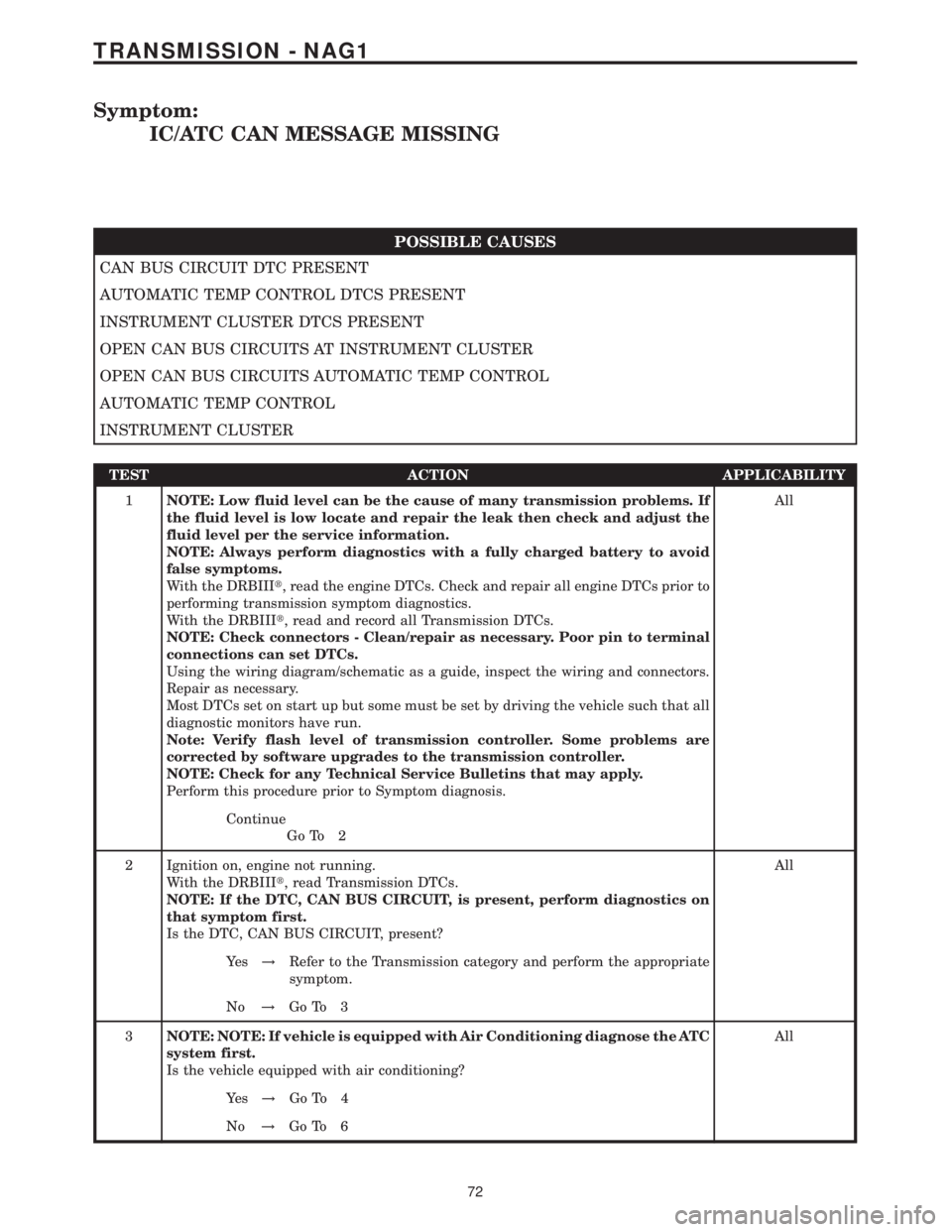

Symptom:

IC/ATC CAN MESSAGE MISSING

POSSIBLE CAUSES

CAN BUS CIRCUIT DTC PRESENT

AUTOMATIC TEMP CONTROL DTCS PRESENT

INSTRUMENT CLUSTER DTCS PRESENT

OPEN CAN BUS CIRCUITS AT INSTRUMENT CLUSTER

OPEN CAN BUS CIRCUITS AUTOMATIC TEMP CONTROL

AUTOMATIC TEMP CONTROL

INSTRUMENT CLUSTER

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 Ignition on, engine not running.

With the DRBIIIt, read Transmission DTCs.

NOTE: If the DTC, CAN BUS CIRCUIT, is present, perform diagnostics on

that symptom first.

Is the DTC, CAN BUS CIRCUIT, present?All

Ye s!Refer to the Transmission category and perform the appropriate

symptom.

No!Go To 3

3NOTE: NOTE: If vehicle is equipped with Air Conditioning diagnose the ATC

system first.

Is the vehicle equipped with air conditioning?All

Ye s!Go To 4

No!Go To 6

72

TRANSMISSION - NAG1

Page 2238 of 2305

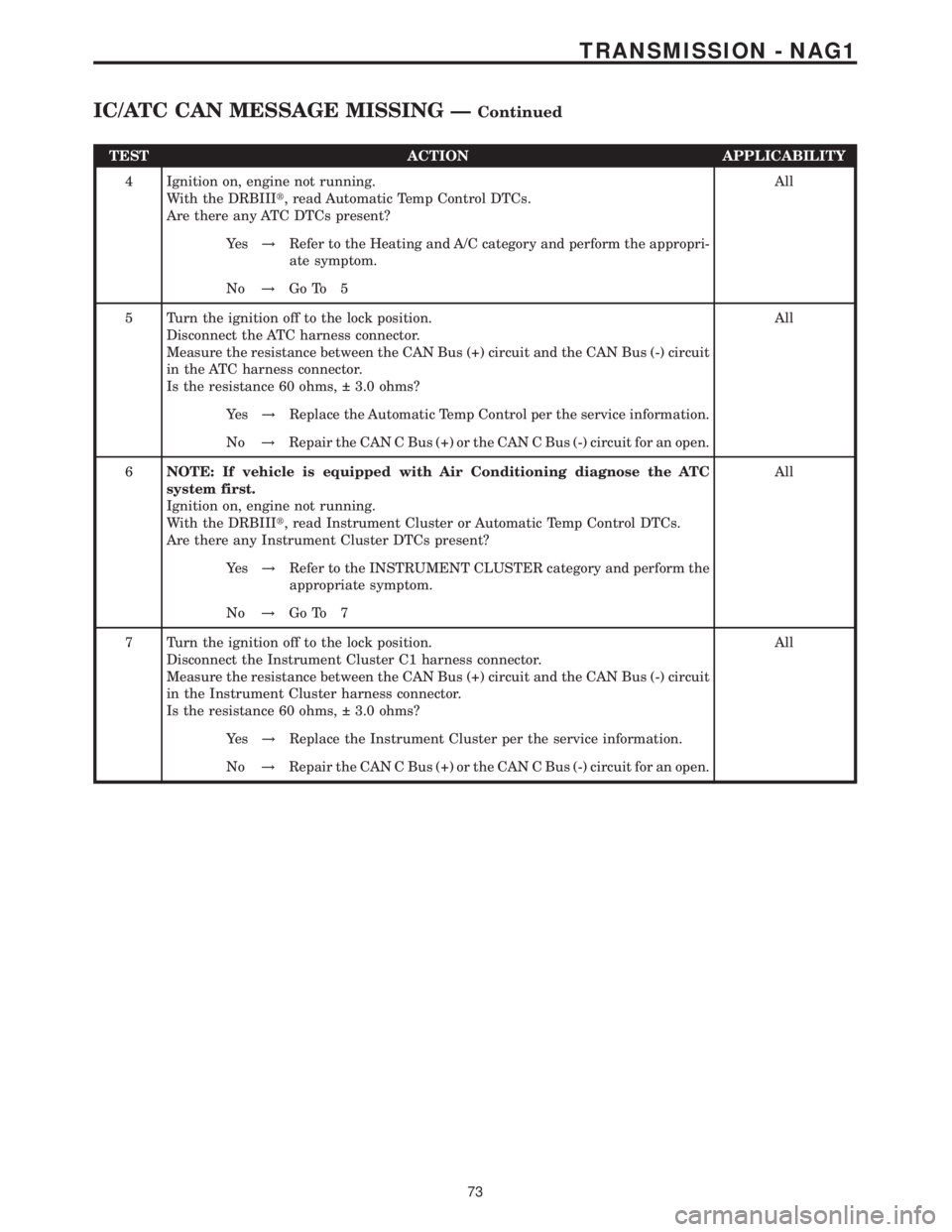

TEST ACTION APPLICABILITY

4 Ignition on, engine not running.

With the DRBIIIt, read Automatic Temp Control DTCs.

Are there any ATC DTCs present?All

Ye s!Refer to the Heating and A/C category and perform the appropri-

ate symptom.

No!Go To 5

5 Turn the ignition off to the lock position.

Disconnect the ATC harness connector.

Measure the resistance between the CAN Bus (+) circuit and the CAN Bus (-) circuit

in the ATC harness connector.

Is the resistance 60 ohms, 3.0 ohms?All

Ye s!Replace the Automatic Temp Control per the service information.

No!Repair the CAN C Bus (+) or the CAN C Bus (-) circuit for an open.

6NOTE: If vehicle is equipped with Air Conditioning diagnose the ATC

system first.

Ignition on, engine not running.

With the DRBIIIt, read Instrument Cluster or Automatic Temp Control DTCs.

Are there any Instrument Cluster DTCs present?All

Ye s!Refer to the INSTRUMENT CLUSTER category and perform the

appropriate symptom.

No!Go To 7

7 Turn the ignition off to the lock position.

Disconnect the Instrument Cluster C1 harness connector.

Measure the resistance between the CAN Bus (+) circuit and the CAN Bus (-) circuit

in the Instrument Cluster harness connector.

Is the resistance 60 ohms, 3.0 ohms?All

Ye s!Replace the Instrument Cluster per the service information.

No!Repair the CAN C Bus (+) or the CAN C Bus (-) circuit for an open.

73

TRANSMISSION - NAG1

IC/ATC CAN MESSAGE MISSING ÐContinued

Page 2239 of 2305

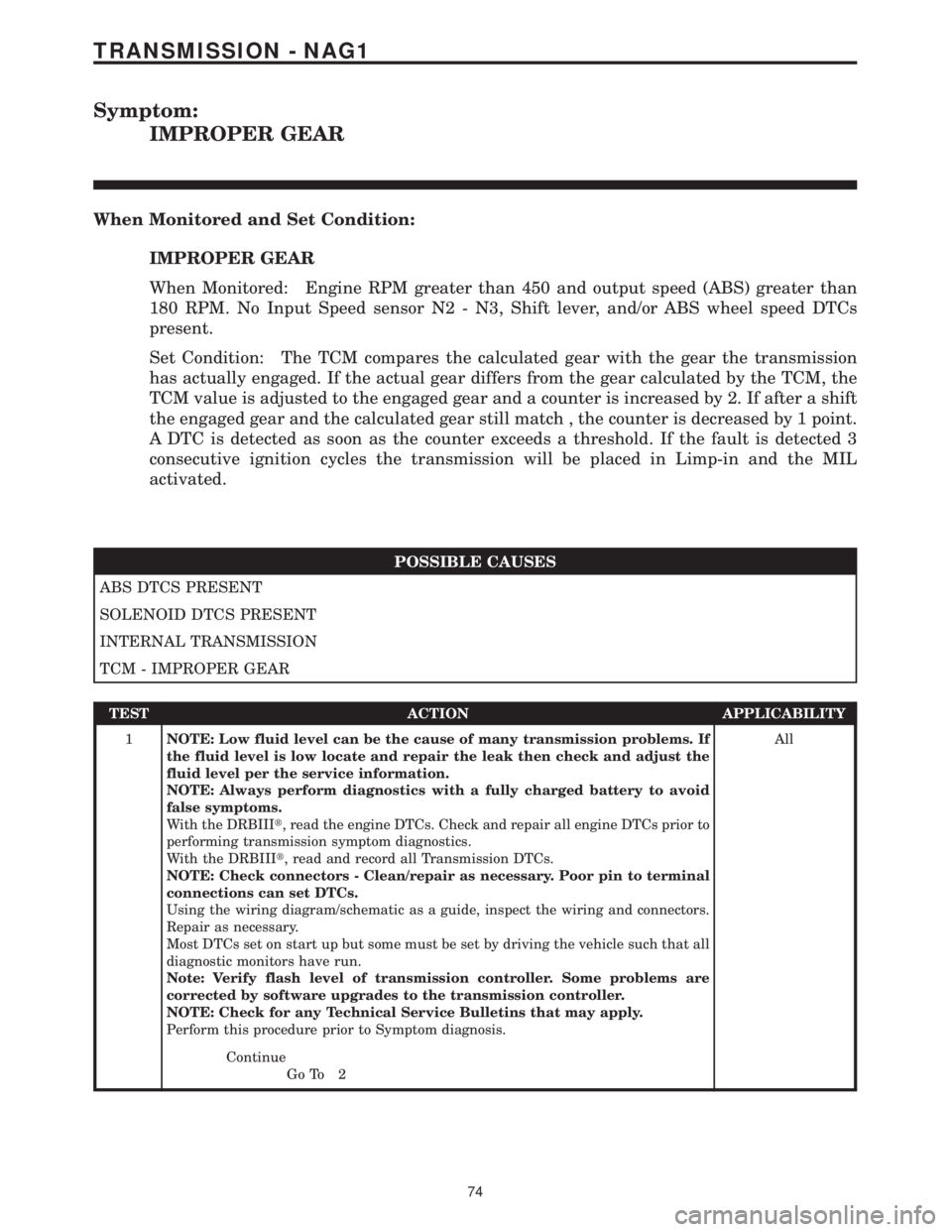

Symptom:

IMPROPER GEAR

When Monitored and Set Condition:

IMPROPER GEAR

When Monitored: Engine RPM greater than 450 and output speed (ABS) greater than

180 RPM. No Input Speed sensor N2 - N3, Shift lever, and/or ABS wheel speed DTCs

present.

Set Condition: The TCM compares the calculated gear with the gear the transmission

has actually engaged. If the actual gear differs from the gear calculated by the TCM, the

TCM value is adjusted to the engaged gear and a counter is increased by 2. If after a shift

the engaged gear and the calculated gear still match , the counter is decreased by 1 point.

A DTC is detected as soon as the counter exceeds a threshold. If the fault is detected 3

consecutive ignition cycles the transmission will be placed in Limp-in and the MIL

activated.

POSSIBLE CAUSES

ABS DTCS PRESENT

SOLENOID DTCS PRESENT

INTERNAL TRANSMISSION

TCM - IMPROPER GEAR

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTCs. Check and repair all engine DTCs prior to

performing transmission symptom diagnostics.

With the DRBIIIt, read and record all Transmission DTCs.

NOTE: Check connectors - Clean/repair as necessary. Poor pin to terminal

connections can set DTCs.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Most DTCs set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

Note: Verify flash level of transmission controller. Some problems are

corrected by software upgrades to the transmission controller.

NOTE: Check for any Technical Service Bulletins that may apply.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

74

TRANSMISSION - NAG1

Page 2240 of 2305

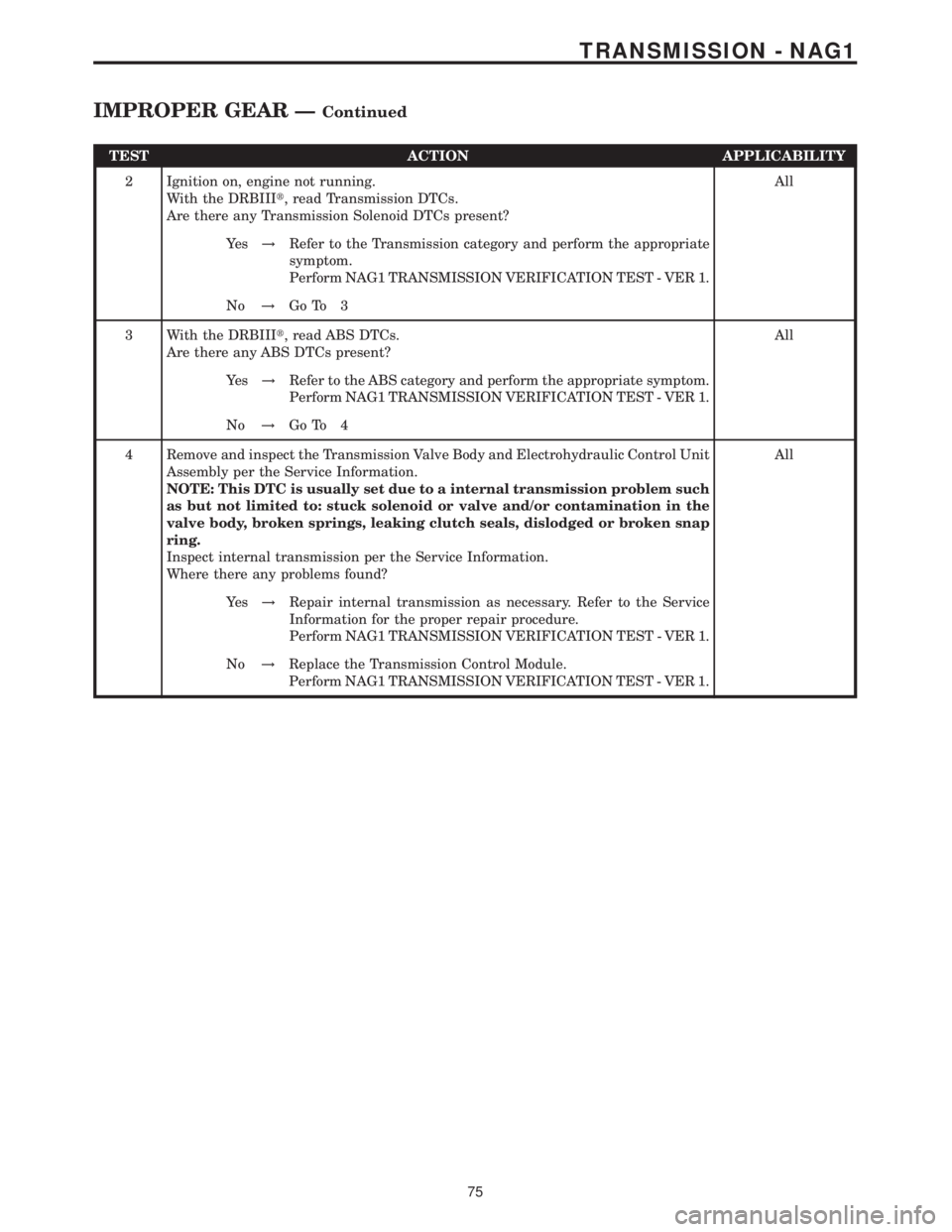

TEST ACTION APPLICABILITY

2 Ignition on, engine not running.

With the DRBIIIt, read Transmission DTCs.

Are there any Transmission Solenoid DTCs present?All

Ye s!Refer to the Transmission category and perform the appropriate

symptom.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 3

3 With the DRBIIIt, read ABS DTCs.

Are there any ABS DTCs present?All

Ye s!Refer to the ABS category and perform the appropriate symptom.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Go To 4

4 Remove and inspect the Transmission Valve Body and Electrohydraulic Control Unit

Assembly per the Service Information.

NOTE: This DTC is usually set due to a internal transmission problem such

as but not limited to: stuck solenoid or valve and/or contamination in the

valve body, broken springs, leaking clutch seals, dislodged or broken snap

ring.

Inspect internal transmission per the Service Information.

Where there any problems found?All

Ye s!Repair internal transmission as necessary. Refer to the Service

Information for the proper repair procedure.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

No!Replace the Transmission Control Module.

Perform NAG1 TRANSMISSION VERIFICATION TEST - VER 1.

75

TRANSMISSION - NAG1

IMPROPER GEAR ÐContinued