MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 481 of 1146

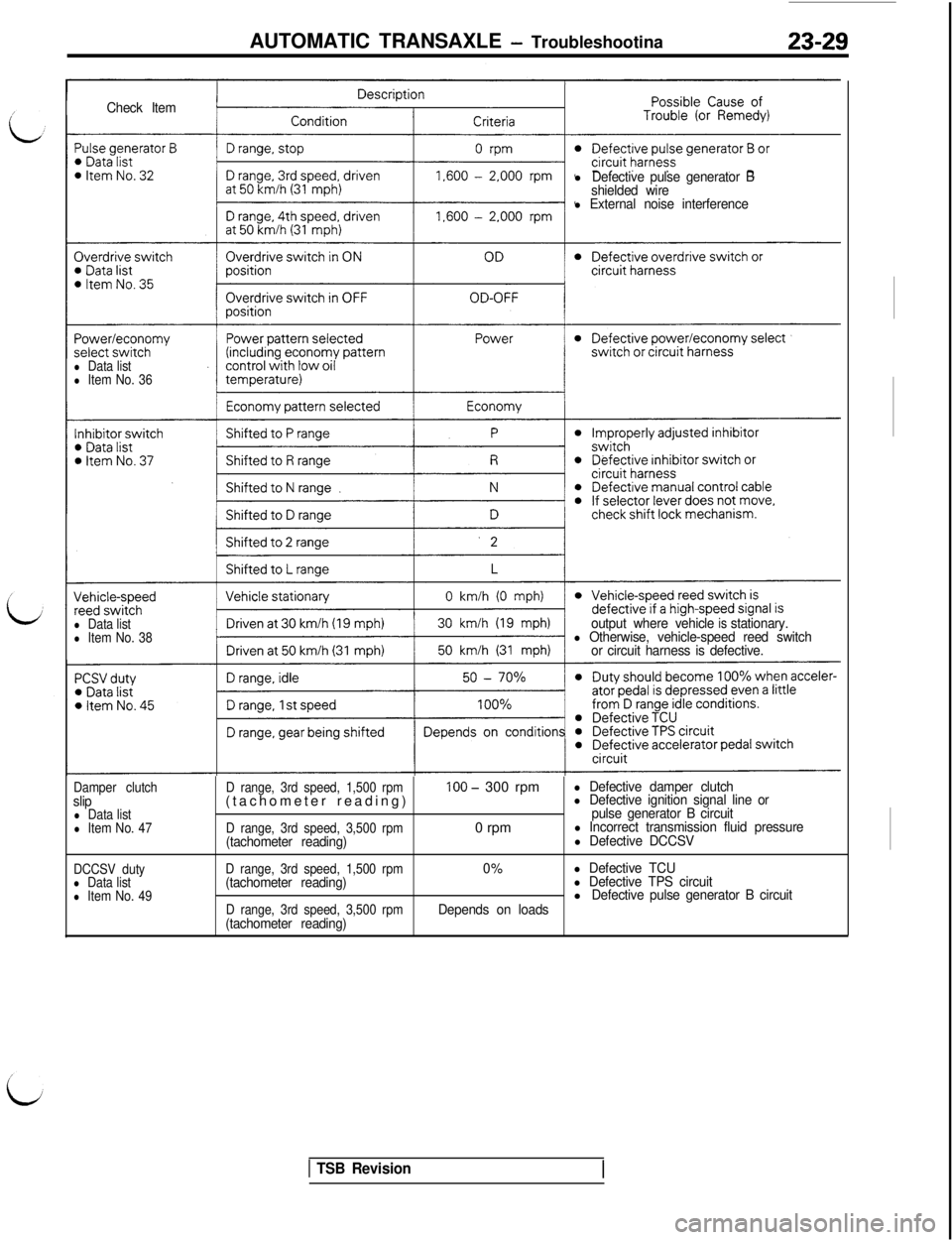

AUTOMATIC TRANSAXLE - Troubleshootina23-29

Check Iteml

Defective pulse generator B

shielded wire

l External noise interference

l Data listl Item No. 36

l Data listl Item No. 38output where vehicleisstationary.l Otherwise, vehicle-speed reed switch

or circuit harness is defective.

Damper clutchslipl Data listl Item No. 47

DCCSV duty

l Data listl Item No. 49D range, 3rd speed, 1,500 rpm(tachometer reading)

D range, 3rd speed, 3,500 rpm(tachometer reading)

D range, 3rd speed, 1,500 rpm(tachometer reading)

D range, 3rd speed, 3,500 rpm(tachometer reading)

100 - 300 rpm

0 rpm

0%

Depends on loads

l Defective damper clutchl Defective ignition signal line or

pulse generator B circuit

l Incorrect transmission fluid pressurel Defective DCCSV

l Defective TCUl Defective TPS circuitlDefective pulse generator B circuit

1 TSB Revision

Page 482 of 1146

23-30AUTOMATIC TRANSAXLE - Troubleshooting

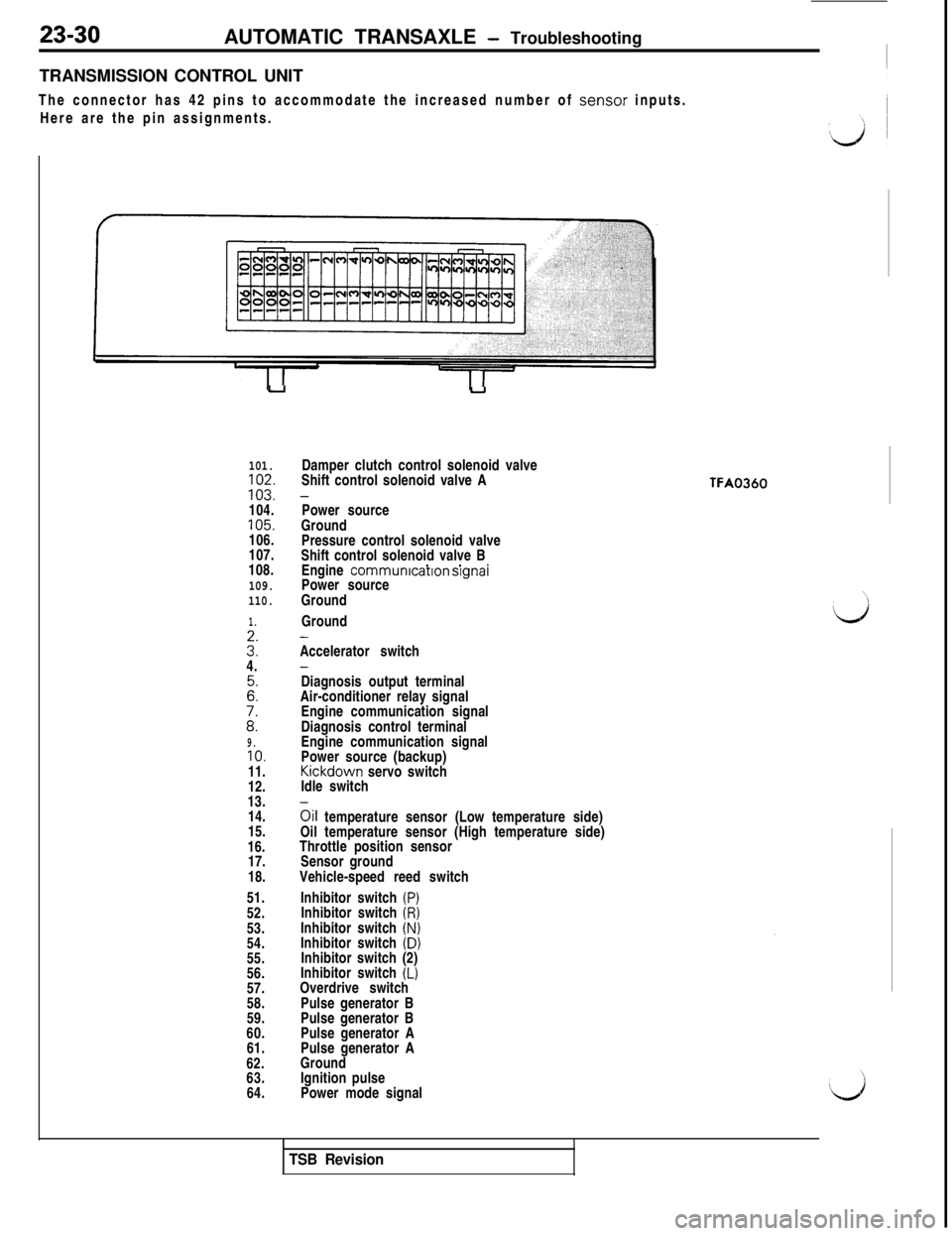

TRANSMISSION CONTROL UNIT

The connector has 42 pins to accommodate the increased number of senso.r inputs.

Here are the pin assignments.

uu

101.102.103.

104.105.

106.

107.

108.

109.

110.

1.

3':4.

Z:

i:9.10.11.

12.

13.

14.

15.

16.

17.

18.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.Damper clutch control solenoid valve

Shift control solenoid valve A

-Power source

Ground

Pressure control solenoid valve

Shift control solenoid valve B

. .

*Engine communrcatron srgnaiPower source

Ground

Ground

-Accelerator switch

-Diagnosis output terminal

Air-conditioner relay signal

Engine communication signal

Diagnosis control terminal

Engine communication signal

Power source (backup)Kickdown servo switch

Idle switch

oil temperature sensor (Low temperature side)

Oil temperature sensor (High temperature side)

Throttle position sensor

Sensor ground

Vehicle-speed reed switch

Inhibitor switch

(P)Inhibitor switch (R)Inhibitor switch (N)Inhibitor switch (D)

Inhibitor switch (2)

Inhibitor switch

(L)Overdrive switch

Pulse generator B

Pulse generator B

Pulse generator A

Pulse generator A

Ground

Ignition pulse

Power mode signal

TFA0360

TSB Revision

Page 483 of 1146

AUTOMATIC TRANSAXLE - Troubleshooting

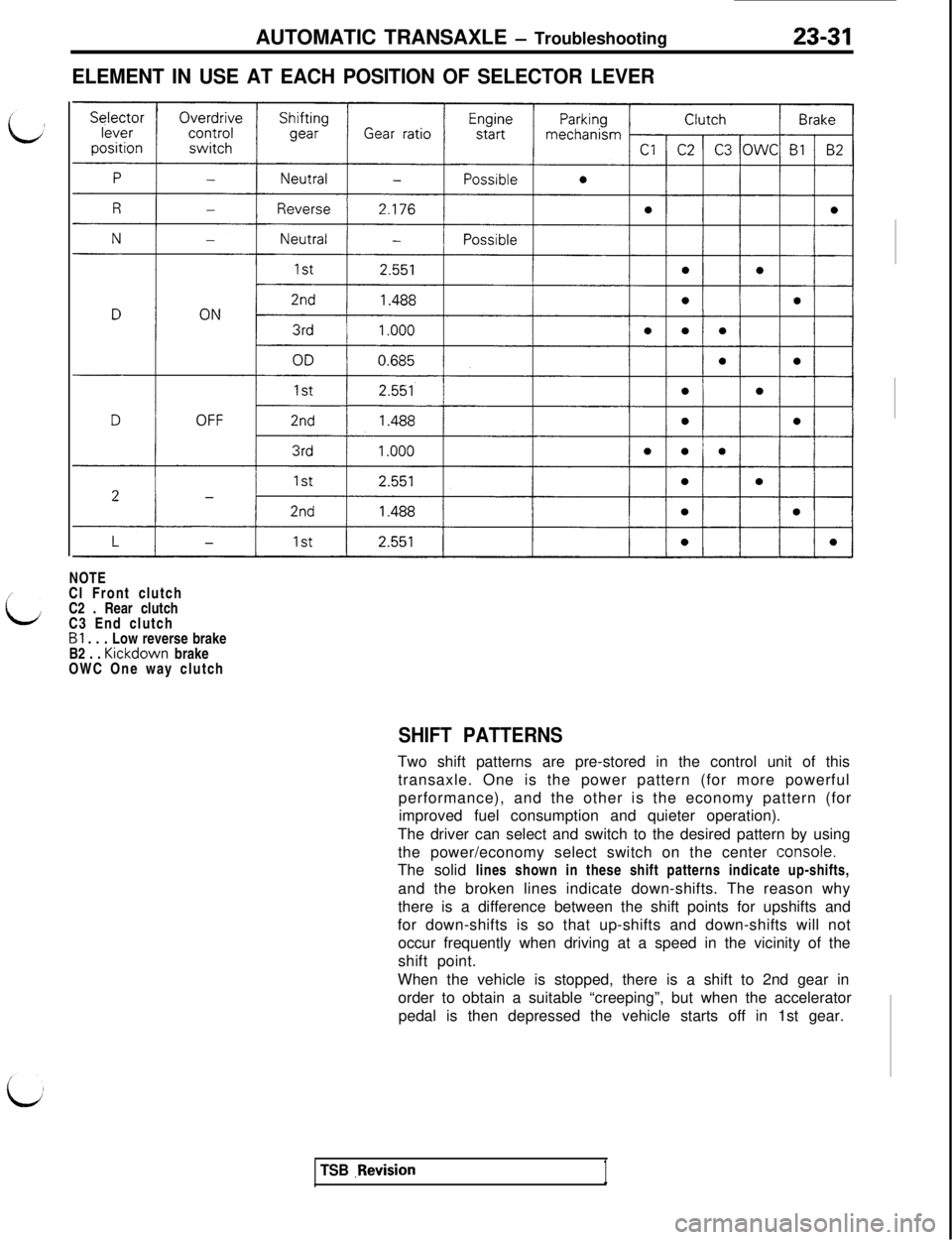

ELEMENT IN USE AT EACH POSITION OF SELECTOR LEVER

23-31NOTE

/

LCl Front clutch

C2 . Rear clutch

C3 End clutch

Bl . . . Low reverse brake

B2 . . Kickdown brake

OWC One way clutch

SHIFT PATTERNSTwo shift patterns are pre-stored in the control unit of this

transaxle. One is the power pattern (for more powerful

performance), and the other is the economy pattern (for

improved fuel consumption and quieter operation).

The driver can select and switch to the desired pattern by using

the power/economy select switch on the center

Iconsole.The solid lines shown in these shift patterns indicate up-shifts,

and the broken lines indicate down-shifts. The reason why

there is a difference between the shift points for upshifts and

for down-shifts is so that up-shifts and down-shifts will not

occur frequently when driving at a speed in the vicinity of the

shift point.

When the vehicle is stopped, there is a shift to 2nd gear in

order to obtain a suitable “creeping”, but when the accelerator

pedal is then depressed the vehicle starts off in 1st gear.

TSB .Revision1

Page 484 of 1146

23-32AUTOMATIC TRANSAXLE - Troubleshooting

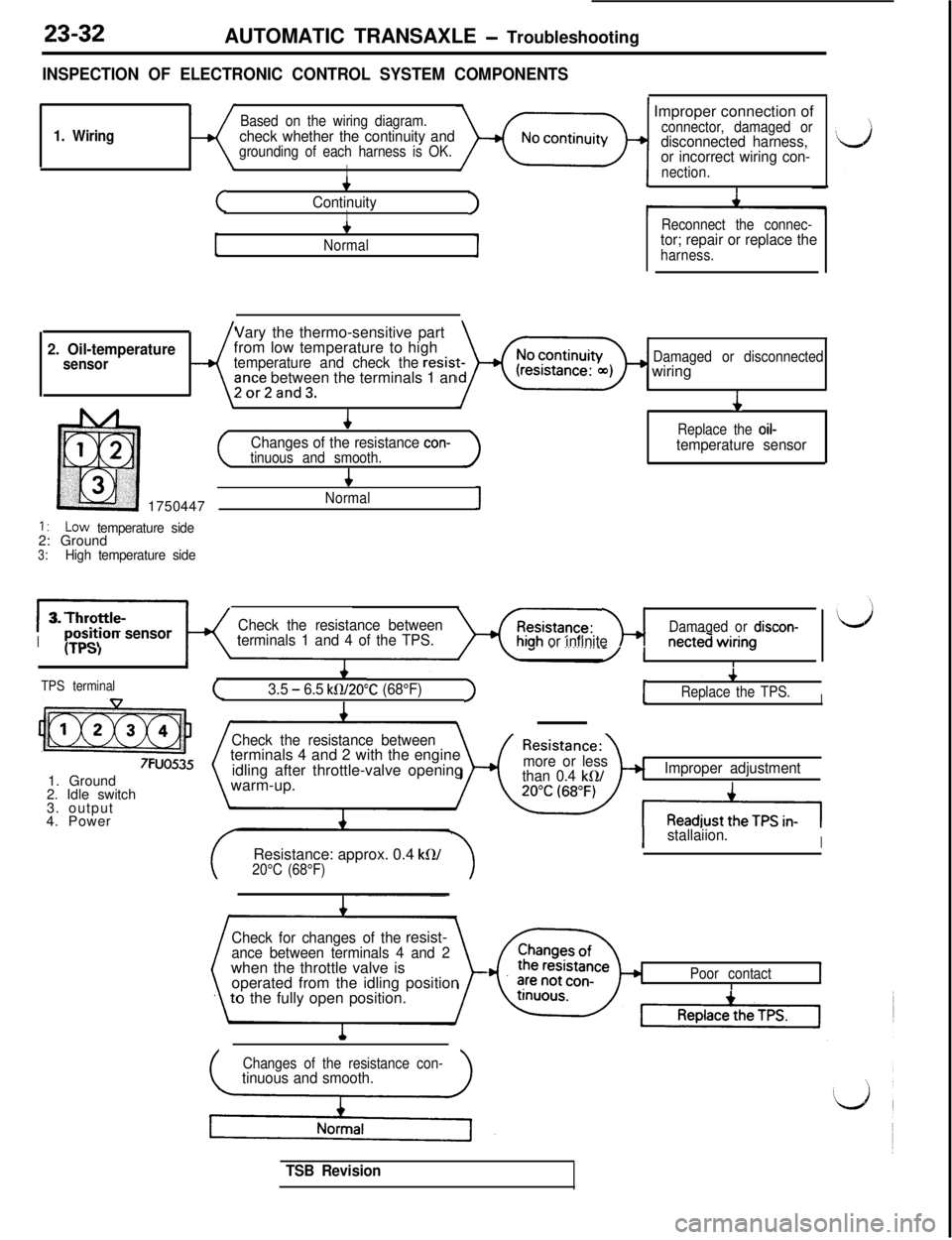

INSPECTION OF ELECTRONIC CONTROL SYSTEM COMPONENTS

1. WiringBased on the wiring diagram.check whether the continuity andgrounding of each harness is OK.

I

(

4

ContinuityII

+

Normal~ Improper connection of

connector, damaged ordisconnected harness,

or incorrect wiring con-

nection.

I

Reconnect the connec-tor; repair or replace theharness.Vary the thermo-sensitive part

2. Oil-temperaturefrom low temperature to highsensortemperature and check theresist-Damaged or disconnected

ante between the terminals 1 anwiring2or2and3.

4

J

Changes of the resistance con-Replace the oil-

tinuous and smooth.temperature sensor

41750447

Normal1

1:LOW temperature side2: Ground

3:High temperature side

I:3. Throttle-

K

Check the resistance between

Ip~~~t,ion sensorterminals 1 and 4 of the TPS.hiah or infinitem- -----inecteciI-

\ IDamaged or discon-..----Awiring

I

c3.5 - 6.5 kW20”C (68°F)t

v

Replace the TPS.I>ITPS terminal

7FUO5351. Ground

2. Idle switch

3. output

4. Power

Check the resistance betweenterminals 4 and 2 with the engine

idling after throttle-valve opening

warm-up.

Resistance: approx. 0.4

kR/20°C (68°F)

Changes of the resistance con-

tinuous and smooth.

/Resistance:\more or less

than 0.4 kQ/Improper adjustment

Istallaiion.I

Check for changes of theresist-ance between terminals 4 and 2when the throttle valve is

operated from the idling position

o the fully open position.

Poor contactII

TSB Revision

Page 485 of 1146

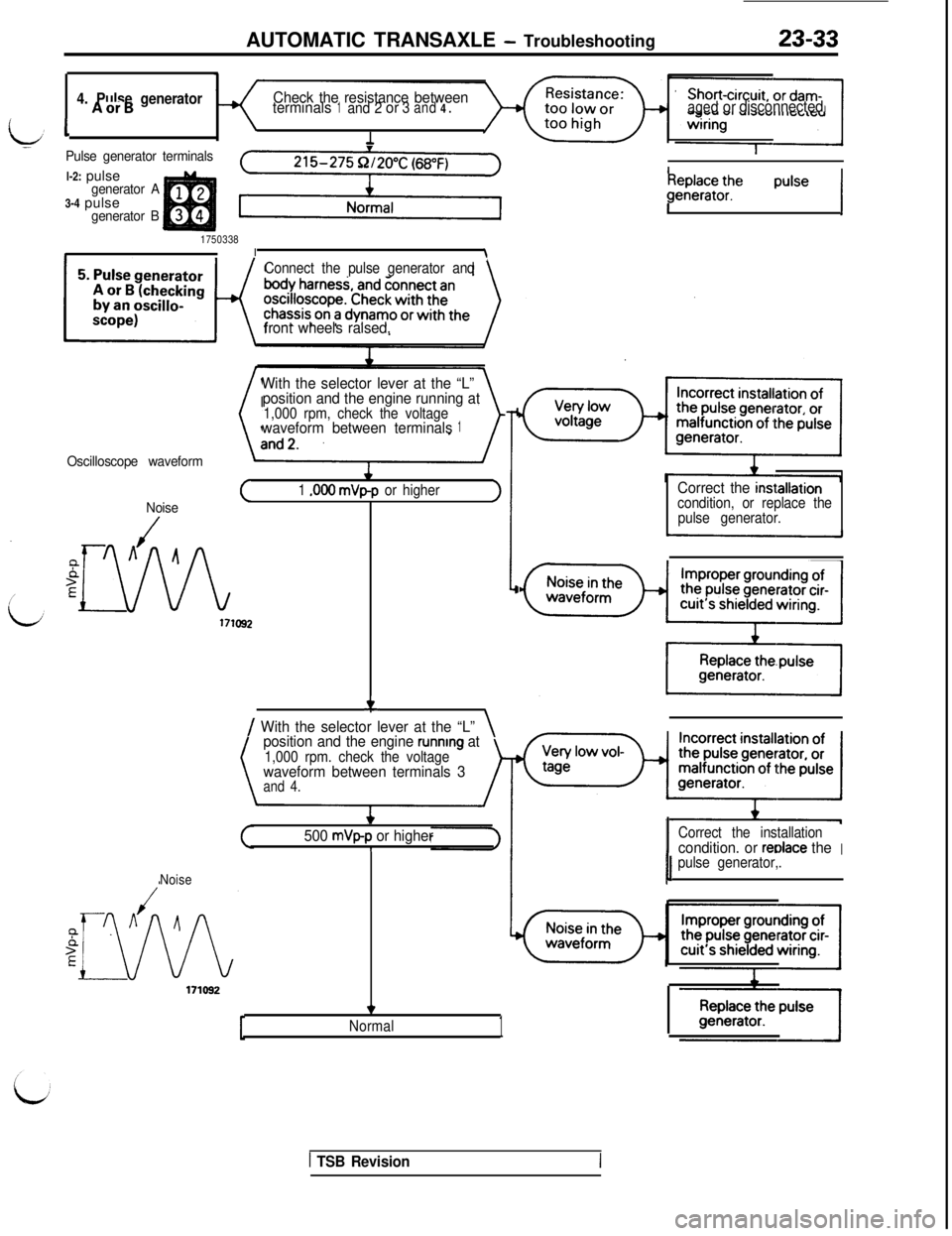

AUTOMATIC TRANSAXLE - Troubleshooting23-33

4. Pulse generatorCheck the resistance betweenAorBterminals1and 2or3and4.agedordisconnected

iv1-Pulse generator terminalsl-2: pulse

generator A3-4 pulse

generator B

17503381I\Connect the pulse generator and

front wheels raised.

Oscilloscope waveform

With the selector lever at the “L”

position and the engine running at

1,000 rpm, check the voltagewaveform between terminals1(

1 .OOO mVp-p or higher

Noise>

iJh

171092

f\/ With the selector lever at the “L”\

position and the engine running at1,000 rpm. check the voltagewaveform between terminals 3and 4.

I

1fWWF;tf: pulse /

Correct the inst.allationcondition, or replace the

pulse generator.

L-

*

500 mVp-p or higherI

Noise

ICorrect the installationcondition. or redace theI1 pulse generator,.1

171092

*

Normal1

1 TSB Revision

Page 486 of 1146

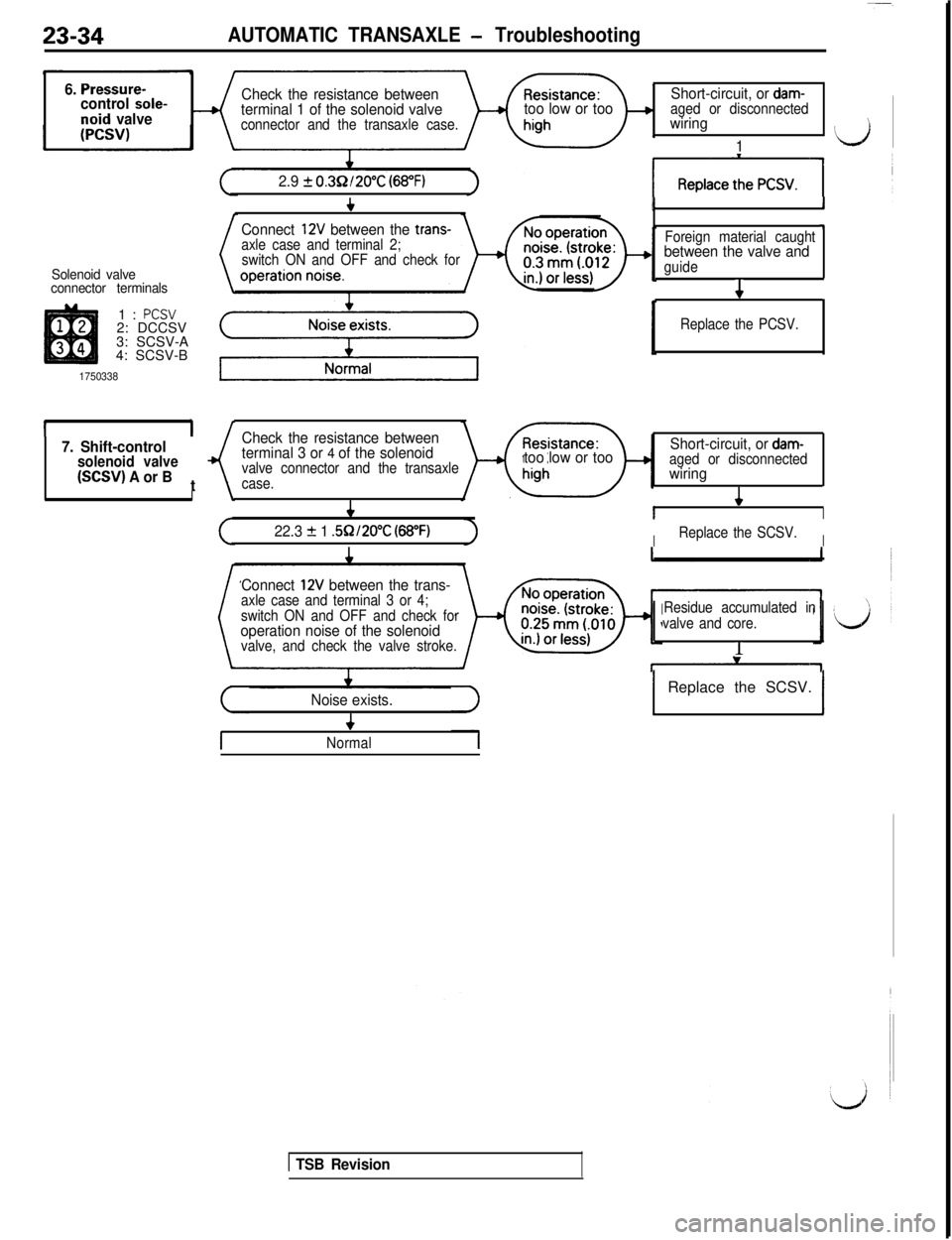

23-34AUTOMATIC TRANSAXLE - Troubleshooting

6. Pressure-control sole-noid valve

Check the resistance between

terminal 1 of the solenoid valve

connector and the transaxle case.

too low or tooShort-circuit, or dam-aged or disconnectedwiring

1IJ

2.9 + 0.3Q/20°C (68°F)

Solenoid valve

connector terminals1:

PCSV2: DCCSV

3: SCSV-A

4: SCSV-B

1750338

II7. Shift-controlsolenoid valve(SCSV) A or Bt

II

c

Connect 12V between the trans-

axle case and terminal 2;

switch ON and OFF and check for

I1

Foreign material caught-l

between the valve andguide

4

Replace the PCSV.

Check the resistance between

terminal 3 or 4 of the solenoidvalve connector and the transaxle

case.

&

Short-circuit, or dam-toolow or tooaged or disconnectedwiring

I4I

22.3 + 1 .5R/20°C (68°F)IReplace the SCSV.I

Connect 12V between the trans-axle case and terminal 3 or 4;

switch ON and OFF and check for

operation noise of the solenoidvalve, and check the valve stroke.Residue accumulated in

valve and core.1

Noise exists.I

1 Replace the SCSV. 1

+

Normal

1 TSB Revision

Page 487 of 1146

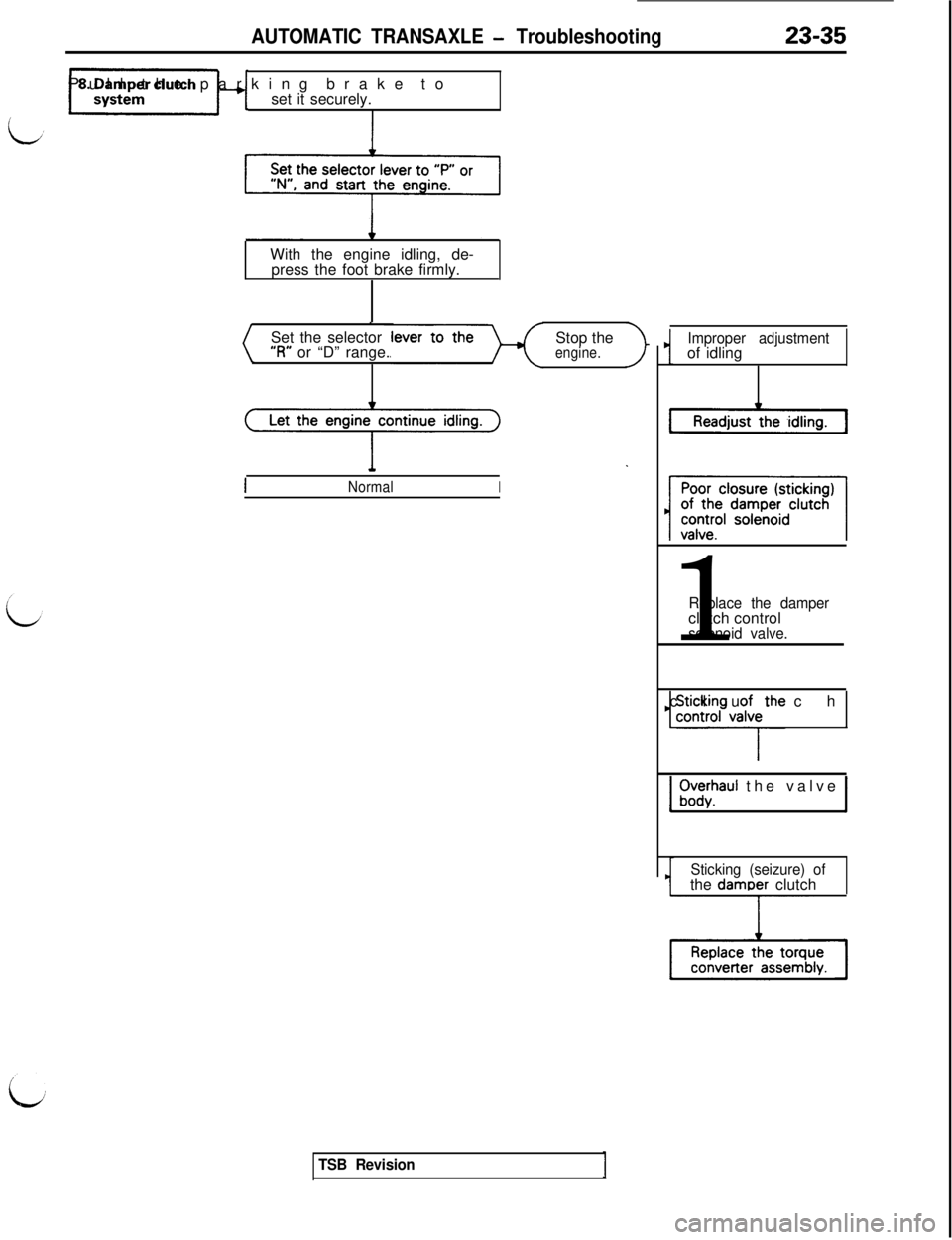

AUTOMATIC TRANSAXLE - Troubleshooting

~I+~Pull the parking brake to

set it securely.

I

23-35With the engine idling, de-

press the foot brake firmly.

.

Set the selector

‘3” or “D” range.Stop theengine.Let the engine continue idling.

c .

INormalI

Improper adjustmentof idling

-Readjust1

Replace the damperclutch control

solenoid valve.

1 9$4nFv;itheclutch 1

1 f;w$aul the valve 1

Sticking (seizure) ofthe damDer clutch

TSB Revision

Page 488 of 1146

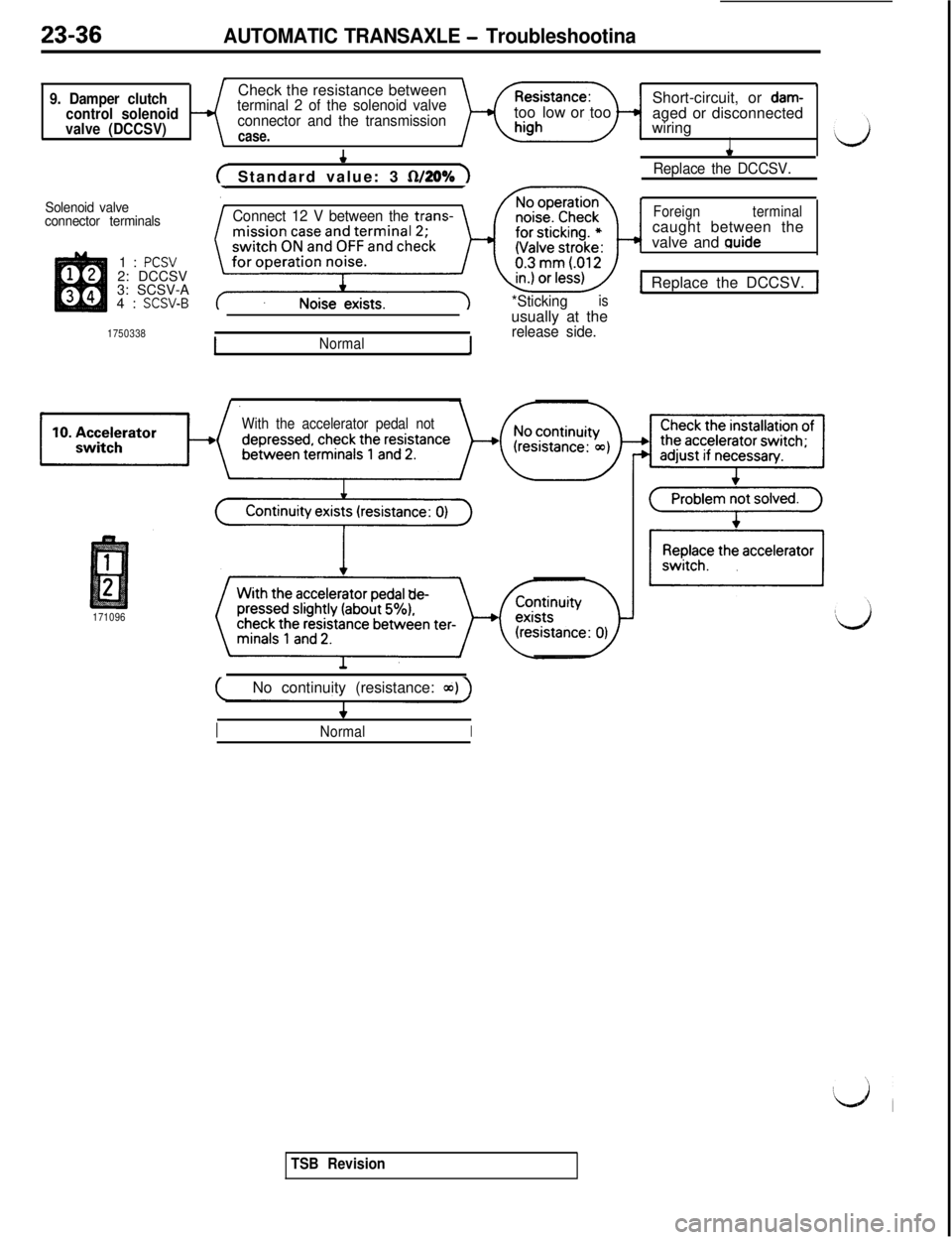

23-36AUTOMATIC TRANSAXLE - Troubleshootina

9. Damper clutch

control solenoid

valve (DCCSV)Check the resistance betweenterminal 2 of the solenoid valve

connector and the transmission

case.

?Short-circuit, or

dam-toolow or too

aged or disconnected

wiring

I

Solenoid valve

connector terminals1:

PCSV2: DCCSV

3: SCSV-A

4:

SCSV-B

1750338

( Standard value: 3 fWO% 1

Connect 12 V between the trans-

*Sticking

isusually at the

release side.

*

Replace the DCCSV.

Foreignterminalcaught between the

valve and

guide

1 Replace the DCCSV. J

INormal1

With the accelerator pedal not

171096

(No continuity (resistance: a~) )

INormalI

TSB Revision

Page 489 of 1146

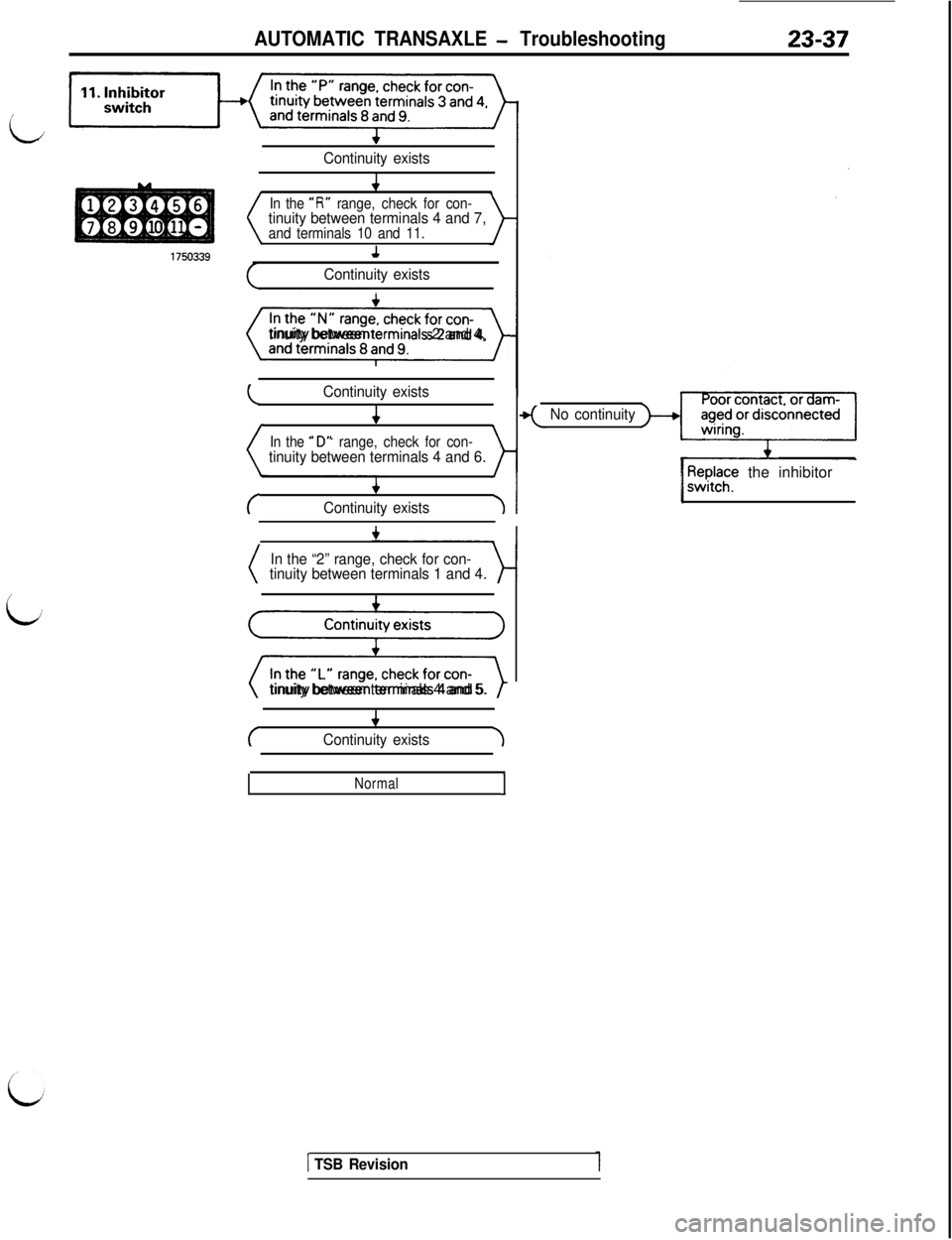

AUTOMATIC TRANSAXLE - Troubleshooting23-37

i

Continuity exists

/’

b

In the “R” range, check for con-tinuity between terminals 4 and 7,and terminals 10 and 11.

Continuity exists,

(t}tinuity between termrnals 2 and 4,

L.Continuity exists

4

In the

ti D“ range, check for con-tinuity between terminals 4 and 6.

c

+

Continuity exists\I

In the “2” range, check for con-

tinuity between terminals 1 and 4.

gzizkzgtinuity between terminals 4 and 5.

c

4

Continuity exists-I

NormalI

No continuity

/ P$f the inhibitor/

1 TSB Revision

Page 490 of 1146

23-38AUTOMATIC TRANSAXLE - Troubleshooting

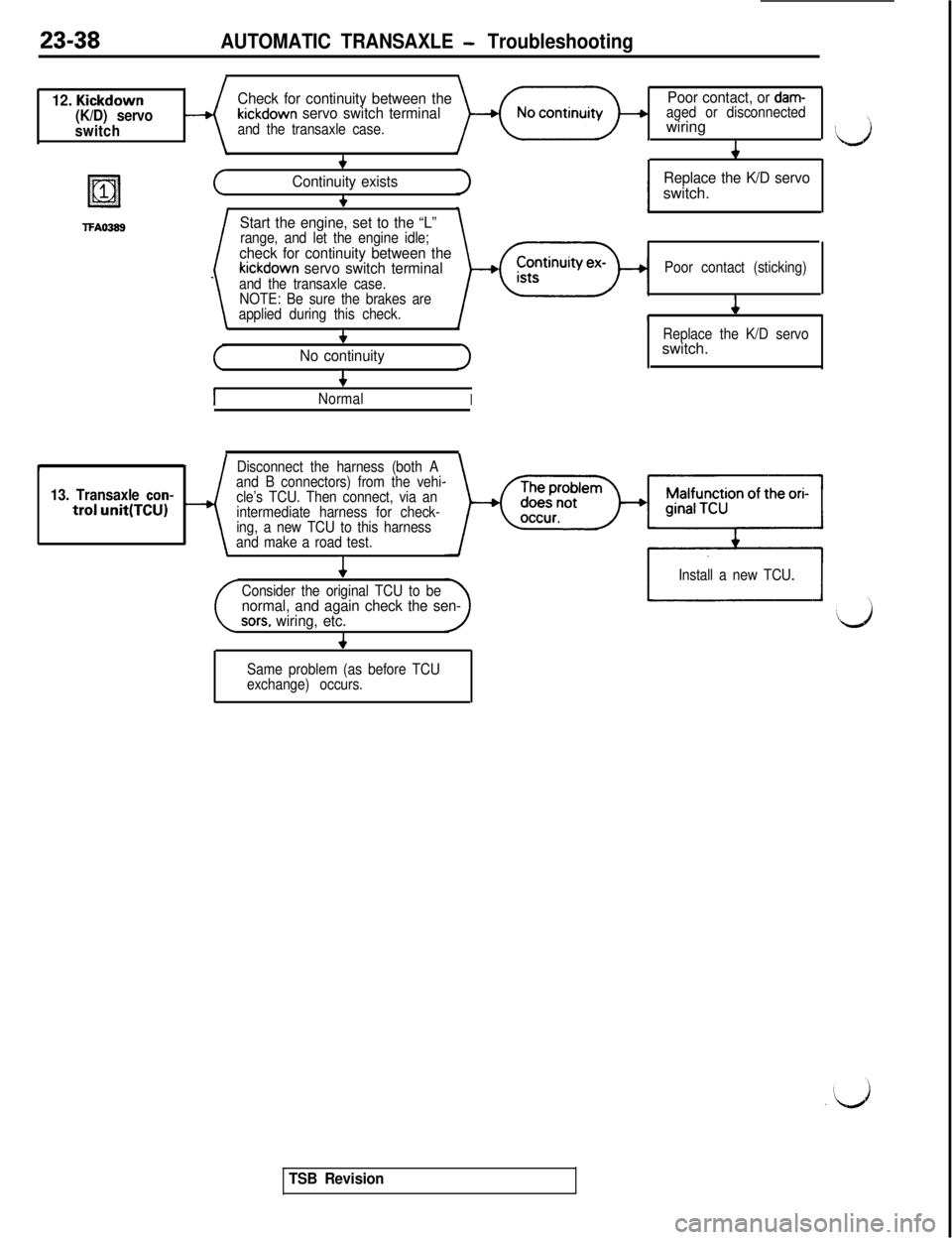

12. Kickdown

(K/D) servo

switch

19=111

TFAO389

Check for continuity between thePoor contact, or dam-

kickdown servo switch terminalaged or disconnected

and the transaxle case.wiring

+c

Continuity existsReplace the K/D servo

+switch.

Start the engine, set to the “L”range, and let the engine idle;check for continuity between thekickdown servo switch terminalPoor contact (sticking)

and the transaxle case.

NOTE: Be sure the brakes are

applied during this check.4

+Replace the K/D servo

No continuityswitch.

+I

NormalIr

Disconnect the harness (both A

13. Transaxle con-and B connectors) from the vehi-

trol unit(TCU)cle’s TCU. Then connect, via an

intermediate harness for check-

ing, a new TCU to this harness

and make a road test.4

Install a new TCU.

Consider the original TCU to be

normal, and again check the sen-sors. wiring, etc.

4

Same problem (as before TCU

exchange) occurs.

TSB Revision