MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 501 of 1146

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-49

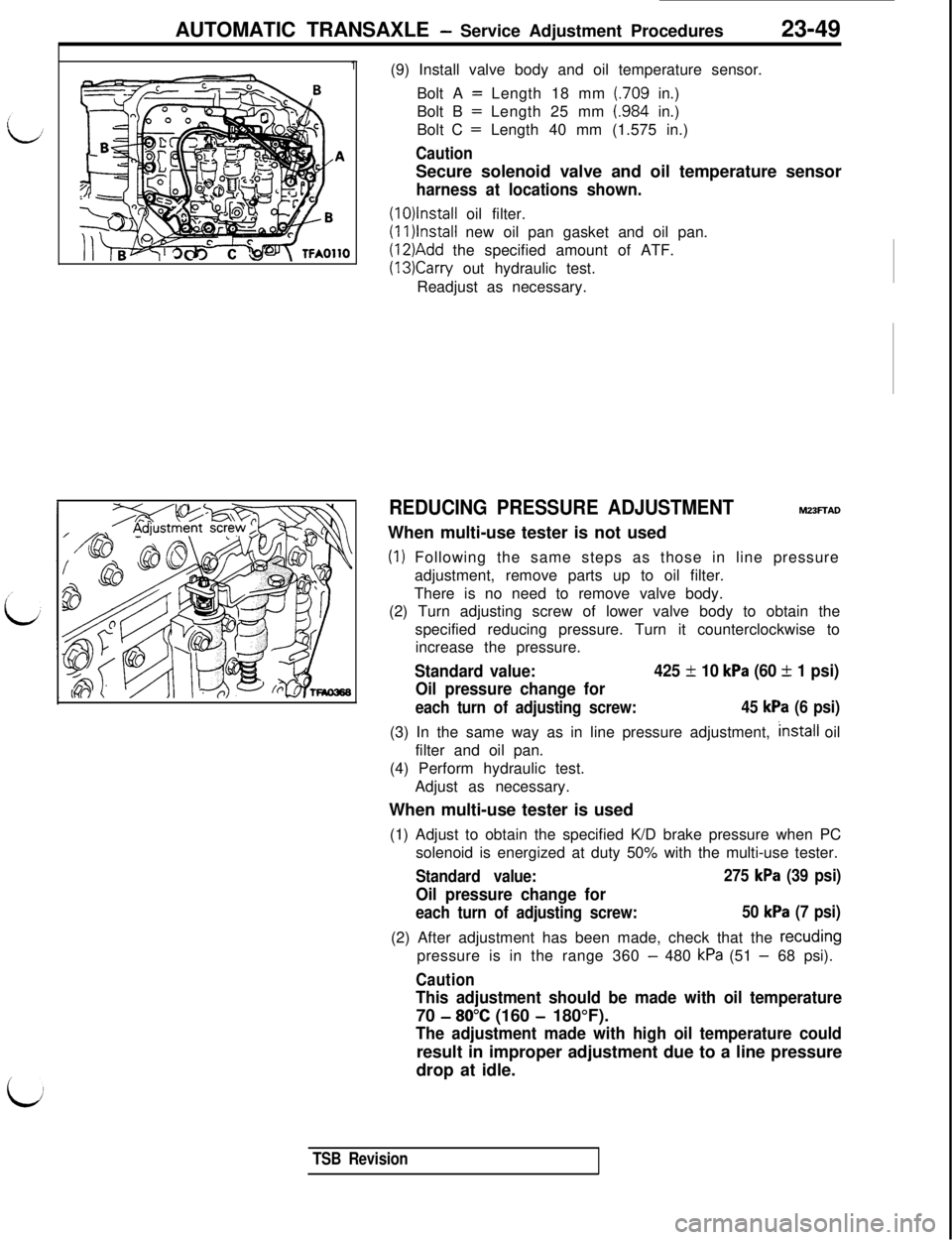

1(9) Install valve body and oil temperature sensor.

Bolt A

= Length 18 mm (.709 in.)

Bolt B

= Length 25 mm (.984 in.)

Bolt C

= Length 40 mm (1.575 in.)

CautionSecure solenoid valve and oil temperature sensor

harness at locations shown.

(1O)lnstall oil filter.(1l)lnstall new oil pan gasket and oil pan.

(12)Add the specified amount of ATF.

(13)Carry out hydraulic test.

Readjust as necessary.

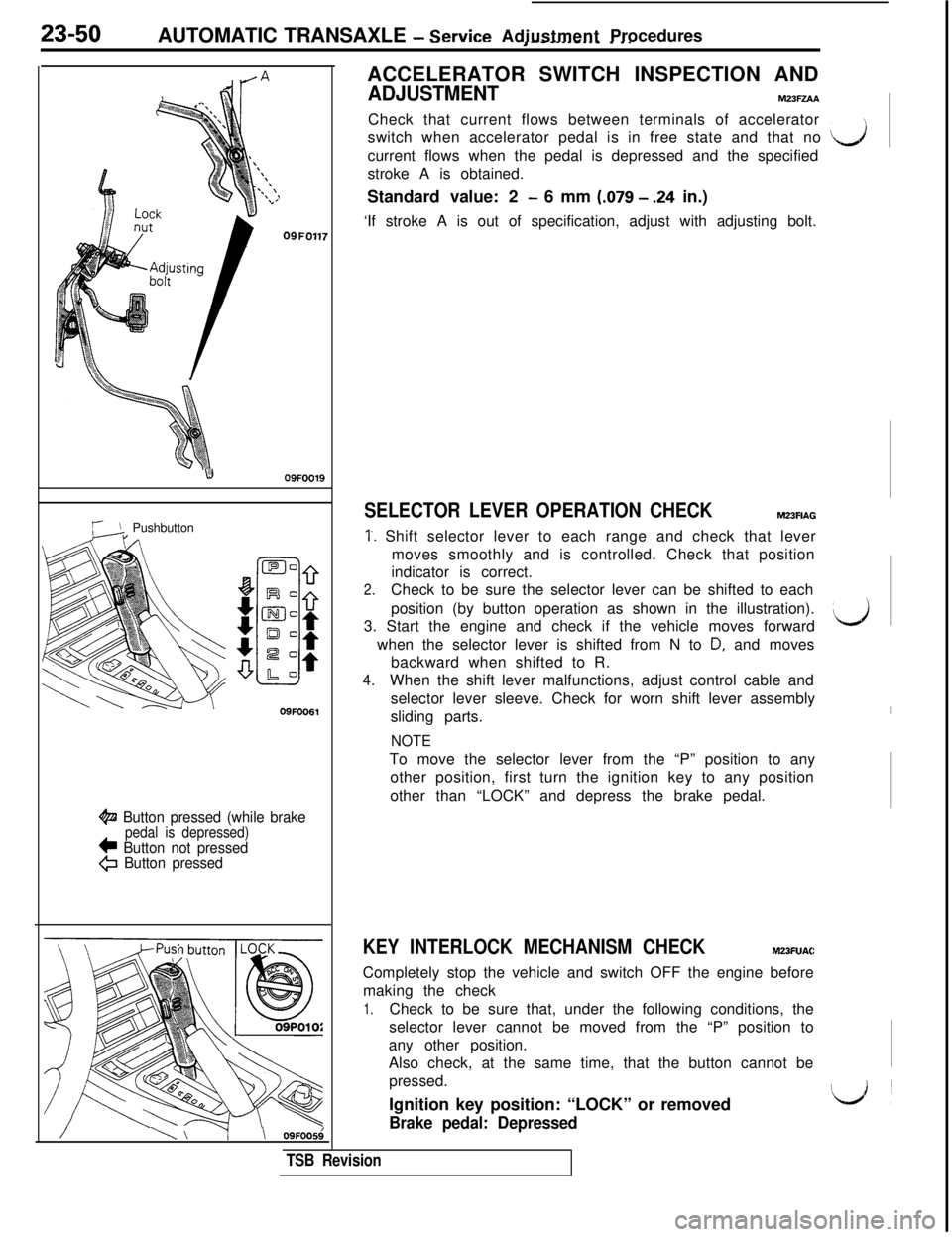

REDUCING PRESSURE ADJUSTMENTh323FfADWhen multi-use tester is not used

(1) Following the same steps as those in line pressure

adjustment, remove parts up to oil filter.

There is no need to remove valve body.

(2) Turn adjusting screw of lower valve body to obtain the

specified reducing pressure. Turn it counterclockwise to

increase the pressure.

Standard value:425 f 10 kPa (60 f 1 psi)

Oil pressure change for

each turn of adjusting screw:45 kPa (6 psi)(3) In the same way as in line pressure adjustment,

/nstall oil

filter and oil pan.

(4) Perform hydraulic test.

Adjust as necessary.

When multi-use tester is used

(1) Adjust to obtain the specified K/D brake pressure when PC

solenoid is energized at duty 50% with the multi-use tester.

Standard value:275 kPa (39 psi)

Oil pressure change for

each turn of adjusting screw:50 kPa (7 psi)(2) After adjustment has been made, check that the recuding

pressure is in the range 360

- 480 kPa (51 - 68 psi).

Caution

This adjustment should be made with oil temperature70

- 80°C (160 - 180°F).

The adjustment made with high oil temperature couldresult in improper adjustment due to a line pressure

drop at idle.

TSB Revision

Page 502 of 1146

23-50AUTOMATIC TRANSAXLE - service AdiustmentProcedures

09FO117

m09FOO19

L Pushbuttonv09FOO61

@ Button pressed (while brakepedal is depressed)c Button not pressed@ Button pressed

/\ \\ OSFODdACCELERATOR SWITCH INSPECTION AND

ADJUSTMENTM23FZAACheck that current flows between terminals of accelerator

switch when accelerator pedal is in free state and that no

dcurrent flows when the pedal is depressed and the specified

stroke A is obtained.

Standard value: 2

- 6 mm (.079 - .24 in.)

‘If stroke A is out of specification, adjust with adjusting bolt.

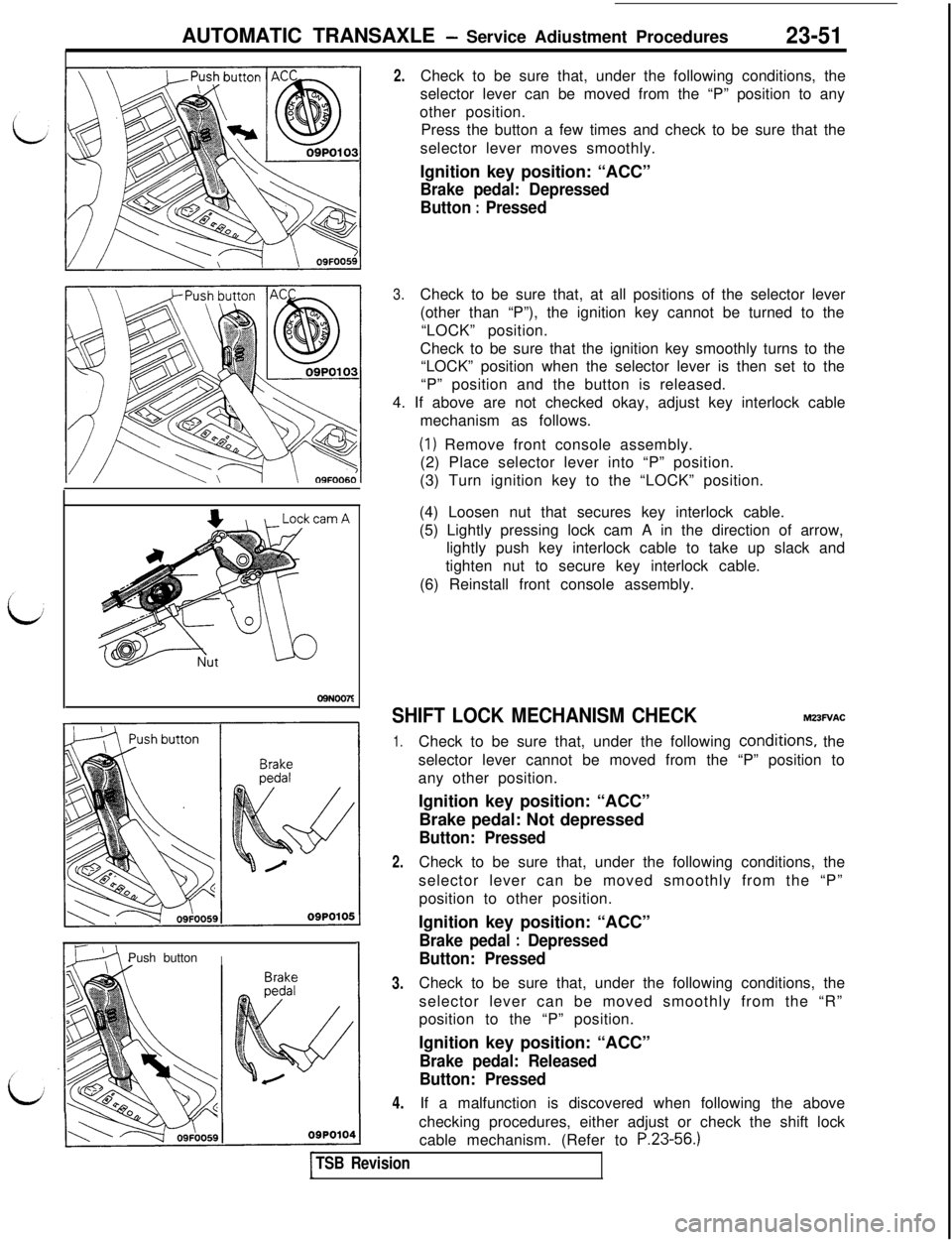

SELECTOR LEVER OPERATION CHECKM23FIAG

1.. Shift selector lever to each range and check that lever

moves smoothly and is controlled. Check that position

indicator is correct.

2.Check to be sure the selector lever can be shifted to each

position (by button operation as shown in the illustration).

3. Start the engine and check if the vehicle moves forward

dwhen the selector lever is shifted from N to

D, and moves

backward when shifted to R.

4.When the shift lever malfunctions, adjust control cable and

selector lever sleeve. Check for worn shift lever assembly

sliding parts.

I

NOTETo move the selector lever from the “P” position to any

other position, first turn the ignition key to any position

other than “LOCK” and depress the brake pedal.

KEY INTERLOCK MECHANISM CHECKM23FlJACCompletely stop the vehicle and switch OFF the engine before

making the check

1.Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P” position to

any other position.

Also check, at the same time, that the button cannot be

pressed.

Ignition key position: “LOCK” or removed

Brake pedal: Depressed

TSB Revision

Page 503 of 1146

AUTOMATIC TRANSAXLE - Service Adiustment Procedures23-51

D9N007SPush button

II

2.Check to be sure that, under the following conditions, the

selector lever can be moved from the “P” position to any

other position.

Press the button a few times and check to be sure that the

selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal: Depressed

Button

: Pressed

3.Check to be sure that, at all positions of the selector lever

(other than “P”), the ignition key cannot be turned to the

“LOCK” position.

Check to be sure that the ignition key smoothly turns to the

“LOCK” position when the selector lever is then set to the

“P” position and the button is released.

4. If above are not checked okay, adjust key interlock cable

mechanism as follows.

(1) Remove front console assembly.

(2) Place selector lever into “P” position.

(3) Turn ignition key to the “LOCK” position.

(4) Loosen nut that secures key interlock cable.

(5) Lightly pressing lock cam A in the direction of arrow,

lightly push key interlock cable to take up slack and

tighten nut to secure key interlock cable.

(6) Reinstall front console assembly.

SHIFT LOCK MECHANISM CHECKMZ3FVAC

1.

2.

3.

4.Check to be sure that, under the following

condi,tions, the

selector lever cannot be moved from the “P” position to

any other position.

Ignition key position: “ACC”

Brake pedal: Not depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “P”

position to other position.

Ignition key position: “ACC”

Brake pedal : Depressed

Button: PressedCheck to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “R”

position to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: PressedIf a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to

P.23-56.)

TSB Revision

Page 504 of 1146

23-52

AUTOMATIC TRANSAXLE - Service Adjustment Procedures

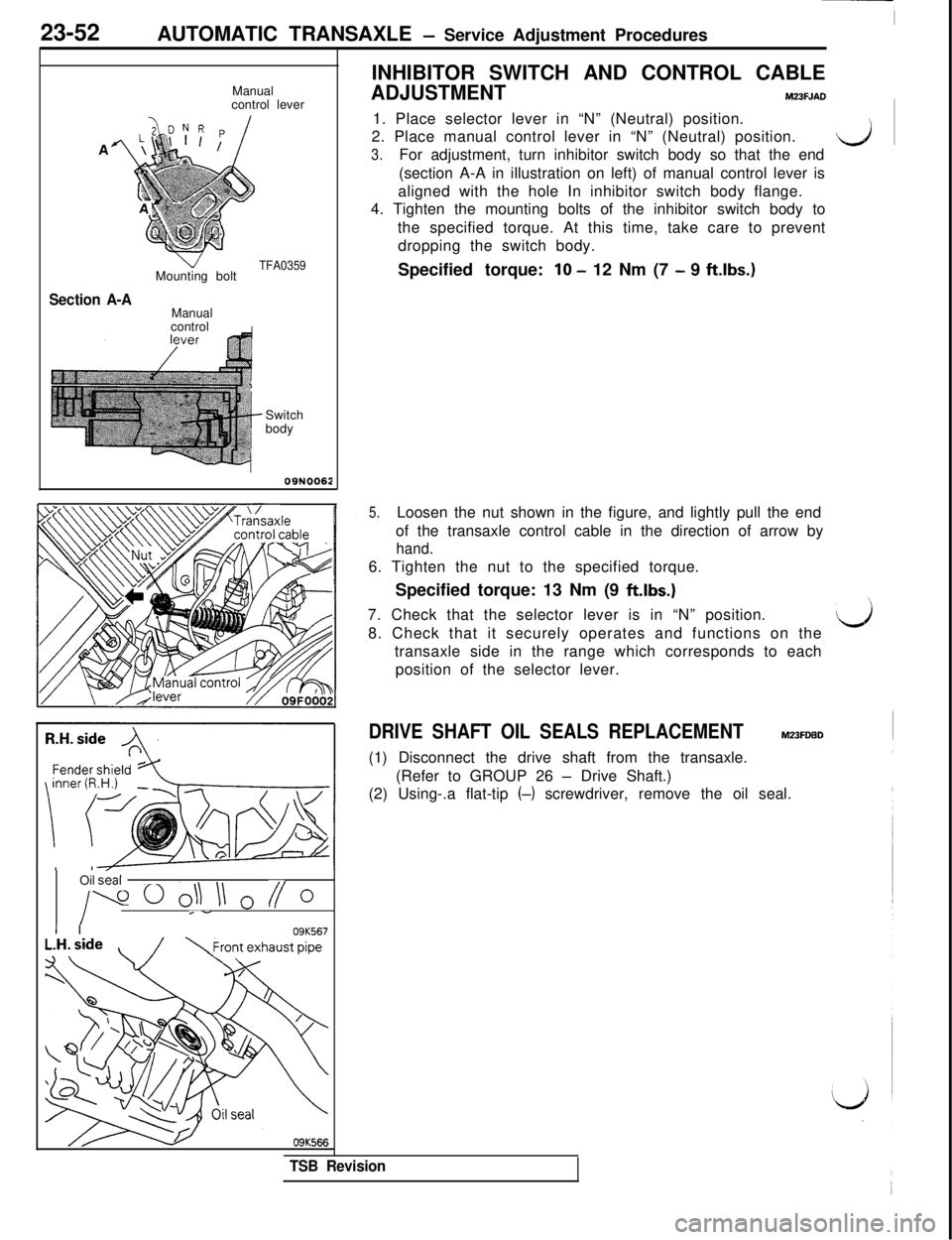

Manual

control leverINHIBITOR SWITCH AND CONTROL CABLE

ADJUSTMENTM23FJADI1. Place selector lever in “N” (Neutral) position.

2. Place manual control lever in “N” (Neutral) position.

d3.For adjustment, turn inhibitor switch body so that the end

(section A-A in illustration on left) of manual control lever is

aligned with the hole In inhibitor switch body flange.

4. Tighten the mounting bolts of the inhibitor switch body to

the specified torque. At this time, take care to prevent

dropping the switch body.

TFA0359Mounting bolt

Section A-AManual

control

ISwitch

body

09N0062Oil

skal

1

v0 o\l II 0 // 0*-

I I09K567

09K566Specified torque:

10 - 12 Nm (7 - 9 ftlbs.)

5.Loosen the nut shown in the figure, and lightly pull the end

of the transaxle control cable in the direction of arrow by

hand.6. Tighten the nut to the specified torque.

Specified torque: 13 Nm (9

ftlbs.)7. Check that the selector lever is in “N” position.

8. Check that it securely operates and functions on the

transaxle side in the range which corresponds to each

position of the selector lever.

d

DRIVE SHAFT OIL SEALS REPLACEMENTM23FLN3D(1) Disconnect the drive shaft from the transaxle.

(Refer to GROUP 26

- Drive Shaft.)

(2) Using-.a flat-tip (-) screwdriver, remove the oil seal.

TSB Revision

Page 505 of 1146

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-53 ~

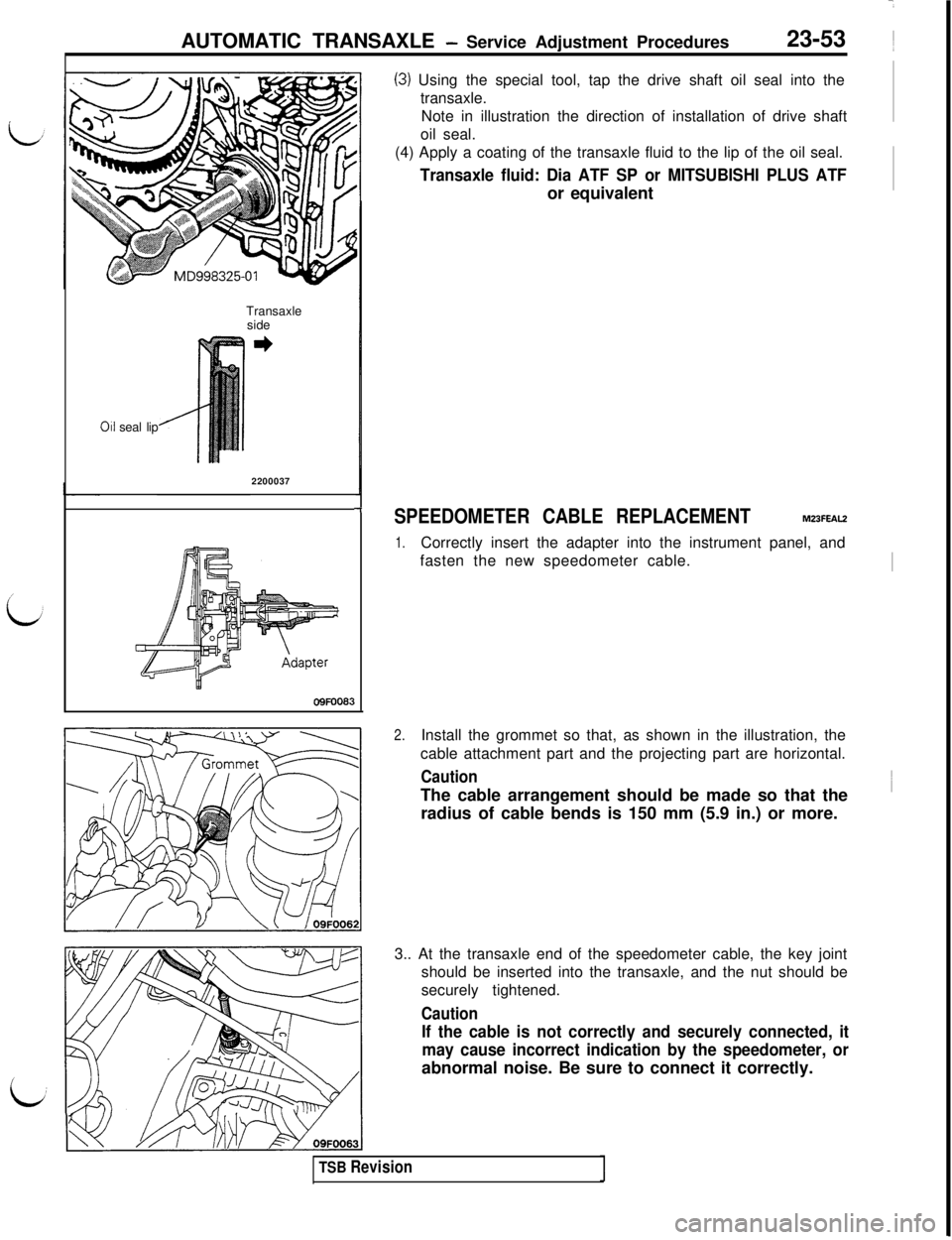

(3) Using the special tool, tap the drive shaft oil seal into the

transaxle.

Note in illustration the direction of installation of drive shaft

oil seal.

(4) Apply a coating of the transaxle fluid to the lip of the oil seal.

Transaxle fluid: Dia ATF SP or MITSUBISHI PLUS ATFor equivalent

Transaxle

side

011 seal lip

2200037

-fSPEEDOMETER CABLE REPLACEMENTM23FEAL2

1.Correctly insert the adapter into the instrument panel, and

fasten the new speedometer cable.

I

OQFOO83

2.Install the grommet so that, as shown in the illustration, the

cable attachment part and the projecting part are horizontal.

Caution1

The cable arrangement should be made so that the

’radius of cable bends is 150 mm (5.9 in.) or more.

3.. At the transaxle end of the speedometer cable, the key joint

should be inserted into the transaxle, and the nut should be

securely tightened.

Caution

If the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, orabnormal noise. Be sure to connect it correctly.

TSB Revision

Page 506 of 1146

23-54AUTOMATIC TRANSAXLE - Transaxle Control.

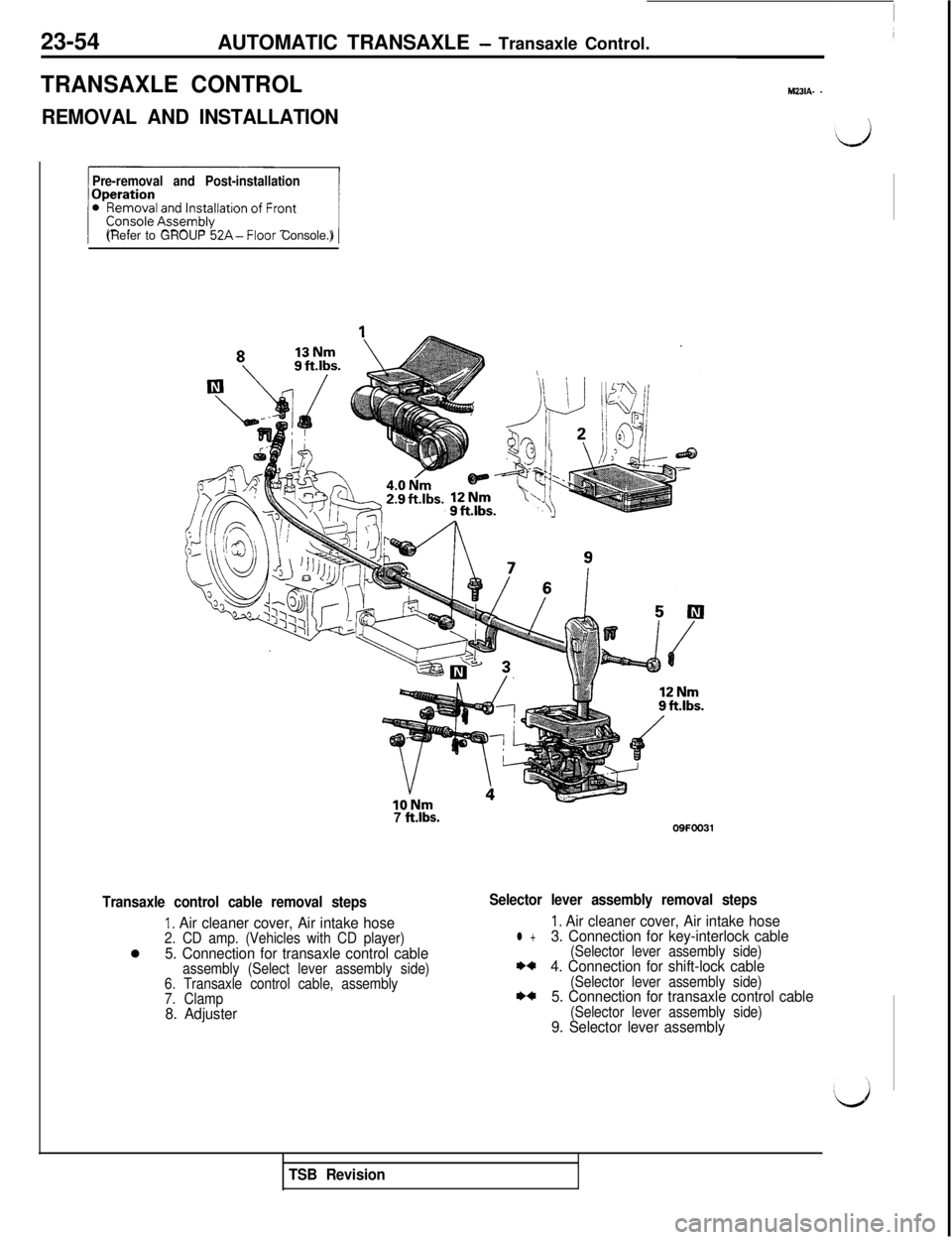

TRANSAXLE CONTROLM231A- _

REMOVAL AND INSTALLATION\

Pre-removal and Post-installation(Refer to GROUP

52A-Floor Console.)

7 ft.lbs.

Transaxle control cable removal steps

1. Air cleaner cover, Air intake hose2. CD amp. (Vehicles with CD player)l5. Connection for transaxle control cableassembly (Select lever assembly side)

6. Transaxle control cable, assembly

7. Clamp

8. Adjuster09FOO31

Selector lever assembly removal steps

1. Air cleaner cover, Air intake hosel +3. Connection for key-interlock cable(Selector lever assembly side)*+4. Connection for shift-lock cable(Selector lever assembly side)I)+5. Connection for transaxle control cable(Selector lever assembly side)9. Selector lever assembly

TSB Revision

Page 507 of 1146

AUTOMATIC TRANSAXLE - Transaxle Control

23-55

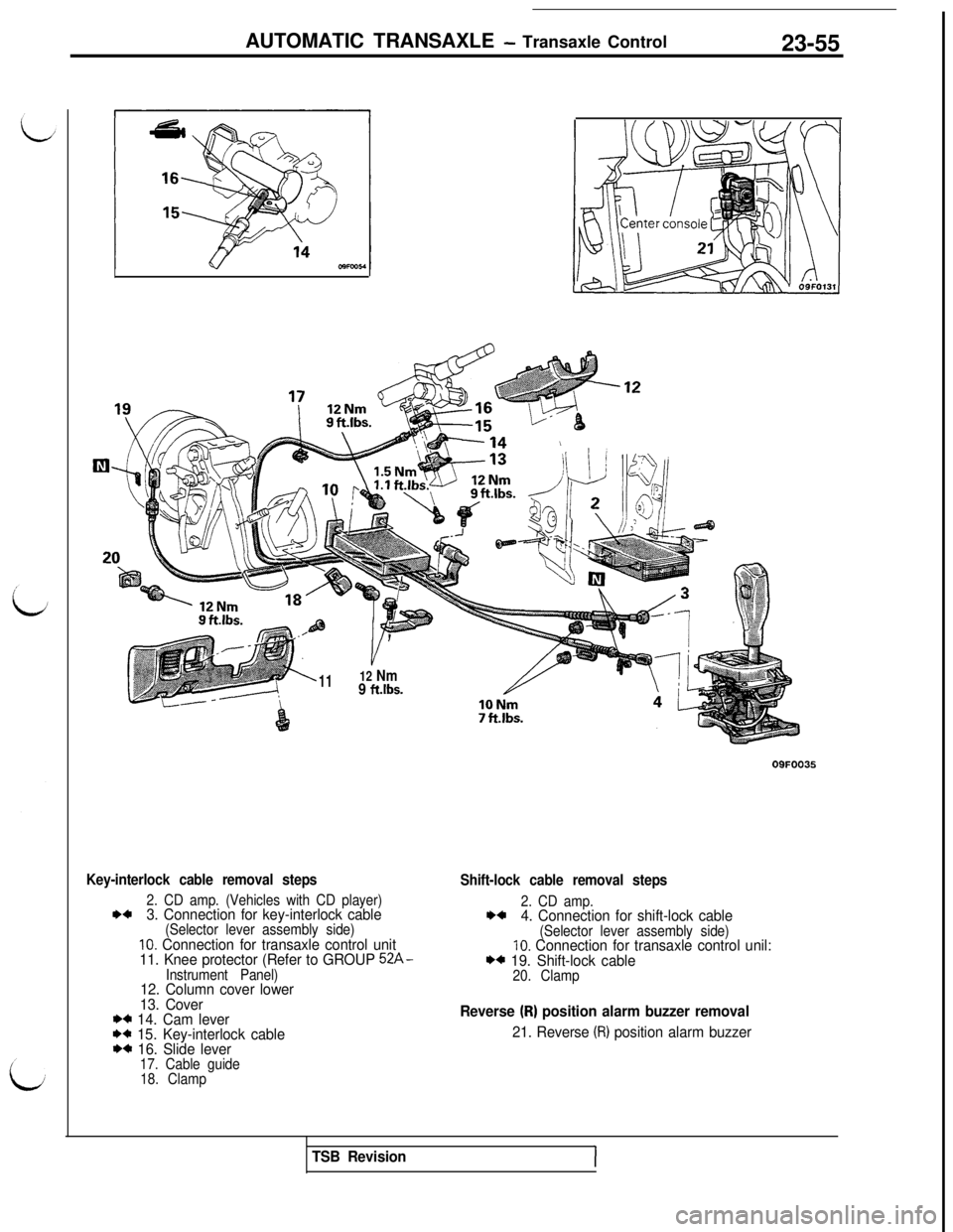

V’

1112 Nm9 ft.lbs.

Key-interlock cable removal steps

2. CD amp. (Vehicles with CD player)I)+3. Connection for key-interlock cable(Selector lever assembly side)10. Connection for transaxle control unit

11. Knee protector (Refer to GROUP 52A-

Instrument Panel)12. Column cover lower

13. Cover

*C 14. Cam lever** 15. Key-interlock cableI)+ 16. Slide lever17. Cable guide

18. ClampOQFOO35

Shift-lock cable removal steps

2. CD amp.**4. Connection for shift-lock cable(Selector lever assembly side)10. Connection for transaxle control unil:*4 19. Shift-lock cable20. Clamp

Reverse (R) position alarm buzzer removal

21. Reverse (R) position alarm buzzer

TSB Revision

Page 508 of 1146

23-56AUTOMATIC TRANSAXLE - Transaxle ControlOQPOOQQ

09FOO5

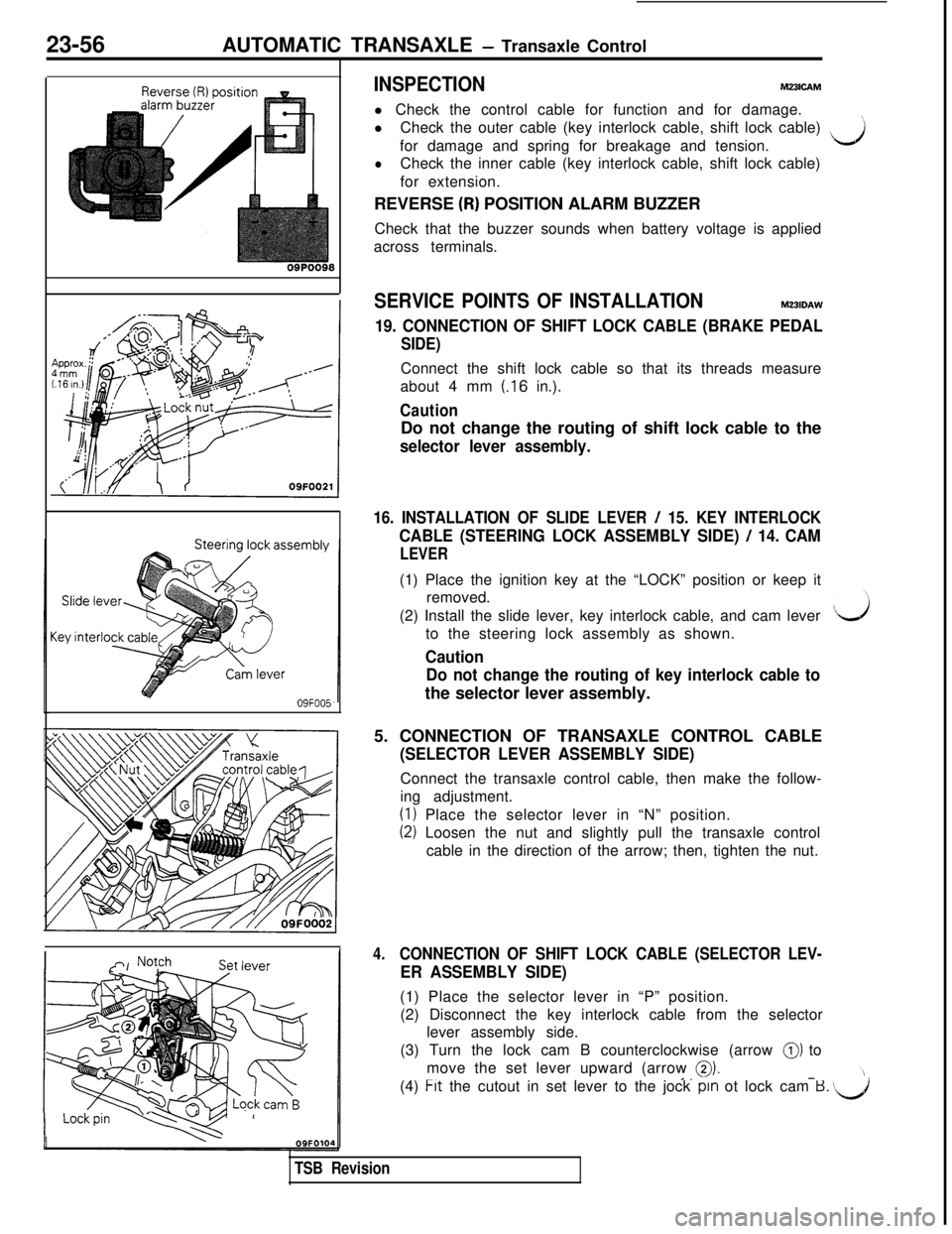

INSPECTIONM231CAMl Check the control cable for function and for damage.

lCheck the outer cable (key interlock cable, shift lock cable)

’for damage and spring for breakage and tension.~J

lCheck the inner cable (key interlock cable, shift lock cable)

for extension.

REVERSE

(R) POSITION ALARM BUZZER

Check that the buzzer sounds when battery voltage is applied

across terminals.

SERVICE POINTS OF INSTALLATIONM231DAW

19. CONNECTION OF SHIFT LOCK CABLE (BRAKE PEDAL

SIDE)Connect the shift lock cable so that its threads measure

about 4 mm

(.16 in.).

CautionDo not change the routing of shift lock cable to the

selector lever assembly.

16. INSTALLATION OF SLIDE LEVER / 15. KEY INTERLOCK

CABLE (STEERING LOCK ASSEMBLY SIDE) / 14. CAM

LEVER(1) Place the ignition key at the “LOCK” position or keep it

removed.

(2) Install the slide lever, key interlock cable, and cam lever

to the steering lock assembly as shown.

Caution

Do not change the routing of key interlock cable tothe selector lever assembly.

5. CONNECTION OF TRANSAXLE CONTROL CABLE

(SELECTOR LEVER ASSEMBLY SIDE)Connect the transaxle control cable, then make the follow-

ing adjustment.

(1) Place the selector lever in “N” position.

(2) Loosen the nut and slightly pull the transaxle control

cable in the direction of the arrow; then, tighten the nut.

4.CONNECTION OF SHIFT LOCK CABLE (SELECTOR LEV-

ER ASSEMBLY SIDE)(1) Place the selector lever in “P” position.

(2) Disconnect the key interlock cable from the selector

lever assembly side.

(3) Turn the lock cam B counterclockwise (arrow

0) to

move the set lever upward (arrow

0)._.-(4) Frt the cutout in set lever to the jock pm ot lock cam B. u

TSB Revision

Page 509 of 1146

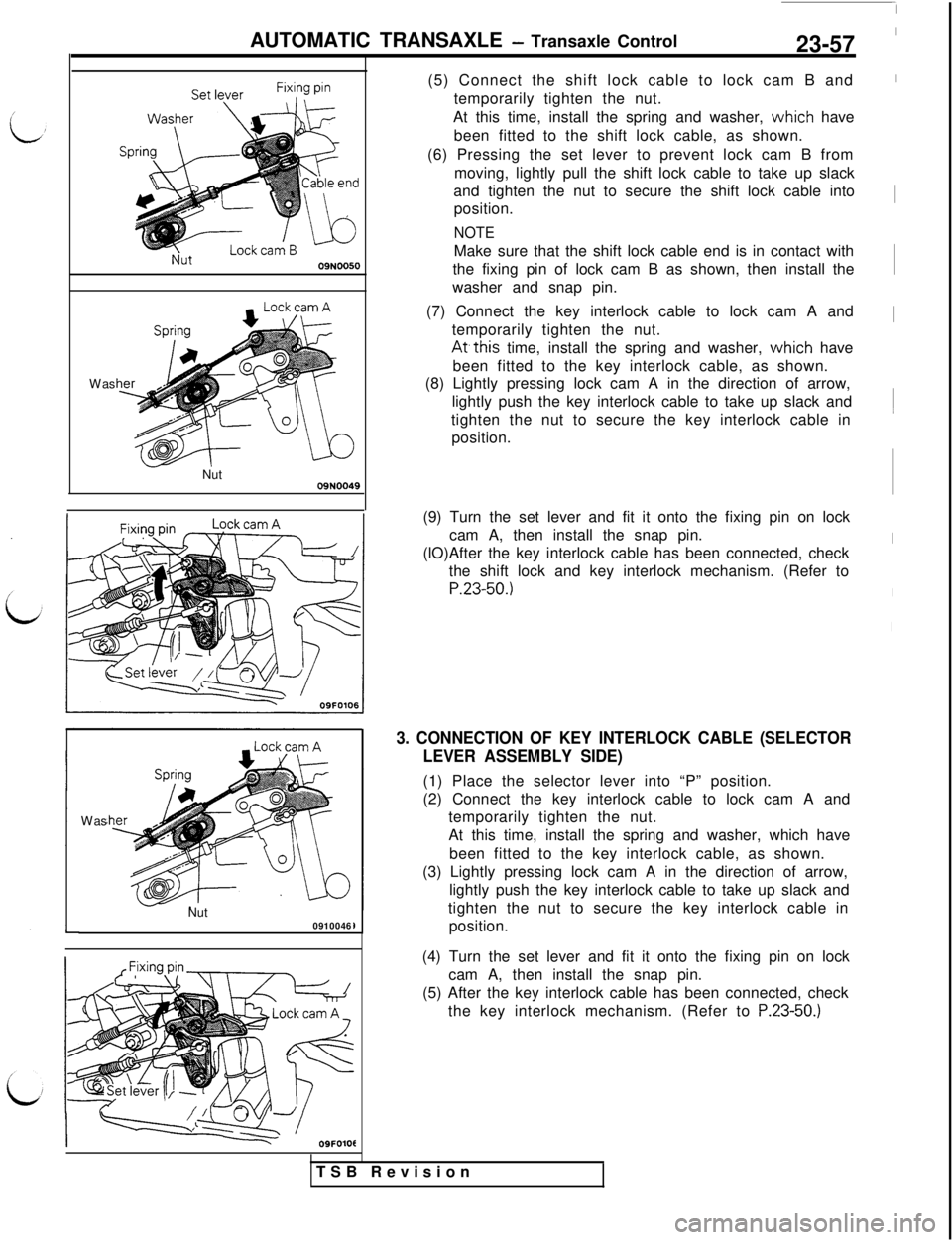

AUTOMATIC TRANSAXLE - Transaxle Control23-57

09N0050Was

Nut

09N0049Was

Nut

0910046

I

-09FOlOt(5) Connect the shift lock cable to lock cam B and

temporarily tighten the nut.

At this time, install the spring and washer,

vvhich have

been fitted to the shift lock cable, as shown.

(6) Pressing the set lever to prevent lock cam B from

moving, lightly pull the shift lock cable to take up slack

and tighten the nut to secure the shift lock cable into

position.

NOTEMake sure that the shift lock cable end is in contact with

the fixing pin of lock cam B as shown, then install the

washer and snap pin.

(7) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At,this time, install the spring and washer, vvhich have

been fitted to the key interlock cable, as shown.

(8) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(9) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(lO)After the key interlock cable has been connected, check

the shift lock and key interlock mechanism. (Refer to

P.23-50.)

3. CONNECTION OF KEY INTERLOCK CABLE (SELECTOR

LEVER ASSEMBLY SIDE)(1) Place the selector lever into “P” position.

(2) Connect the key interlock cable to lock cam A and

temporarily tighten the nut.

At this time, install the spring and washer, which have

been fitted to the key interlock cable, as shown.

(3) Lightly pressing lock cam A in the direction of arrow,

lightly push the key interlock cable to take up slack and

tighten the nut to secure the key interlock cable in

position.

(4) Turn the set lever and fit it onto the fixing pin on lock

cam A, then install the snap pin.

(5) After the key interlock cable has been connected, check

the key interlock mechanism. (Refer to

P.23-50.)TSB Revision

-1

I

I

I~

I~

I

I

I

Page 510 of 1146

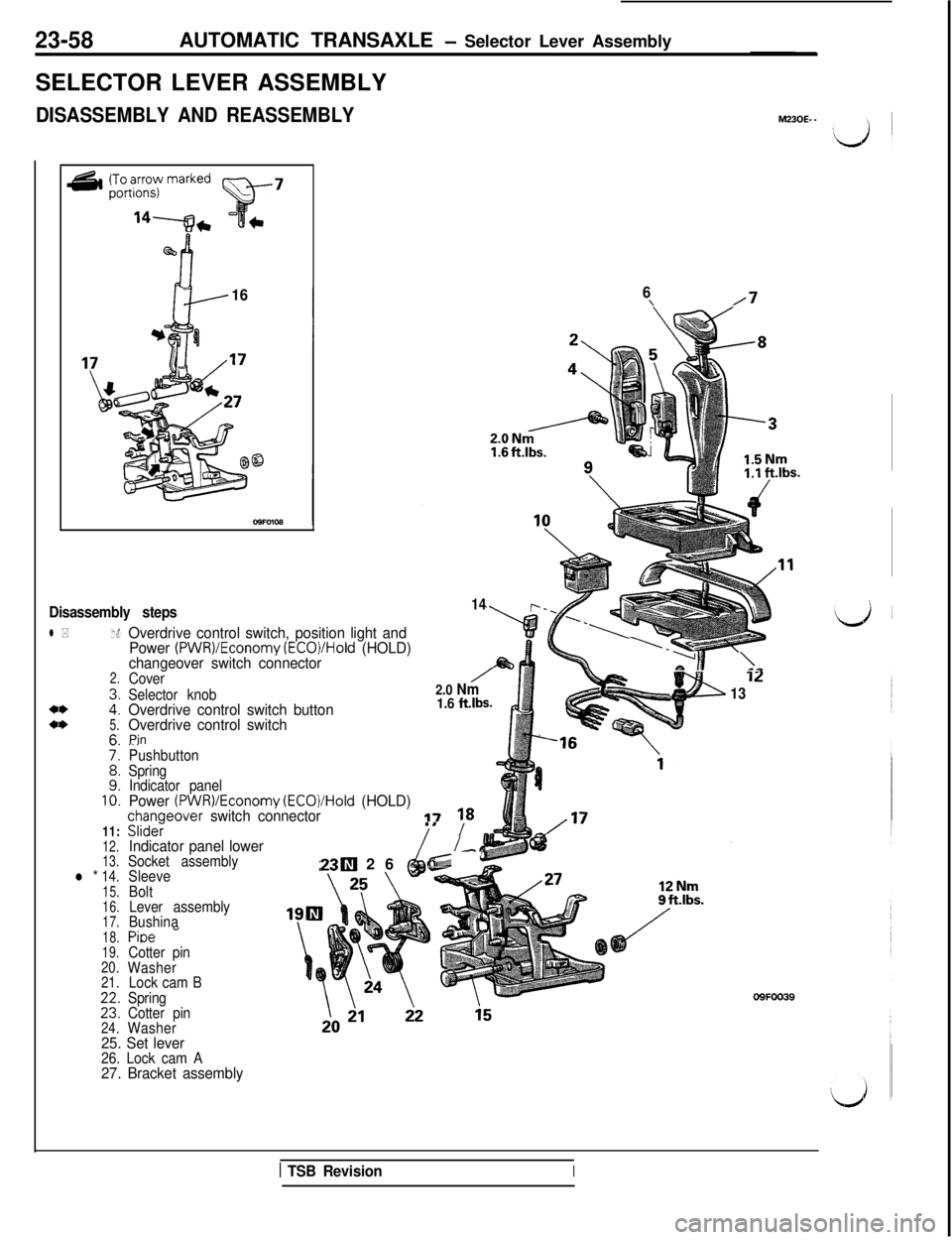

23-58AUTOMATIC TRANSAXLE - Selector Lever Assembly

SELECTOR LEVER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

@b

h-

16

Disassembly steps

l *1.

2.

**i:a*5.

76:

::10.11:

12.

13.

l * 14.15.

16.

17.

18.

19.

20.

21.

224.

6\/7

14

Overdrive control switch, position light and

Power (PWRVEconomy (ECO)/Hold (HOLD)\.GLg

changeover switch connectorCover/>I \-

Selector knob2.0 Nm

Overdrive control switch button1.6 ftlbs.

13

Overdrive control switchPin..,Pushbutton

Spring

Indicator panel

Power (PWRVEconomy (ECOVHold (HOLD)chanaeover switch connector17 18SliderIndicator panel lowerSocket assembly

Sleeve

Bolt

Lever assembly

BushinaI

23W 26fi& -’

Pioe ”Cotter pin

Washer

Lock cam B

Spring

Cotter pin

Washer

25. Set lever26. Lock cam A27. Bracket assembly09FOO39

1 TSB RevisionI