MITSUBISHI 3000GT 1991 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 51 of 1146

11-I

ENGINECONTENTS

IMllAA--

CAMSHAFT OIL SEALS....................................

CRANKSHAFT, FLYWHEEL AND

DRIVEPLATE........................................................

CYLINDER BLOCK................................................

CYLINDER HEAD AND VALVE........................

CYLINDER HEAD GASKET................................

ENGINE ASSEMBLY............................................

ENGINE OIL COOLER........................................

GENERAL INFORMATION................................

lbLubricationSystem............................................SectionalView

....................................................

OIL PAN AND OIL PUMP....................................

OIL PAN AND OIL SCREEN................................20

49

5334

23

17

552

3

240

22

PISTON AND CONNECTING ROD....................

ROCKER ARM AND CAMSHAFT....................

SERVICE ADJUSTMENT PROCEDURES........Compression Pressure Check

........................Curb Idle Speed Inspection

............................Drive Belts Tension Adjustment

....................Ignition Timing Adjustment

............................

LashAdjusters

Check........................................Manifold Vacuum

Inspection

.............................

SPECIAL TOOLS....................................................

SPECIFICATIONS................................................General Specifications

....................................

Sealants

.......................................

.....................Service Specifications

....................................

TIMING BELT........................................................

TROUBLESHOOTING........................................44

31

11

15

14

11

13

16

16

84

4

84

26

10

Page 52 of 1146

II-2ENGINE - General Information

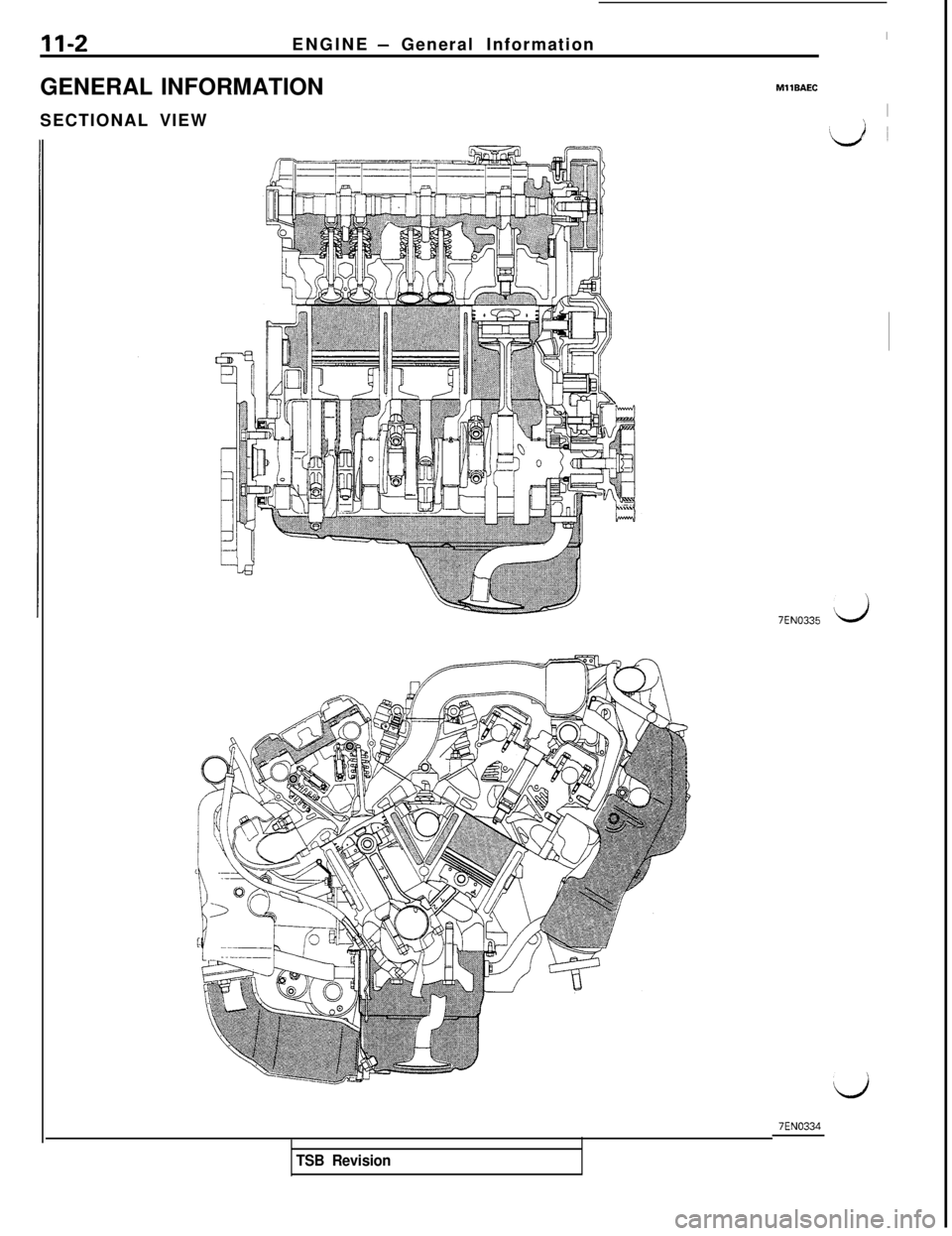

GENERAL INFORMATIONMllBAEC

SECTIONAL VIEW

I:

7EN0335ii

7EN0334

TSB Revision

Page 53 of 1146

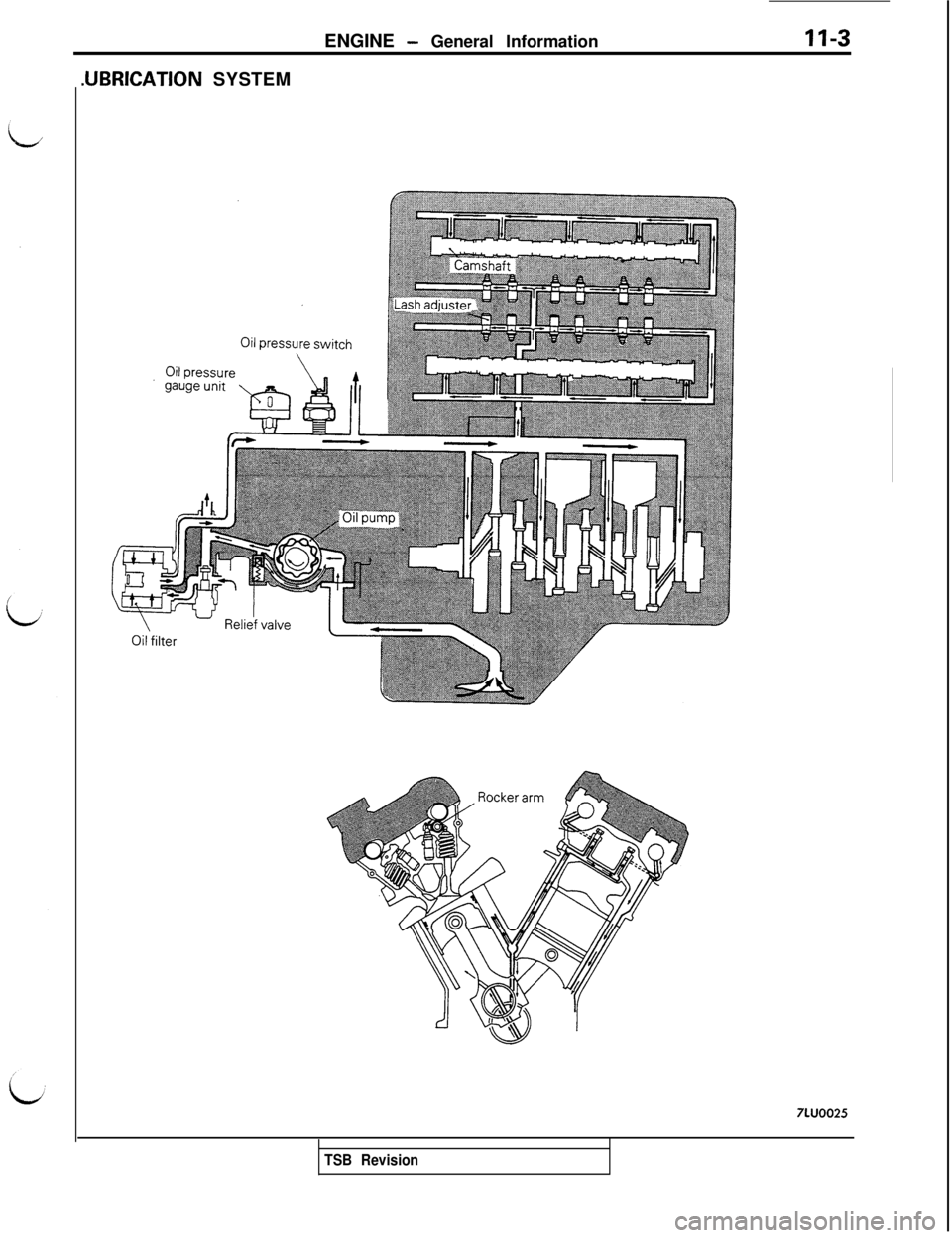

ENGINE - General InformationII-3.UBRICATION SYSTEM

7LUOO25

TSB Revision

Page 54 of 1146

II-4ENGINE - Specifications

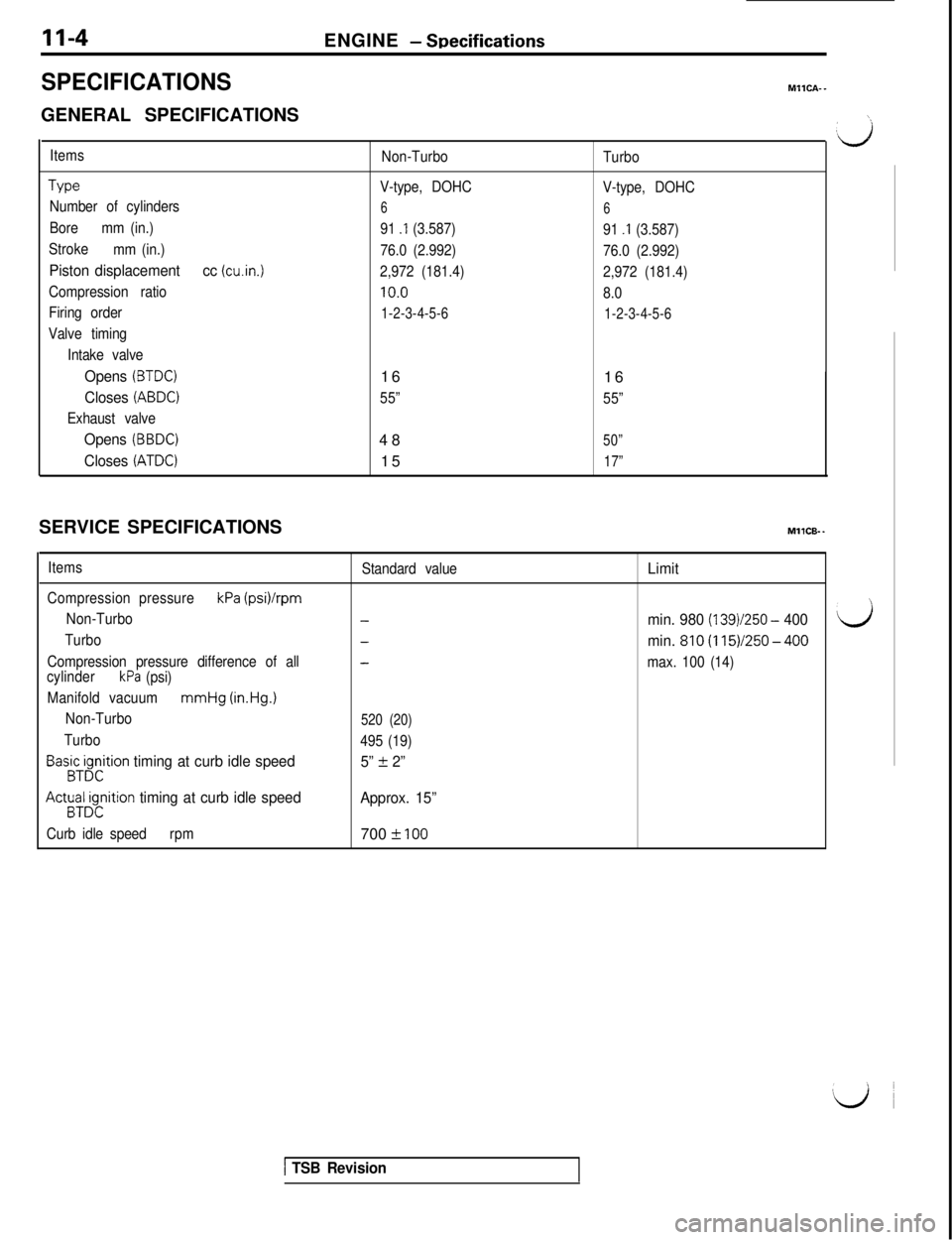

SPECIFICATIONSMllCA--GENERAL SPECIFICATIONS

‘,

‘dItems

Non-Turbo

Turbo

TypeV-type, DOHC

V-type, DOHC

Number of cylinders

6

6

Boremm (in.)

91 .I (3.587)

91 .I (3.587)

Stroke

mm (in.)

76.0 (2.992)

76.0 (2.992)

Piston displacementcc (win.)2,972 (181.4)

2,972 (181.4)

Compression ratio

10.08.0

Firing order

1-2-3-4-5-6

1-2-3-4-5-6

Valve timing

Intake valve

Opens (BTDC)16

16

Closes (ABDC)55”

55”

Exhaust valve

Opens (BBDC)4850”

Closes (ATDC)1517”SERVICE SPECIFICATIONS

MllCE -

Items

Compression pressure

kPa (psi)/rpm

Non-Turbo

Turbo

Compression pressure difference of all

cylinder

kPa (psi)

Manifold vacuum

mmHg (in.Hg.)

Non-Turbo

Turbo

Bas2Tig;ition timing at curb idle speedAct;ir-&yition

timing at curb idle speed

Curb idle speedrpmStandard value

-

-

-

520 (20)

495 (19)

5” f 2”

Approx. 15”700

ZII 100

Limit

min. 980

(139)/250 - 400

min. 810(115)/250-400

max. 100 (14)

d

1 TSB Revision

Page 55 of 1146

L’

LENGINE

- Specifications11-5

Items

Standard value

Limit

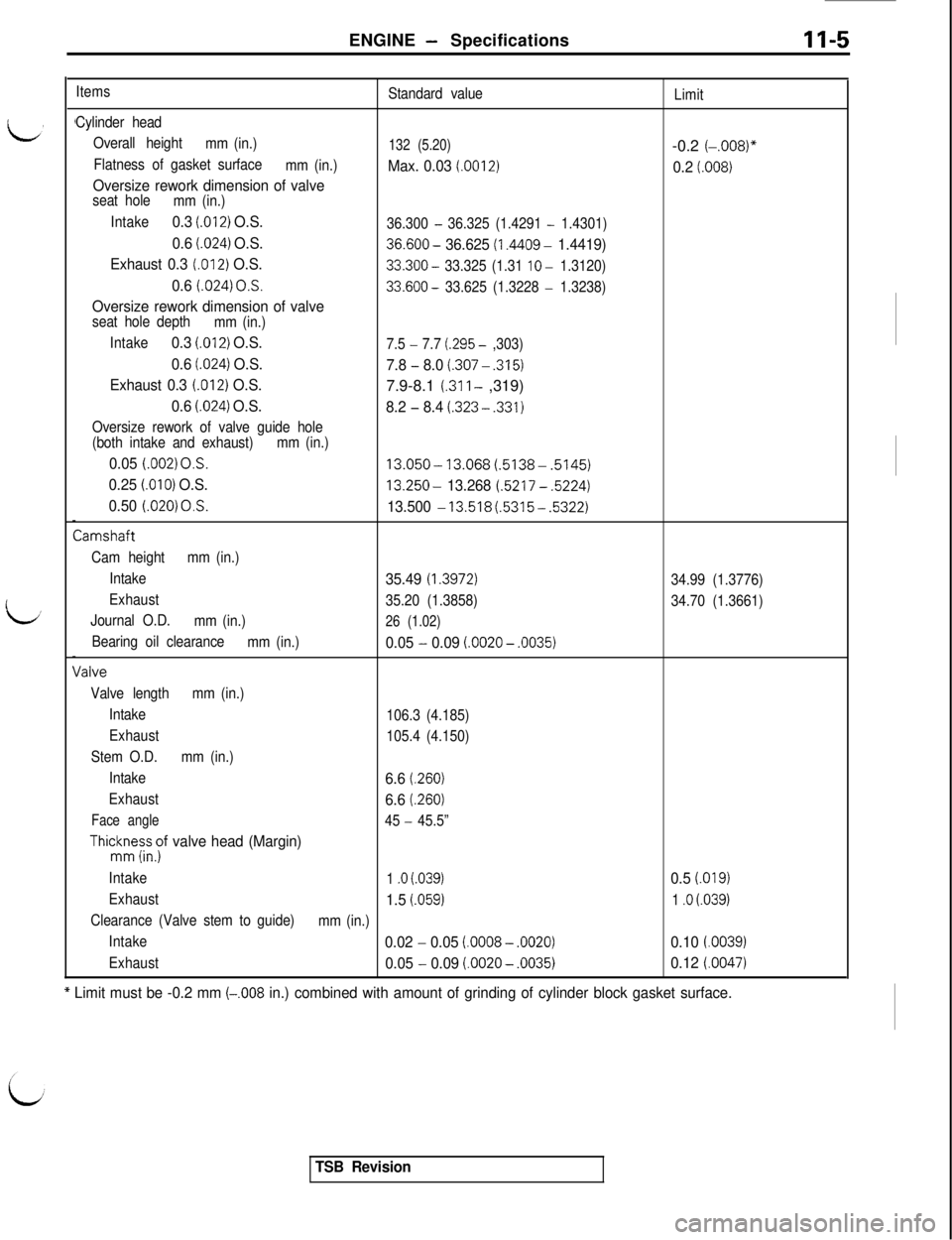

Cylinder head

Overall height

mm (in.)

132 (5.20)-0.2 (-,008)’

Flatness of gasket surface

mm (in.)Max. 0.03 l.0012)0.2 (.008)

Oversize rework dimension of valveseat hole

mm (in.)

Intake

0.3 f.012) O.S.36.300 - 36.325 (1.4291 - 1.4301)

0.6 l.024) O.S.36.600 - 36.625 (1.4409 - 1.4419)

Exhaust 0.3

l.012) O.S.33.300 - 33.325 (1.31 IO - 1.3120)

0.6 (.024) O.S.33.600 - 33.625 (1.3228 - 1.3238)

Oversize rework dimension of valveseat hole depth

mm (in.)

Intake

0.3 l.012) O.S.7.5 - 7.7 (.295 - ,303)

0.6 t.024) O.S.

7.8 - 8.0 (.307 - ,315)

Exhaust 0.3 t.012) O.S.7.9-8.1 (.311 - ,319)

0.6 (.024) O.S.

8.2 - 8.4 (.323 - .331)

Oversize rework of valve guide hole

(both intake and exhaust)mm (in.)

0.05 f.002) 0,s.13.050- 13.068(.5138-.5145)

0.25 (.OlO) O.S.13.250- 13.268 (.5217- .5224)

0.50 (.020) 0,s.13.500 - 13.518 (.5315 - .5322)

Samshaft

Cam heightmm (in.)

Intake

35.49 (I .3972)34.99 (1.3776)

Exhaust

35.20 (1.3858)

34.70 (1.3661)

Journal O.D.

mm (in.)

26 (1.02)

Bearing oil clearance

mm (in.)0.05 - 0.09 f.0020 - .0035)

Jalve

Valve lengthmm (in.)

Intake

106.3 (4.185)

Exhaust

105.4 (4.150)

Stem O.D.mm (in.)

Intake

6.6 (.260)

Exhaust6.6 i.260)

Face angle

45 - 45.5”Thick;;ss,yf

valve head (Margin)

Intake

1 .o (.039)0.5 (.019)

Exhaust1.5 (.059)1 .o (.039)

Clearance (Valve stem to guide)

mm (in.)

Intake

0.02 - 0.05 (.0008 - .0020)0.10 l.0039)

Exhaust0.05 - 0.09 l.0020 - .0035)0.12 i.0047)

* Limit must be -0.2 mm (--.008 in.) combined with amount of grinding of cylinder block gasket surface.

TSB Revision

Page 56 of 1146

11-6ENGINE - Specifications

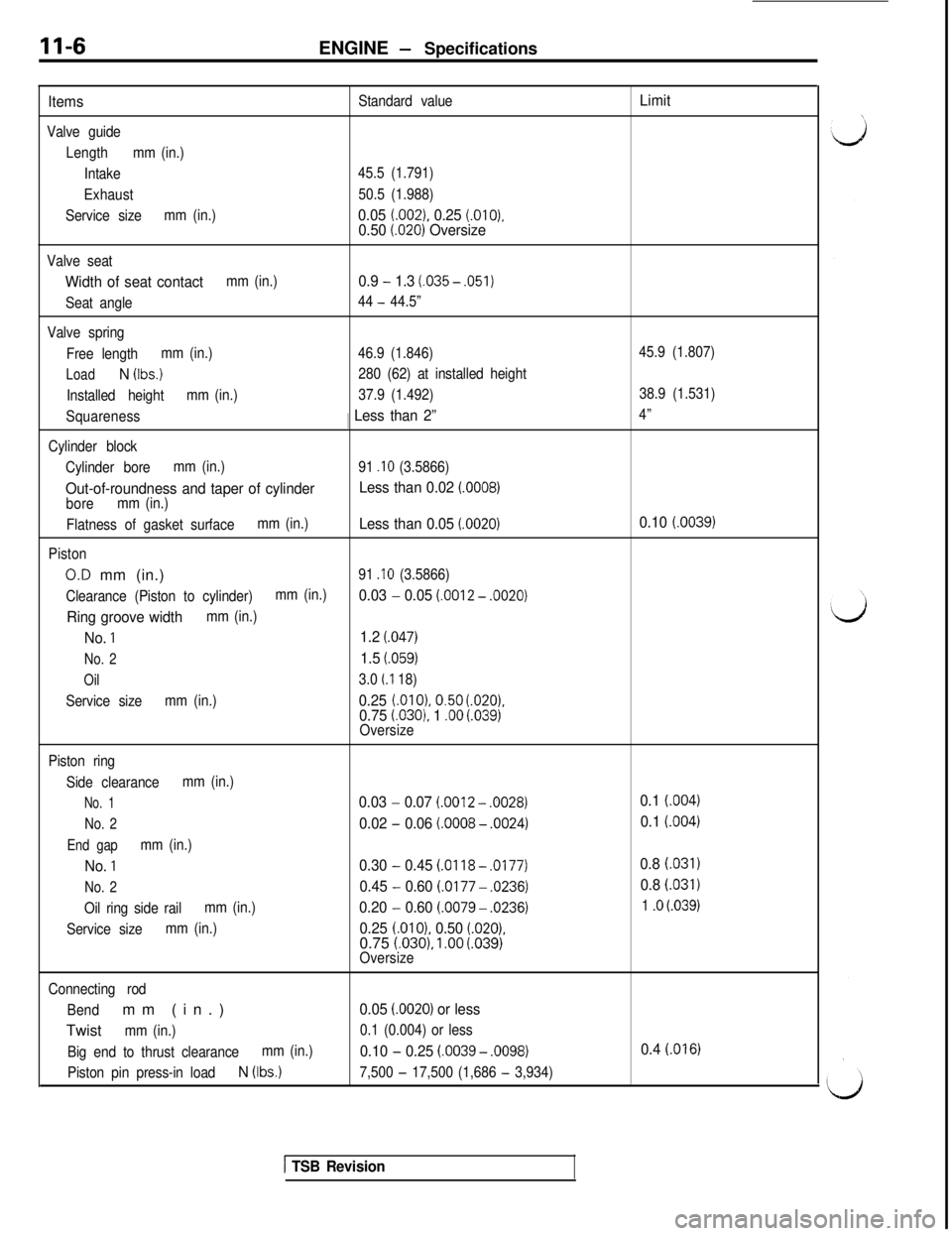

Items

Valve guide

Lengthmm (in.)

Intake

Exhaust

Service sizemm (in.)Standard value

45.5 (1.791)

50.5 (1.988)

0.05 f.002). 0.25 (.OlO),0.50 f.020) OversizeLimit

Valve seat

Width of seat contactmm (in.)0.9 - 1.3 (.035 - ,051)

Seat angle44 - 44.5”

Valve spring

Free lengthmm (in.)46.9 (1.846)45.9 (1.807)

LoadN (Ibs.)280 (62) at installed height

Installed heightmm (in.)37.9 (1.492)38.9 (1.531)

Squareness1

Less than 2”4”

Cylinder block

Cylinder boremm (in.)

91 .I0

(3.5866)

Out-of-roundness and taper of cylinderLess than 0.02 i.0008)

boremm (in.)

Flatness of gasket surfacemm (in.)

Less than 0.05 t.0020)0.10 (.0039)

Piston0.D mm (in.)

91 .I0 (3.5866)

Clearance (Piston to cylinder)mm (in.)

0.03 - 0.05 (.0012 - .0020)

Ring groove widthmm (in.)

No. 11.2 (.047)

No. 21.5 f.059)

Oil

3.0 (.I 18)

Service sizemm (in.)

0.25 LO1 0),0.50 (.020),0.75 (.030), 1 .oo l.039)Oversize

Piston ring

Side clearancemm (in.)

No. 1

No. 2

End gap

mm (in.)

No. 1

No. 2

Oil ring side railmm (in.)

Service sizemm (in.)

0.03 - 0.07 (.0012 - .0028)

0.02 - 0.06 l.0008 - .0024)

0.30 - 0.45 (.0118 - .0177)

0.45 - 0.60 (.0177 - .0236)

0.20 - 0.60 (.0079 - .0236)

0.25 (.OlO), 0.50 (.020),0.75 (.030), 1 .oo (.039)Oversize

0.1 (.004)

0.1 (.004)

0.8 i.031)

0.8 l.031)

1 .o (.039)

Connecting rod

Bendmm (in.)

Twist

mm (in.)

Big end to thrust clearancemm (in.)

Piston pin press-in load

N (Ibs.)

0.05 i.0020) or less

0.1 (0.004) or less

0.10 - 0.25 (.0039 - .0098)

7,500 - 17,500 (1,686 - 3,934)

0.4 l.016)

1 TSB Revision

Page 57 of 1146

ENGINE - Specifications

/

L

L/

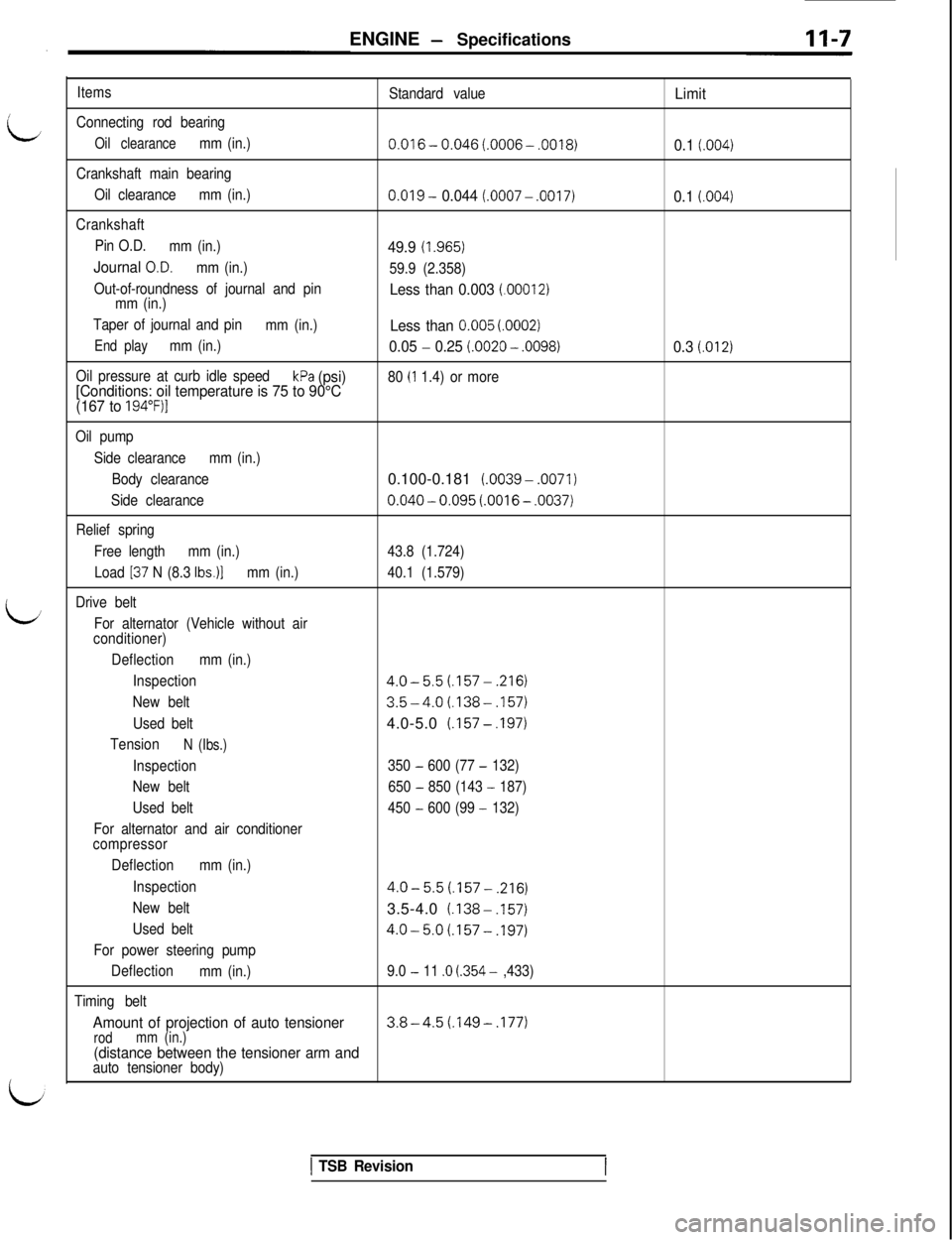

Items

Connecting rod bearing

Oil clearancemm (in.)

Crankshaft main bearing

Oil clearancemm (in.)

Crankshaft

Pin O.D.

mm (in.)

Journal O.D.mm (in.)

Out-of-roundness of journal and pin

mm (in.)

Taper of journal and pin

mm (in.)

End playmm (in.)

Oil pressure at curb idle speed

kPa (psi)

[Conditions: oil temperature is 75 to 90°C

(167 to

194”F)l

Standard value

0.016- 0.046 (.0006- .0018)

0.019 - 0.044 (.0007 - .0017)

49.9 (I ,965)

59.9 (2.358)

Less than 0.003 (.00012)

Less than 0.005 (0002)

0.05 - 0.25 (0020 - .0098)

80 (I 1.4) or more

Limit

0.1

(.004)

0.1 (.004)

0.3 (.012)

Oil pump

Side clearancemm (in.)

Body clearance0.100-0.181 (.0039-.0071)

Side clearance0.040 - 0.095 (.0016 - .0037)

Relief spring

Free lengthmm (in.)43.8 (1.724)

Load

137 N (8.3 Ibs.)]mm (in.)40.1 (1.579)

Drive belt

For alternator (Vehicle without air

conditioner)

Deflectionmm (in.)

Inspection

4.0-5.5(.157-,216)

New belt3.5-4.0(.138-,157)

Used belt4.0-5.0 (.157- ,197)

TensionN (Ibs.)

Inspection350 - 600 (77 - 132)

New belt650

- 850 (143 - 187)

Used belt450

- 600 (99 - 132)

For alternator and air conditioner

compressor

Deflectionmm (in.)

Inspection

4.0-5.5(.157-,216)

New belt3.5-4.0 (1388.157)

Used belt4.0-5.0(.157-,197)

For power steering pump

Deflection

mm (in.)9.0

- 11 .o (354 - ,433)

Timing belt

Amount of projection of auto tensioner3.8-4.5(.149-,177)rodmm (in.)(distance between the tensioner arm andauto tensioner body)

1 TSB Revision

Page 58 of 1146

11-8ENGINE - Specifications / Special Tools

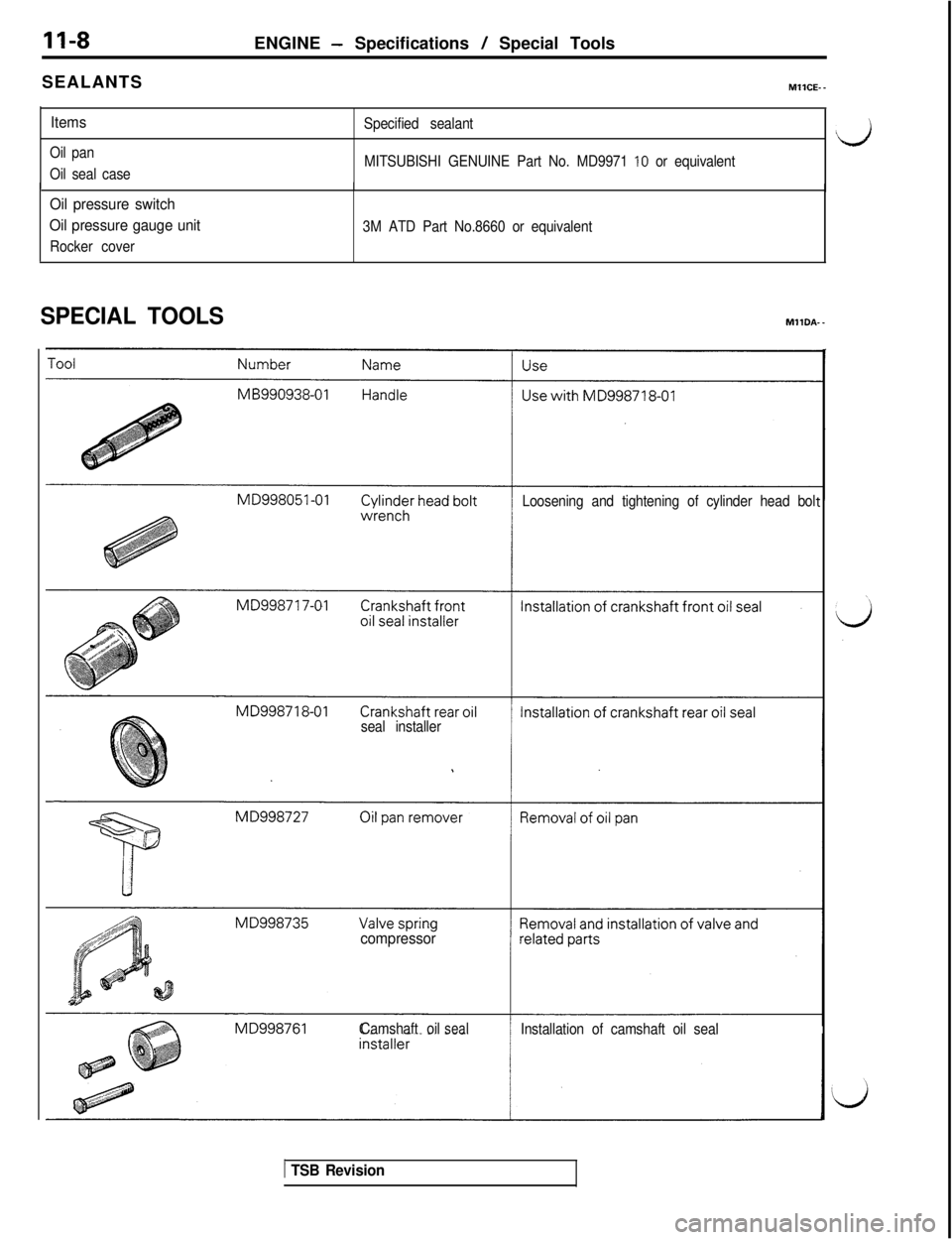

SEALANTS

MIKE- -

Items

Oil pan

Oil seal case

Oil pressure switch

Specified sealant

MITSUBISHI GENUINE Part No. MD9971

10 or equivalent

Oil pressure gauge unit

Rocker cover3M ATD Part No.8660 or equivalent

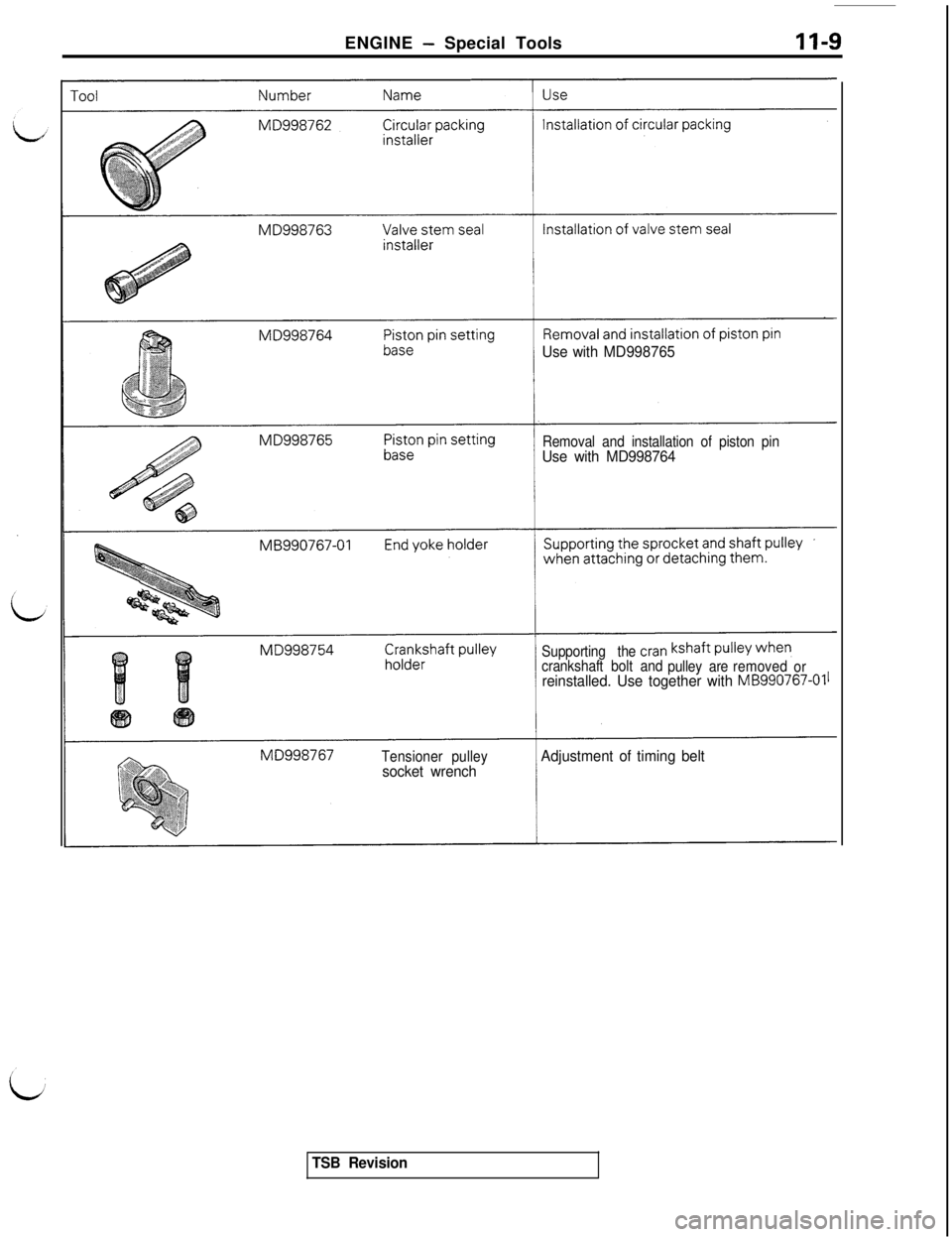

SPECIAL TOOLSMIlDA--

MD998051-01

Loosening and tightening of cylinder head bol

seal installer

compressor

Camshaft oilsealInstallation of camshaft oil seal

1 TSB Revision

Page 59 of 1146

ENGINE - Special ToolsII-9

Use withMD998765

Removal and installation of piston pinUse with MD998764

Supporting thecrancrankshaft bolt and

pulley areremoved

orreinstalled. Use together with MB990767-01

Tensioner pulley

socket wrenchAdjustment of timing belt

TSB Revision

Page 60 of 1146

II-IOENGINE - Troubleshooting

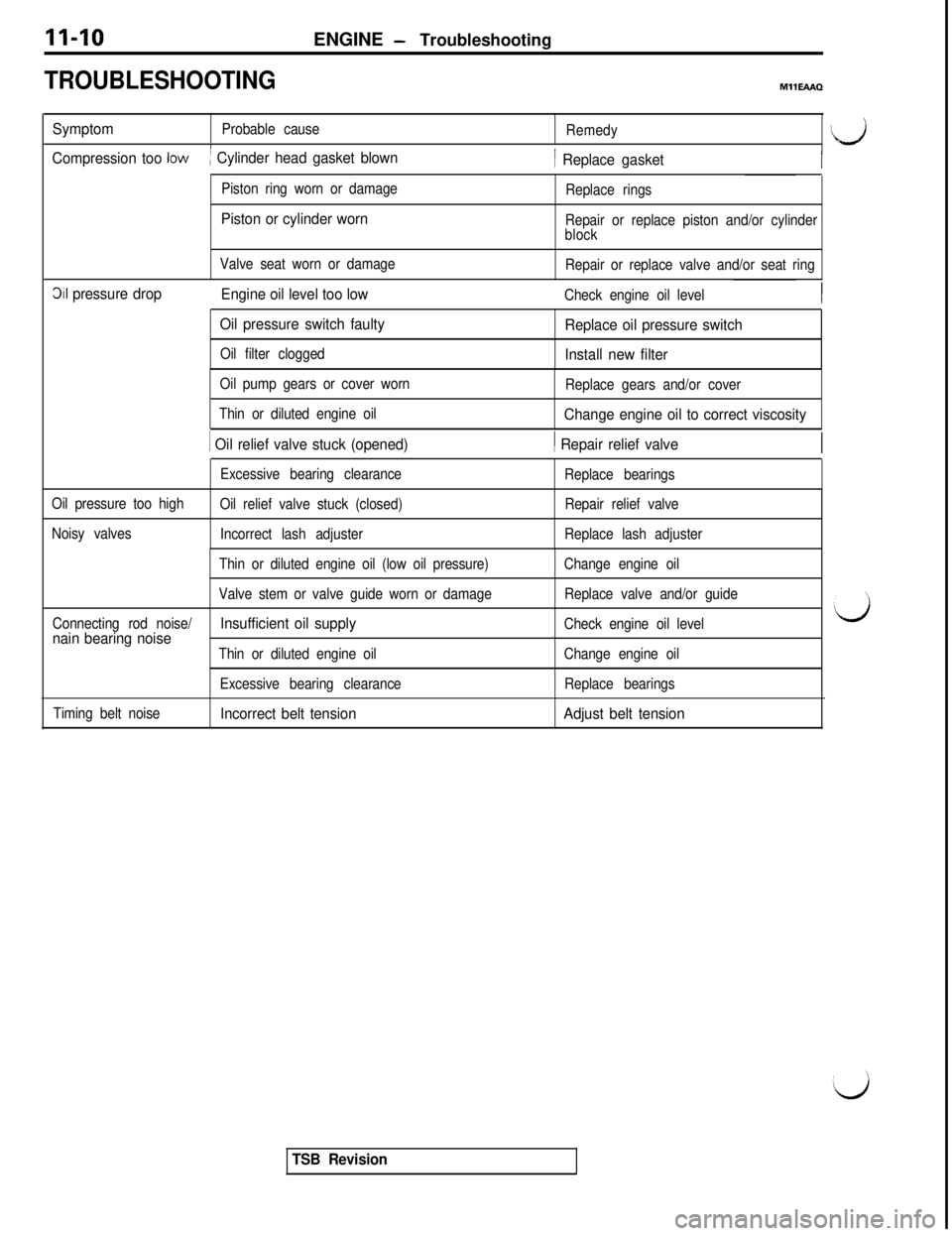

TROUBLESHOOTINGmiwm

SymptomProbable cause

RemedyI,aJ

Compression too low) Cylinder head gasket blown1 Replace gasketI

Piston ring worn or damage

Piston or cylinder worn

Replace rings

Repair or replace piston and/or cylinder

block

Valve seat worn or damage

Repair or replace valve and/or seat ring

3il pressure drop

Engine oil level too lowCheck engine oil level

Oil pressure switch faulty

Oil filter clogged

Replace oil pressure switch

Install new filter

Oil pump gears or cover worn

Thin or diluted engine oilReplace gears and/or cover

Change engine oil to correct viscosity

1 Oil relief valve stuck (opened)) Repair relief valve

Excessive bearing clearance

Replace bearingsIbOil relief valve stuck (closed)

Incorrect lash adjusterRepair relief valve

Replace lash adjuster Oil pressure too high

Noisy valves

Thin or diluted engine oil (low oil pressure)Change engine oil

Valve stem or valve guide worn or damageReplace valve and/or guide

Connecting rod noise/

nain bearing noiseInsufficient oil supplyCheck engine oil level

Thin or diluted engine oilChange engine oil

Excessive bearing clearanceReplace bearings

Timing belt noise

Incorrect belt tensionAdjust belt tension

TSB Revision