MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1071 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) -SRS Diagnosis Unit (SDU) 52B-611330721

13R072i

ht-----

SERVICE POINTS OF INSTALLATION

PRE-INSTALLATION INSPECTIONBefore SRS diagnosis unit is installed in the vehicle, it must be

visually inspected. If a dent, crack or other deformation is

detected, discard the SRS diagnosis unit and replace it with a

new one that passes the visual inspection.

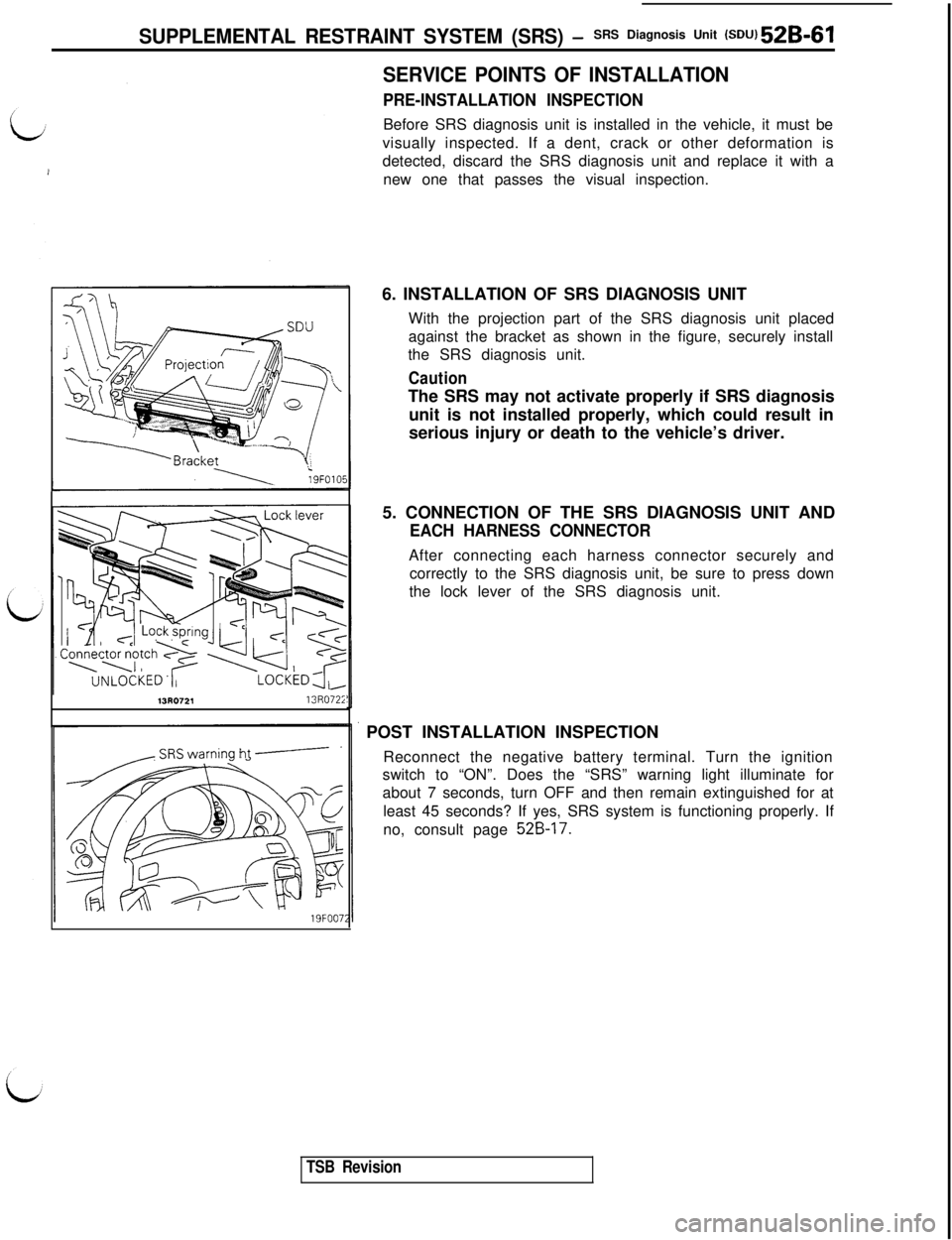

6. INSTALLATION OF SRS DIAGNOSIS UNIT

With the projection part of the SRS diagnosis unit placed

against the bracket as shown in the figure, securely install

the SRS diagnosis unit.

CautionThe SRS may not activate properly if SRS diagnosis

unit is not installed properly, which could result in

serious injury or death to the vehicle’s driver.

5. CONNECTION OF THE SRS DIAGNOSIS UNIT AND

EACH HARNESS CONNECTORAfter connecting each harness connector securely and

correctly to the SRS diagnosis unit, be sure to press down

the lock lever of the SRS diagnosis unit.

POST INSTALLATION INSPECTION

Reconnect the negative battery terminal. Turn the ignition

switch to “ON”. Does the “SRS” warning light illuminate for

about 7 seconds, turn OFF and then remain extinguished for at

least 45 seconds? If yes, SRS system is functioning properly. If

no, consult page

52B-17.

TSB Revision

Page 1072 of 1146

52B-62Air Bag ModuleSUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock Spring

AIR BAG MODULE AND CLOCK SPRINGM52PDCA

Caution1. Never attempt to disassemble or repair the

air bag module or clock spring.

If faulty, replace it.

2. Do not drop the air bag module or clock

spring or allow contact with water, grease or

oil.Replace it if a dent, crack, deformation or

rust are detected.

3.The air bag module should be stored on a flat

surface and placed so that the pad surface isfacing upward.

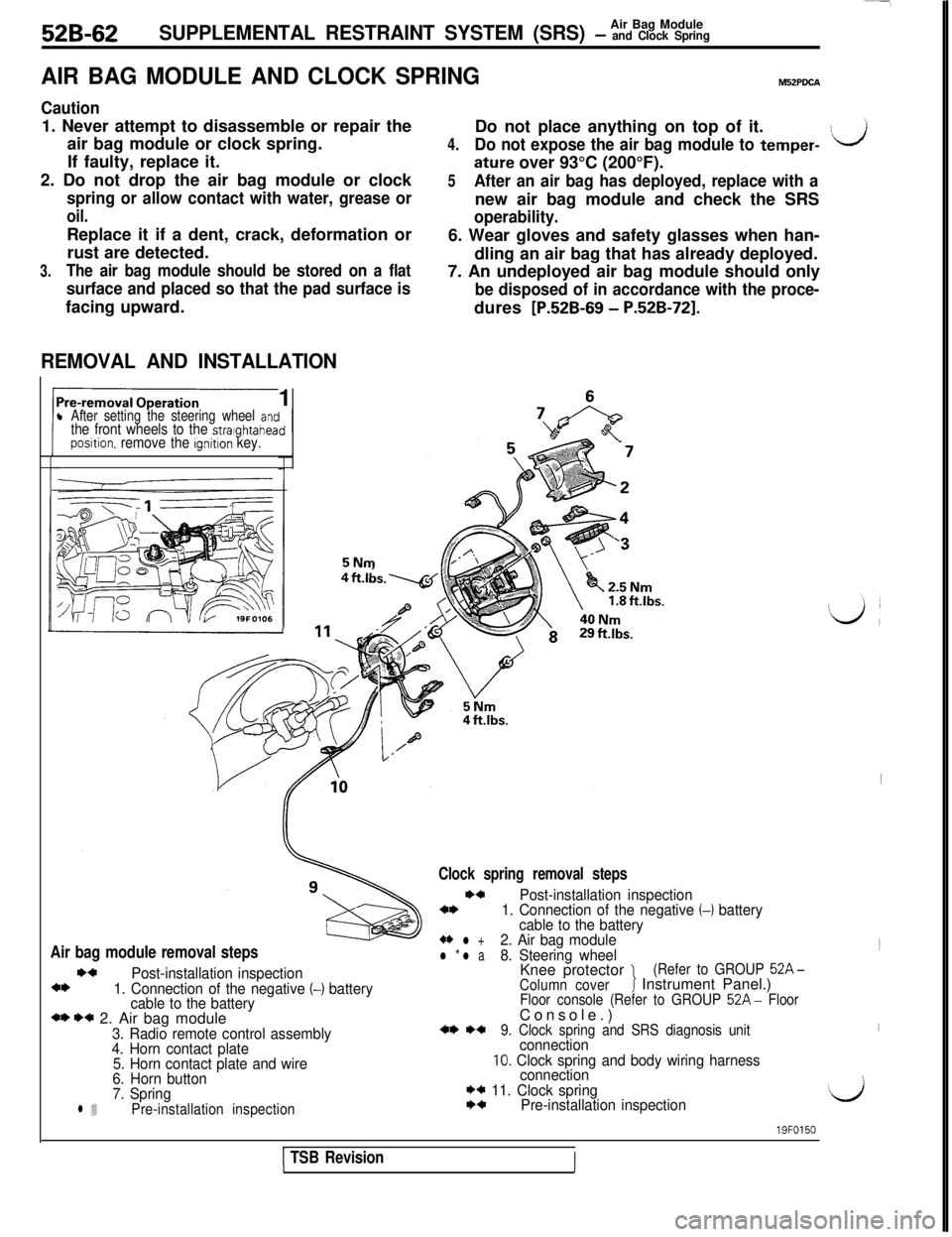

REMOVAL AND INSTALLATION1

l After setting the steering wheel antthe front wheels to the stralghtaheaposltion. remove the ignition key.5NmDo not place anything on top of it.

4.Do not expose the air bag module to temper-ILJ

ature over 93°C (200°F).

5After an air bag has deployed, replace with anew air bag module and check the SRS

operability.6. Wear gloves and safety glasses when han-

dling an air bag that has already deployed.

7. An undeployed air bag module should only

be disposed of in accordance with the proce-dures

[P.52B-69 - P.52B-721.

Air bag module removal stepsI)4

Post-installation inspection4*1. Connection of the negative (-1 battery

cable to the battery

*I) I)* 2. Air bag module3. Radio remote control assembly

4. Horn contact plate

5. Horn contact plate and wire

6. Horn button

7. Spring

l 4Pre-installation inspection

Clock spring removal steps

I)4Post-installation inspection4*1. Connection of the negative (-1 battery

cable to the battery

+* l +2. Air bag modulel * l a8. Steering wheelKnee protector 1(Refer to GROUP 52A-

Column coverJ Instrument Panel.)Floor console (Refer to GROUP 52A- FloorConsole.)

*I) *+9. Clock spring and SRS diagnosis unitconnection10. Clock spring and body wiring harness

connection

I)* 11. Clock springI)4Pre-installation inspection

I1

I

‘d

1 TSB Revision

19FO150

III

Page 1073 of 1146

Air Bag ModuleSUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock Spring526-6319FOlll

3

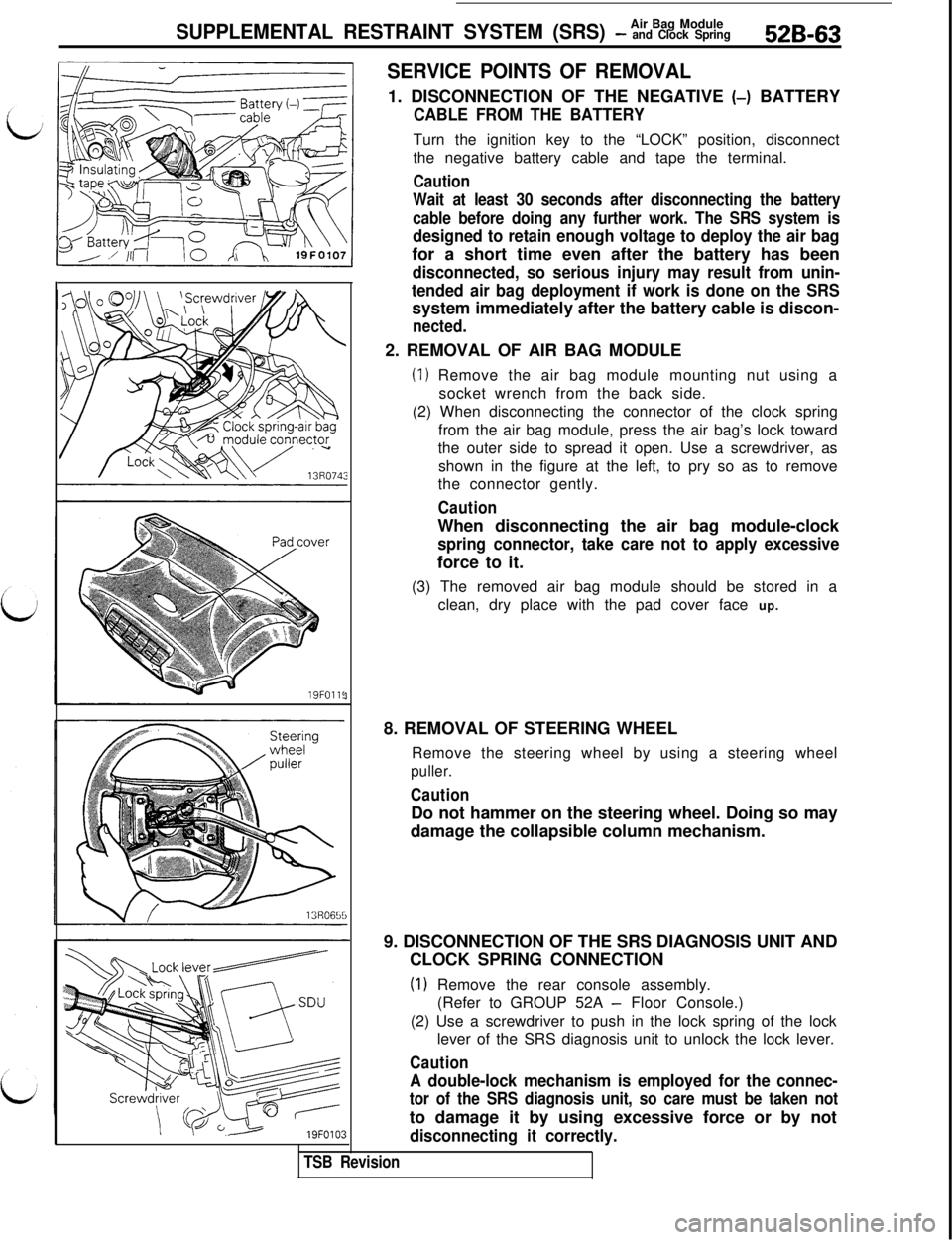

SERVICE POINTS OF REMOVAL1. DISCONNECTION OF THE NEGATIVE (-) BATTERY

CABLE FROM THE BATTERYTurn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

nected.2. REMOVAL OF AIR BAG MODULE

(1) Remove the air bag module mounting nut using a

socket wrench from the back side.

(2) When disconnecting the connector of the clock spring

from the air bag module, press the air bag’s lock toward

the outer side to spread it open. Use a screwdriver, as

shown in the figure at the left, to pry so as to remove

the connector gently.

CautionWhen disconnecting the air bag module-clock

spring connector, take care not to apply excessiveforce to it.

(3) The removed air bag module should be stored in a

clean, dry place with the pad cover face up.

8. REMOVAL OF STEERING WHEEL

Remove the steering wheel by using a steering wheel

puller.

CautionDo not hammer on the steering wheel. Doing so may

damage the collapsible column mechanism.

9. DISCONNECTION OF THE SRS DIAGNOSIS UNIT AND

CLOCK SPRING CONNECTION

(1) Remove the rear console assembly.

(Refer to GROUP 52A

- Floor Console.)

(2) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

Caution

A double-lock mechanism is employed for the connec-

tor of the SRS diagnosis unit, so care must be taken notto damage it by using excessive force or by not

disconnecting it correctly.

TSB Revision

Page 1074 of 1146

52B-64Air Eag Module

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock SpringConnector note

\\ I,

13R072113R0722

Air

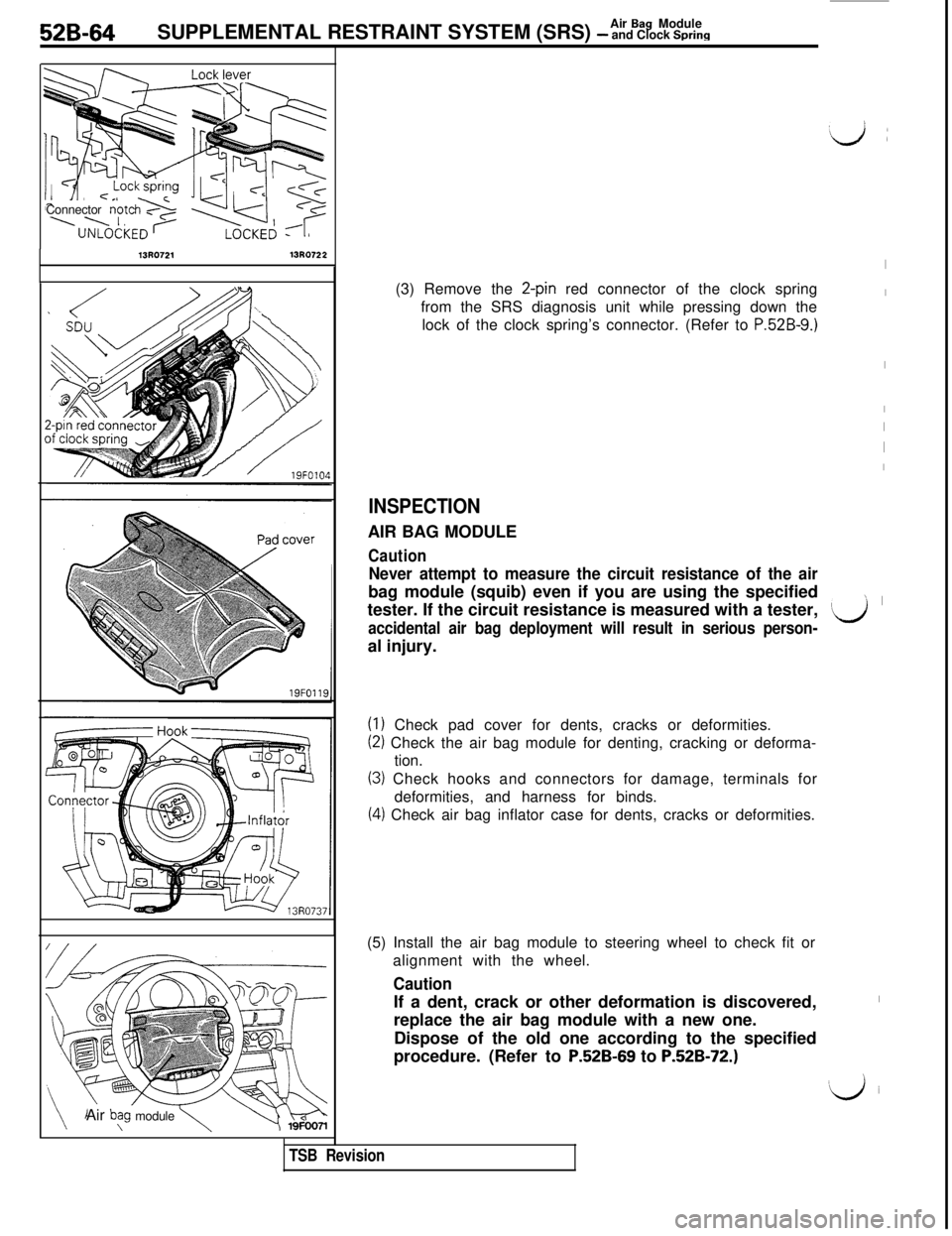

b\“g module \(3) Remove the

2-pin red connector of the clock spring

from the SRS diagnosis unit while pressing down the

lock of the clock spring’s connector. (Refer to

P.52B-9.)

INSPECTIONAIR BAG MODULE

Caution

Never attempt to measure the circuit resistance of the airbag module (squib) even if you are using the specified

tester. If the circuit resistance is measured with a tester,

accidental air bag deployment will result in serious person-al injury.

(1) Check pad cover for dents, cracks or deformities.

(2) Check the air bag module for denting, cracking or deforma-

tion.

(3) Check hooks and connectors for damage, terminals for

deformities, and harness for binds.

(4) Check air bag inflator case for dents, cracks or deformities.

TSB Revision(5) Install the air bag module to steering wheel to check fit or

alignment with the wheel.

CautionIf a dent, crack or other deformation is discovered,

replace the air bag module with a new one.

Dispose of the old one according to the specified

procedure. (Refer to

P52B-69 to P.52B-72.)

I

I

I

I

I

I

I

’ I

‘Lj

I

‘iJ i

Page 1075 of 1146

Air Bag ModuleSUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock Spring52B-65To SRS diagnosis unit

19FO101

i

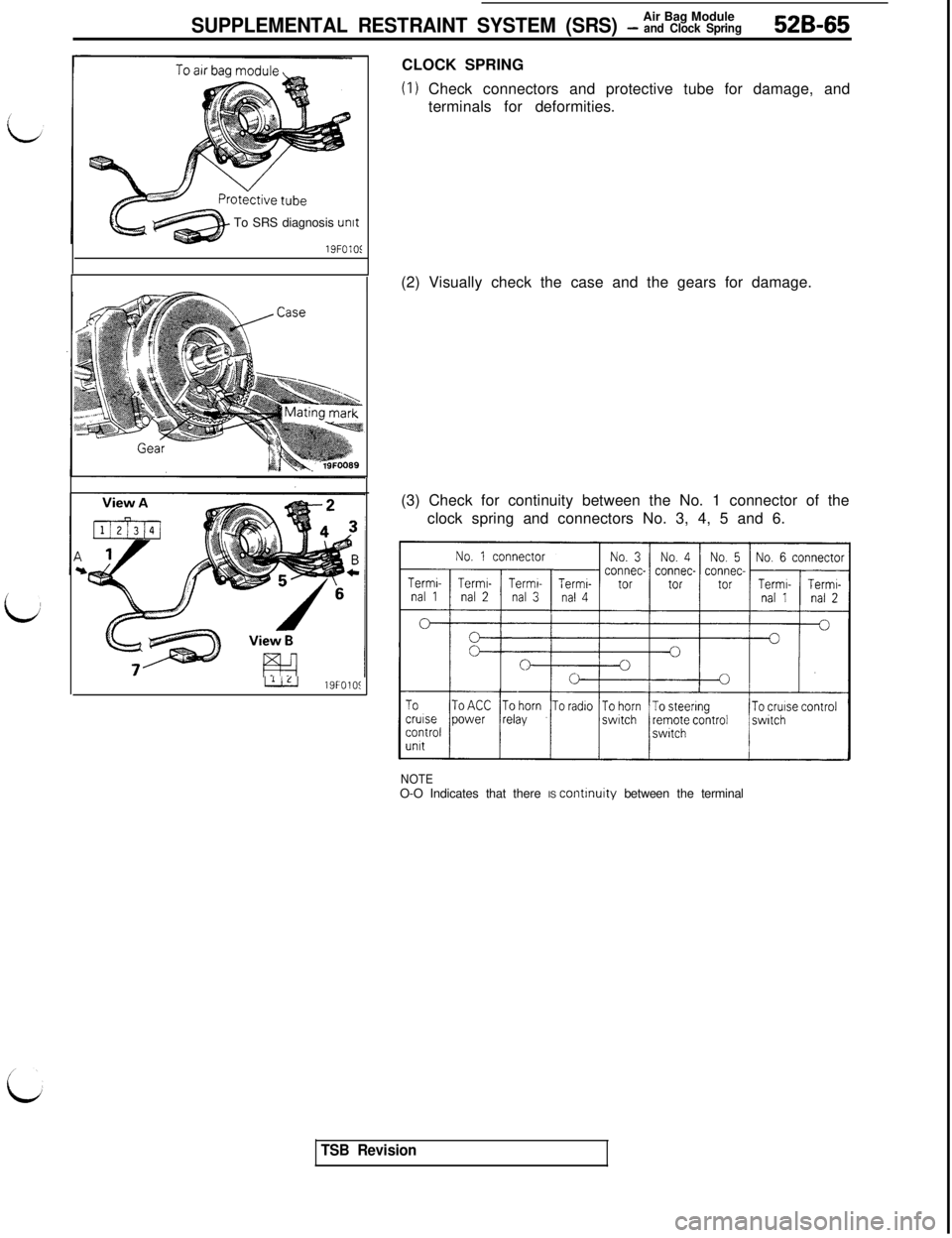

LJLJ19FOlOSCLOCK SPRING

(I) Check connectors and protective tube for damage, and

terminals for deformities.

(2) Visually check the case and the gears for damage.

(3) Check for continuity between the No. 1 connector of the

clock spring and connectors No. 3, 4, 5 and 6.

NOTEO-O Indicates that there IS continuity between the terminal

TSB Revision

Page 1076 of 1146

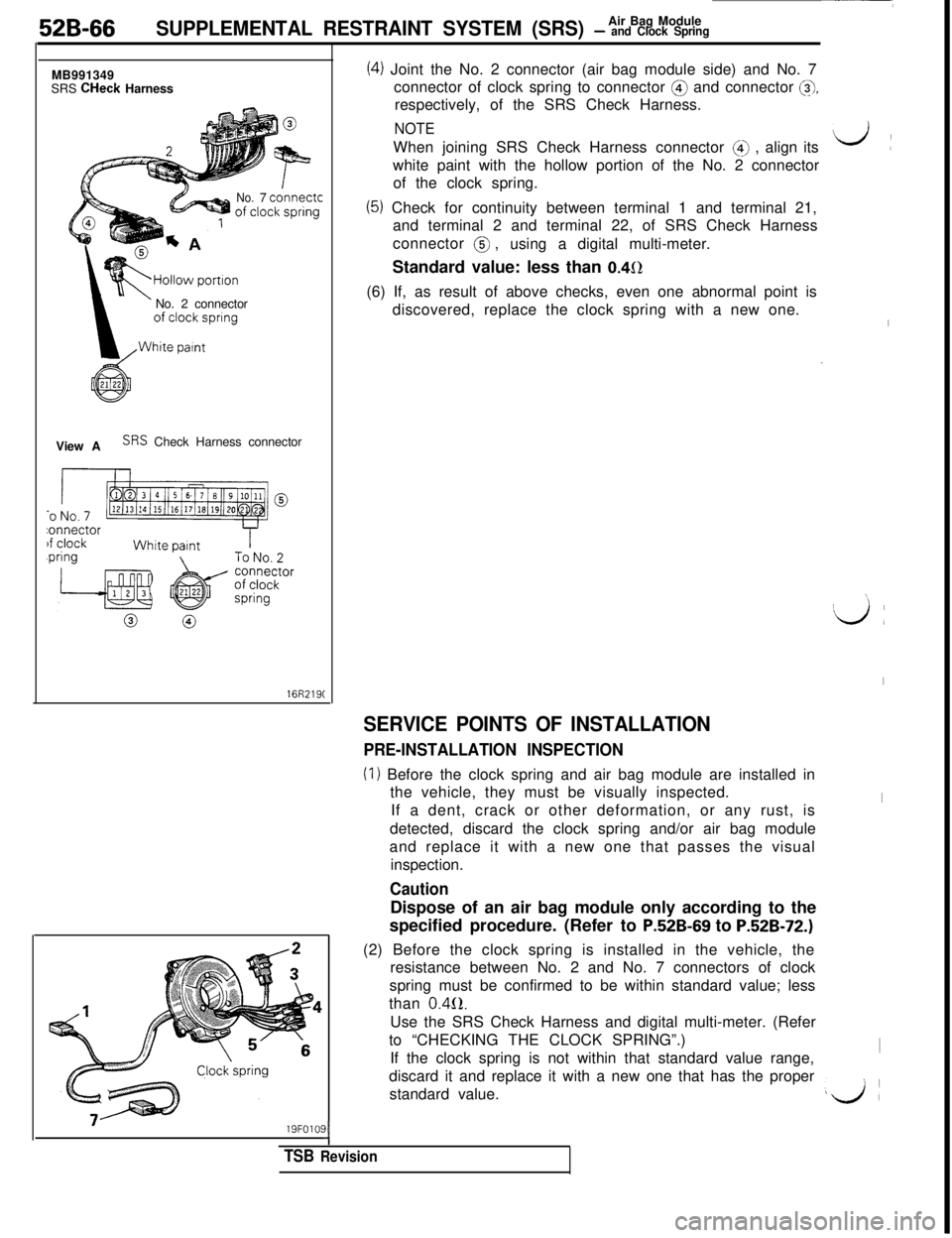

52B-66Air Bag ModuleSUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock SpringMB991349

SRS CHeck Harness

No.7 connectcNo. 2 connector

View A

SRS Check Harness connector

16R219C

19FOlO!I

TSB Revision

(4) Joint the No. 2 connector (air bag module side) and No. 7

connector of clock spring to connector @ and connector

@,respectively, of the SRS Check Harness.

NOTEWhen joining SRS Check Harness connector

(4) , align its

white paint with the hollow portion of the No. 2 connector

of the clock spring.

(5) Check for continuity between terminal 1 and terminal 21,

and terminal 2 and terminal 22, of SRS Check Harness

connector @ ,

using a digital multi-meter.

Standard value: less than

0.452(6) If, as result of above checks, even one abnormal point is

discovered, replace the clock spring with a new one.

SERVICE POINTS OF INSTALLATION

PRE-INSTALLATION INSPECTION

(I) Before the clock spring and air bag module are installed in

the vehicle, they must be visually inspected.

If a dent, crack or other deformation, or any rust, is

detected, discard the clock spring and/or air bag module

and replace it with a new one that passes the visual

inspection.

CautionDispose of an air bag module only according to the

specified procedure. (Refer to

P.52B-69 to P.52B-72.)(2) Before the clock spring is installed in the vehicle, the

resistance between No. 2 and No. 7 connectors of clock

spring must be confirmed to be within standard value; less

than

0.4(2.Use the SRS Check Harness and digital multi-meter. (Refer

to “CHECKING THE CLOCK SPRING”.)

If the clock spring is not within that standard value range,

discard it and replace it with a new one that has the proper

standard value.

d:

I

\

‘d :

I

I

I

LA

Page 1077 of 1146

Air Bag Module

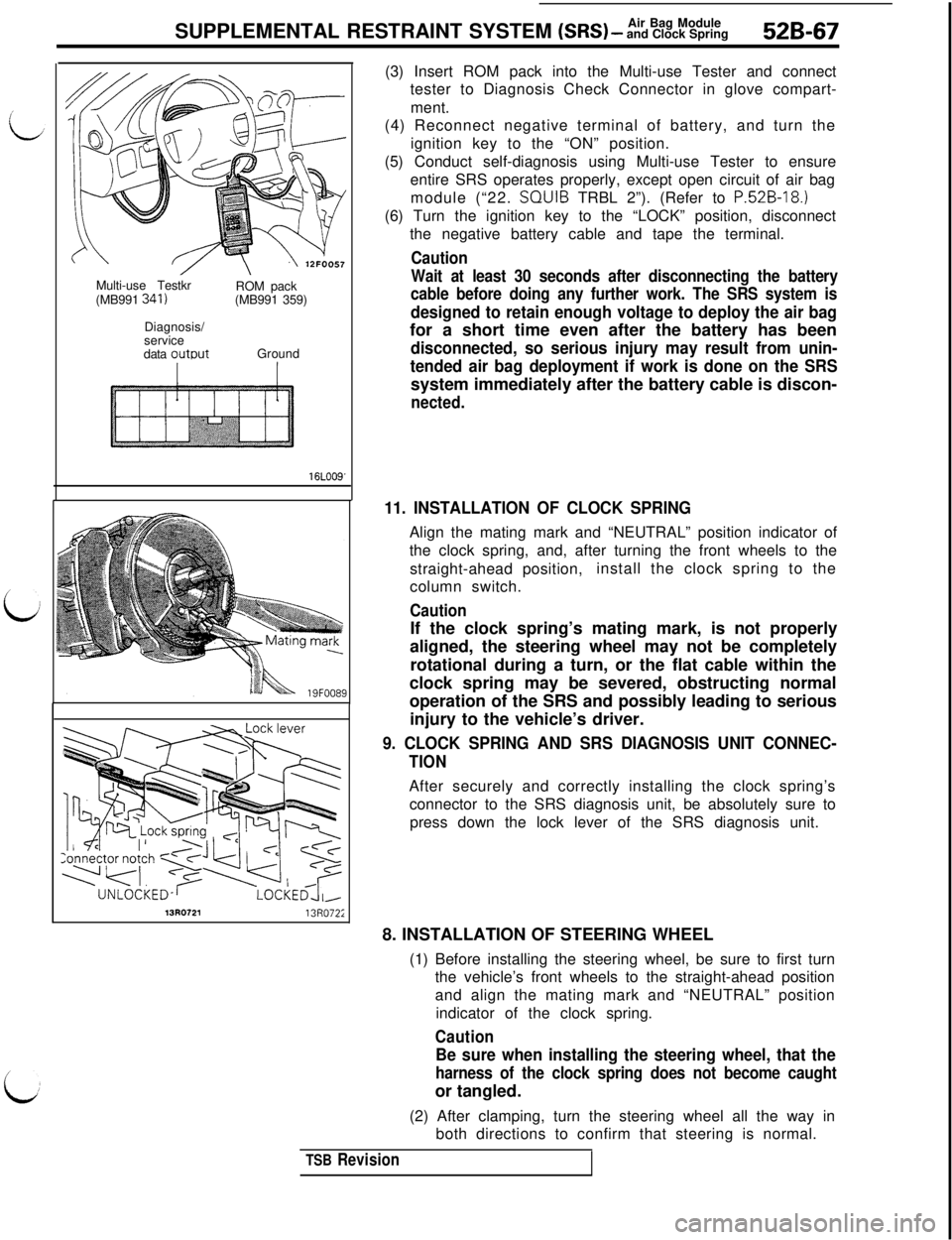

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - and Clock Spring52B-67Multi-use Testkr

ROM pack

(MB991 341)(MB991 359)

Diagnosis/

service

data

oumutGround

16LOO9'(3) Insert ROM pack into the Multi-use Tester and connect

tester to Diagnosis Check Connector in glove compart-

ment.

(4) Reconnect negative terminal of battery, and turn the

ignition key to the “ON” position.

(5) Conduct self-diagnosis using Multi-use Tester to ensure

entire SRS operates properly, except open circuit of air bag

module (“22. SQUIB TRBL 2”). (Refer to

P.52B-18.)(6) Turn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

nected.

11. INSTALLATION OF CLOCK SPRINGAlign the mating mark and “NEUTRAL” position indicator of

the clock spring, and, after turning the front wheels to the

straight-ahead position,install the clock spring to the

column switch.

CautionIf the clock spring’s mating mark, is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal

operation of the SRS and possibly leading to serious

injury to the vehicle’s driver.

9. CLOCK SPRING AND SRS DIAGNOSIS UNIT CONNEC-

TIONAfter securely and correctly installing the clock spring’s

connector to the SRS diagnosis unit, be absolutely sure to

press down the lock lever of the SRS diagnosis unit.

13R072113R072;8. INSTALLATION OF STEERING WHEEL

(1) Before installing the steering wheel, be sure to first turn

the vehicle’s front wheels to the straight-ahead position

and align the mating mark and “NEUTRAL” position

indicator of the clock spring.

Caution

Be sure when installing the steering wheel, that the

harness of the clock spring does not become caughtor tangled.

(2) After clamping, turn the steering wheel all the way in

both directions to confirm that steering is normal.

TSB Revision

Page 1078 of 1146

52B-68SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - %%%$kgSRS warning

light

/------ r--l

I

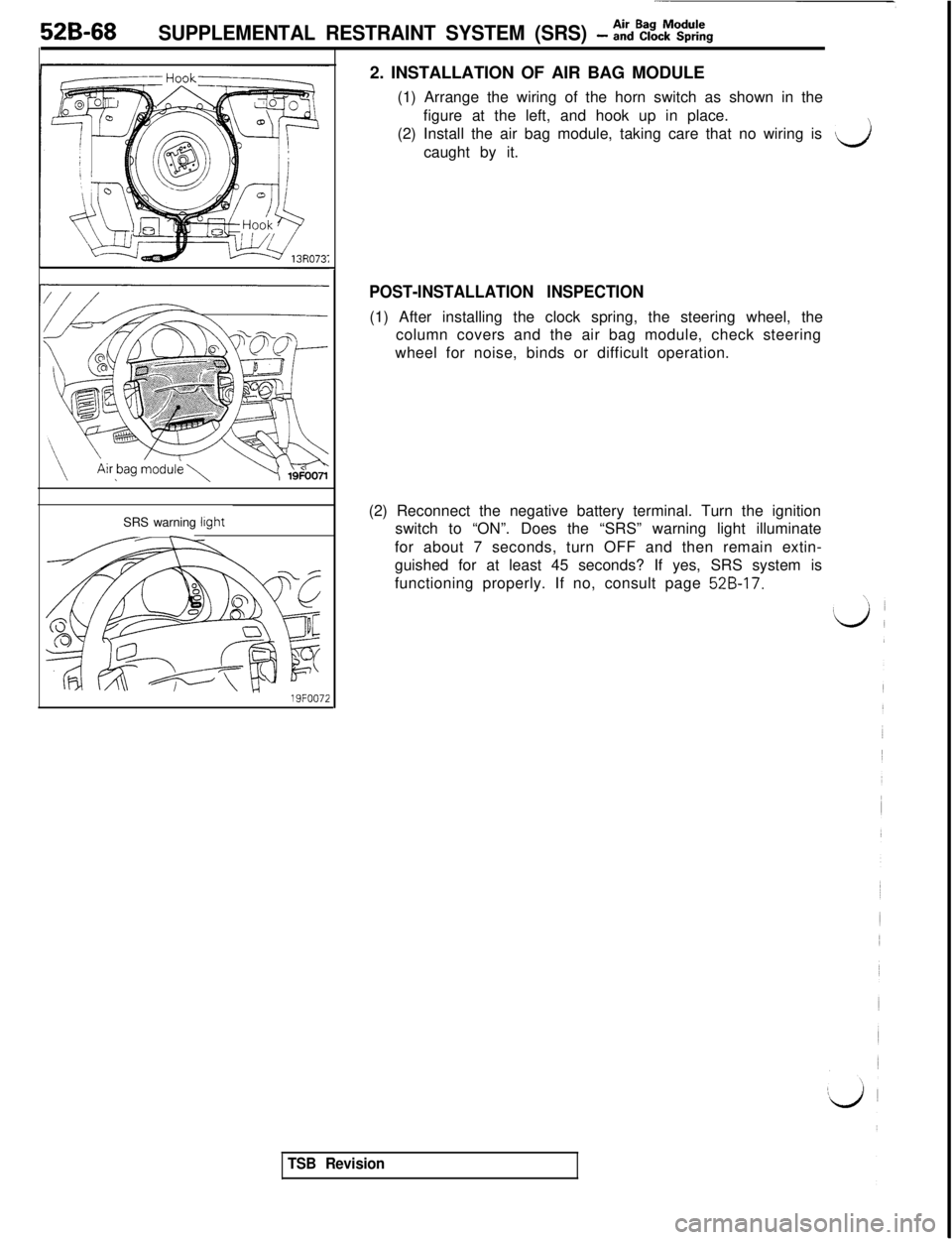

19FOO722. INSTALLATION OF AIR BAG MODULE

(1) Arrange the wiring of the horn switch as shown in the

figure at the left, and hook up in place.

(2) Install the air bag module, taking care that no wiring is

vicaught by it.

POST-INSTALLATION INSPECTION(1) After installing the clock spring, the steering wheel, the

column covers and the air bag module, check steering

wheel for noise, binds or difficult operation.

(2) Reconnect the negative battery terminal. Turn the ignition

switch to “ON”. Does the “SRS” warning light illuminate

for about 7 seconds, turn OFF and then remain extin-

guished for at least 45 seconds? If yes, SRS system is

functioning properly. If no, consult page

52B-17.

TSB Revision

Page 1079 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - ~&%,MprOodcUures 52B-69

AIR BAG MODULE DISPOSAL PROCEDURESM52PmA

LBefore either disposing of a vehicle equipped withmodule, be sure to first follow the procedures

an air bag, or prior to disposing of the air bagdescribed below to and deploy the air bag.

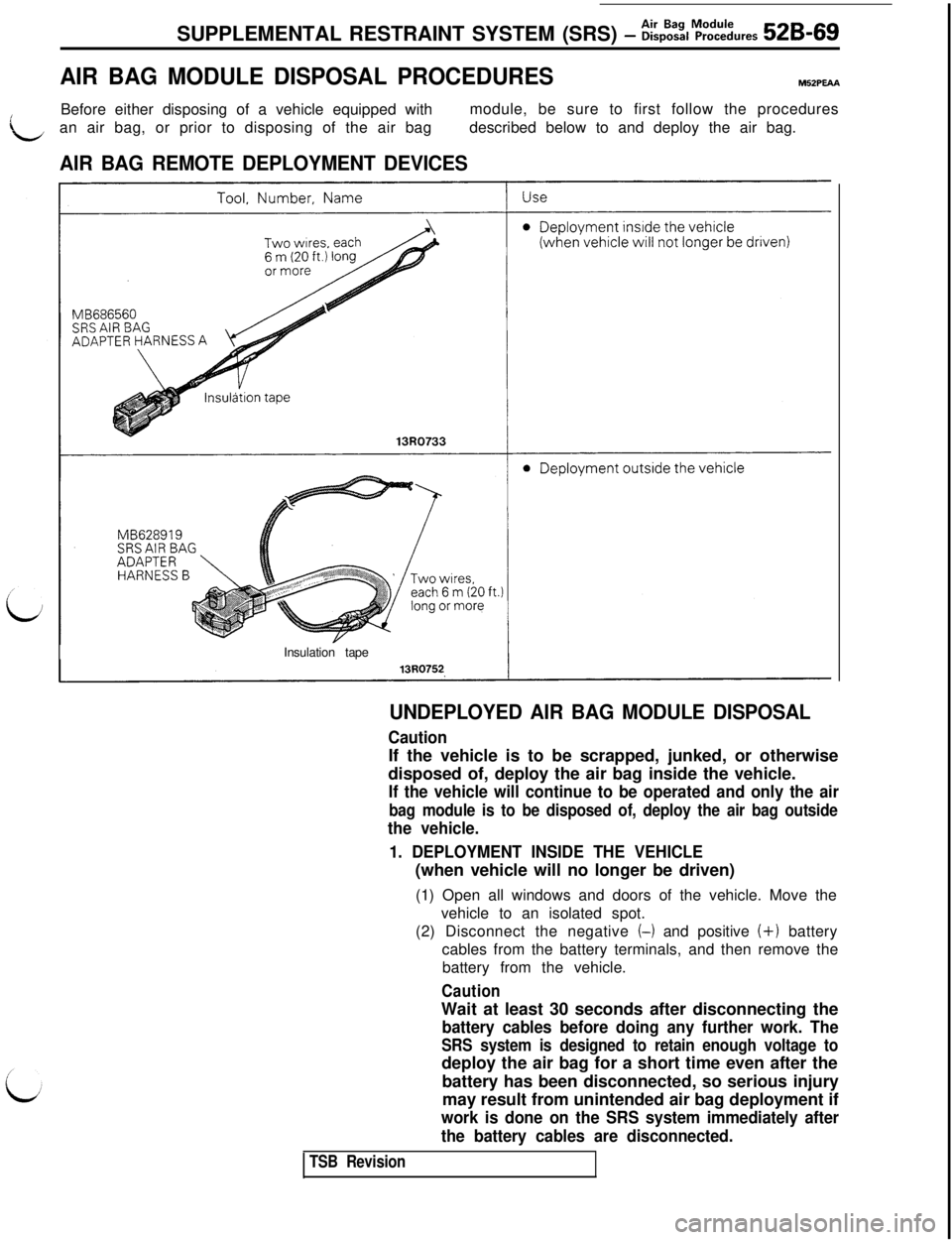

AIR BAG REMOTE DEPLOYMENT DEVICESInsulation tape

UNDEPLOYED AIR BAG MODULE DISPOSAL

CautionIf the vehicle is to be scrapped, junked, or otherwise

disposed of, deploy the air bag inside the vehicle.

If the vehicle will continue to be operated and only the air

bag module is to be disposed of, deploy the air bag outside

the vehicle.

1. DEPLOYMENT INSIDE THE VEHICLE(when vehicle will no longer be driven)

(1) Open all windows and doors of the vehicle. Move the

vehicle to an isolated spot.

(2) Disconnect the negative

(4 and positive (i-1 battery

cables from the battery terminals, and then remove the

battery from the vehicle.

CautionWait at least 30 seconds after disconnecting the

battery cables before doing any further work. The

SRS system is designed to retain enough voltage todeploy the air bag for a short time even after the

battery has been disconnected, so serious injury

may result from unintended air bag deployment if

work is done on the SRS system immediately after

the battery cables are disconnected.

TSB Revision

Page 1080 of 1146

52B-70Air Bag ModuleSUPPLEMENTAL RESTRAINT SYSTEM (SRS) - Disposal Procedures

13R072113R0722

I

lnsulatlon

Clock\spring

connector

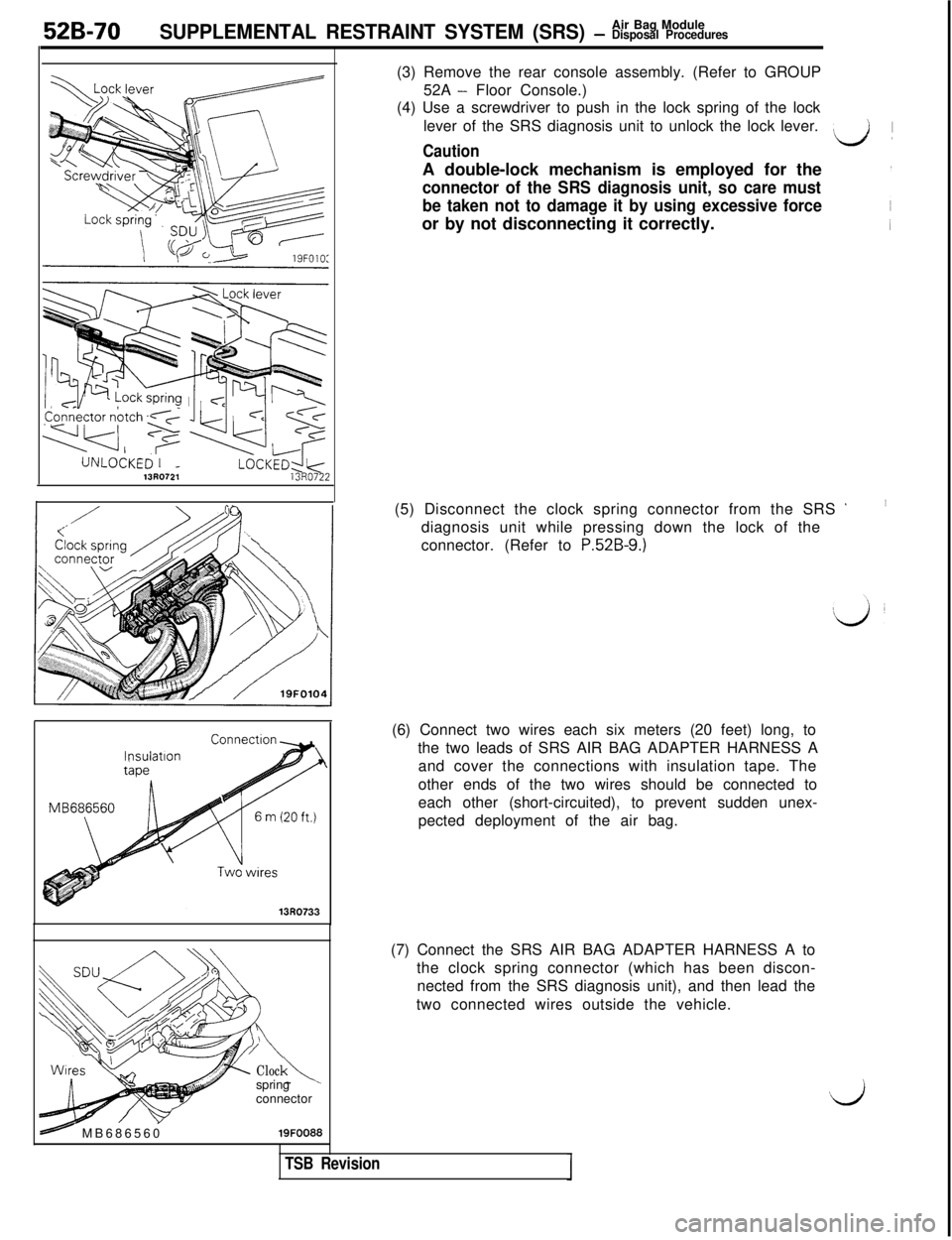

s+- MB68656019FOO88(3) Remove the rear console assembly. (Refer to GROUP

52A

- Floor Console.)

(4) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

Caution

L/! )A double-lock mechanism is employed for the

connector of the SRS diagnosis unit, so care must

be taken not to damage it by using excessive forceor by not disconnecting it correctly.

(5) Disconnect the clock spring connector from the SRS

’diagnosis unit while pressing down the lock of the

connector. (Refer to

P.52B-9.)(6) Connect two wires each six meters (20 feet) long, to

the two leads of SRS AIR BAG ADAPTER HARNESS A

and cover the connections with insulation tape. The

other ends of the two wires should be connected to

each other (short-circuited), to prevent sudden unex-

pected deployment of the air bag.

(7) Connect the SRS AIR BAG ADAPTER HARNESS A to

the clock spring connector (which has been discon-

nected from the SRS diagnosis unit), and then lead the

two connected wires outside the vehicle.

‘d

TSB Revision