MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 491 of 1146

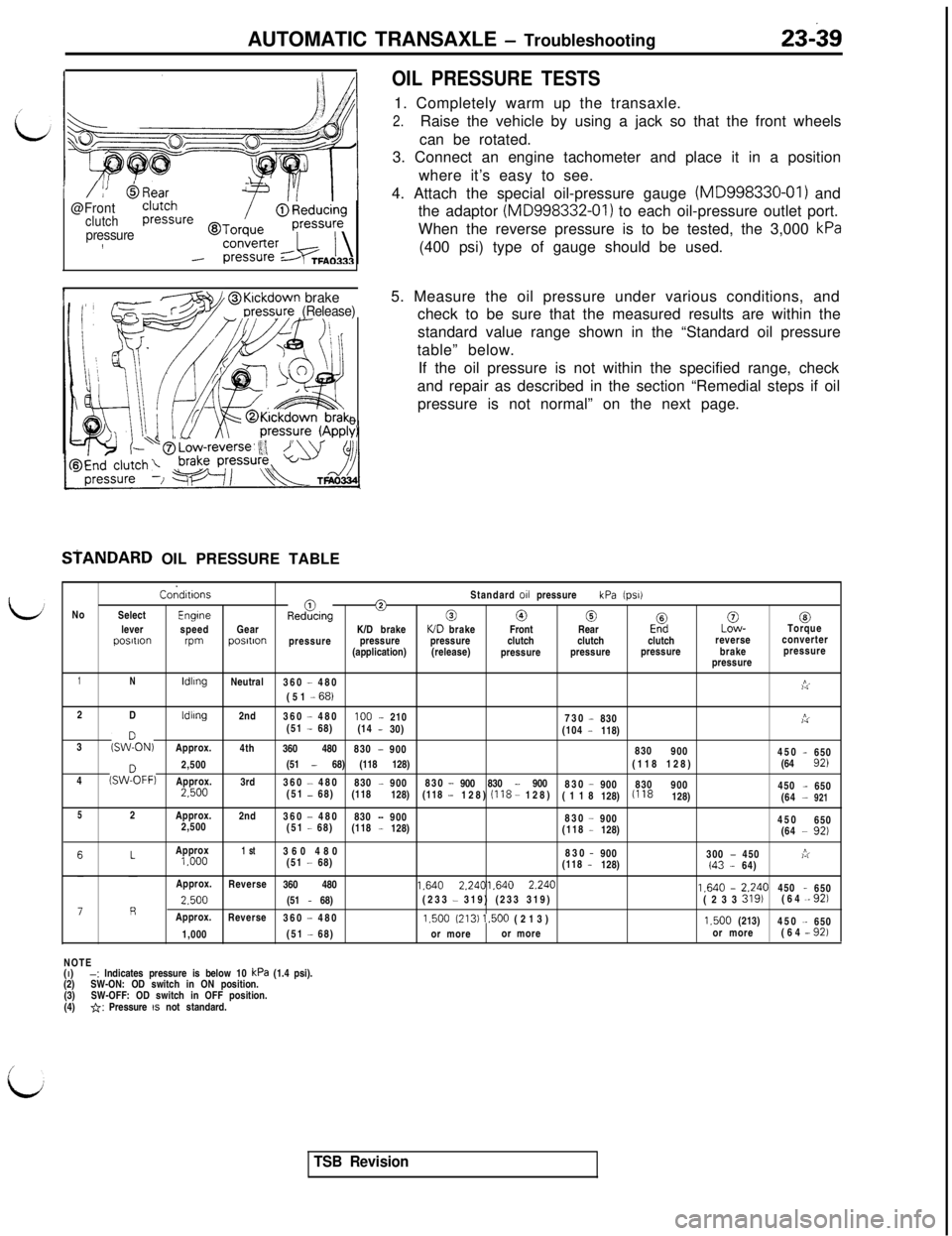

AUTOMATIC TRANSAXLE - Troubleshooting23-39

//!’ 6Rear@FrontclutchpressureI

@Kickdown brakeoressure (Release)

e

OIL PRESSURE TESTS1. Completely warm up the transaxle.

2.Raise the vehicle by using a jack so that the front wheels

can be rotated.

3. Connect an engine tachometer and place it in a position

where it’s easy to see.

4. Attach the special oil-pressure gauge (MD998330-01) and

the adaptor (MD998332-01) to each oil-pressure outlet port.

When the reverse pressure is to be tested, the 3,000

kPa(400 psi) type of gauge should be used.

5. Measure the oil pressure under various conditions, and

check to be sure that the measured results are within the

standard value range shown in the “Standard oil pressure

table” below.

If the oil pressure is not within the specified range, check

and repair as described in the section “Remedial steps if oil

pressure is not normal” on the next page.

STANDARD OIL PRESSURE TABLECondtttonsStandard

011 pressurekPa (PSI)No

SelectEngme

Red&g@000E%00leverspeedGearK/D brakeWD brakeFrontRearLow-TorqueposItlollvposltlon

pressurepressurepressureclutchclutchclutchreverseconverter

(application)(release)

pressurepressurepressurebrakepressure

pressure

1Nldlmg

Neutral

360 - 4808,(51 - 6812

Dldlmg

2nd

360

- 480100-210

730 -830k(51 - 68)

(14-30)

(104 -118)

3(SWFON,

Approx.

4th

360 480

830

-900

830

900

450-650

2,500(51 - 68) (118 128)(118 128)(64 92)

(SWZFF)Approx.

3rd

360 - 480

830

900830 -900 830 - 900

830 -900830

900

450-4

650-2.500(51 - 68)

(118

128)(118 -128) (118 - 128)

(118

128)(118128)

(64-921

52

Approx.

2nd

360

- 480

830--900

830 -900

450

650

2,500

(51 - 68)

(118-128)

(118 -128)

(64-921

Approx

1 st360 480

830 -900

300-450A1.000(51 - 68)

(118 -128)I43 .-64)

Approx.

Reverse

360 480

1.6402.2401.640 2.2401.640 -2.240450-6502.500(51 - 68)(233 - 319) (233 319)(233 319)(64 ~- 921

Approx.

Reverse

360

- 4801.500(213) 1.500 (213)1.500(213)

450~-650

1,000(51 - 68)or moreor moreor more(64 - 92)NOTE

(I)

-: Indicates pressure is below 10 kPa (1.4 psi).

(2)SW-ON: OD switch in ON position.

(3)SW-OFF: OD switch in OFF position.

(4)

a: Pressure IS not standard.

TSB Revision

Page 492 of 1146

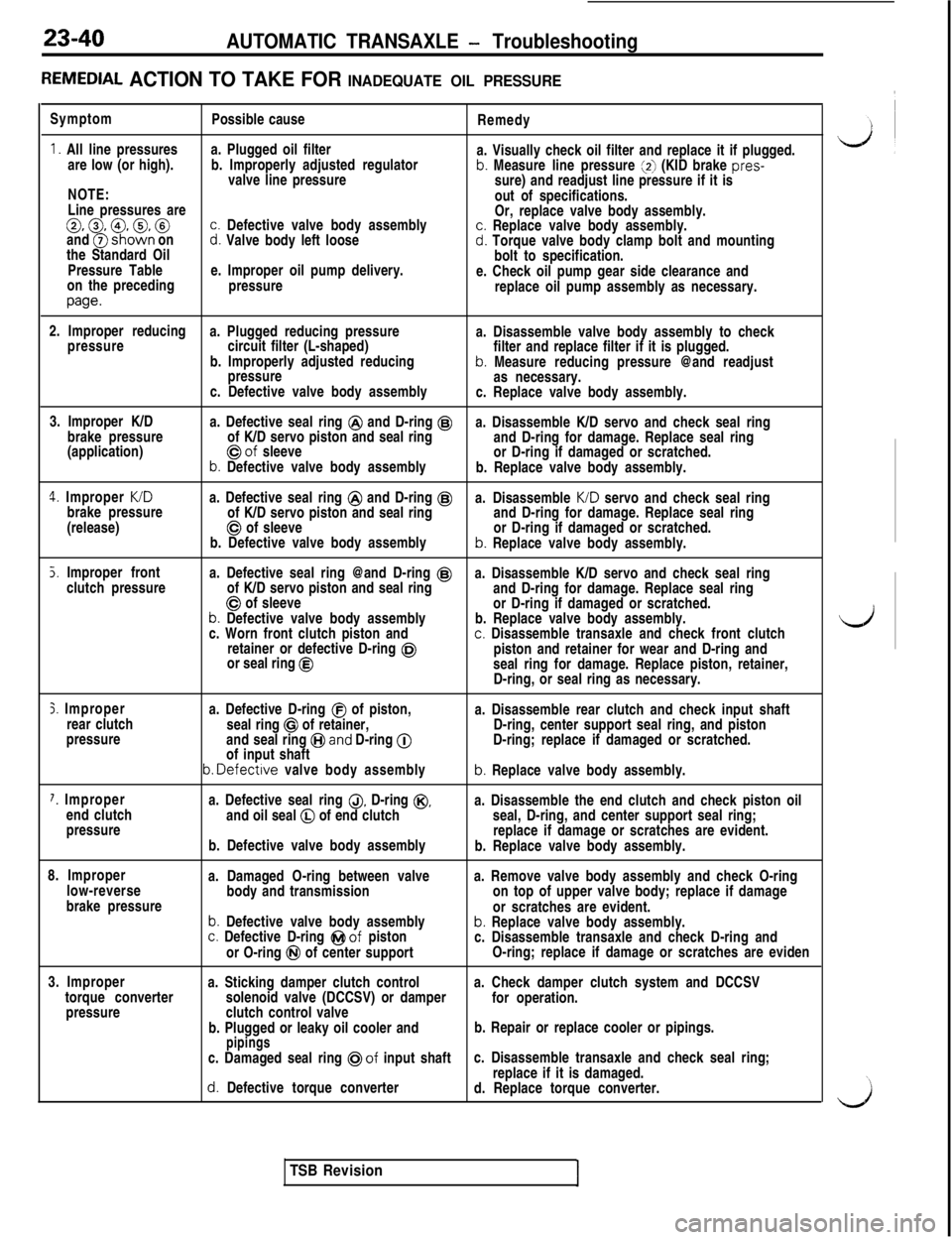

23-40AUTOMATIC TRANSAXLE - Troubleshooting

REMEDIAL ACTION TO TAKE FOR INADEQUATE OIL PRESSURESymptom

Possible cause

Remedy

1. All line pressuresa. Plugged oil filter

are low (or high).b. Improperly adjusted regulatora. Visually check oil filter and replace it if plugged.

valve line pressure

b. Measure line pressure (2) (KID brake pres-

NOTE:sure) and readjust line pressure if it is

Line pressures areout of specifications.

@.@.@).@.@and @shown onc. Defective valve body assemblyOr, replace valve body assembly.

the Standard Oil

Pressure Table

on the preceding

paw.

d. Valve body left loose

e. Improper oil pump delivery.

pressurec. Replace valve body assembly.d. Torque valve body clamp bolt and mounting

bolt to specification.

e. Check oil pump gear side clearance and

replace oil pump assembly as necessary.

2. Improper reducing

a. Plugged reducing pressure

a. Disassemble valve body assembly to check

pressurecircuit filter (L-shaped)

b. Improperly adjusted reducingfilter and replace filter if it is plugged.

b. Measure reducing pressure @and readjust

pressure

c. Defective valve body assemblyas necessary.

c. Replace valve body assembly.

3. Improper K/D

brake pressure

(application)a. Defective seal ring

@ and D-ring @of K/D servo piston and seal ringa. Disassemble K/D servo and check seal ring

@of sleeveand D-ring for damage. Replace seal ringb. Defective valve body assemblyor D-ring if damaged or scratched.

b. Replace valve body assembly.

4. Improper KIDbrake pressure

(release)

J. Improper front

clutch pressurea. Defective seal ring

@ and D-ring @of K/D servo piston and seal ringa. Disassemble KID servo and check seal ring

@ of sleeveand D-ring for damage. Replace seal ring

b. Defective valve body assemblyor D-ring if damaged or scratched.b. Replace valve body assembly.

a. Defective seal ring @and D-ring

@of K/D servo piston and seal ringa. Disassemble K/D servo and check seal ring

@ of sleeveand D-ring for damage. Replace seal ringb. Defective valve body assemblyor D-ring if damaged or scratched.

c. Worn front clutch piston andb. Replace valve body assembly.c. Disassemble transaxle and check front clutch

retainer or defective D-ring @or seal ring @piston and retainer for wear and D-ring and

seal ring for damage. Replace piston, retainer,

D-ring, or seal ring as necessary.

3. Improper

rear clutch

pressure

7. Improper

end clutch

pressurea. Defective D-ring

@ of piston,

seal ring @ of retainer,

and seal ring @and D-ring @of input shaft

b. Defectrve valve body assembly

a. Defective seal ring

0. D-ring 0,and oil seal (iJ of end clutch

b. Defective valve body assemblya. Disassemble rear clutch and check input shaft

D-ring, center support seal ring, and piston

D-ring; replace if damaged or scratched.

b. Replace valve body assembly.

a. Disassemble the end clutch and check piston oil

seal, D-ring, and center support seal ring;

replace if damage or scratches are evident.

b. Replace valve body assembly.

8. Improper

low-reverse

brake pressurea. Damaged O-ring between valve

body and transmission

b. Defective valve body assemblyc. Defective D-ring @of piston

or O-ring

@I of center supporta. Remove valve body assembly and check O-ring

on top of upper valve body; replace if damage

or scratches are evident.

b. Replace valve body assembly.

c. Disassemble transaxle and check D-ring and

O-ring; replace if damage or scratches are eviden

3. Improper

torque converter

pressurea. Sticking damper clutch controla. Check damper clutch system and DCCSV

solenoid valve (DCCSV) or damper

for operation.

clutch control valve

b. Plugged or leaky oil cooler and

pipingsb. Repair or replace cooler or pipings.

c. Damaged seal ring @of input shaftc. Disassemble transaxle and check seal ring;

d. Defective torque converterreplace if it is damaged.

d. Replace torque converter.

TSB Revision

d

‘\

d

Page 493 of 1146

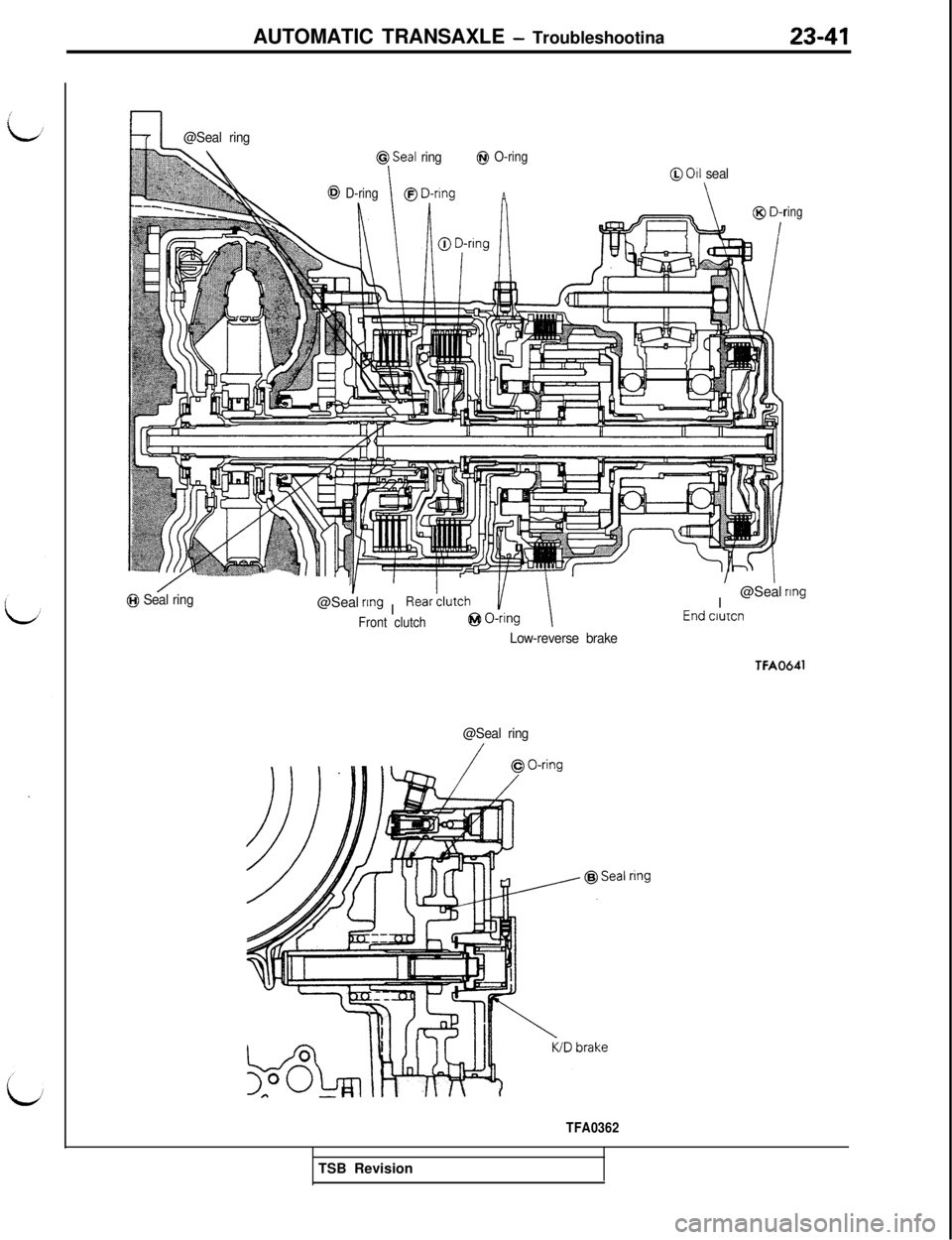

AUTOMATIC TRANSAXLE - Troubleshootina23-41

L-l@Seal ring

$&-g&J\@Seal ring@I O-ring!A>. .Yr&w

\

@ 011 seal

h.43 D-ring@ D-rmgA\ring

/@I Seal ring@Seal rmgI

Front clutchI@Seal

rmg

rItna cIuIcn

Low-reverse brake

TFA0641

@Seal ring

/

TFA0362TSB Revision

Page 494 of 1146

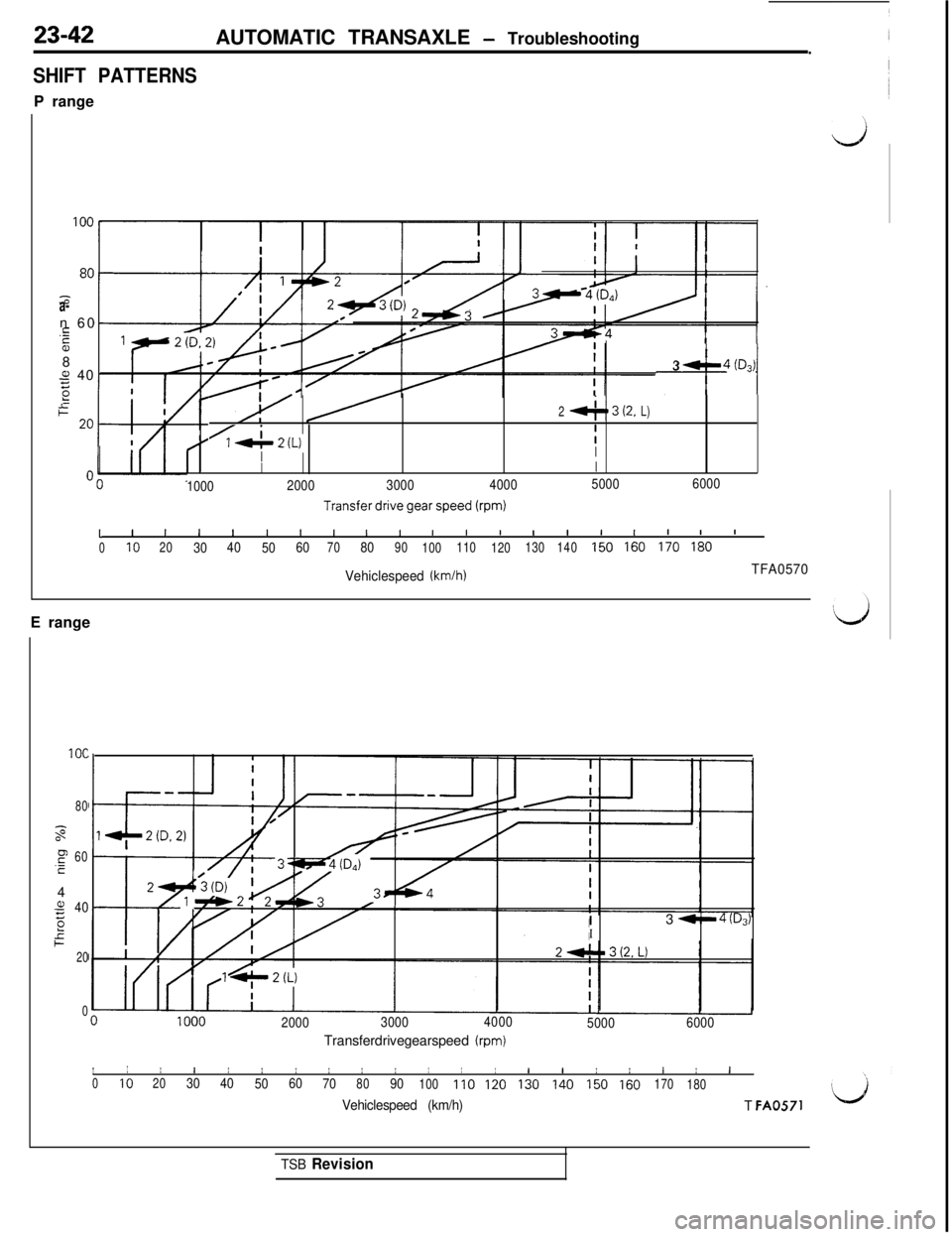

23-42AUTOMATIC TRANSAXLE - Troubleshooting.

SHIFT PATTERNSP range

-i;a-n 60

.rs

8

-z" 405

-+-!

34(b)

2413(2,L)

IIII

100020003000400050006000Transferdrivegearspeedtrpm)

IIIIIIIIIIIIIIIIIIII

010203040

5060708090

100110

120130140150160170180

Vehiclespeed (km/h)TFA0570E range

IOC

80-z

6

F60'E4

$40

5E

20

0

I3 e-4 (DAI

200030004000

50006000Transferdrivegearspeed

(rpm)

IIIIIIIIIIII

IIIIIIII010203040

5060

708090100110120130140150160170

180

Vehiclespeed (km/h)

T FA0571

TSB Revision

Page 495 of 1146

AUTOMATIC TRANSAXLE - Troubleshootinn23-43

CONVERTER STALL TESTStall test consist of determining maximum engine

speed obtained at full throttle in “D” and

“I?”positions. This test checks torque converter

statoroverrunning clutch operation, and holding ability of

transaxle clutches and low-reverse brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature

[70 - 80°C (160 -

18O”F)I. Engine coolant should also be at normal

operating temperature

[80 - 90°C (180 - 19O”F)l.2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximately 1,000 rpm in

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 2,200

- 3,200 rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “R”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping.

In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance, etc. If these are good, torque

converter is faulty.

TRANSAXLE CONTROL

Symptom

Selector lever operationis stiff

Probable cause

Incorrect adjustment of sleeve

Remedy

Adjust

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton

and sleeve

Adjust

Replace

Replace

Starter motor does notMalfunction in inhibitor switchReplace

operate with the selector

lever in the “N” or “P”Incorrect adjustment of control cableAdjust

position

Will not shift to

4-speed

Malfunction of starter relay

Malfunction of OD switchReplace

Replace

1 TSB RevisionI

Page 496 of 1146

23-44AUTOMATIC TRANSAXLE - Troubleshootina

A/T SAFETY-LOCK SYSTEM TROUBLESHOOTINGbe selectedinto

Rfrom P by depressing

brake pedal with

ignition key in

position other than

LOCK.n or sagging outer cable(shift

loteck andadjust slide lever

ide lever and ca

Selector lever

Iperation from P to Rs not smooth.

TSB Revision

Page 497 of 1146

AUTOMATIC TRANSAXLE - Troubleshooting23-45Symptom

Probable cause

RemedyRef. page

Selector lever cannot

be shifted from

R to P.Defective selector lever assembly

Check and replace selector23-54

lever assembly.

Improperly adjusted transaxle control cable

Adjust transaxle control

23-56

cable.Ignition key cannot

Foreign matter wedged in lock cams A and B

23-58

be turned to LOCKCheck and replace lock cams

A and B.

position with selector

lever in

P.Improperly adjusted key interlock cable,

sticking inner cableCheck, adjust, and replace213-55key interlock cable.

Binding slide lever inside key cylinder

Check slide lever.

23-55

Ignition key can be

Damaged lock cam A

Check and replace lock cam A.

2:3-58turned to LOCK

position even withLoose key cylinder cover

Check and retighten cover.

2:3-55selector lever in

position other than P.

Broken key interlock cable, loose connec-

Check and replace key

2355tions, elongated inner cable

interlock cable.

Damaged cam lever inside key cylinder

Check and replace cam lever.

2:3-55Buzzer does not soundDefective buzzer

Check and replace buzzer.

2:3-55even when selector

lever is placed in

ROpen-circuited buzzer circuit harness

Check or correct harness.-position.

Defective inhibitor switchCheck and replace inhibitor

-switch.

Improperly adjusted transaxle control cableAdjust transaxle control

2:3-52

cable.

TSB Revision

Page 498 of 1146

23-46AUTOMATIC TRANSAXLE - Service Adjustment Procedures

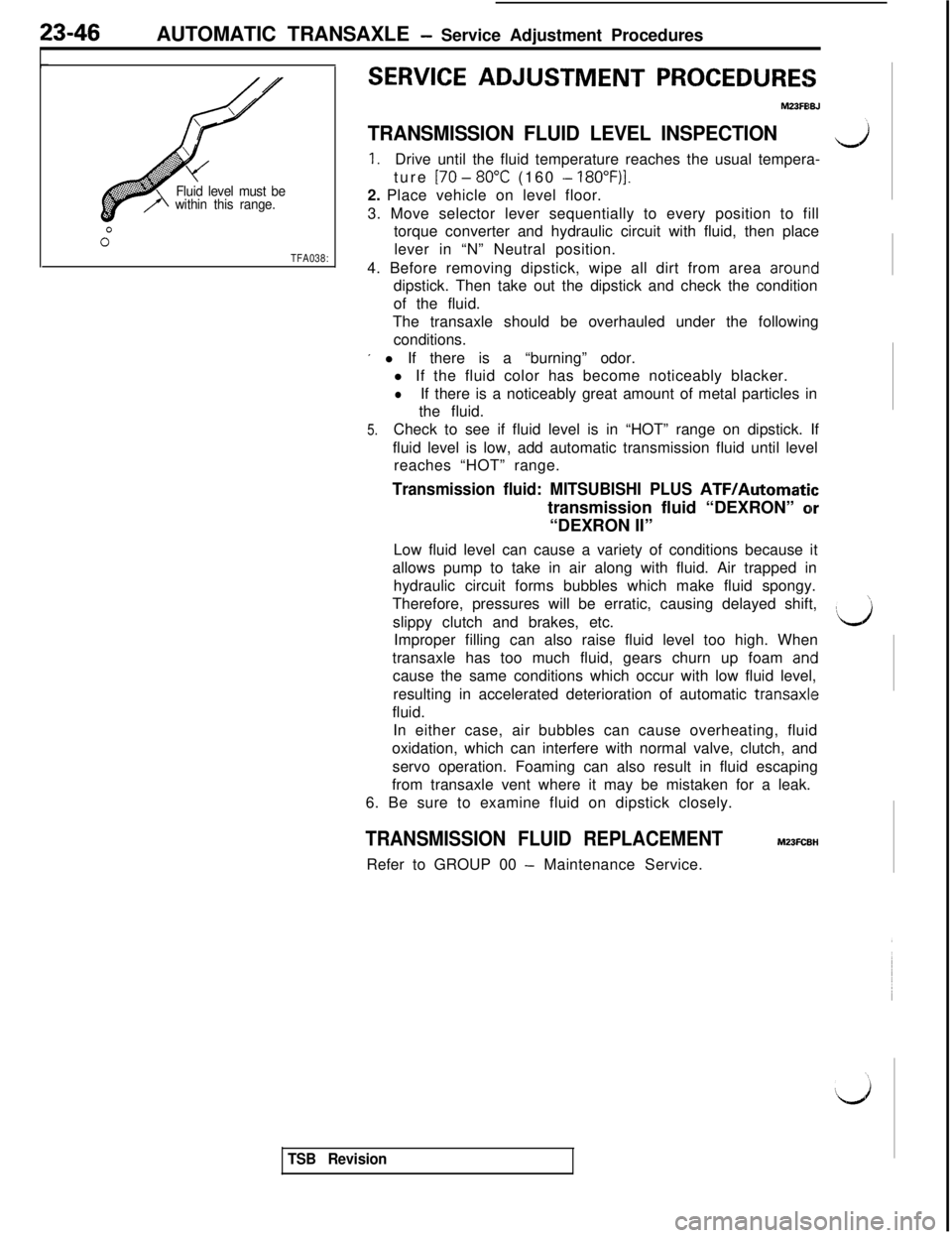

Fluid level must be

within this range.

TFA038:

SERVICE ADJUSTMENT PROCEDURE!5

MZ3FElBJ

TRANSMISSION FLUID LEVEL INSPECTION

1.Drive until the fluid temperature reaches the usual tempera-

ture

170 - 80°C (160 - 18O”F)].2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position.

4. Before removing dipstick, wipe all dirt from area

arouniddipstick. Then take out the dipstick and check the condition

of the fluid.

The transaxle should be overhauled under the following

conditions.

’ l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

lIf there is a noticeably great amount of metal particles in

the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transmission fluid until level

reaches “HOT” range.

Transmission fluid: MITSUBISHI PLUS ATF/Automatictransmission fluid “DEXRON”

abr“DEXRON II”

Low fluid level can cause a variety of conditions because it

allows pump to take in air along with fluid. Air trapped in

hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic, causing delayed shift,

slippy clutch and brakes, etc.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam

anldcause the same conditions which occur with low fluid level,

resulting in accelerated deterioration of automatic

transaxllefluid.

In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch, and

servo operation. Foaming can also result in fluid escaping

from transaxle vent where it may be mistaken for a leak.

6. Be sure to examine fluid on dipstick closely.

TRANSMISSION FLUID REPLACEMENTM23FCBHRefer to GROUP 00

- Maintenance Service.

TSB Revision

Page 499 of 1146

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-47

MD998916-3-01

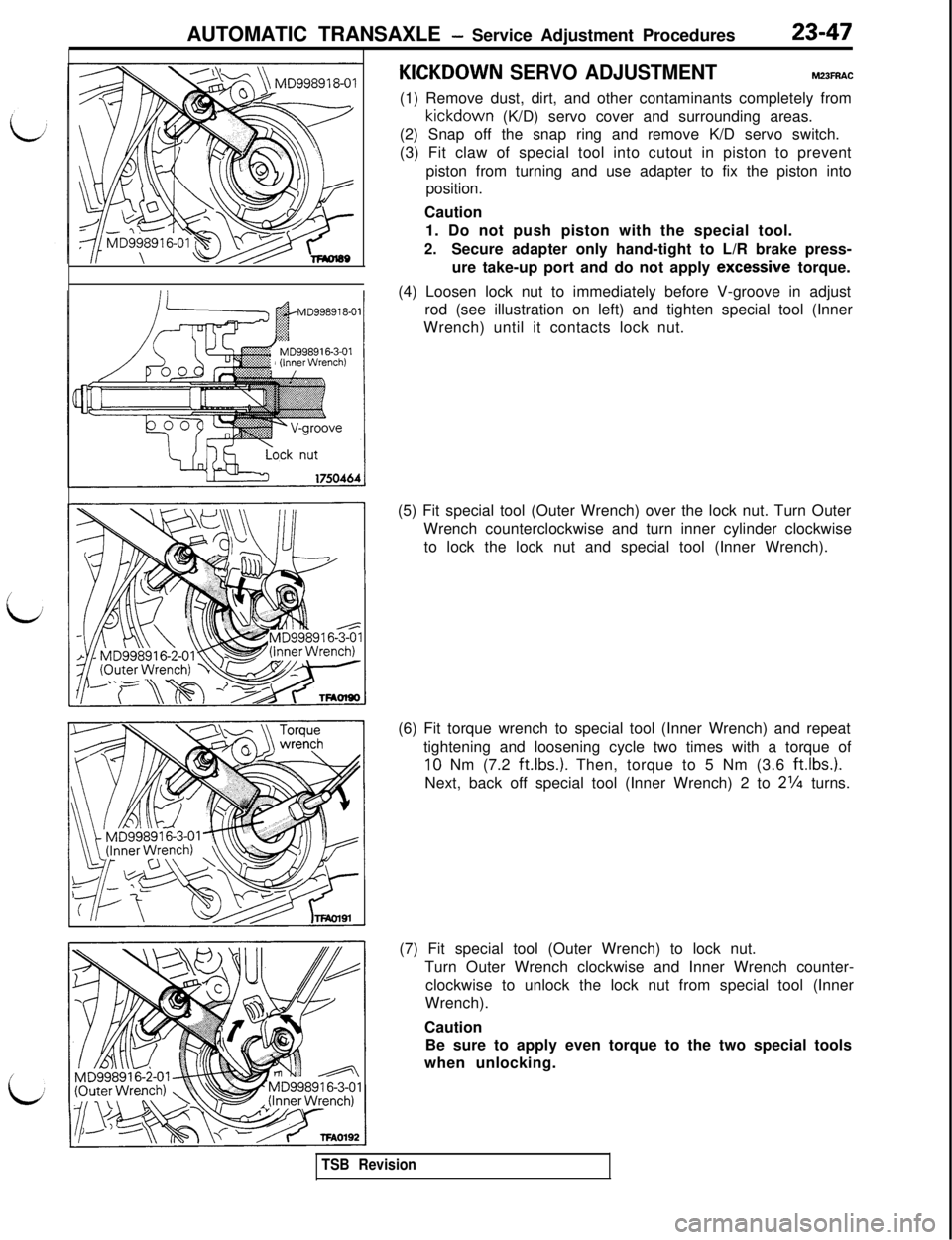

KICKDOWN SERVO ADJUSTMENTM23FRAC(1) Remove dust, dirt, and other contaminants completely fromkickdown (K/D) servo cover and surrounding areas.

(2) Snap off the snap ring and remove K/D servo switch.

(3) Fit claw of special tool into cutout in piston to prevent

piston from turning and use adapter to fix the piston into

position.

Caution

1. Do not push piston with the special tool.

2.Secure adapter only hand-tight to L/R brake press-

ure take-up port and do not apply

excessiwe torque.

(4) Loosen lock nut to immediately before V-groove in adjust

rod (see illustration on left) and tighten special tool (Inner

Wrench) until it contacts lock nut.

(5) Fit special tool (Outer Wrench) over the lock nut. Turn Outer

Wrench counterclockwise and turn inner cylinder clockwise

to lock the lock nut and special tool (Inner Wrench).

(6) Fit torque wrench to special tool (Inner Wrench) and repeat

tightening and loosening cycle two times with a torque of

10 Nm (7.2 ft.lbs.). Then, torque to 5 Nm (3.6 ftlbs.).Next, back off special tool (Inner Wrench) 2 to

2’/4 turns.

(7) Fit special tool (Outer Wrench) to lock nut.

Turn Outer Wrench clockwise and Inner Wrench counter-

clockwise to unlock the lock nut from special tool (Inner

Wrench).

Caution

Be sure to apply even torque to the two special tools

when unlocking.

TSB Revision

Page 500 of 1146

23-48AUTOMATIC TRANSAXLE - Service Adjustment Procedures

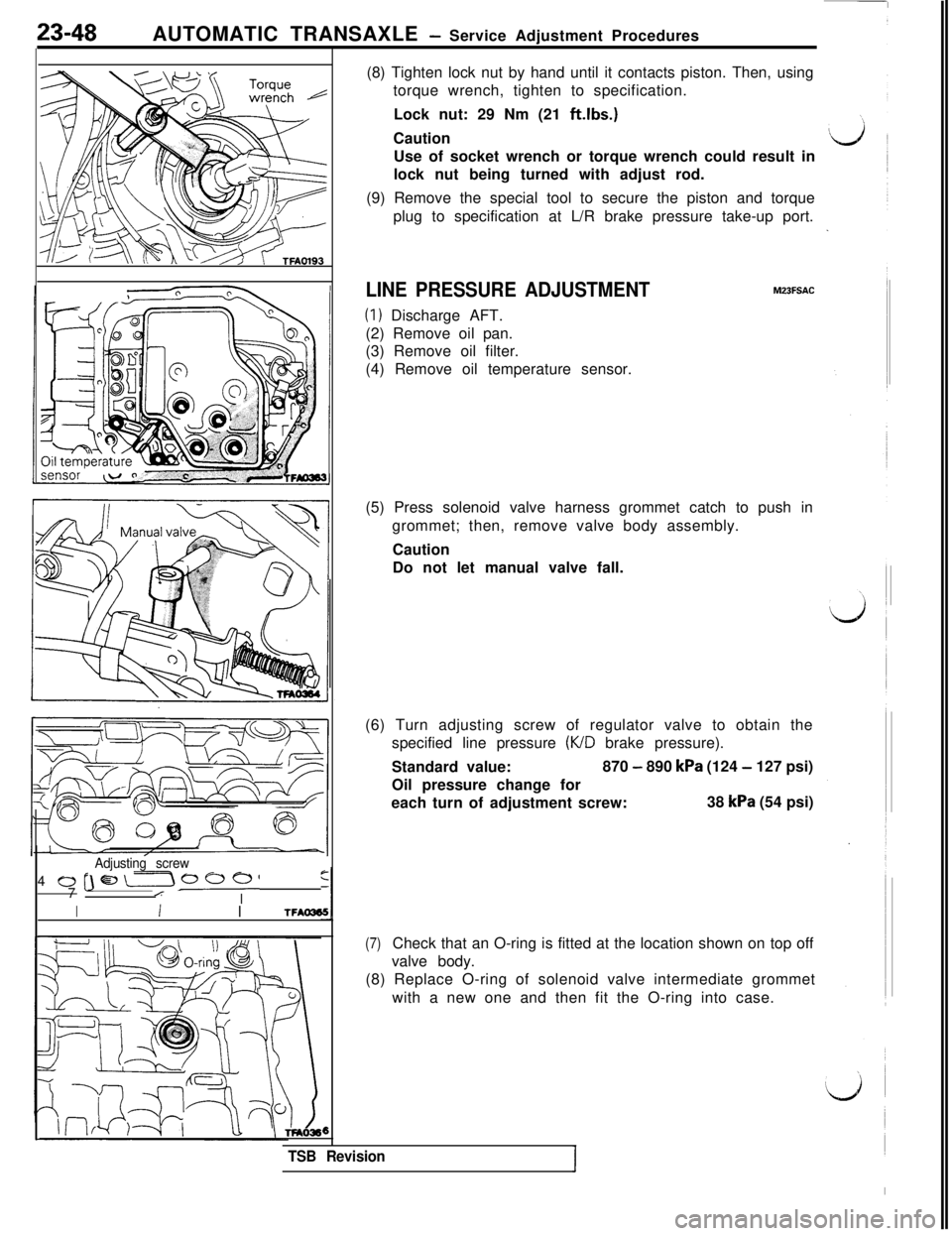

Adjusting screw4

or~0\====m00~7/IIIITFAm

c-1

Pi(8) Tighten lock nut by hand until it contacts piston. Then, using

torque wrench, tighten to specification.

Lock nut: 29 Nm (21

ftlbs.)Caution

Use of socket wrench or torque wrench could result in

lock nut being turned with adjust rod.

(9) Remove the special tool to secure the piston and torque

plug to specification at L/R brake pressure take-up port.

LINE PRESSURE ADJUSTMENT

(I) Discharge AFT.

(2) Remove oil pan.

(3) Remove oil filter.

(4) Remove oil temperature sensor.

M23FSAC(5) Press solenoid valve harness grommet catch to push in

grommet; then, remove valve body assembly.

Caution

Do not let manual valve fall.

(6) Turn adjusting screw of regulator valve to obtain the

specified line pressure

(K/D brake pressure).

Standard value:870

- 890 kPa (124 - 127 psi)

Oil pressure change for

each turn of adjustment screw:38

kPa (54 psi)

(7)Check that an O-ring is fitted at the location shown on top off

valve body.

(8) Replace O-ring of solenoid valve intermediate grommet

with a new one and then fit the O-ring into case.6

TSB RevisionI